MichaelW

Members-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MichaelW

-

My next project is the Bluejacket Shipcrafters Diesel Tugboat. I purchased the kit this summer when I visited the shop in Maine. Nic gave me a great tour of the production areas. Thanks again Nic!

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thanks everyone. I learned a lot in this build, which I plan to use on my next build. This site is a great tool and a place to find encouragement.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thanks! On to the next model.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Using some skills from placing model railroad ballast, I soaked the anchor rode in a 1/3 rubbing alcohol - 2/3 water solution. That made the line very pliable. I then used the handle of an Xacto knife to prepare the coil - it was the right size. I carefully looped the line into a normal looking rope pile. I then used very dilute white glue with a dropper to soak the line with white glue. Let dry overnight. I then seized a loop for the anchor shackle. To make it easier to tie off the rode on the Samson post, I used a dropper and re-wetted the line with the alcohol/water solution. Done.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

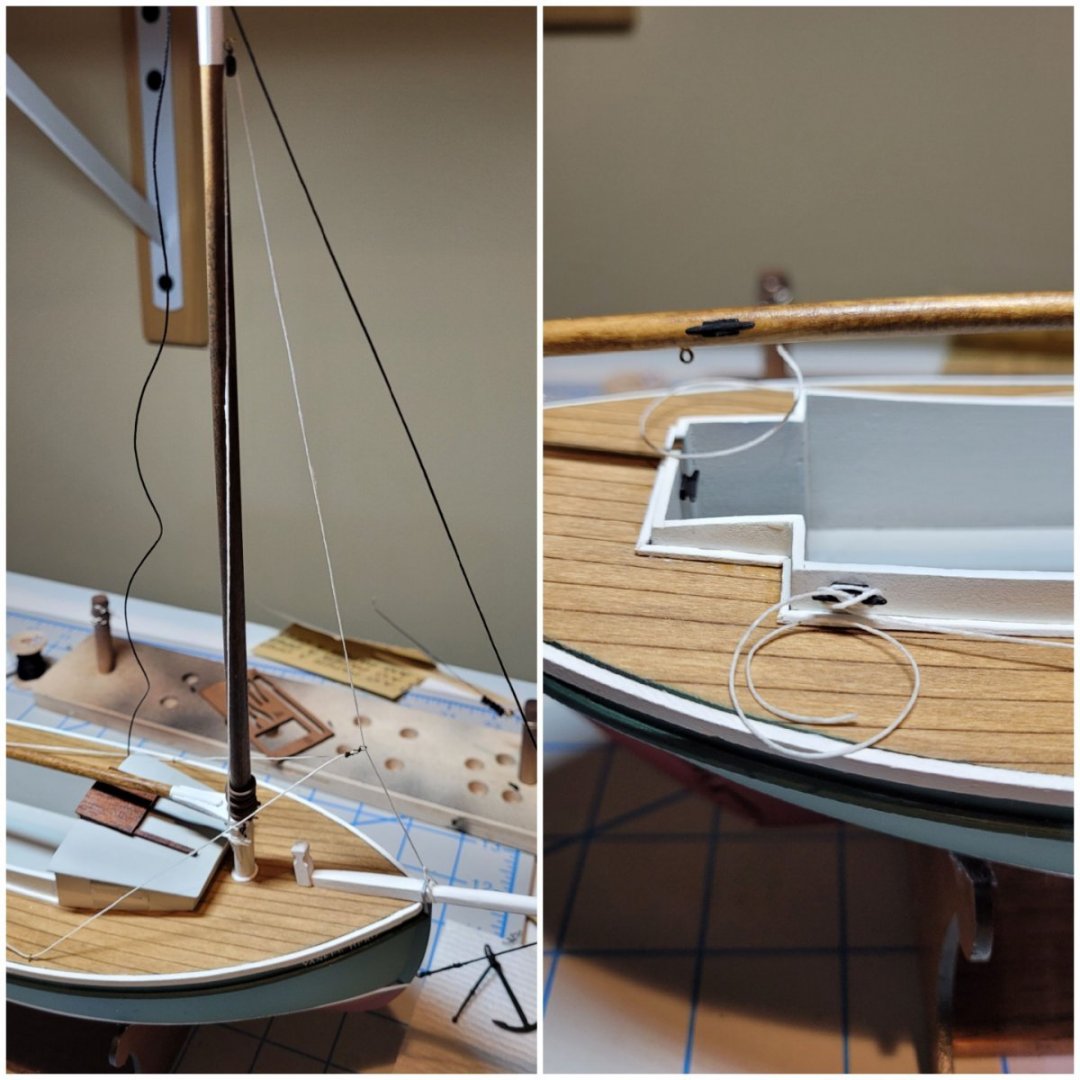

The next task as to square away the lines. After cleating off the jib sheets, I wanted to coil the remaining line in a Flemish coil. I knew I'd have to glue the coil into a round, but didn't want to try that right on the deck. I clamped a small piece of glass from a small picture frame into a hobby vice and positioned that next to the cockpit. I then carefully coiled the line using tweezers to coil the line and my finger to hold the coiled line down. Once I got the