Wreck1919

Members-

Posts

64 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Interests

Wreck diving, WW1 navies, good whisky

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

dcicero reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

dcicero reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

Retired guy reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

Retired guy reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

-

FreekS reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

FreekS reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

mtaylor reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

mtaylor reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

GrandpaPhil reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

GrandpaPhil reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

yvesvidal reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

yvesvidal reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

Canute reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

Canute reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

KeithAug reacted to a post in a topic:

SMS Karlsruhe by Wreck1919 - 1/100

-

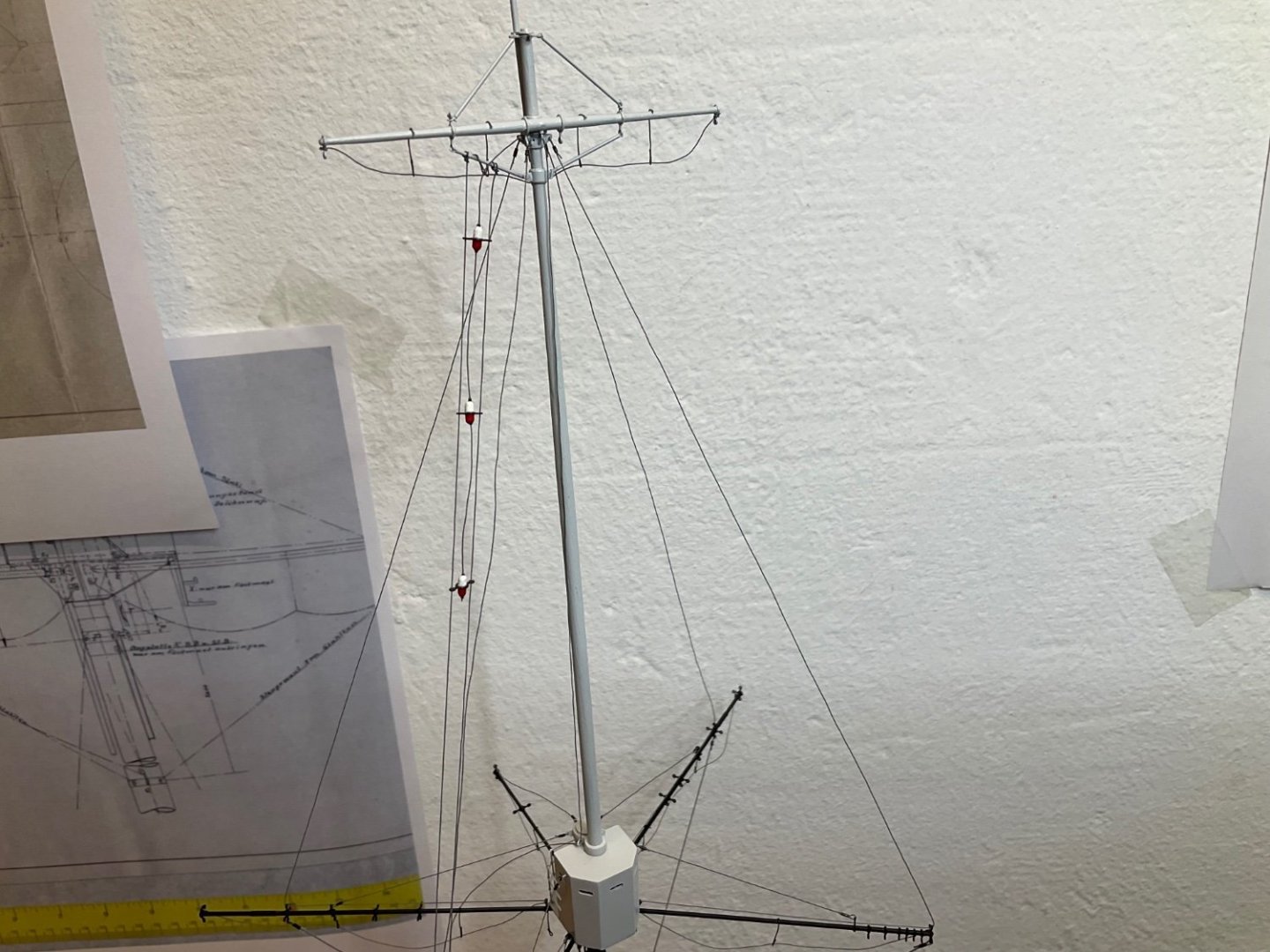

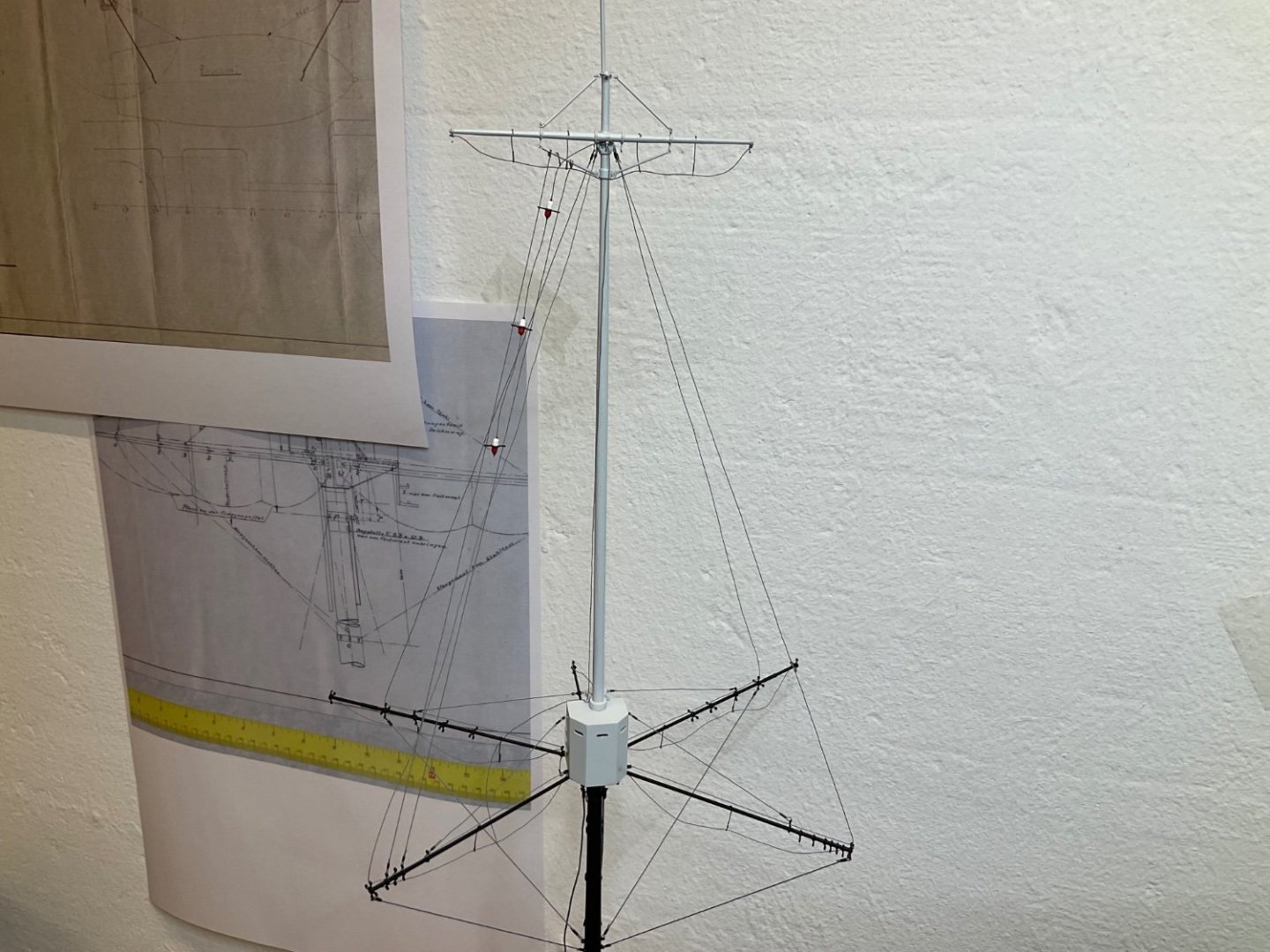

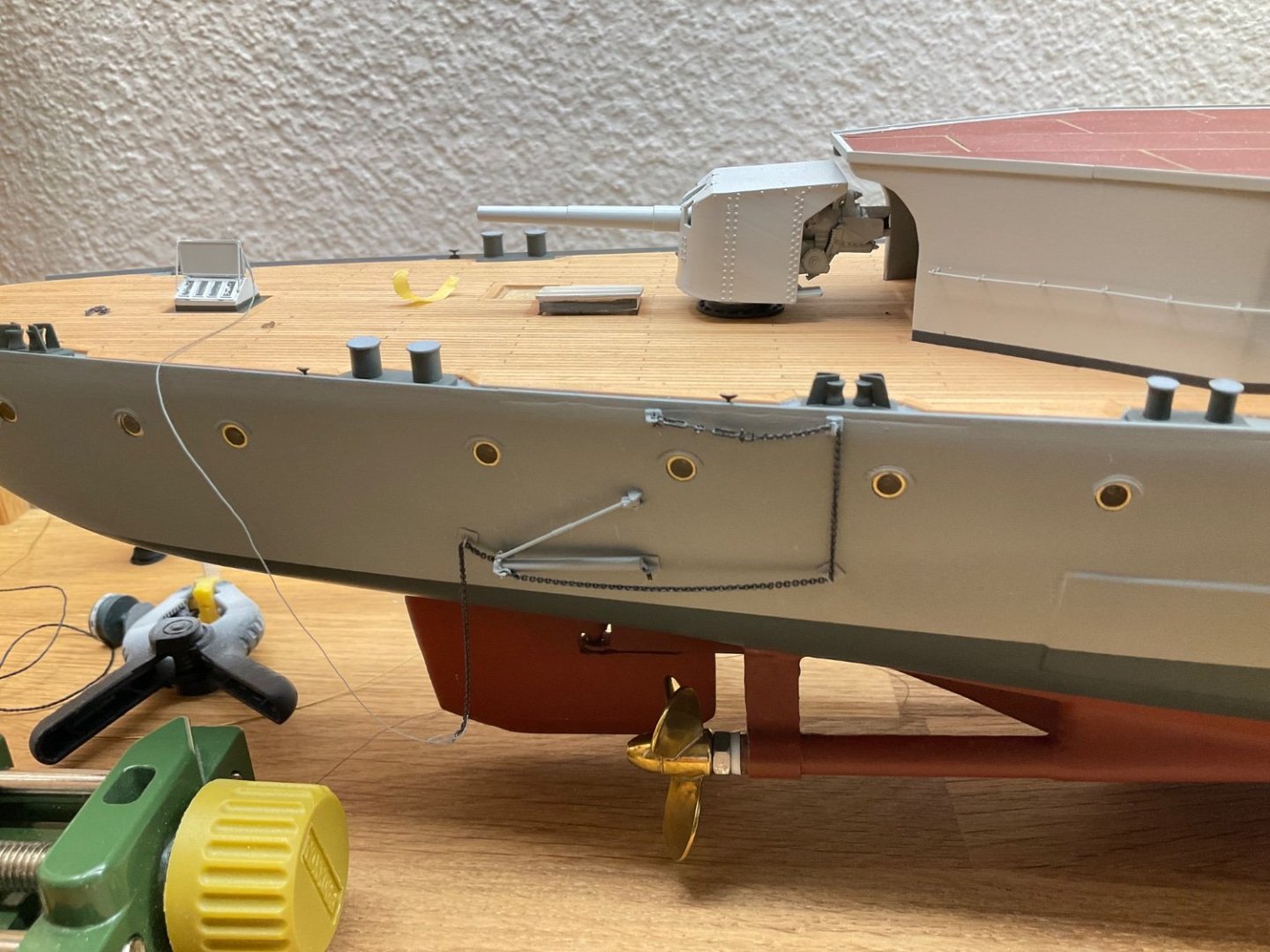

Another update: rigging is almost done. All that can be attached to the masts off model is finished. Remains „only“ to do the lower attachment points on deck. How to attach the signal lines on the foremast to the bridge without tearing everything apart is still a mystery to me though…🤪. Looks a bit wild now but once straigthened out it should be ok,..i hope. cheers sascha

-

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

Wreck1919 reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

Wreck1919 reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

-

Wreck1919 reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

Wreck1919 reacted to a post in a topic:

