-

Posts

17 -

Joined

-

Last visited

-

Andrew Purdy reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Andrew Purdy reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

Cap'n Rat Fink reacted to a post in a topic:

Working copper bilge-pump 1820, 1:64 scale

-

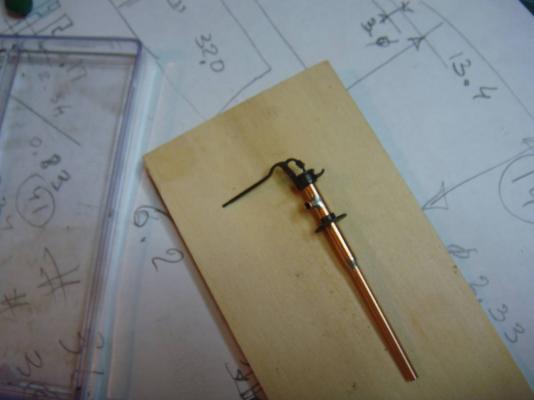

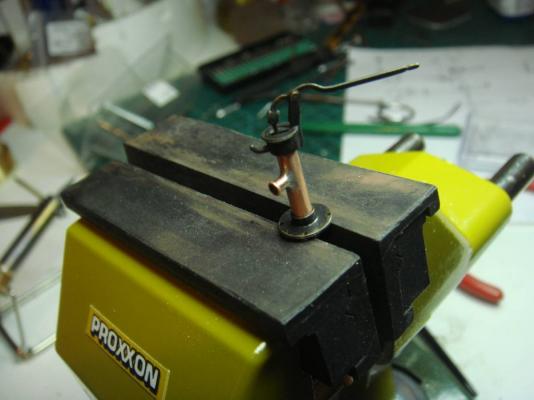

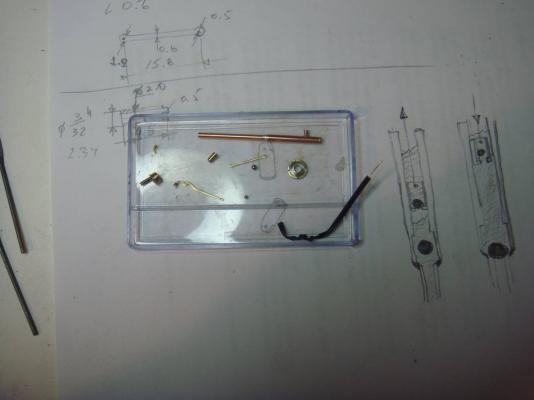

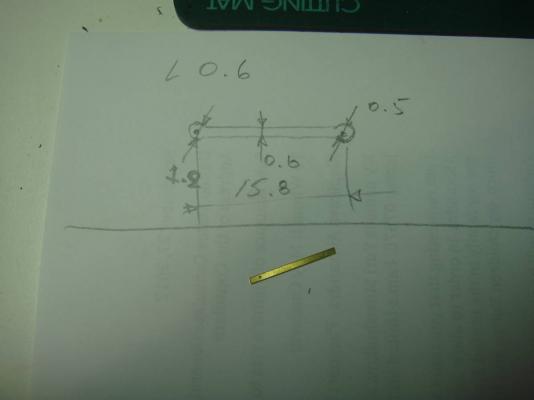

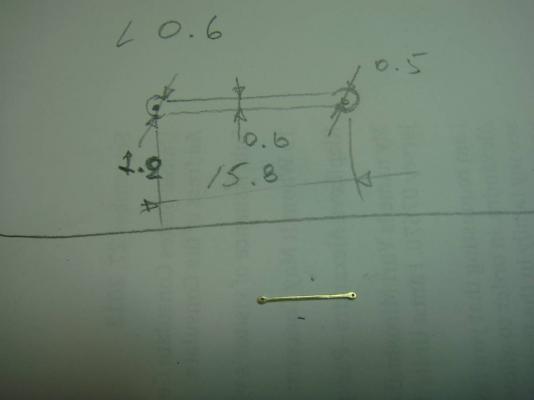

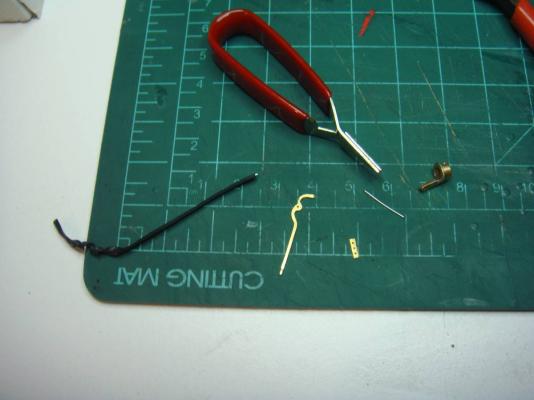

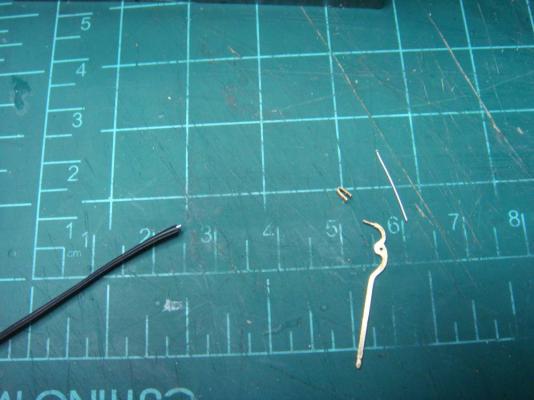

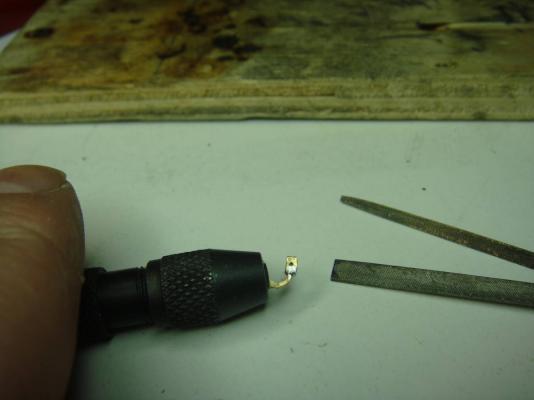

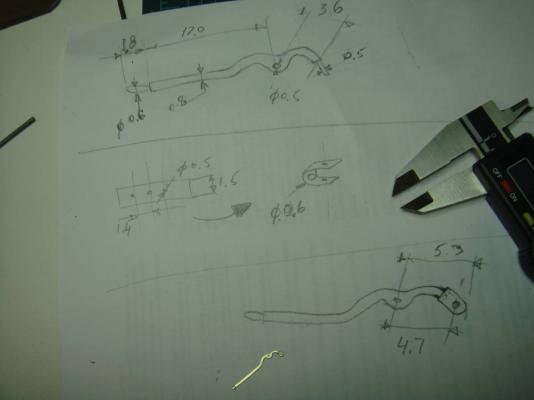

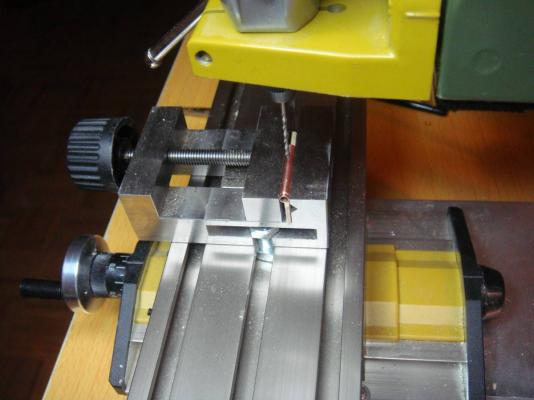

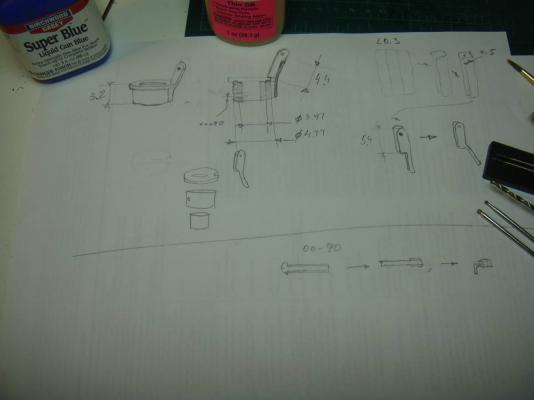

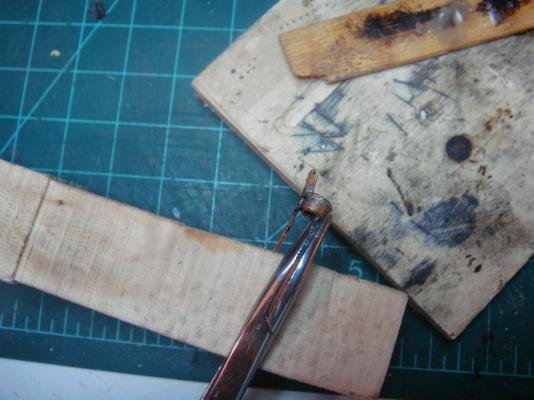

The rocker arm ( The handle) Brass 0.6mm: cutting out and forming of the rocker’s sly form Brass 0.3 mm: drilling three 0.5mm holes with 1.4mm step Bending stock holder, whetting the rocker tip up to 0.5 mm Soldering Grinding off excess Handle assembled!!! In handle support: boring a required spot for rocker movements Fitting

