-

Posts

322 -

Joined

-

Last visited

About Jack H

- Birthday 03/26/1973

Contact Methods

-

Website URL

1165259961@qq.com

Profile Information

-

Gender

Male

-

Location

hangzhou China

-

Interests

CG, wood shipmodel

Recent Profile Visitors

-

zxjiaomohuol reacted to a post in a topic:

SOLEIL ROYAL 1669 by michel saunier

zxjiaomohuol reacted to a post in a topic:

SOLEIL ROYAL 1669 by michel saunier

-

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

-

Saburo reacted to a post in a topic:

La Belle Poule 1765 by MTaylor - Scale 1:64 - POB- French Frigate from ANCRE plans

Saburo reacted to a post in a topic:

La Belle Poule 1765 by MTaylor - Scale 1:64 - POB- French Frigate from ANCRE plans

-

scrubbyj427 started following Jack H

-

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

FrankWouts reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

botra288 reacted to a post in a topic:

La Belle Poule 1765 by MTaylor - Scale 1:64 - POB- French Frigate from ANCRE plans

botra288 reacted to a post in a topic:

La Belle Poule 1765 by MTaylor - Scale 1:64 - POB- French Frigate from ANCRE plans

-

Marco Mercuri started following Jack H

-

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

-

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

Jack H reacted to a post in a topic:

HMS Portland 1770 by scrubbyj427 - 1:48 - 4th rate 50 gun ship

-

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Jack H reacted to a post in a topic:

Savo from Serbia

Jack H reacted to a post in a topic:

Savo from Serbia

-

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Jack H reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Jack H reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

Jack H reacted to a post in a topic:

HMS Winchelsea 1764 by Rustyj - FINISHED - 1:48

-

Jack H reacted to a post in a topic:

HMS Winchelsea 1764 by Jim Rogers - FINISHED - 1/48

Jack H reacted to a post in a topic:

HMS Winchelsea 1764 by Jim Rogers - FINISHED - 1/48

-

FrankWouts started following Jack H

-

Arthur Goulart started following Jack H

-

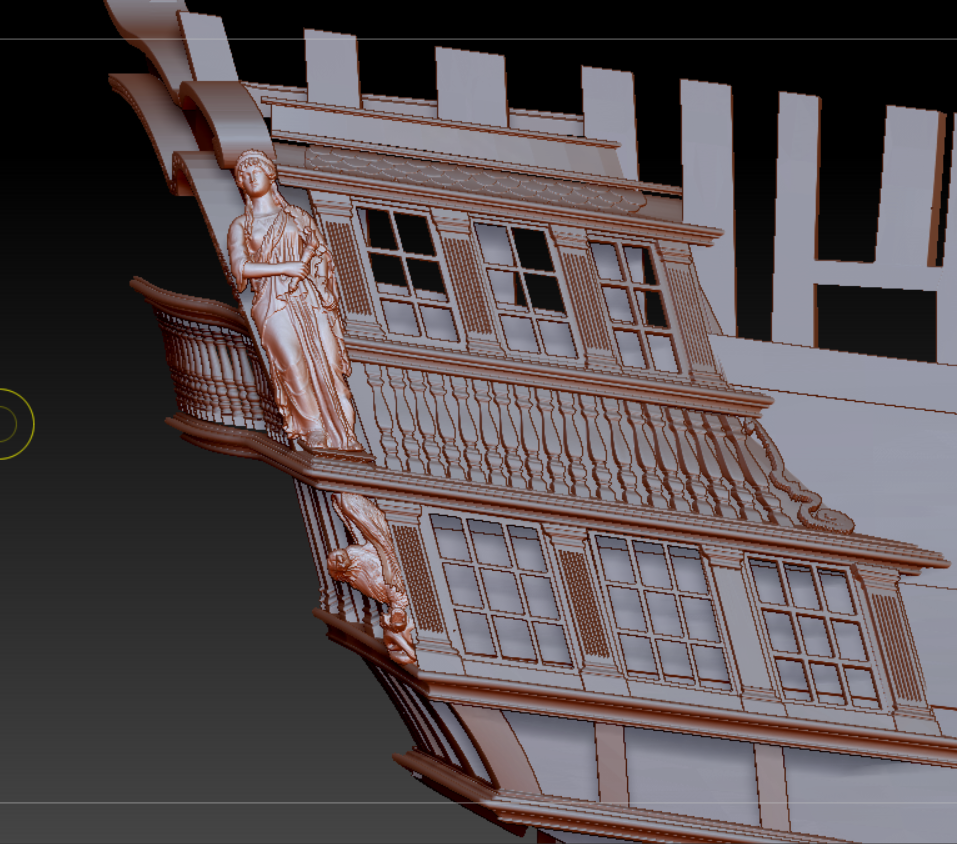

I'm sorry I forgot to reply to you. I saw your question at that time, but I was busy with other things. Later, I forgot. I saw this post today one more time accidentally ... I use rhino6, silo2.5 ,zbrush2018, and then program machining with rhinocam 2018. The commercial licenses of these software are relatively cheap. I mean, compared with expensive software such as Solidworks + solidcam, 3DMAX, UG, PowerMILL .... But personal use of these software(rhino/cam,zb...) is still a big expense. I spent about $4900 at that time.The price of SolidWorks + solidcam in China is $11,500, from Chinese agent in 2018. Jack

-

Thank you JJ ,Allan,and all your "likes". For some reasons in my business, it may be another few months before this project continues. Also, due to the pandemic, one of my partners, who made prototype of 1:36 in scale, he wanted to pause for a while.so I needed to restart working on the 1:48 prototype. Thank you all for your attention. Jack

-

Hi Jack, There were a couple recent posts on Model Ship World asking if you have any updates on the Cumberland kit. It looks so good, many are hoping to get an update from you.

Many thanks

Allan

-

Hi Allan,thank you for your kind words, for some reasons in my business, it may be another few months before this project continues.

Jack

-

THANK YOU!!! I hope it works out. This is the first kit that I have ever seen in 50 years that would make me consider going from my own scratch build to a kit! GOOD LUCK