Lightship ELBE 1 by Mirabell61 - scale 1:87 - launched 1948

-

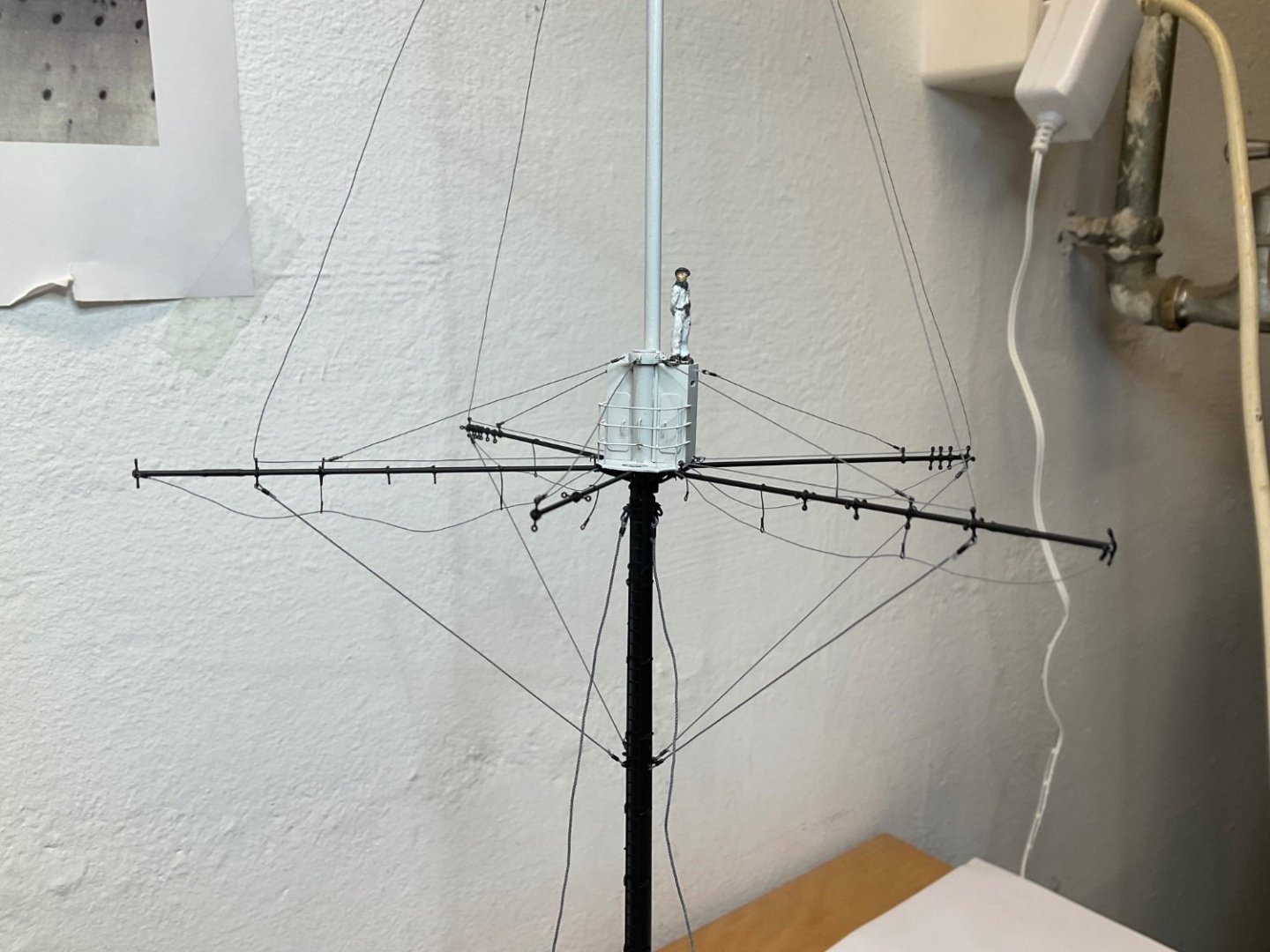

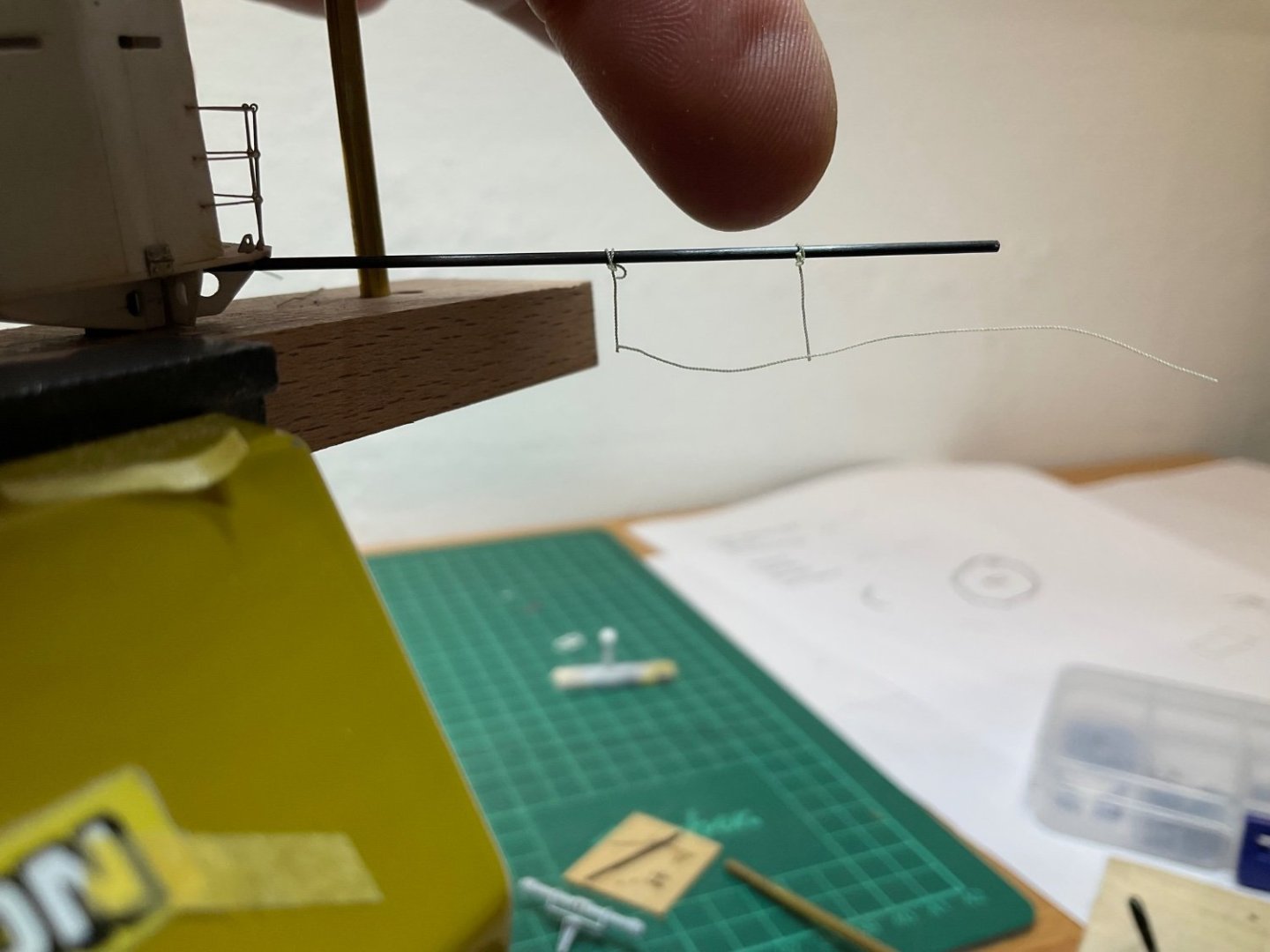

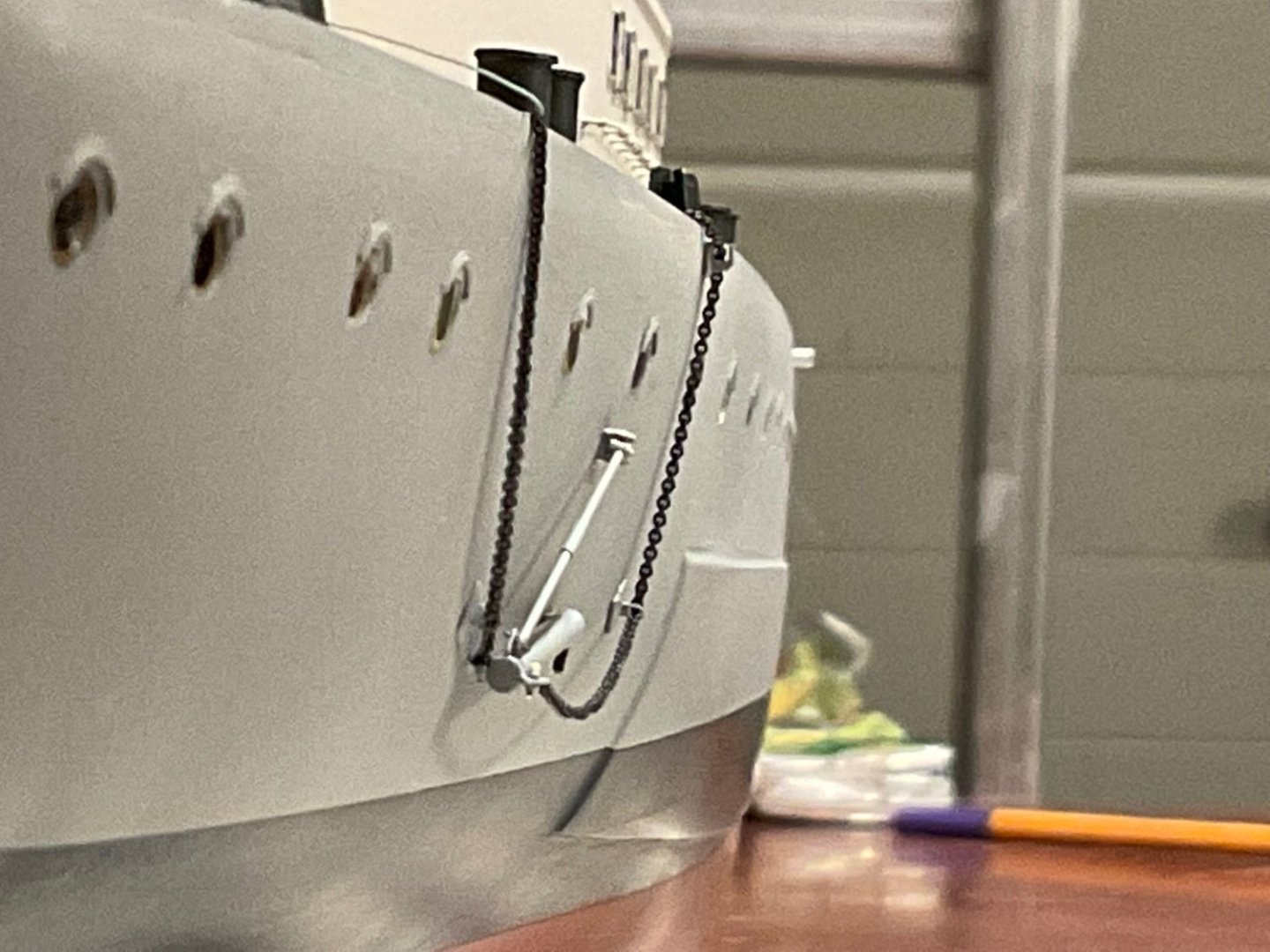

Morning(?😎) Keith. Yes, of course you may👍🏻. the stirrups are 6.5mm(0.25“??) so maybe the picture wasnt good. So here is another one where my inspector is being hoisted up. Note that i tied the rope under his arms and not around the neck since his services will still be required 😎. The shape of the ropes is work in progress, am still experimenting (off model) with varnish. Edit: