Paul Le Wol

NRG Member-

Posts

456 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

Hey Micha, looking good. If you haven’t already, now that you have a few planks attached on each side maybe you could flip it over and check to see how the notched frames sit against them. Perhaps even attach them. These plywood planks seem to have a mind of their own.😀

- 72 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Hi Micha, the only experience that I have with this type of Billing construction is with their Nordland Boat. It wasn’t built in two halves but rather the molds were one piece and mounted upside down on a build board. Since you have glued the two halves of your molds together, maybe you could consider converting your build to an upside down one. By the looks of it you will have to remove everything from the build board to attach the planking. You might have to add some plywood to the molds to extend them so that the stem and the stern clear the base. The molds are just etched to guide you where the planks will sit and will be removed later so should not be glued to anything. I wired my keel ( ? ) to the molds to keep it secure. The link to my Nordland is below. It may give you some ideas although it is a totally different type of boat.

- 72 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Thank you Jacques. When I started planking the bottom I started in the middle and worked in both directions using the basswood that came with the Glad Tidings kit. When I ran out of 3/16” x 1/16” basswood I changed to the 3/16” x 1/16” leftover Alaskan Yellow Cedar that I had bought to plank the Glad Tidings. So the bottom has a few inches of AYC at the bow and the stern. The sides of the hull are AYC. Started with 3/16” x 1/16” until it ran out. The rest of the hull will be finished with 1/4” AYC. She will be painted white so it should be okay. That was kind of long-winded wasn’t it 😀

