-

Posts

8 -

Joined

-

Last visited

Recent Profile Visitors

-

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

Jorge Diaz O reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

GrandpaPhil reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

mtaylor reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

mtaylor reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

mtaylor reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

mtaylor reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

Roger Pellett reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

Roger Pellett reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

harlequin reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

harlequin reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

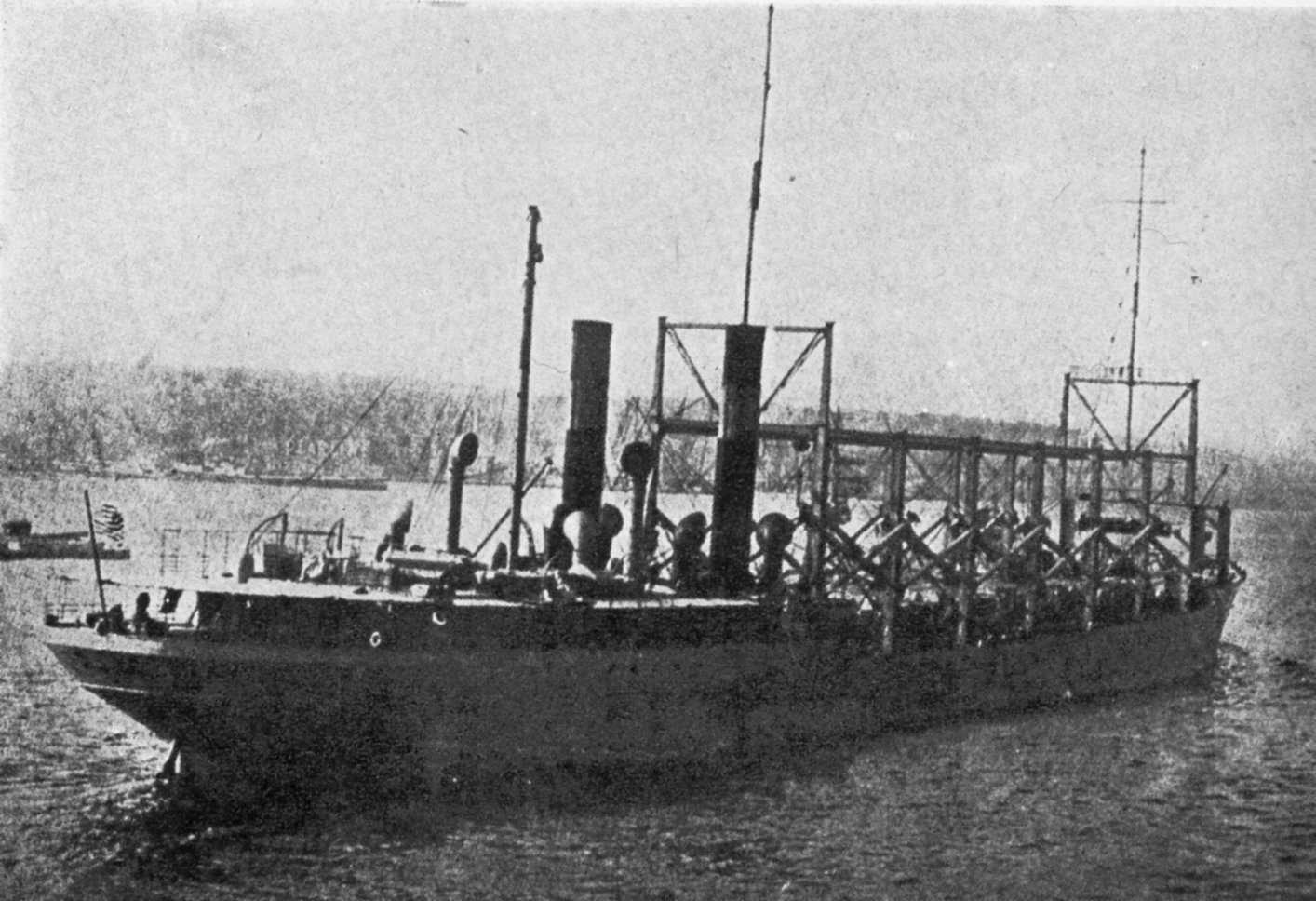

Yes,it's definitely difficult to aquire plans for a quite generic thing like a lifeboat on a specific vessel. Shipwrights at the time all built their lifeboats using a quite similar(if not identical)set of methods and plans, these well tested and practised ways of boatbuilding have already been passed down for generations of boatbuilders with minor or no innovations. For a large shipyard like Harland & Wolff, the techniques and procedures of building a wooden lifeboat would be so handy and well established to them, to the point that their boat shop could assemble one right away by using stock parts without any plan ever being needed to draw up. Hence the likely reason why no detailed plans about the boats have ever been found among Harland & Wolff files. (although some shipyards did outsourced their boats to dedicated lifeboat companies, but in the case of Titanic, her lifeboats were still built in the shipyard's own boat shop).

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

-

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

Thanks for the following. I shall keep the logs updated as frequently as possible.