and i did cheat with the attachment points for the ropes under the platform, because i forgot to include them when building. Now its too late.

-

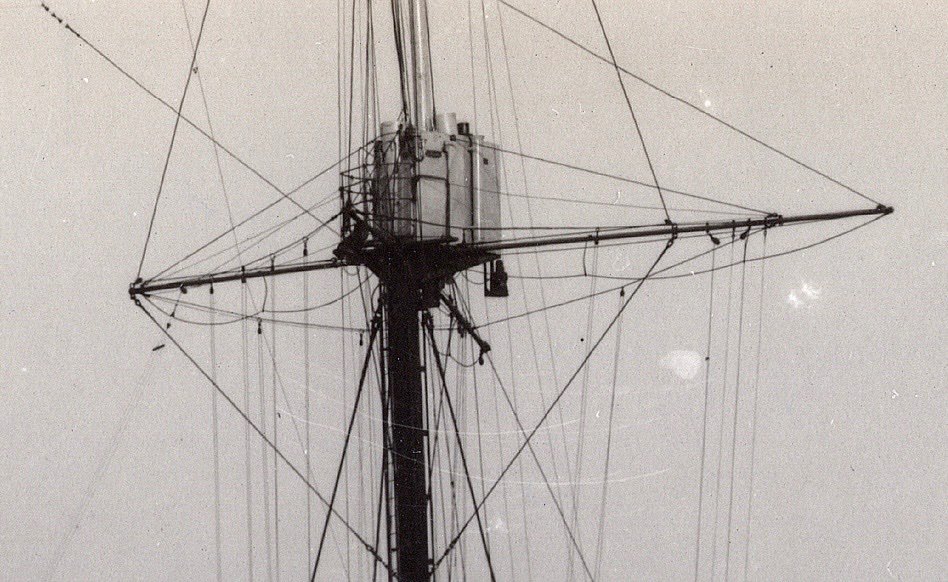

Progress… nothing broken yet. Missing the varnish/„natural“ slack still, but will experiment. Halfway done. Unbelievable how many lines/ropes are on that mast given its not a sailing ship. Oh and thanks eberhard/valeriy for the comments about the position of the footropes. The are shown to be „aft“ /behind the spar/yardarm on the plan, but i totally missed that detail. cheers sascha