coil to the size I wanted, I used a drop of CA to hold the coil together. I used some accelerant to speed up the CA cure, then slid the coil onto the deck. I had to glue the coil down to it laid flat. After repeating the process on the other side I cleated off the main halyard and coiled the remaining line and hung it on the pin at the mast. I coiled the mainsheet and left it on the cockpit grate. All that's left to do is place the anchor on the fore deck and coil the anchor rode.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

The next task was to square away the lines. After cleating off the jib sheets, I wanted to coil the remaining line in a Flemish coil. I knew I'd have to glue the coil into a round, but didn't want to try that right on the deck. I clamped a small piece of glass from a small picture frame into a hobby vice and positioned that next to the cockpit. I then carefully coiled the line using tweezers to coil the line and my finger to hold the coiled line down. Once I got the coil to the size I wanted, I used a drop of CA to hold the coil together. I used some accelerant to speed up the CA cure, then slid the coil onto the deck. I had to glue the coil down for to lay flat. After repeating the process on the other side, I cleated off the main halyard and coiled the remaining line and hung it on the pin at the mast. I coiled the mainsheet and left it on the cockpit grate. All that's left to do, I think, is place the anchor on the fore deck and coil the anchor rode.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thank you sir! I've finished the rigging and am finishing the last few tasks. I'll have photos shortly. MSW has been a huge source of tips and encouragement.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