-

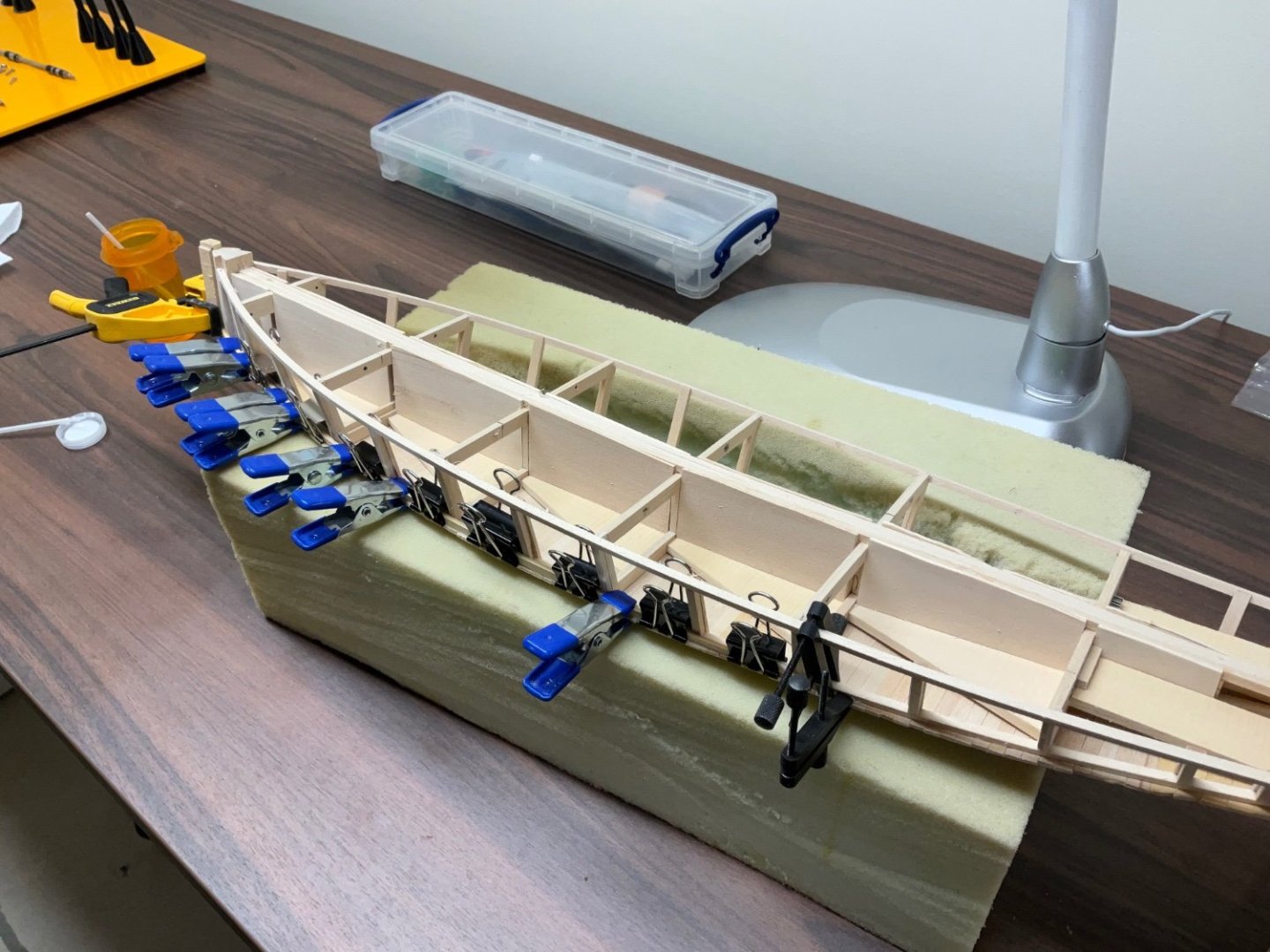

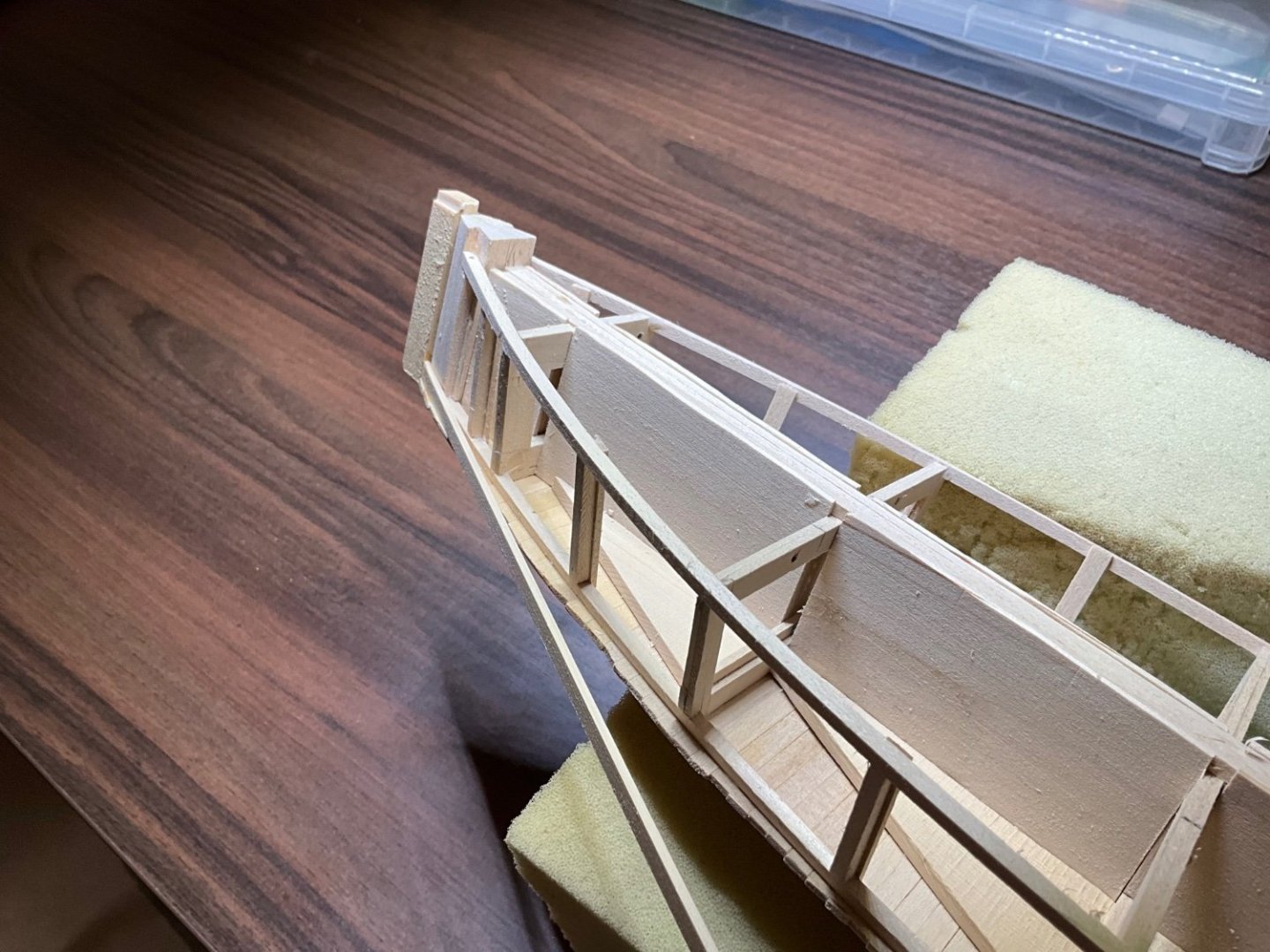

Hi Gary, thank you for your nice comment and for checking in on the sharpie. I’ve been slowly planking her. Been using two planks in each strake so usually I glue the end of the plank at either the stem or the stern and then the next day finish gluing the rest of the plank. So it’s been taking four days to complete a strake. A couple of months ago I picked up an Ultimation disk sander and started using it to taper the planks. I like using it a lot. And it’s so quiet! That’s it for the planking for now. Going to do some sanding and then work on giving the deck beams some camber before laying down the sub deck.

-

Hi Micha, I am glad that you have accepted the Billing challenge. It will turn out great!

- 72 replies

-

- Roar Ege

- Billing Boats

-

(and 2 more)

Tagged with:

-

Congratulations on completing your Yakatabune. Fine looking boat and great pics!

- 5 replies

-

- Japanese boat

- yakatabune

-

(and 1 more)

Tagged with:

-

P-51D Mustang by CDW - FINISHED - Dragon - 1:32 Scale

Paul Le Wol replied to CDW's topic in Non-ship/categorised builds

Craig, congratulations on finishing your Mustang!. Thanks to you and everyone for sharing so much great information. -

Challenger86, congratulations on completing this beautiful Duyfken.

- 16 replies

-

- Duyfken

- Modellers Shipyard

-

(and 1 more)

Tagged with:

-

Hi Everyone, I got sidetracked when I moved last summer but I’ve managed to find some time between the renovations to work on the sharpie. The bottom of the hull was finished being planked and the stem was attached just before I moved. A couple of weeks ago the 1/8” x 1/8” strip of wood that blocked the center board slot was removed with an 1/8” chisel. A 1/16” strip of wood was added to the skeg to make it stand a little more proud. Then the shoe was made using 5/32” x 1/32” AYC. and attached. It should have been a bit narrower but it won’t be noticeable once it’s finished. The staves were glued to the round stern with PVA so that