-

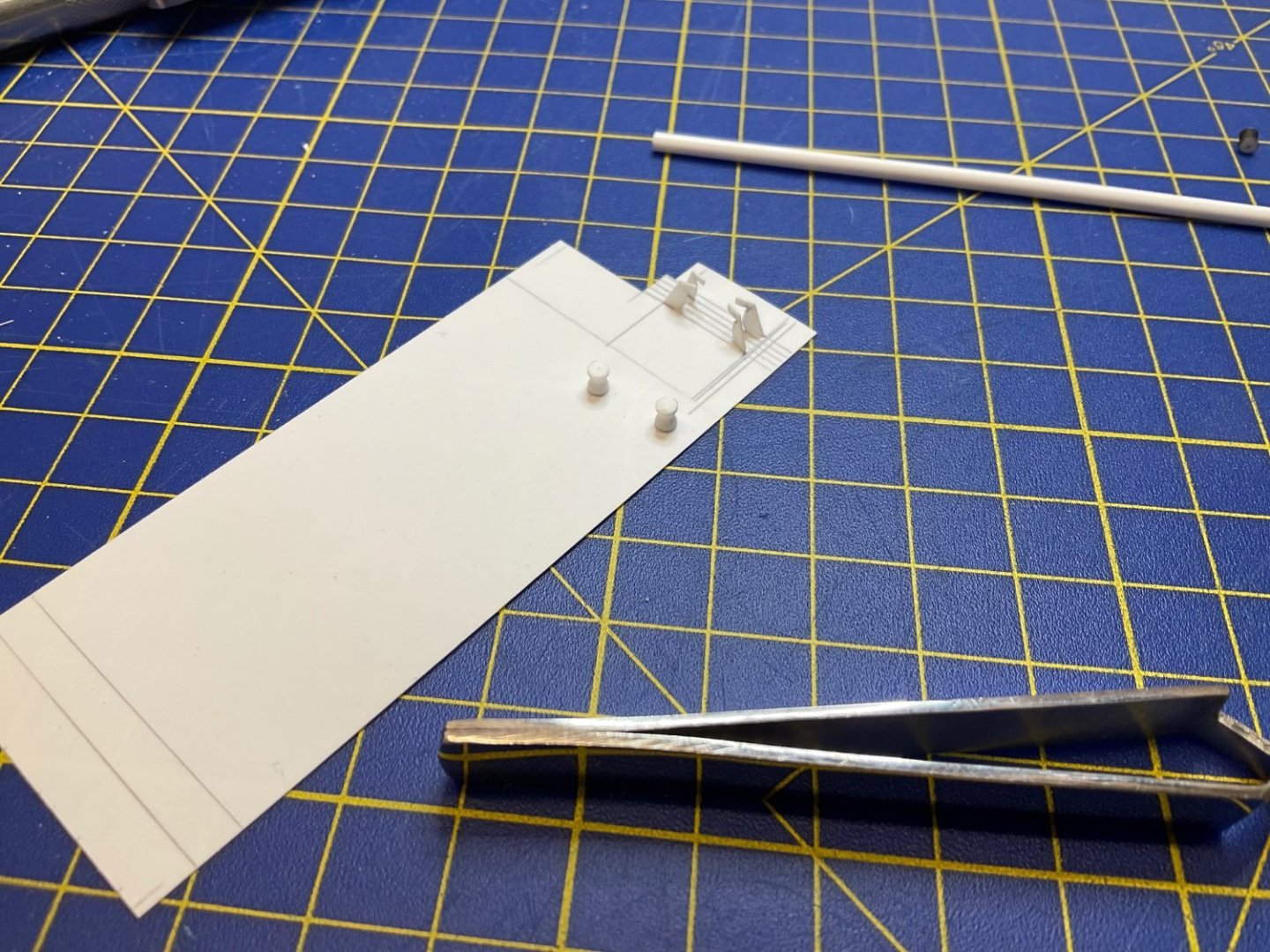

Hi, so here is the first one. I hope to improve execution for the remaining spars/yardarms. Getting the vertical ropes (stirrups) to the same lenght and position is tricky for me.guess i will find a method by the time the last ones a made. Fortunately a photograph shows footropes/stirrups as also not being straight. Thats my excuse 😎. cheers sascha

-

Moin Nils, nice to see another one starting from the keel up (or rather down😎). Please keep up the detailed reporting. Sascha

- 120 replies

-

- lightship

- Feuerschiff Elbe 1

-

(and 1 more)

Tagged with:

-

Hi both, thanks. Will do away with the rings. Sadly i didnt think ahead enough to make some attachment points on the spar. So i now have to attach on the spar (knot) and at the bottom (splice?) for the foot rope. And all on the assembled mast. Its a very short lenght of rope too. Thats why i thought a ring would be easier than making a loop at the lower end. Lets see what comes out. Will report. cheers sascha