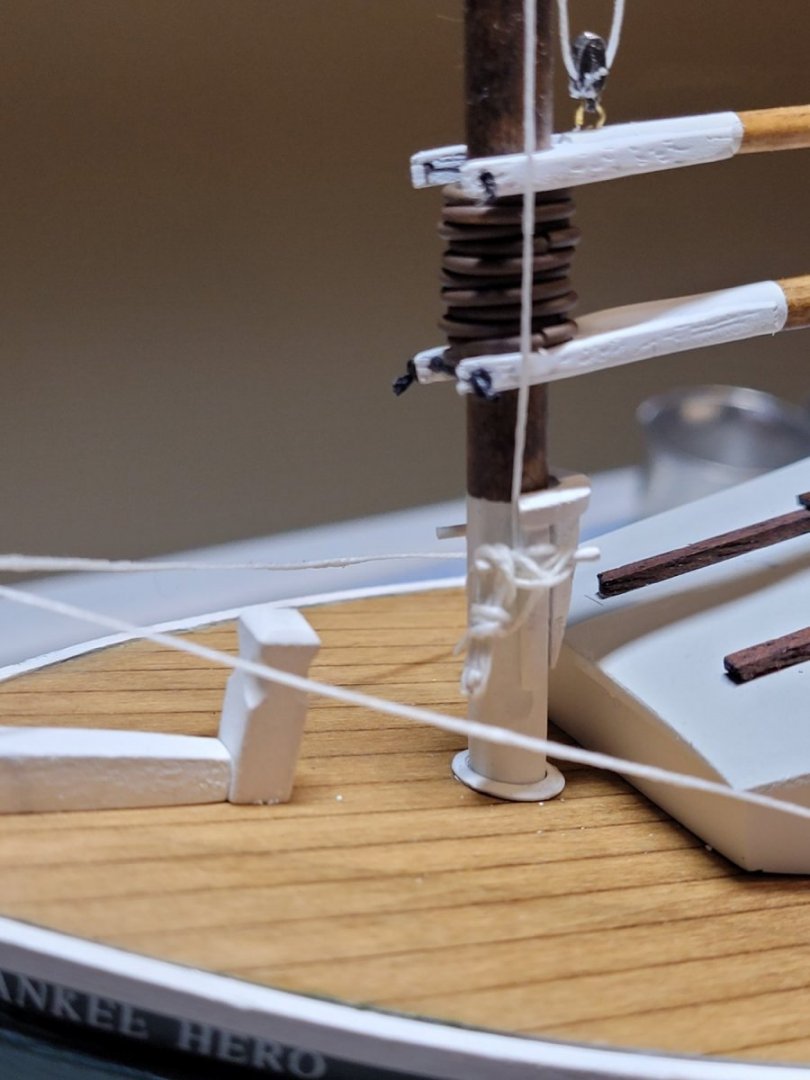

I painted the blocks, cleats, and anchor flat black. I then waded into rigging the boat. The first step was to find YouTube videos on seizing loops at the end of lines. I picked the technique that worked best for me. It take some practice to get the turns of the seizing to line up. I read through and carefully followed the rigging directions in the BlueJacket instructions. As shown in the following photos I ran the forestay, topping lift, jib halyard, and jib sheets. I also attached the boom and threaded and tied off the parrels, which keep the boom attached to the mast. Still more rigging to go. Apparently there are many ways to coil the ends of lines (i.e. search "Flemish coil"). I'll need to figure out what works best for me.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Great! I'll go with that. Thanks!

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

At a snail's pace now.... After a false start on the mast step (glued it on before placing the hoops on the mast), I have made some progress. The mast is up, mast step attached (after loading the hoops to the mast the second go-around), boot stripe on, and spars ready to be attached. The next step - rigging! I still need to shape and attach the tiller. I am wondering if I should paint the blocks or leave them gray...... Any suggestions?

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thanks Tom! Just the shot in the arm I needed to get this boat finished!

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Ok, the spars and mast are finished. I also assembled and painted the boom step. Because I figure the boat owner would have varnished the spars, I sprayed them with some lacquer to give them a little shine. On very close inspection it looks like I should have sanded the boom step parts a bit more. The parts seemed quite delicate so I didn't want to mess with them much. I may clean it up a little more before installing.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thank you! I am probably writing too much and adding too many photos. My hope is that this will help the next modeler.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Tonight I tackled the boom step for the mast. It has small pieces and is a small part. I wanted to make sure the side pieces would fit tight to the mast, but in making it I can not glue the pieces to the mast. The boom step is to be painted white - so you can't glue it to the mast. First, I tapped the brass rods into the holes drilled in two of the "legs" of the step. After placing the pin in the hole, I gently tapped the pin into place using a small hammer. Second, I wrapped some plastic around a small piece of dowel the same size as the mast; I then mounted it in my vice. As I glued each "leg" to the step I held the step against the plastic and dowel and as I glued the leg onto the step I made sure the leg was tight against the dowel. A small amount of CA glue on the leg stuck it to the step. I used some accelerator to speed up the cure of the CA. I didn't want the legs breaking off the step. After the CA cured for a minute or two I moved to the next leg until all three legs were glued to the step. I took my time and used just a spot of CA on the end of each leg when gluing it to the step. A little accelerant secured each leg. The next step, I think, is to paint the tips of the spars and mast and the boom step white.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