-

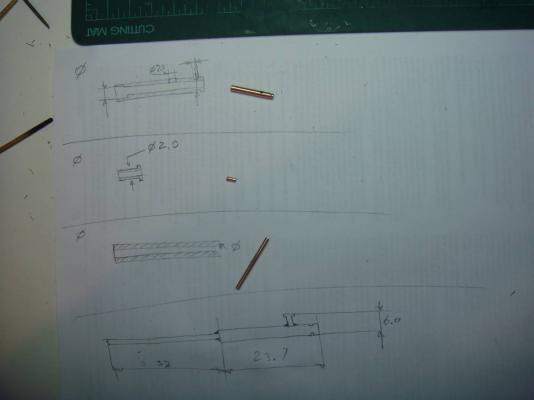

The “pipe”: On copper tube 1/8'' (main pipe): grinding out a little groove for the locking bolt Cutting off to the size (see the sketch below...) On other side of the 1/8'' main pipe drilling a 2.8mm bore; that would be a place for a ball of lower valve Copper tube 3/32 ""(overflow pipe): Grinding down the desired area up to 1.9mm (see sketch below...) In the 1/8’’ main pipe: drilling a 1.8 mm bore for the overflow pipe Another piece of 3/32" tube and all 3 parts for pump pipe are ready Soldering all together using simple conductor Reseating the soldering of lower and upper pipes with help of 3/32" diamond sphere

-

The head: 0.3 mm brass piece: bending, drilling, grinding out a support of handle (have no photo, but looks like everything is clear from the sketch) Soldering the 3/16'' tube (with bore for 00-90 thread) to the head cover. Inserting the 5/32'' tube into Fluting and cutting the threads for the locking bolt First fitting Soldering the support of a handler Chopping, grinding out, trying on

-

Materials: The real implementation forces to change pump proportions for a little: follow up to standard set of copper (and brass) tubes: 3/16'', 5/32'', 1/8'', 3/32'' and 1/16''. The chosen tube set is giving a great opportunity - the inner diameter of a tube corresponds to the outside diameter of the tube оf next number – the tube move -in and -out into each other as closely as possible. Designed etched details on brass 0.6mm thick were good for nothing – I had no inexperience, and did not add 20% of the thickness to the edges of small parts, so they were eaten to be useless ... Nevertheless head cover and the base bed are ok. But the remaining parts – handle, support and stock - should be done by hands. And yes!!!: a metal wire from the package of bread and brass washer with 1.5 mm inner diameter. Also I have to say: an idea to make the pump “working” came while of assembling: that was happen that I have steel balls with 3/32’’ and 1/16’’ diameters (I bought them to simulate charges for 24’ carronades and 6' guns, respectively) Oops!! One more thing: a 00-90 bolt

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.