-

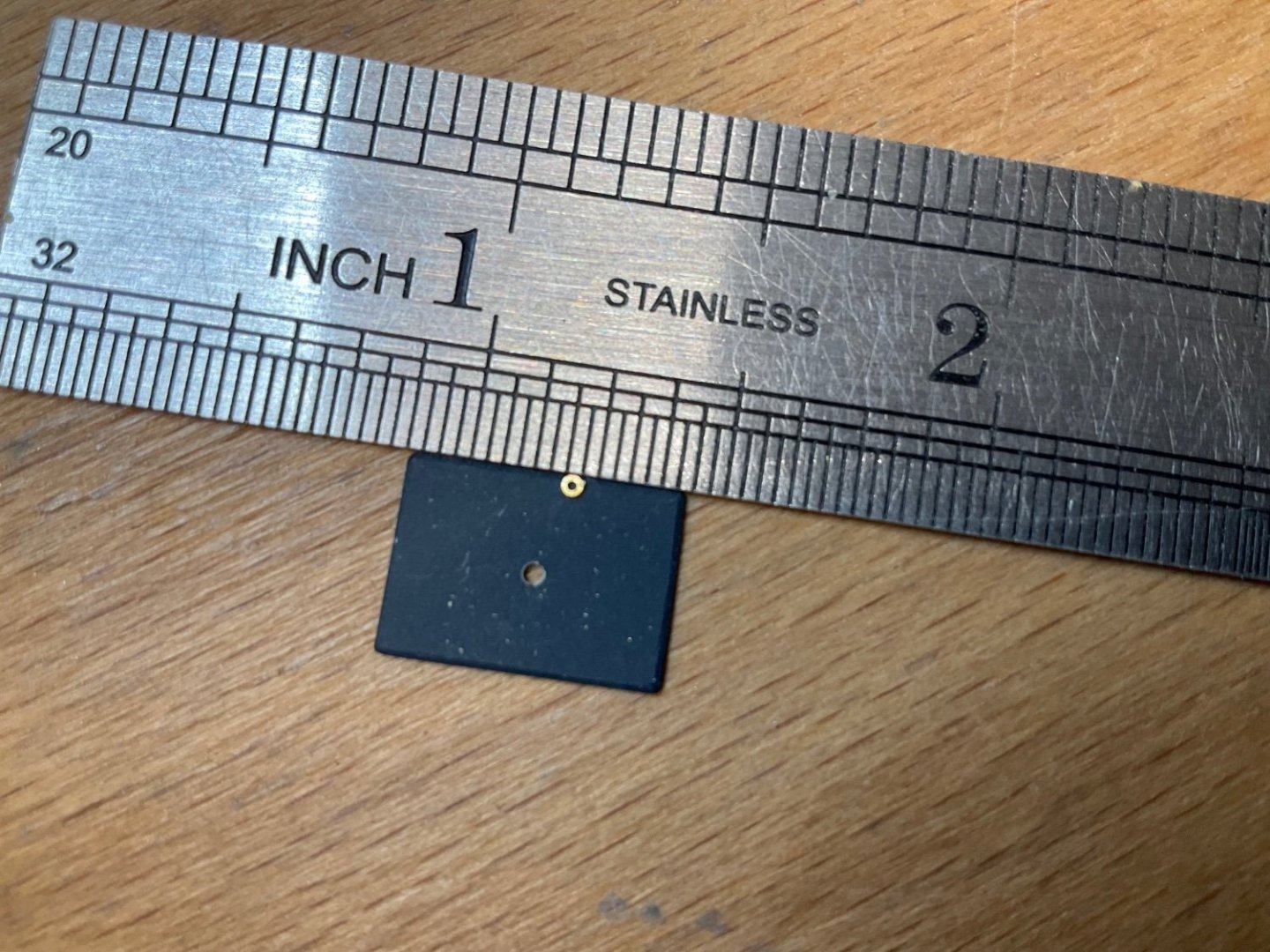

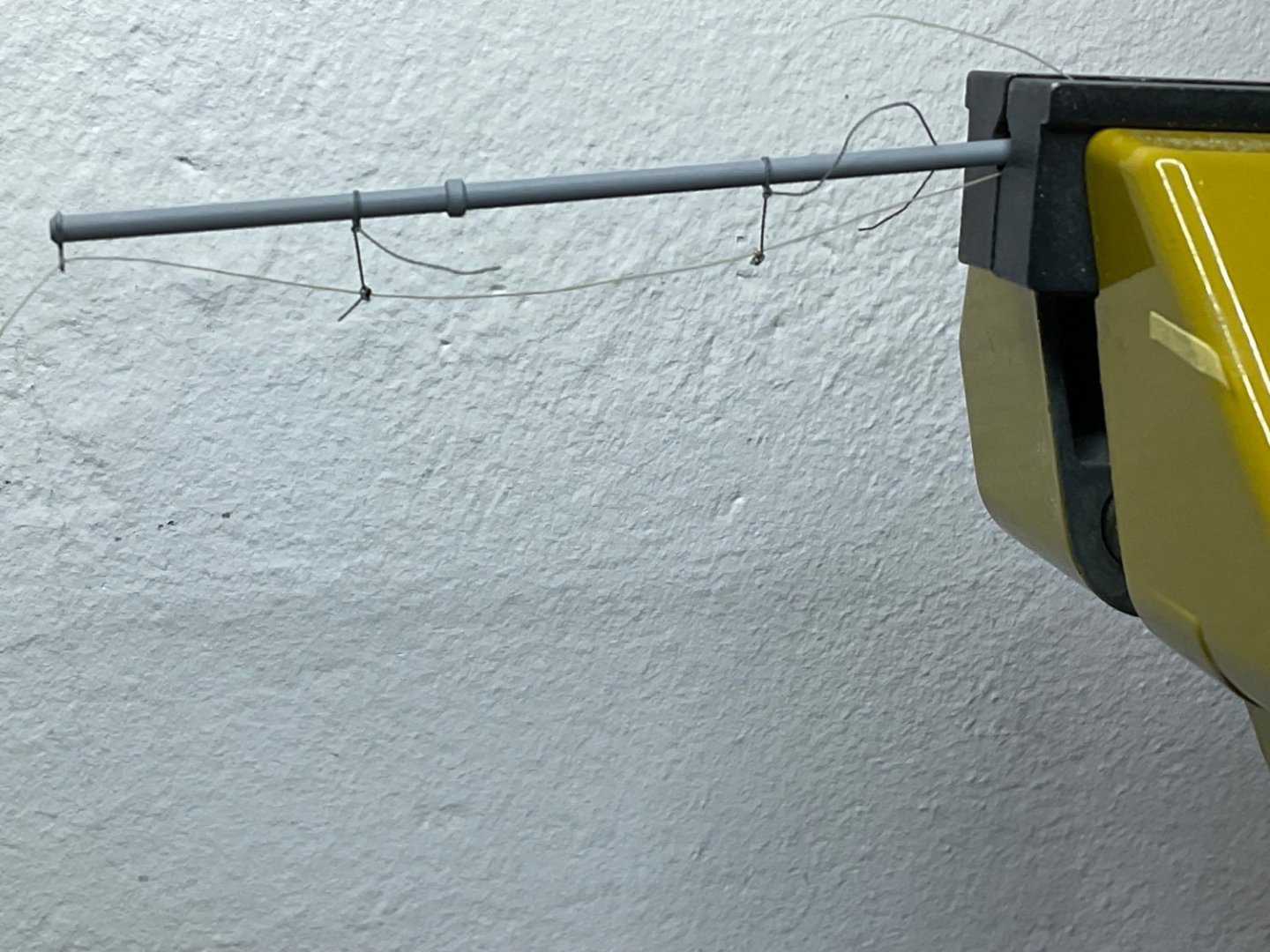

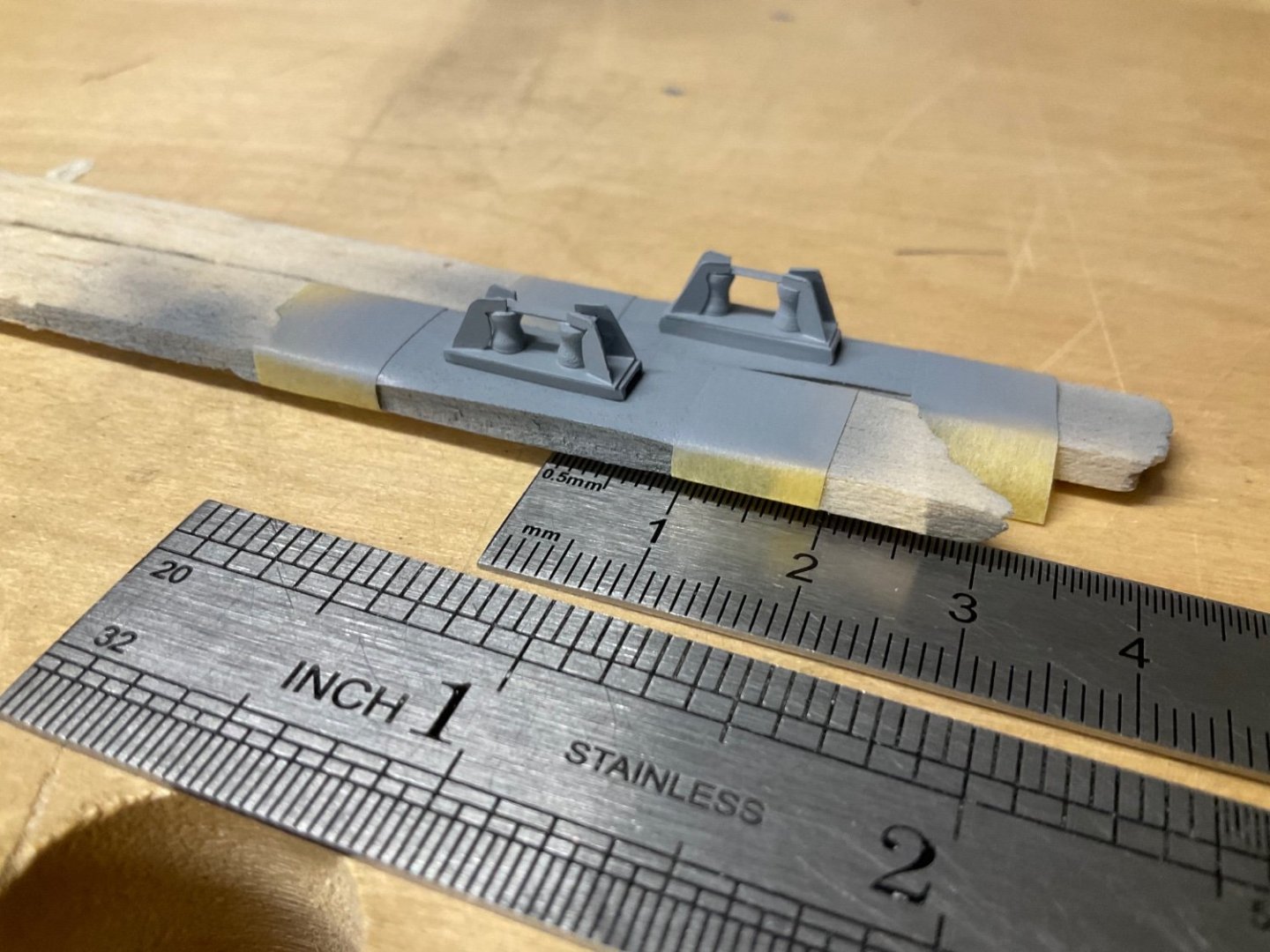

Hi all and thanks for picutres (valeriy) , translation for the fusspferde (eberhard) and tips to make the thing. I fear that the scale surpasses my abilities eberhard 🤪. Here‘s some result of trials. i made some small rings to thread the rope through (picture with inch measure for our imperial friends 😬). However when attached they always want to turn in the wrong direction making the whole thing bend. Thats the picture with the grey spar - it being a random 2mm diameter piece. The third picture is a using valeriys method (i believe) on a prototype with actual dimensions (1 mm diameter spar and 0,1mm rope. The huge shadow is the tip of my finger… on the upside i did manage to tie a correct knot,.. kind of. i will continue experimenting because i would have destroyed the mast had i done the experiments on the actual piece. further tips are pf course welcome. Cheers sascha

