-

Posts

314 -

Joined

-

Last visited

About ronald305

- Birthday 05/24/1953

Profile Information

-

Gender

Male

-

Location

Metairie La.

Contact Methods

-

Yahoo

ronaldlabiche

Recent Profile Visitors

-

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Canute reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

Landlubber Mike reacted to a post in a topic:

best size drills for pilot holes for the planking nails

Landlubber Mike reacted to a post in a topic:

best size drills for pilot holes for the planking nails

-

ok thanks everyone to answer your question if I'm using the nails only to hold the planks in place till the glue dries YES also, I was recommended to use nails thought model space Reps and the instruction even Allen shows using nails in his HMS Victory build. on YouTube and thank you Mike about the plier idea for micro mark Ronald

-

Hello there everyone. can anyone recommend the correct drill size for pilot holes to help with the planking nails I was told by the instructions to predrill the planks to help the planking and I'm running out drills to use I'm guessing they have to be smaller the nails right otherwise they would not help hold the planks down until the glue dries. thank you Ronald

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by ronald305 - Model Space

GrandpaPhil reacted to a post in a topic:

HMS Victory by ronald305 - Model Space

-

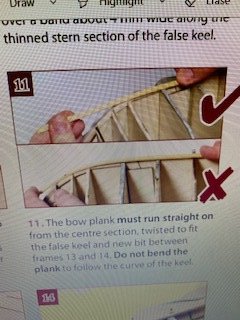

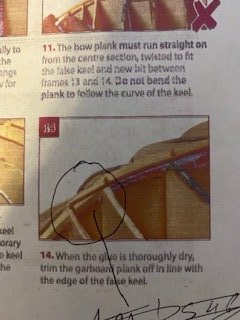

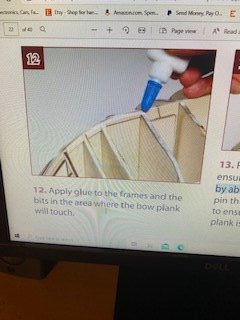

Hi there fellow ship modelers I know it has been a while since I requested help with my model space HMS Victory, but I need your help again I'm at the point where you add the forward garbed plank to the forward bow near the false keel pack 4 stage 36 -page 146 part 12,13 and 14 I do not quite understand part 14 and 14 I had to remove the two planks twice already, I understand about having the planks touch the false keel by 1mm and only put glue on the ribs and the bits and to sand them along the line of the ribs but when I try to add the planks they are close to the bits and they are suppose to be bent as in the photo 11 attached has anyone come across the same issue and the video is not help full at all and Allen is not allowed to help me because the lovely Admin when I try it again what should I do this time the last photo is not pretty but you can see where the plank needs to be trimmed, if I have tear any paper shims out I'm ok with it any suggestions would be appreciated,thank you Ronald

-

mtaylor reacted to a post in a topic:

HMS Victory by ronald305 - Model Space

mtaylor reacted to a post in a topic:

HMS Victory by ronald305 - Model Space

-

thanks everyone who replied to my help questions regarding bending the planks, to answer the last Gentleman about the construction method that is the way model space wrote the instructions sir, Im following what they tell me to even though the instructions are hard to figure out, but I will try the pre-formed method, I have tried soaking the planks in hot water but don't know how long to soak them as far the wood purchased, they were purchased last year, to answer charter33 question I do predrill a small pilot hole before nailing Ronald

-

hello there can anyone tell me why the planking strips keeps splitting? or breaking when I try to bend them for the stern did, I faired it to much or is the wood Im using I got the first two in place, but the third plank keeps on breaking or splitting I even trying to use my crimpers as well and heat bending, do I use a bigger head on the plank bender it's a good thing I have a lot of planks I purchased from Age of sail some time ago, can anyone help me please thank you PS enclosed is a photo of the area in question Ronald

-

Hi guys and Gal's would any one know why Model space is down all I get a server error I wanted to tell Mark the Administrator that my planks that he said went out to me in October never did show up and I am about to run out of 5mm X 2MM planks to fix the stern area what can I use to substitute for that size planking I was able to find that size buy only in balsa but I find it to soft can it be used can it be bent in to shape using the same method as the for the harder planks Ronald

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

modelshipbuild2.jpg.a6175a1f3a09520acce96be98881ecb7.jpg)

modelshipbuild3.jpg.e74ac340acccab01db9e4288adbeb69a.jpg)