Allan

-

-

Jack H changed their profile photo

-

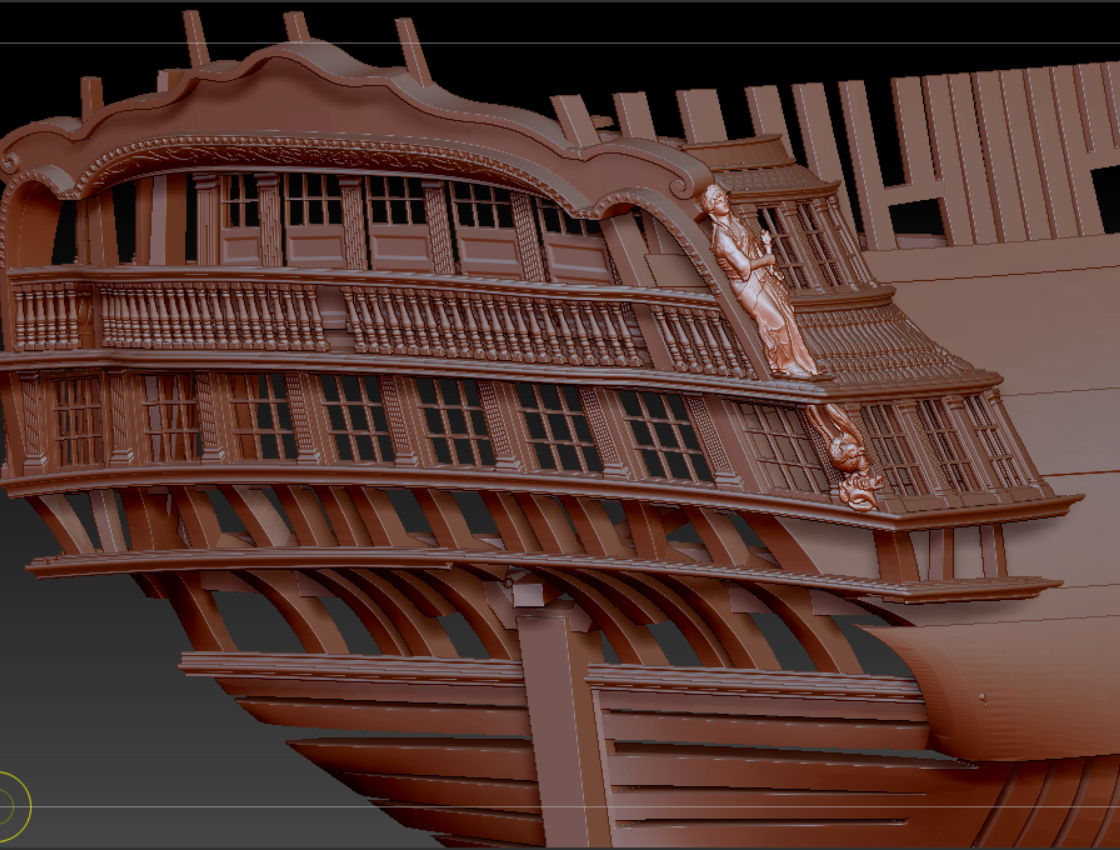

If it's just a bow section, 1:36 may have better details, but as the full kit of the first POF project, I think 1:48 can be considered because many modelers will put her and winchelea side by side, the same scale is better. Moreover, POF projects are very complex, smaller projects are undoubtedly a wise choice (they can be developed faster). In addition, if I am lucky enough to cooperate with Chuck one more time, I hope do better than last time.

- 1,784 replies

-

- syren ship model

- winchelsea

-

(and 1 more)

Tagged with:

-

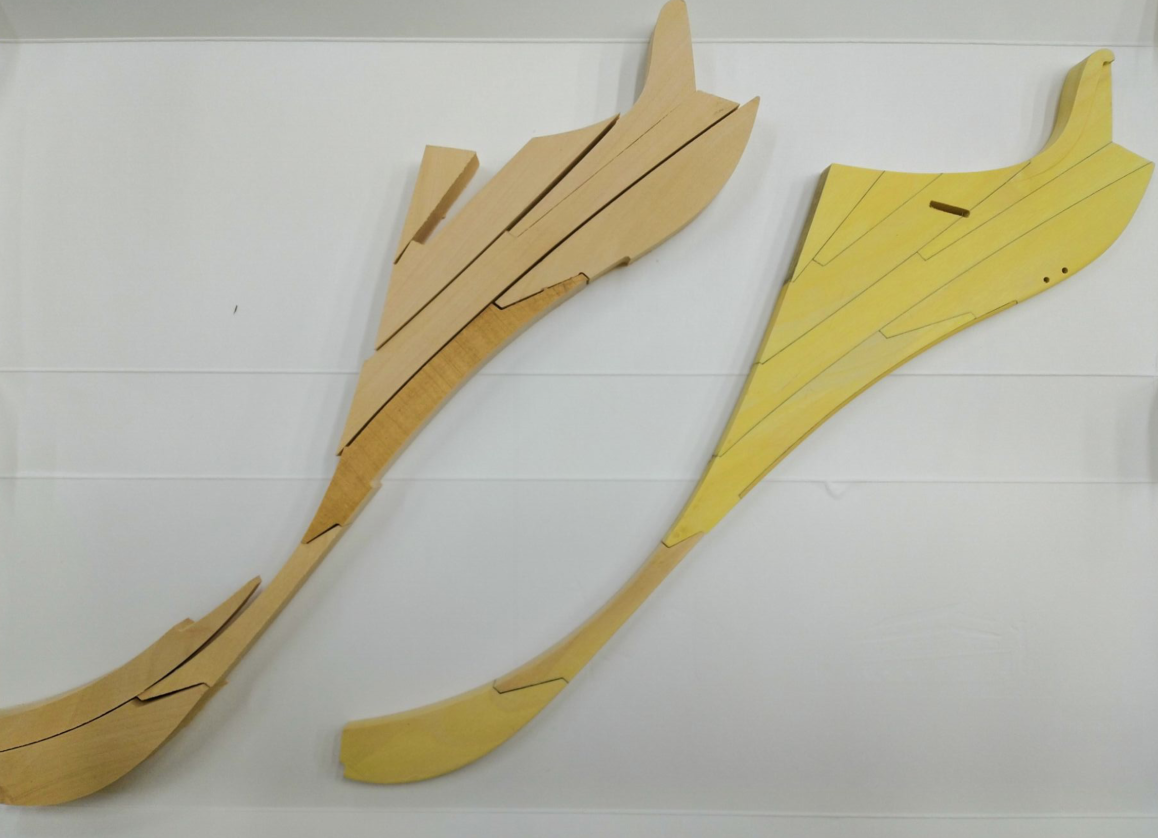

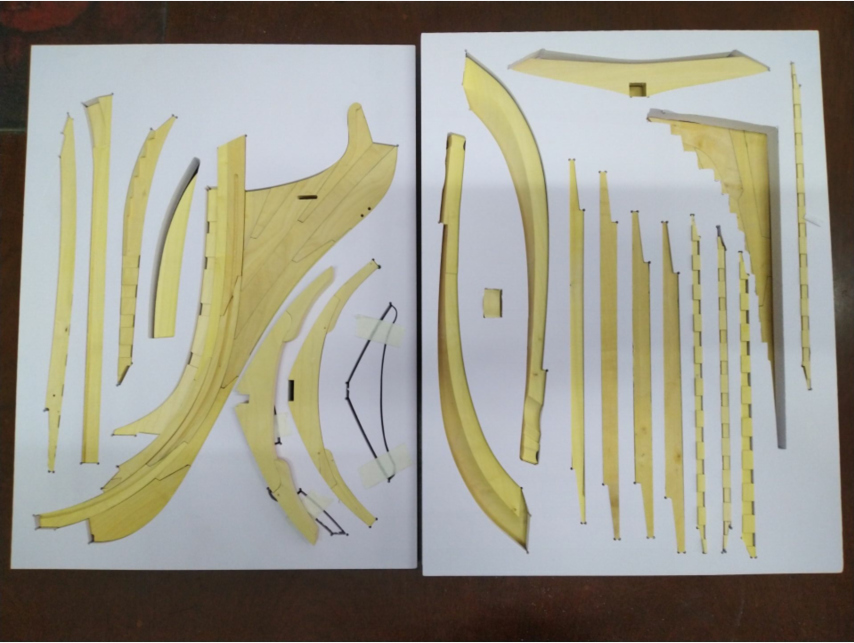

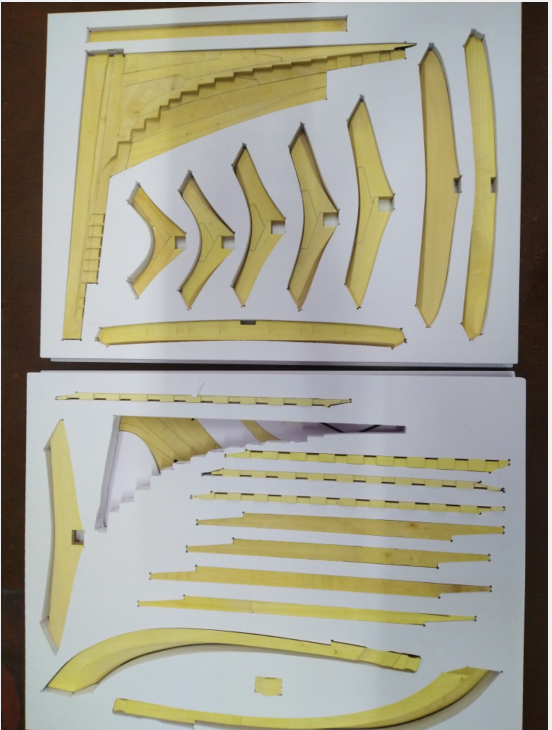

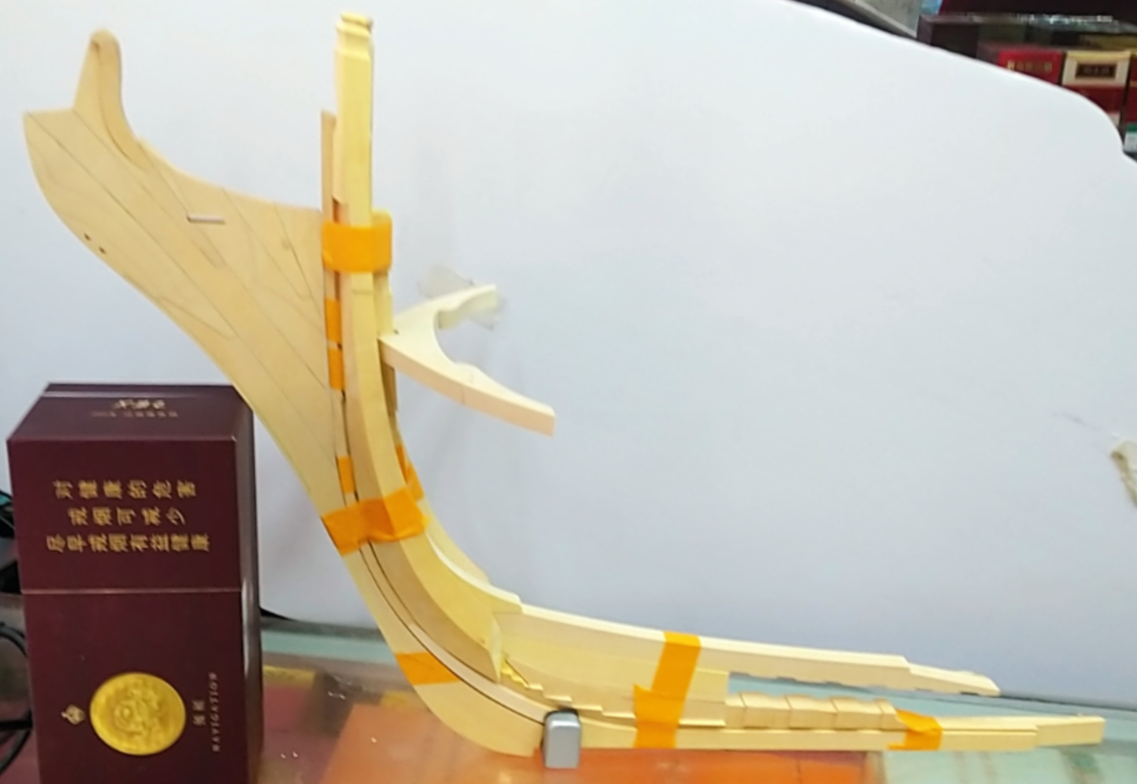

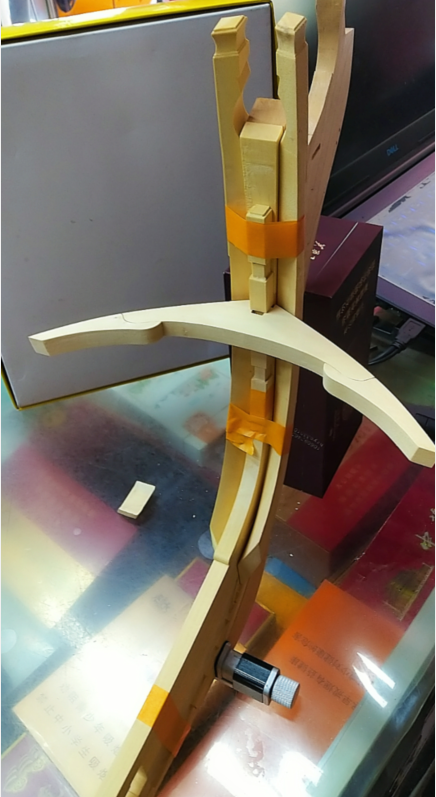

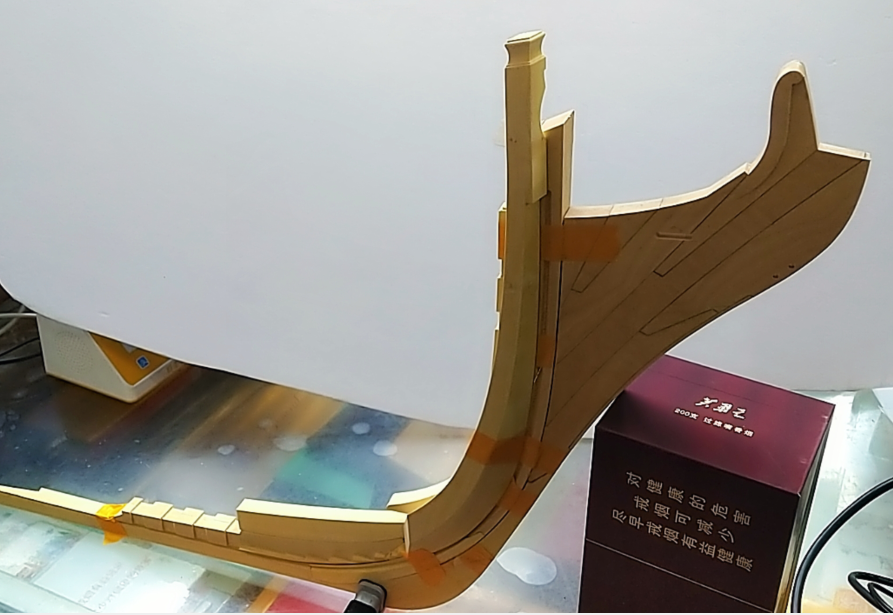

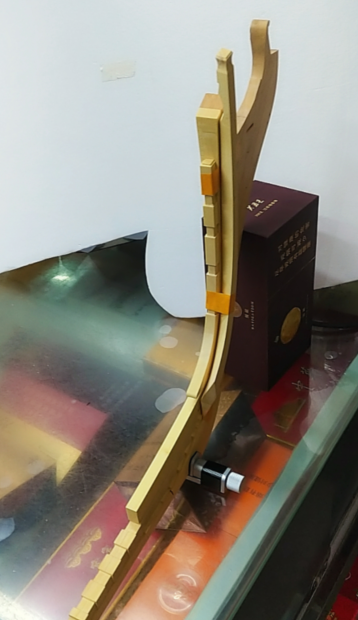

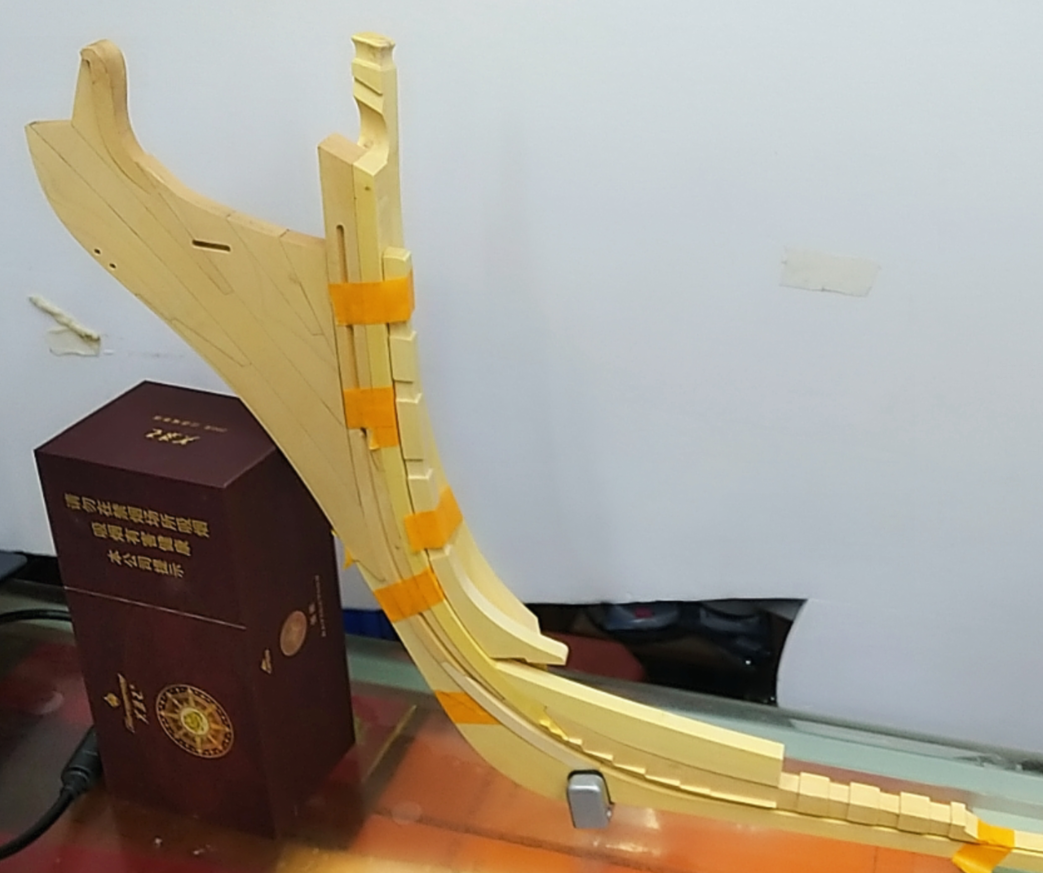

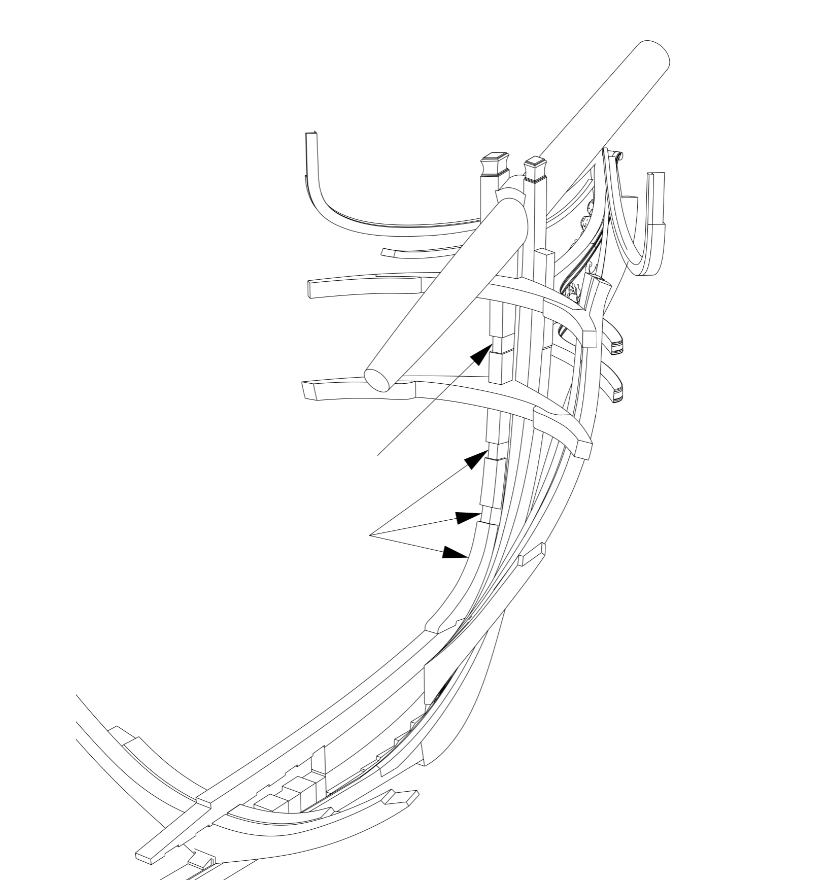

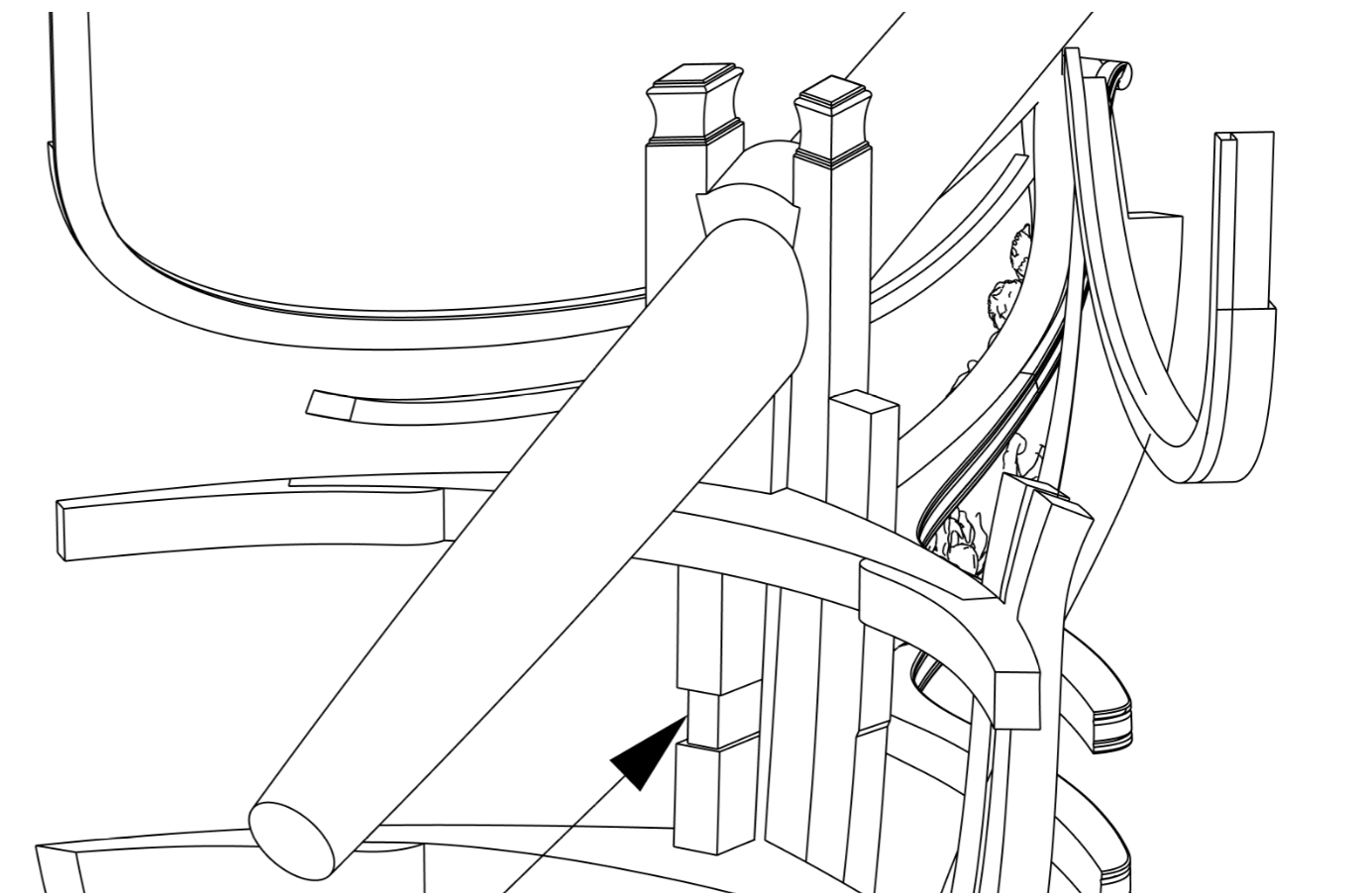

Yes,that's basically the first chapter. And then I went on to process the 1:48 parts, and I started to make this model in a real sense, I want to show you my idea, that is, how to simplify a complex POF model into several large parts by machine and hands, so that modelers with common skills and no professional tools can make this complex model. This is the first step. Let's take a look at the basic parts of pear wood and the pre assembled parts of