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

-

Thanks Roger for your kind word, as for the full size replica,I would assume that you are referring to the one in National Maritime Museum Cornwall. I havent seen this particular boat in person other than a bunch of online photos taken by tourists. However, I was told that the Museum's boat shop and I were indeed using the very same plan, provided by the very same Titanicist: Robert Read, whom I've mentioned earlier. That had relieved me of much effort in attaining a reliable source of plan. Yes,I'd definitely second your opinion that the Titanic crew did an excellent job in lowering and manning the boats, and I think a considerable amount of credit should go to those officers overseeing the launching procedure. It is their duty to make sure the weight of the occupants were always distributed evenly from port to starboard during embarking, and giving commands to seamen manning the falls so as to keep the boat even from fore and aft during its entire way down to the sea in an almost pitch dark condition. It's a miracle that they eventually pulled it off. Any mishaps during these would resulted into catastrophic events(spilling boat passengers into the sea,etc)

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

-

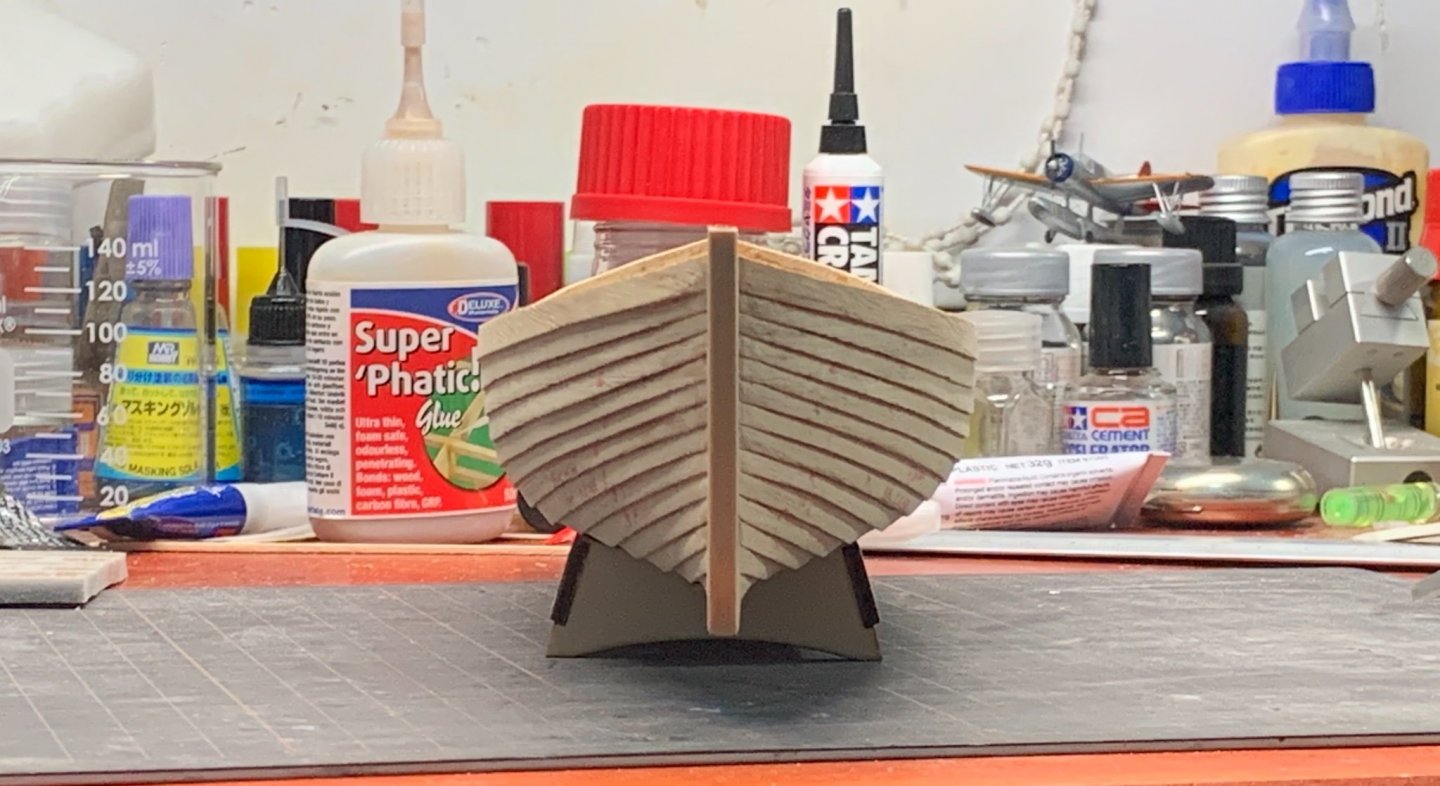

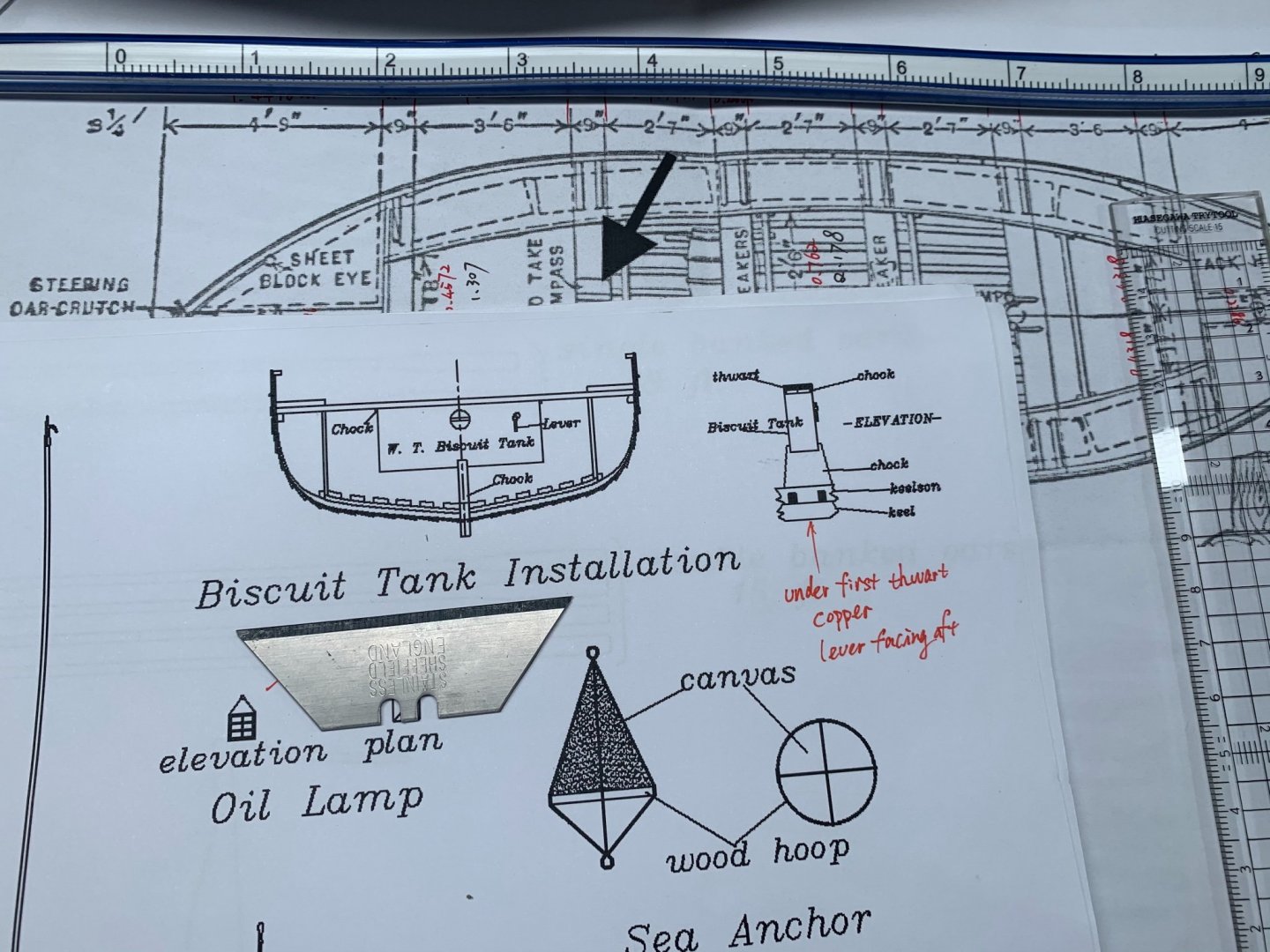

Just finished fitting the true stempost. Time for filling cracks and joints. Some additional parts also arrived. Among them were over a dozen 1/48 scale brass belaying pins, these are ideal substitudes for the thole pins(rowlocks) and will be fitted to the gunwale capping. It has been quite an excruciating job to build the hull,so I've been thinking of making some boat's provisions for a change, starting tomorrow. I shall start on the biscuit tank .

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

-

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

USS CYCLOPS reacted to a post in a topic:

RMS Titanic Lifeboat No.15 by USS Cyclops - scale 1/35

-

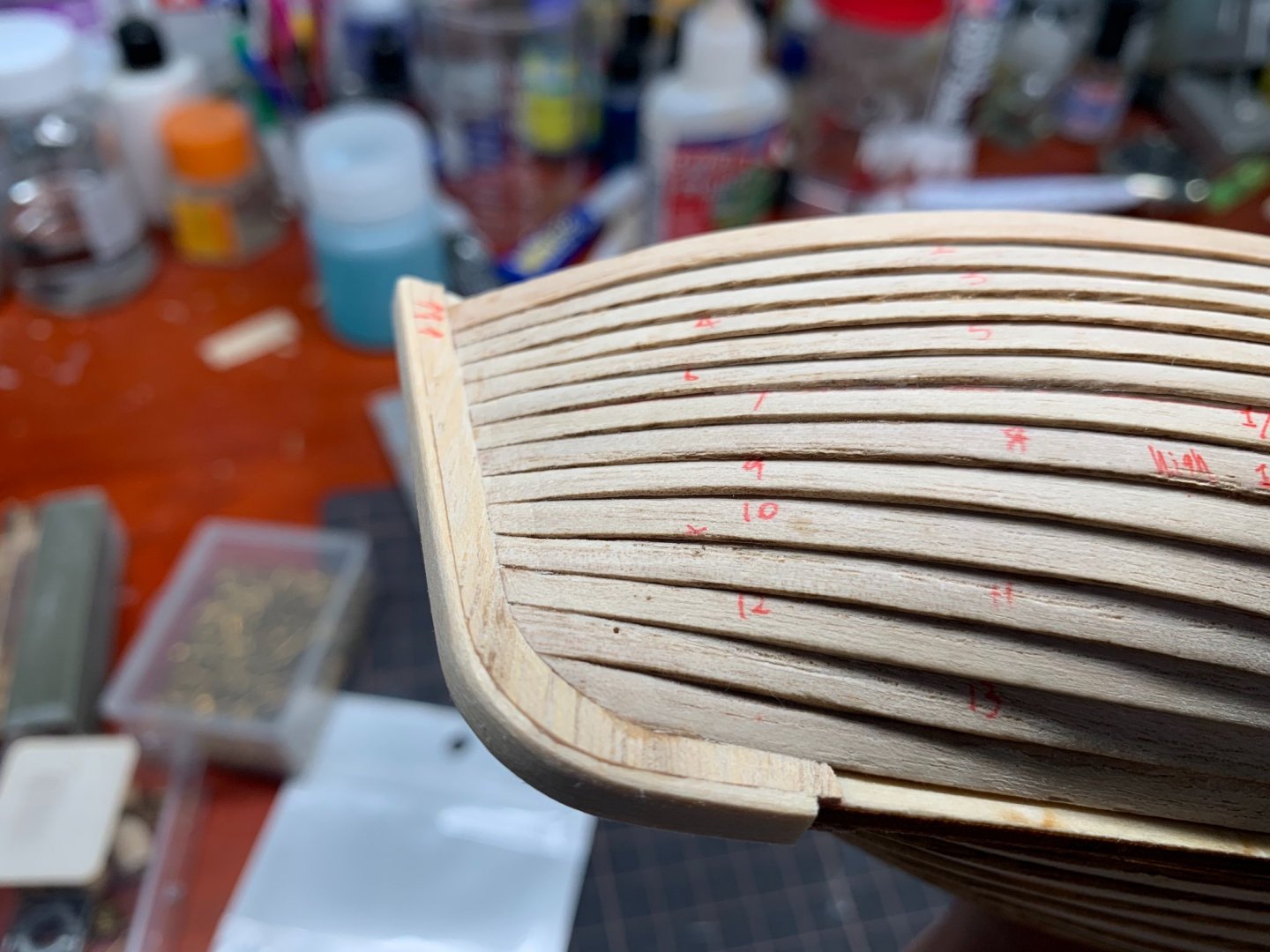

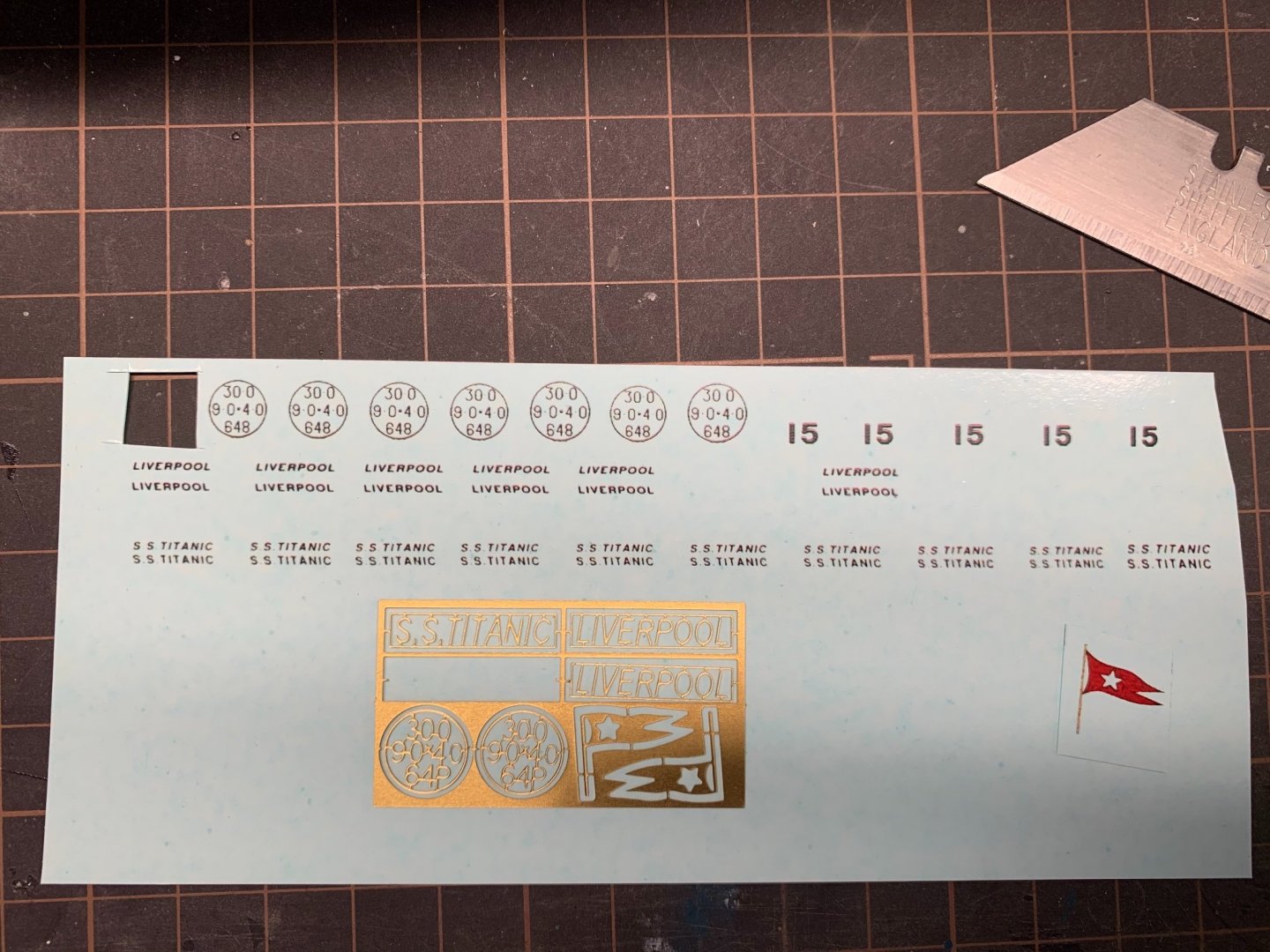

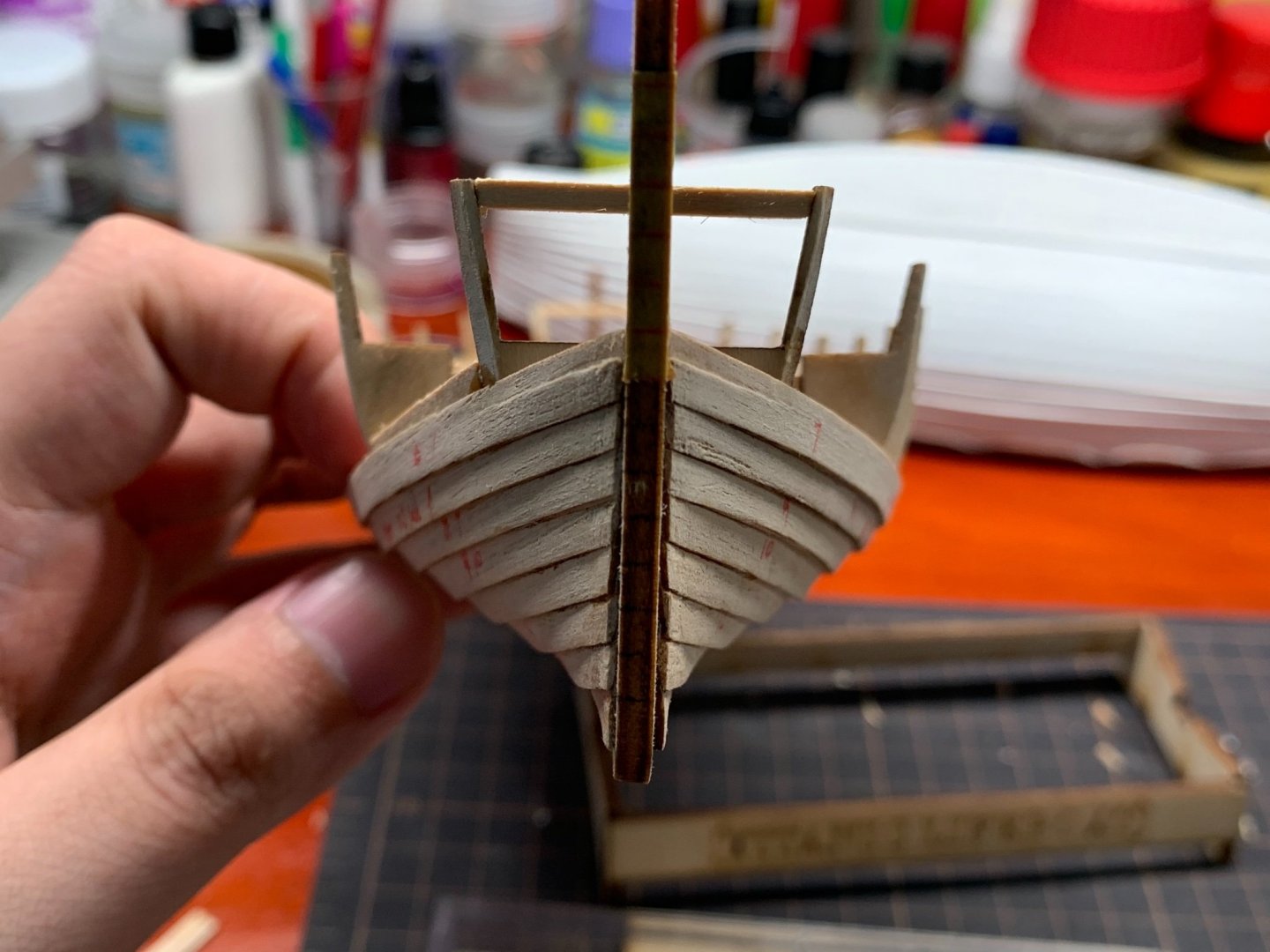

Hull planking on Boat 15 finally finishes. Next job would be fitting the rubbing strakes and capping to the gunwale. Also some filling and trimming job is needed on the stempost and breasthook(shape needs to be corrected). Some water decals for the boat plaques arrived today. The original photo eched parts supplied in the Artesania Latina kit is placed bellow it for comparison. One could easily notice that the AL plaques are all hopelessly overscaled.