took a week to complete. From what I’ve read the planking on the sides of the hull weren’t tapered but that might have been on the smaller sharpies. It seemed to be easier to taper them so that’s what I did. The planks were glued at the stem using Medium CA and then PVA for the rest of the plank. Now on to the starboard side with three strakes. Hope to see you soon.

-

Hi Jacques, everything is looking great. If the coating on the steel wire is giving you grief you can try sanding it off and then heat the wire with a butane lighter or mini torch.. The metal will turn dark grey giving it a more natural look. Someone posted this suggestion a little while ago but regrettably I can’t remember who it was.

- 162 replies

-

I've lost it....need a refresher to get my confidence back

Paul Le Wol replied to bigcreekdad's topic in Wood ship model kits

I’ve never built one but I keep looking at the Wasen - Japanese style boats made by Woody JOE. They look like they would be an interesting and fun build. Good luck with your decision. -

Gary, congratulations on finishing your Lobster Smack. Beautiful looking boat!

- 87 replies

-

- Muscongus Bay Lobster Smack

- Finished

-

(and 1 more)

Tagged with:

-

Major, congratulations on finishing your Lobster Smack! She may have been ornery, but she is a fine looking boat.

- 39 replies

-

- Model Shipways

- Muscongus Bay Lobster Smack

-

(and 1 more)

Tagged with:

-

Jacques, congratulations on finishing your Juana y Jose. Your scratch builds have been very interesting and informative. Always enjoy seeing your updates.

-

AMC DH9 by davec - Wingnut Wings - 1/32

Paul Le Wol replied to davec's topic in Non-ship/categorised builds

Thanks Dave, this will be a very interesting build to follow 👍 -

AMC DH9 by davec - Wingnut Wings - 1/32

Paul Le Wol replied to davec's topic in Non-ship/categorised builds

Hi Dave, glad to see that you are starting this log here. What do you think of the GasPatch accessories. Are they a lot nicer than the kit parts?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.