jujube wood on the right.I will process a set of Asian boxwood samples at the same time.Maybe you are tired of looking at those model parts all the time. Indeed, I am too busy. I have to go to work during the day, and then design and process the ship model in my spare time. Maybe I only have a few hours of spare time every day. However, my classmate's processing factory can process these parts in batch ,I insist on testing these parts myself in the hope of finding more mistakes and modifying them. On the left is Chinese pear wood, and on the right is jujube wood. Asian boxwood and jujube wood look similar, but undoubtedly boxwood is the best, more delicate than pear wood, and has good color. In the future, I will release about 3-10 full boxwood kits, if anyone likes them.

-

No, it's not the final product. I mean the parts I'm going to send out, but it's the first chapter of my plan. I need to finish at least the hull part, which means that I have to complete all the design and prototype of carving set. Secondly, in addition to the first chapter you have seen, there are also need all cant and square frames, then decide whether I can release chapter one. As for those "β parts" ,there are very anxious modelers who are willing to take the risk of project failure and willing buy β Version to participate in the verification of this project, I promise them that if the project fails, I will return all the payment to them.But we don't accept such orders now. My German friend will participate in the second batch of prototypes,if everything goes well, my UK partner will probably make this model in the third batch because he is very busy now. The final English version, including instructions and components, needs to be determined