-

Posts

472 -

Joined

-

Last visited

About Richard Dunn

- Birthday 10/14/1971

Profile Information

-

Gender

Male

-

Location

Brisbane Australia

-

Interests

3D Artist and Ship Modelling

Recent Profile Visitors

-

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

druxey reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

mugje reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

mugje reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

cajunrandy214 reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

-

Currently I am not planning to produce this at any other scale than 1/40, as I said at the start this was a request for a single client and I merely wanted to put it out into the community in case any others wanted it in this scale as well. To produce this even at 1/48 would involve having to completely redo the 3d model and start from scratch again, not only is it a huge amount of work but I would have to charge my time and make an already expensive semi kit simply too much for most people. I am happy to do it at 1/40 though, any request, for this please pm from now on as the prototype is finished now and client has the model. I do want a minimum number of orders to make this viable and this is not the only site I have done a build on for this particular project.

-

Scottish Guy started following Richard Dunn

-

That's right. here is a picture to show it, the plate you see extending up is the centre of the knightheads, there is 8" of wood fore and aft of this, with the knightheads being 16" thick overall. In this profile picture the fore part is on so the aft half is missing, and the rabbet is clear as planking is off.. The second and third images the plate can be seen white and fixed to the back of the stempost, in fact it runs right down and becomes part of the keel assembly This image clearly shows the plate is lined up to the back of the stem. Here is a drawing partly done that was issued to site staff requesting measurements, the arrangement can be clearly seen, and the combined dimension 6 &7 is 2'2" horizontally from top of stems aft side. the plate is also 5.5" aft of the bearding line, not the rabbet the back one. It is 17.5" from the front of the actual knighthead to the front of the stempost and from the front of the knightheads to the line of the rabbet is 7.5" A foot note about the below drawing, the vertical double blue line on the stem is the rabbet line.

-

Back to work today to my full time job after Christmas so progress will slow down now. Stern finished, just a layer of 1mm ply to go on poop. Planking also cut ready for final sizing. This is structurally as far as the kit gets taken as far as parts for the hull excluding fittings. Still the bulwarks and hatch coamings to cut from .5mm ply.

-

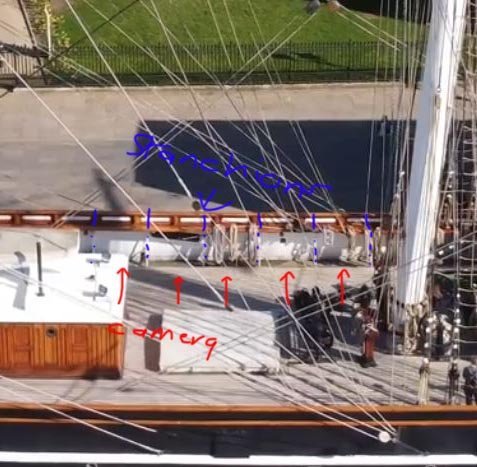

I have a request of somebody if they are interested. I need series of images taken onboard so anyone who is local and able to do this it would be of huge help to any modellers of Cutty Sark. What I want is to have a stitched image of the full length of her bulwarks. I can do the stitching in my software but need images taken all the way along from the heads to the ships wheel at the centres of the space between the stanchions. see image, standing where the red is between the stanchions, this image can be put up for anyone if wanted but its not been done and is really quite easy. I have a person I have asked privately as well who is going back soon but just in case he can't. It's about 35 images

-

Decks glued down, Titebond on the beams and CA on the notches to get immediate hold down as it's hard to clamp. the frame notches and waterways are now sealed and primed ready for rubbing down, this way the sheerplate which stands proud will have a nice clean crisp corner. This is in case I don't do the cement filled waterway and leave it exposed. The counter glued on now to.

-

It depends on the job, sometimes I screw the board down and use tabs, sometimes vacuum table but on small parts like this the masking tape and CA trick A laser also will not do for my work as I need to build guitars and also a CNC with a router can carve things in 3d space which you can't do with a laser. Re size if you have a small table you can probably only cut one frame at a time, this means lots of wastage. with a sheet you can nest them all together and get 8-9 per sheet. But for a hobbyist or model builder I can understand not wanting a big one. Just we aware that they require a lot of maintenance time and make sure the table it sits on is solid and level

-

Richard Dunn reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

Richard Dunn reacted to a post in a topic:

Cutty Sark by Richard Dunn - 1/40 scale - scratch built semi-kit prototype

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.