-

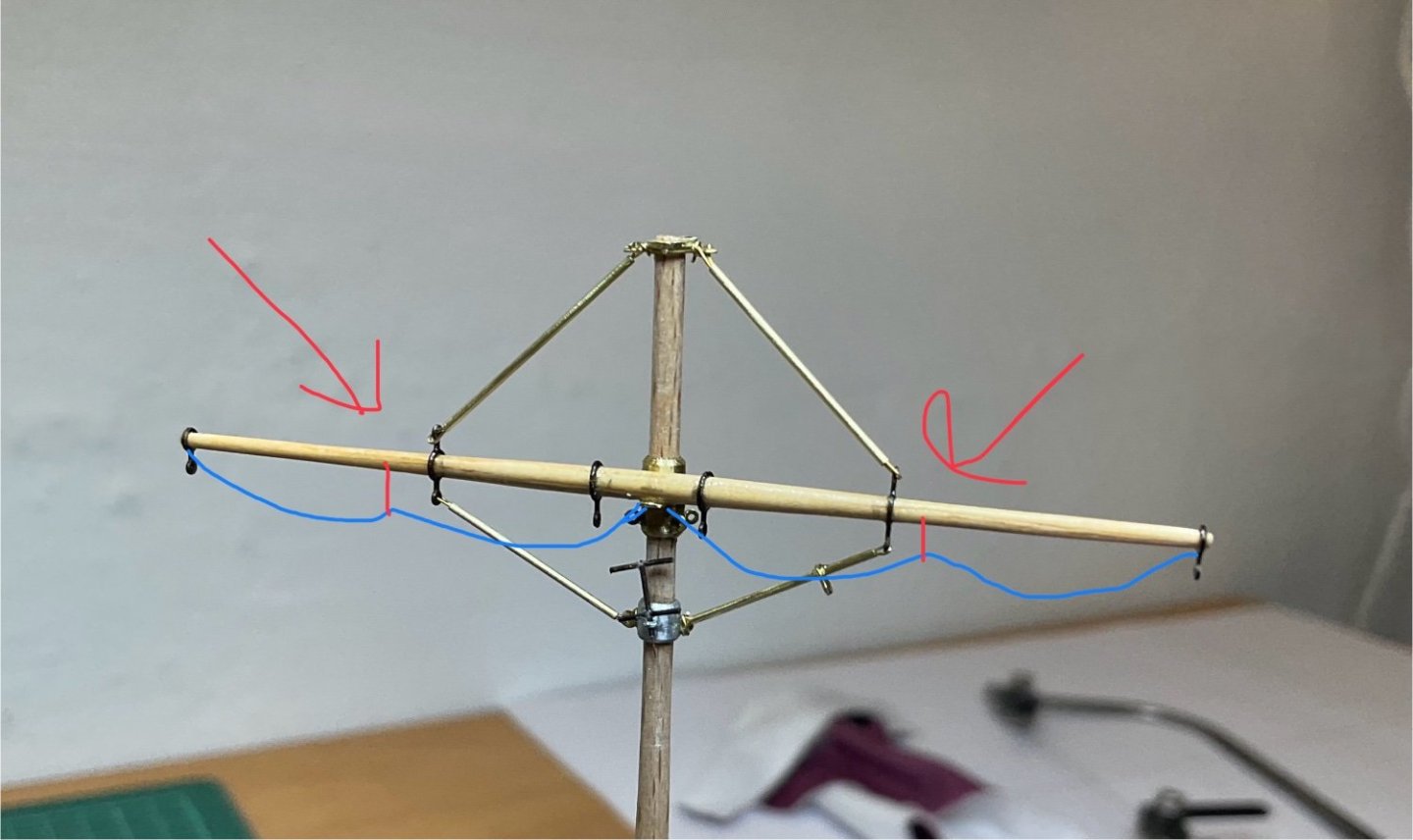

Hello all and thanks for following. I come to you with a question now😎. This is about rigging , and i think there are a lot of sailing boat experts here. Its about the lines in blue and red . Since i dont know what they are called in english i attach a photo and crude drawing. Sailors step on them when working on the spar. the questions: 1) how to achieve the blue line hanging down „naturally“ between the point where it is supended? 2) general tips how to get it done. Currently thinking of having a brass ring at lower end of the red rope , and thread the blue one through it. Assemble that separately and then mount to spar using a knot (round turn and two half hitches, as this one allows the standing line to drop down straight) As its 1/100 my fingers/tweezers seem incredibly big 🤪. cheers sascha