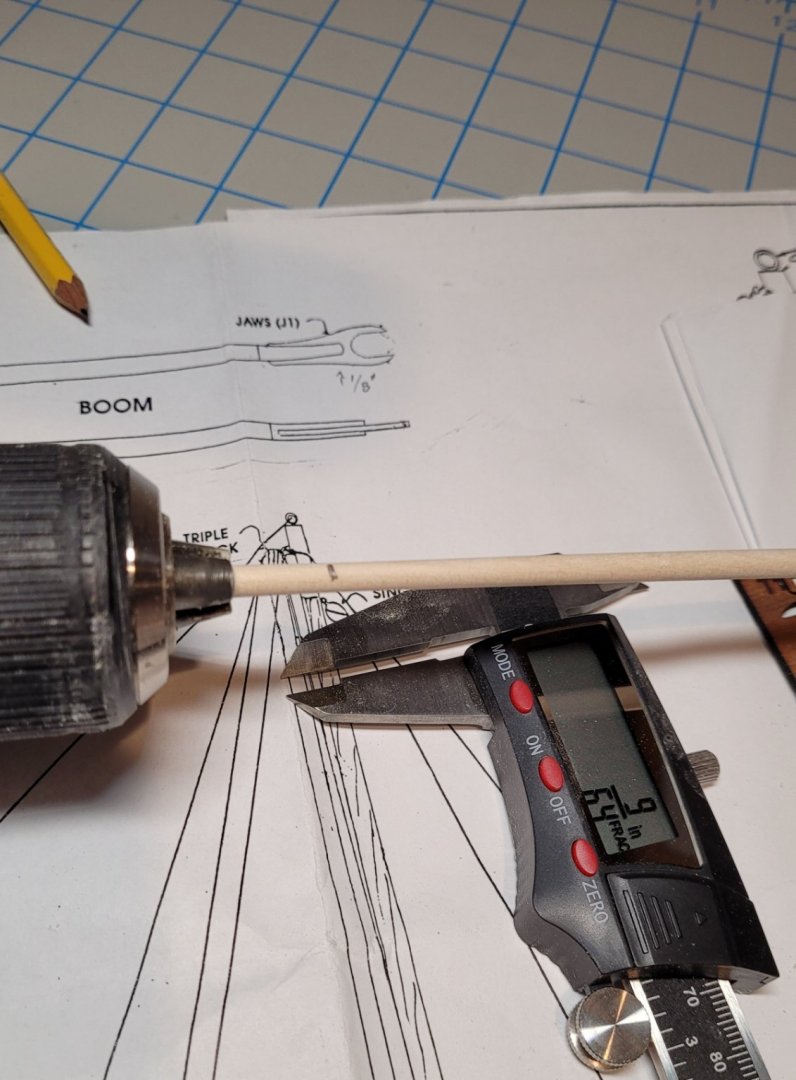

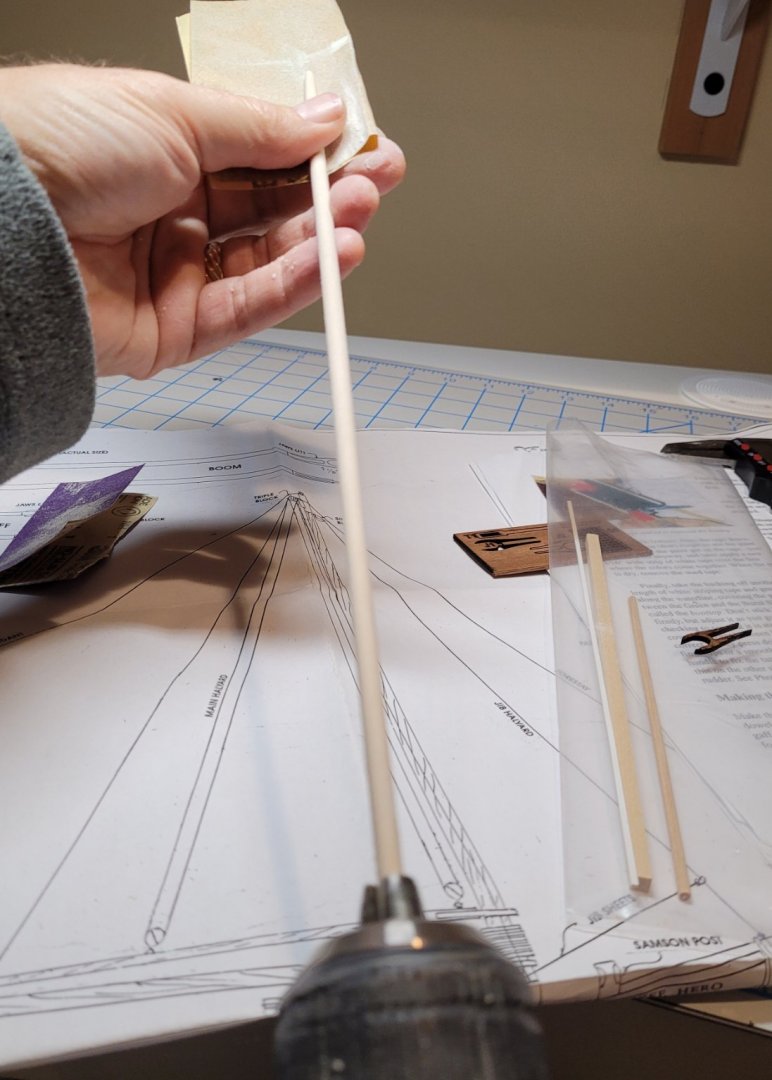

Now that the sailing season is winding down I am making more progress on my Yankee Hero. I finished shaping and staining the mast and spars. I read several posts and the instructions - all of which tend to indicate that shaping the mast and spars can be a tedious process. Hey, let's face it, building a model is tedious - it's why we do it. Anyway, as a way to speed up the process and make sure the shaping work did not affect the roundness of the spars, I used a cordless drill to "turn" the dowel. Using a cordless drill, a micrometer, fine sandpaper, and the plans I was able to accurately and efficiently shape the mast and spars. Using the instructions and plans I determined where the dowel needed to be reduced in diameter and what the finished diameter needed to be. I marked those measurements on the plans. I then put tick marks on the dowel corresponding to where the diameter needed to be adjusted. I then used the drill to SLOWLY turn the mast or spar holding the sandpaper where I needed to adjust the diameter of the dowel. I used the micrometer often to check the diameter of the mast or spar to make sure I wasn't making the diameter too small. I pinched the sandpaper against the dowel using my fingers. You risk snapping the dowel if you apply pressure to only one side (I learned the hard way!). By holding the sandpaper in one place for longer than others, you can adjust the taper of the adjustment - that is make the end narrower than the diameter as you move towards the middle of the dowel. DO NOT spin the drill fast enough to generate heat as you sand. Smoke rising from the sandpaper probably means you're turning the drill too fast! I was very cautions and checked the diameter often. I also checked to see if the mast dowel would fit into the mast hole on the hull. I found that I had to slightly sand the dowel where it enters the hull so that it fit and fit tightly. After I was satisfied with the shape of each piece - comparing it to the plans - I used Minwax pine stain on the mast and spars. I will go back over the mast with a darker stain to simulate the grease often applied to the mast where the hoops would run. More to come!

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Thanks Nick! I can use these building techniques for the Swampscott dory.

- 14 replies

-

- dory

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Looking good. I haven't experienced that problem with the boot tape. I usually use narrow masking tape. With all masking tape you don't want to leave it on any longer than is necessary. I remove it soon after the paint is dry enough to handle lightly. The boot tape should lift off - if it takes some paint, you can touch that up. It won't be visible as you will be putting the final boot tape on top of that line. f it looks like the boot tape is taking up paint to the left and the right of the tape, use a hobby knife to lightly score the paint along the tape. That will help limit any paint removal to what's under the tape. It's all a learning experience.