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

-

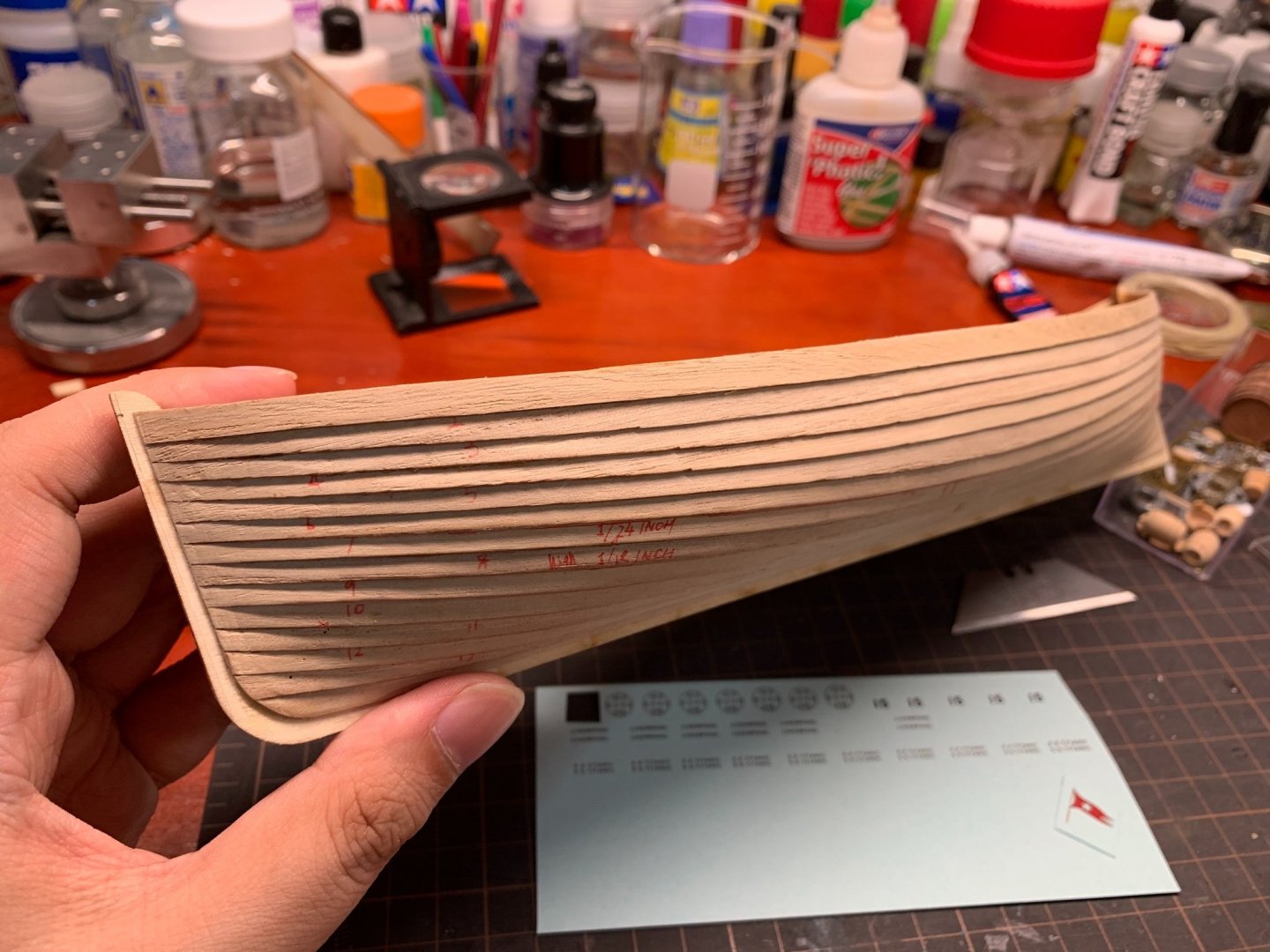

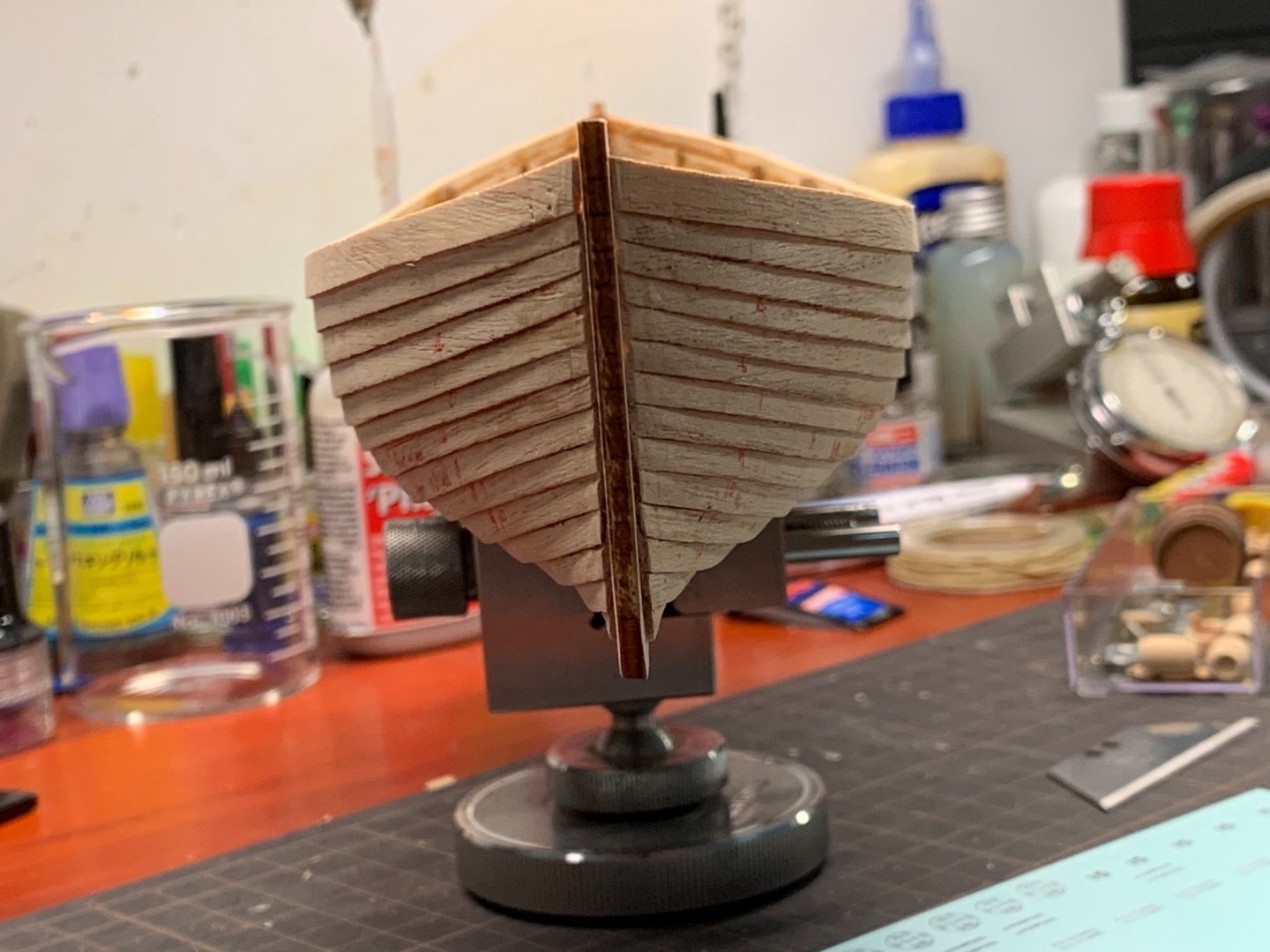

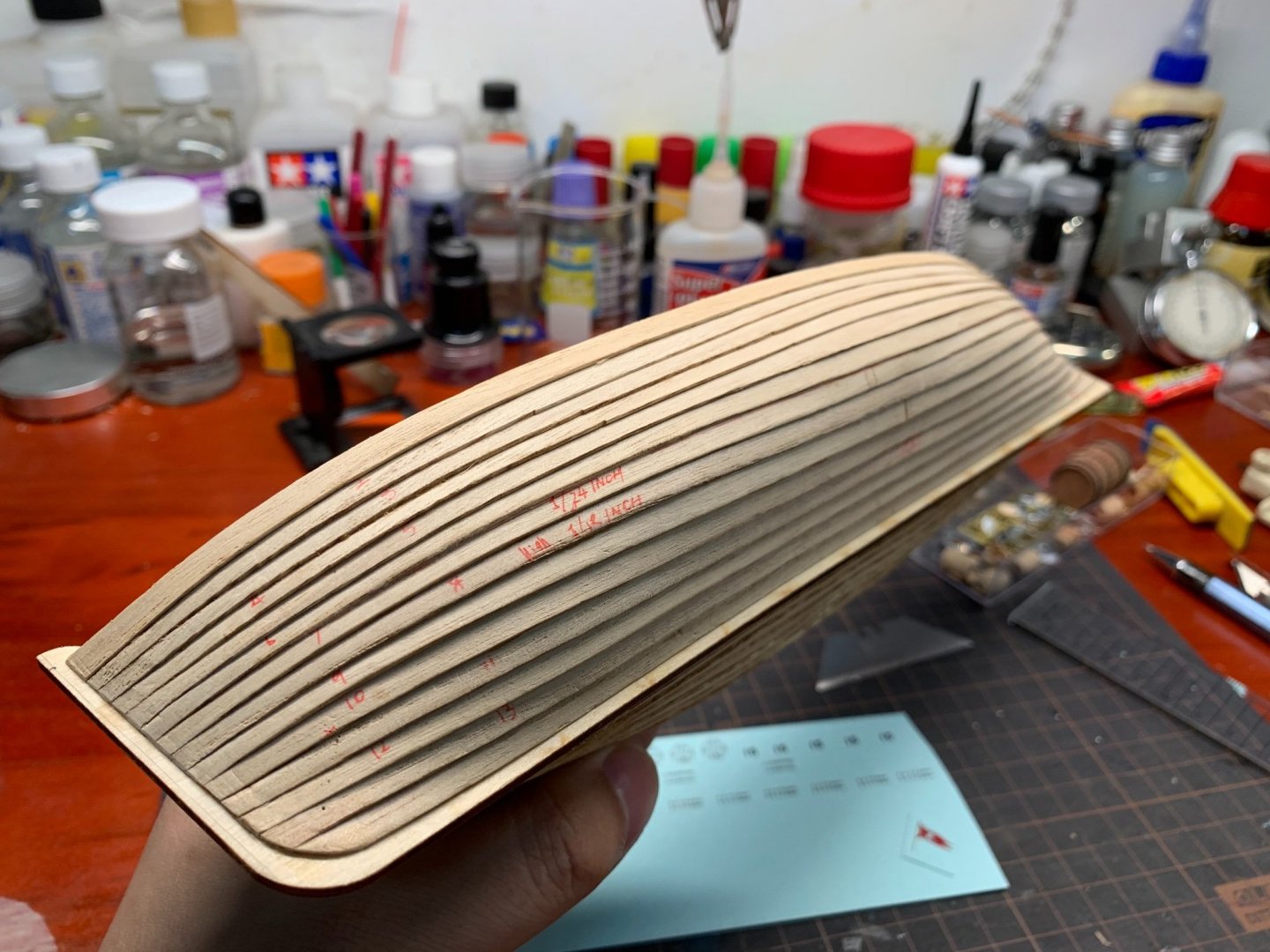

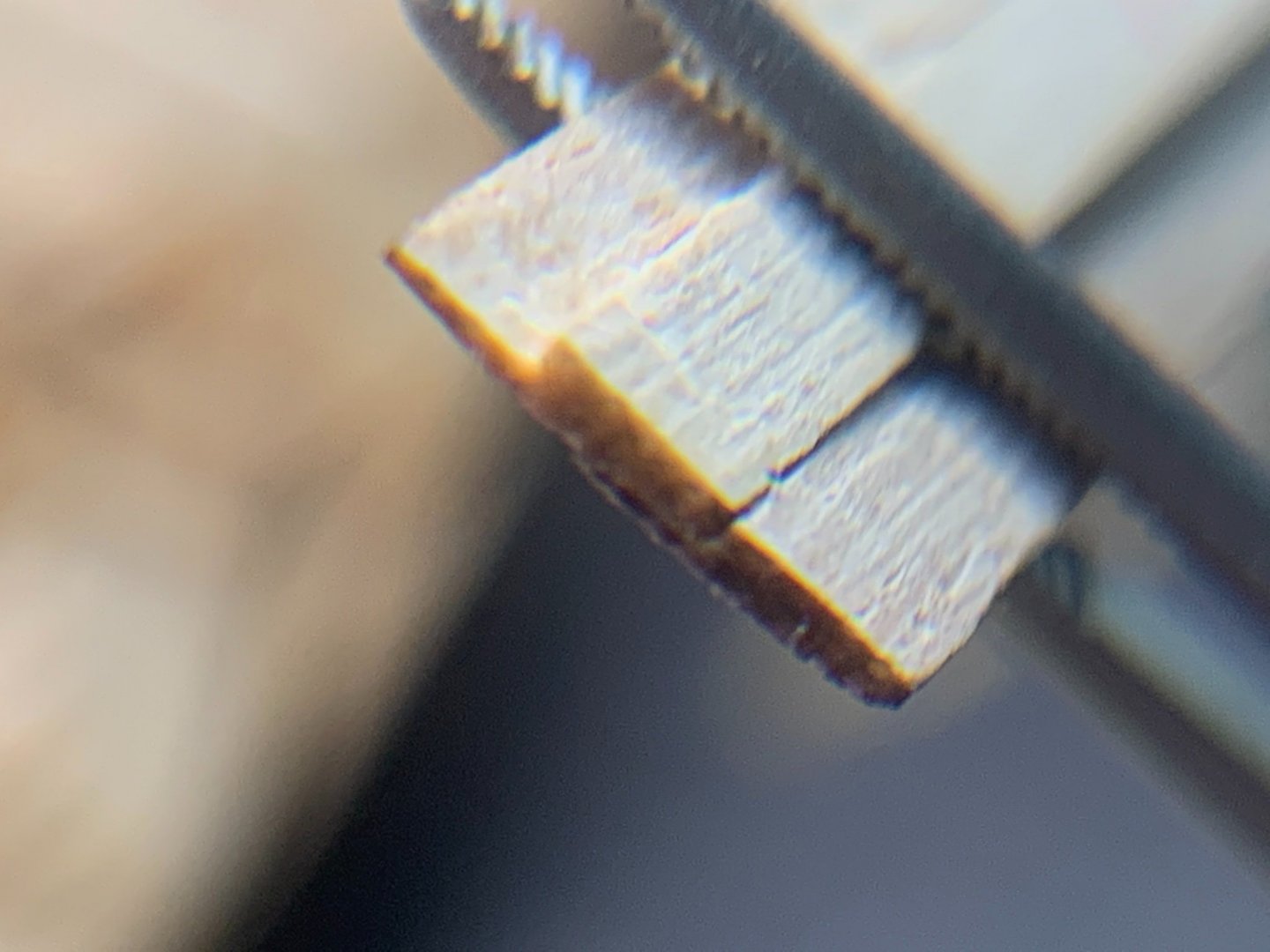

Doing the planking job on a scratch made 1/35 scale model of Titanic Lifeboat 15, one of the standard 30ft boats and also the aftmost one stored on starboard side. The boat is not the Artesania Latina one by the way, although I do own it and while I was building the thing years ago, I nearly sent it flying across the room out of utter frustration, the kit still stays unfinished as of today. I would say that the AL kit is neither accurate nor friendly enough with first timers in wooden kits,let along the fact that clinker planking itself is already way much challenging than the straight forward carvel planking. The current lifeboat plans was directly tanken from an expert Titanicist on TRMA, I ditched all the thoughts of using AL parts and completely reengineered the entire hull. The keel, strakes were all new fashioned. This is the second wooden model boat I've worked on, the previous one being the AL kit. I've followed a traditional clinker boat technique to smooth out the plank joints where their ends meet with the false stem and sternpost. That is, having all the plank tips slightly rebated, and all the inward, lower area of planks bevelled(see last two pics). After I've finished all the planks on the hull including the gunwale, the plank joints at both ends will receive a final sanding to ensure that they lined up neatly in a straight line.

- 12 replies

-

- titanic lifeboat

- titanic

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.