-

Wreck1919 reacted to a post in a topic:

Cyclone-Class Destroyer 1902 by Valeriy V - scale 1:45 - Russian Imperial Navy

Wreck1919 reacted to a post in a topic:

Cyclone-Class Destroyer 1902 by Valeriy V - scale 1:45 - Russian Imperial Navy

-

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

Wreck1919 reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

Wreck1919 reacted to a post in a topic:

RMS Titanic by NavyShooter - 1/100 - 3D Print - Pond Float display - Halifax Public Gardens

-

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

Wreck1919 reacted to a post in a topic:

SS Blagoev (ex Songa )1921 by Valery V - scale 1:100 - Soviet Union

-

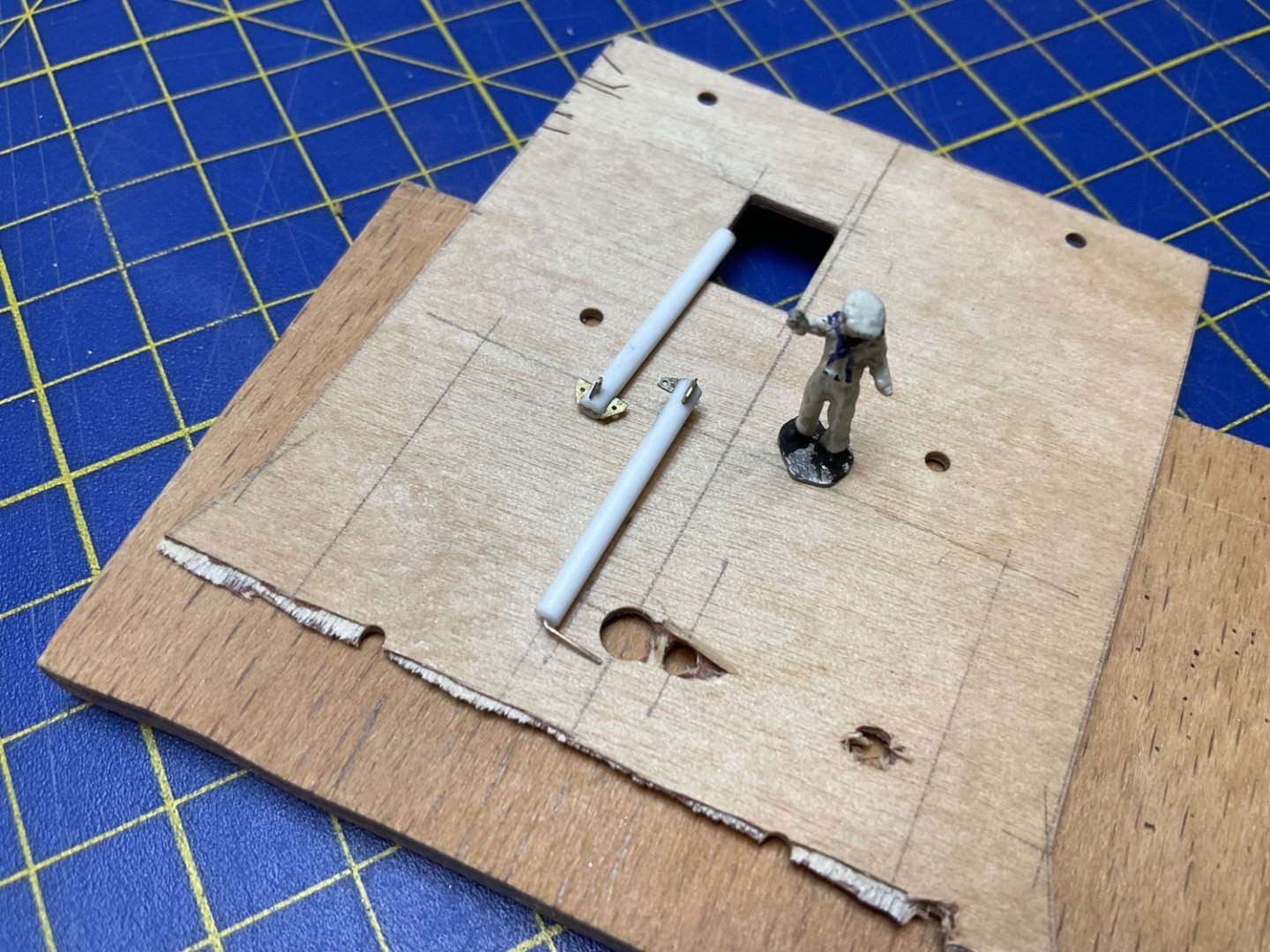

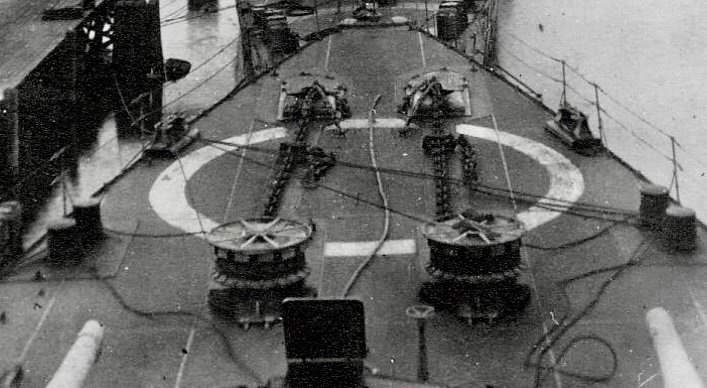

Hi guys, and thanks for your likes (if thats a word now) 😬. i continued work on the boat racks, fitting them out and giving them a coat of primer. Before fixing them in place i needed to understand where the various steel ropes go (attachment points) as those need to be made and mounted first. For this i needed to make davits. The ones in the photo are raw prototypes for shape only. Originals are H-profiles 320x320mm. also made the first two fairleads (? Correct translation). Those were not flat on deck, but on a u-shaped profile. enough text 😎 cheers sascha

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.