-

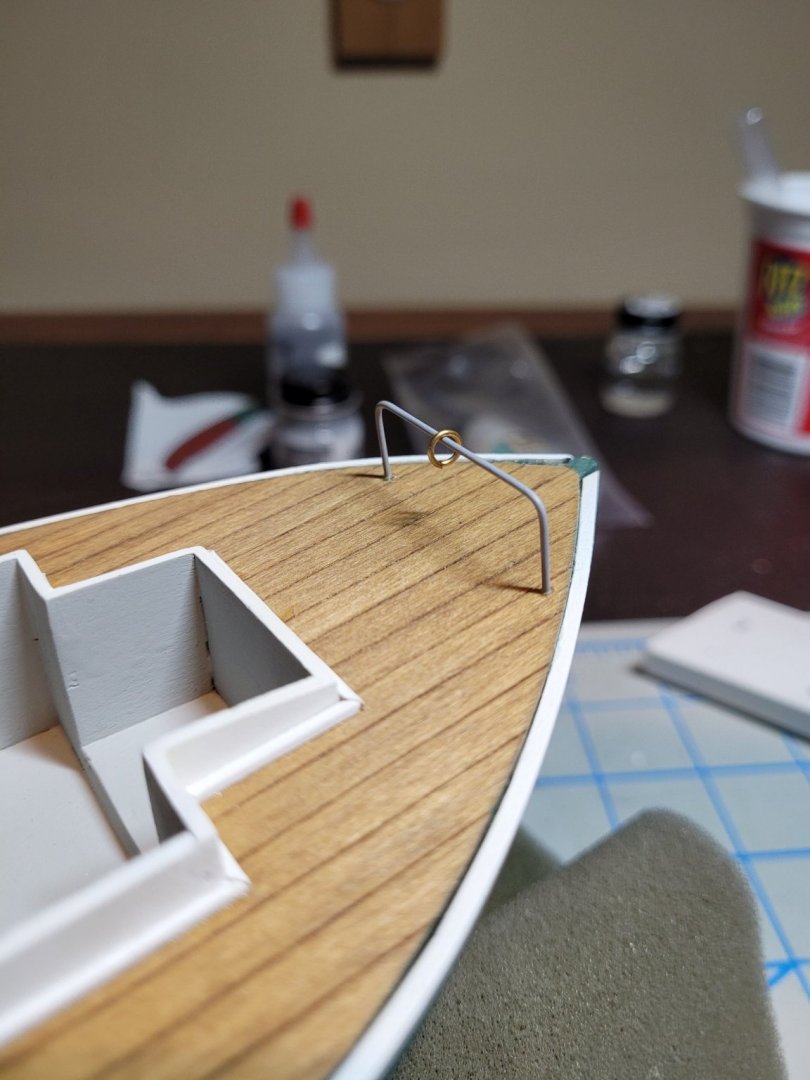

I have not been idle! I took some time off to get the "big" boat ready for the water and to get some sailing in this season. On rainy days I have been making progress on the Yankee Hero. Next up was painting the trim for around the hold, mitering the ends as appropriate, and attaching the pieces to the hold sides. Next, I put the final coats of white paint on the Samson Post and bow sprit. The next (and tricky) process was shaping the Gammon Iron. Fortunately, BlueJacket gives you extra brass for forming the iron. Although I was carefully (or so I though) bending the brass per the instructions (the template is super helpful), I managed to snap the brass in half. The second time around did the trick. I painted it with two coats of gray (see photo). I then discovered that I should not have attached the toe rails to the bow stem. You need room on the stem to mount the Gammon Iron. I cut back the toe rails a a bit and did some paint touch up. I then attached the bow sprit, Samson Post and Gammon Iron to the bow per the blueprint drawings. Most recently I added some deck hardware, including the mainsheet rail. I am now shaping the spars and mast (as rainy weather permits!).

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Eric - I started sailing Hobie Cat catamarans when I was much younger. I had a 23' Compac for many years. I currently have a 1978 25' Cape Dory sail boat. It's an older boat and I probably take about as much time caring for her as I do sailing it - but that's fine by me. Here is me at the tiller last fall - it might have even been late October.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Looks great! I have the swampscott dory on my shelf as well. I think the Pauline is on my short list of boats. I am learning plenty by watching your build.

- 100 replies

-

- pauline

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

I finished fitting and gluing the starboard toe rail - gluing with CA as I went along. I then cut and fit a small piece near the bow to make up for the short rail. I cut a 45 degree angle in the existing toe rail and cut a corresponding angle on the piece to be fitted. I then fit the other end of the small piece to fit against the stem. I have a little touch up to do both to the toe rail and where I had a little glue outflow on the hull. Thanks to Nic at BlueJacket I have another, and longer length of toe rail to fit to the port side. The next step is to shape that rail and paint it white. In the meantime, I think I'll start shaping the mast.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

Hey! Thanks Nic! I'll call the shop.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

-

HELP! My toe rails are too short! I sanded the deck to fit the hull. I did not cut the toe rails at all. I beveled one end to fit at the stern and was gluing as I went along and took a quick look and the toe rails are two short! The two toe rails are the same length. What did I do wrong?? Anyone have this problem? I may have to splice a piece in at the end, but I'm worried that will look like ....well.....not good. I don't have any other wood that size.

- 81 replies

-

- Bluejacket Shipcrafters

- Yankee Hero

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.08be9f93184af647579a503faa892381.jpg)

.thumb.jpg.4fdeddd0918cb6df5b9c2596bec1c8f7.jpg)

.thumb.jpg.f3be57d7fadfc6af1a22536281b3b209.jpg)