by him--He also owns the copyright for the project and owns 'True Image Models'. We are looking for cooperation with MSW. It will take time to determine many details. In order to reduce tariffs and freight, I am considering whether we can process some parts in the United States. Similarly, I am also considering processing some parts in Germany or UK.But all these need to be accounted for before the final decision can be made. If really can't reduce the expensive price , I will consider the concept of "basic parts". I only process a small number of parts, such as steps, hawse pieces, can frame... and carving set,--i call it ‘plans+basic parts’ or 'semi-kit', which are difficult to be made by hand. The rest are made by modeler himself, which can reduce the cost greatly.You guys can tell us any your suggestions and ideas. Thank you! Jack

-

Hi! Maybe I'm processing 1:36 and 1:48 pear wood and boxwood parts at the same time, so it seems a bit messy,but I'll mark the scale of prototype. 1: 36 is a customized model, I can only verify the 1:48 version of pear wood and boxwood myself. Pear wood will be the basic version. I should release the parts of the basic version immediately. As mentioned earlier, the basic version is equivalent to the parts of laser cutting. The difference is that the laser has black carbon , but the CNC has no black carbon . Because the thickness of the laser cutting board will not be too thick, the kit scale for laser cutting is generally small, such as 1:72 or 64. The first chapter parts (1:36)will be sent out soon, and then I will process 1:48 parts of pear and boxwood, you will see the material and color of pear wood more intuitively. Jack

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.