-

Posts

511 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by pompey2

-

Small desktop mill for modelling

pompey2 replied to Roks82's topic in Modeling tools and Workshop Equipment

Here is another option for desktop mills. It is from a UK company Warco http://www.warco.co.uk/milling-machines/32-wm-16-variable-speed-milling-machine.html They offer a big range of sizes and functionality as well as a host of tooling and other options plus very competitive prices. I offer up this because I have just bought the one shown, just waiting for delivery, very excited. Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

OK understood hjx. Thanks for asking. -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

Hi hjx Thanks for the details and photos. Does your friend market them? Do you have a link of something? nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

A further note, hjx. Could you tell us which type of machine you use? Do you have any photos of it please. Thanks Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

Hi hjx Thanks for the comments. Rigidity is certainly an important factor especially to achieve a decent accuracy. But these are not milling machines so I would only expect to be taking light cuts. That is why I hope to evaluate our work one, so far it looks good, but it has not been challenged, it's mostly used for foam cutting. I don't think I have a great need for a fourth axis. That would be useful for rotating the work piece whilst machining, like turning. But I can handle that on a lathe. Being able to approach the work with the spindle at an angle is not something I think I need. But I will update this subject as I move further forward. Thanks Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

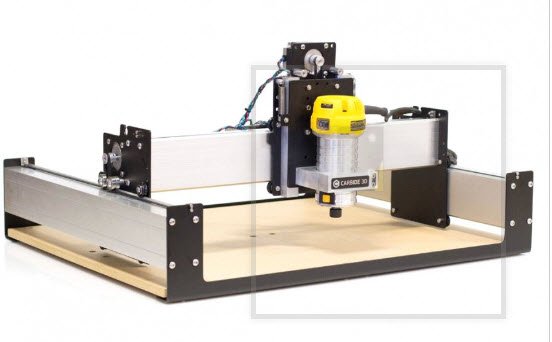

I have let the subject of a new tool rest for a bit but I'm picking it back up now. Part of the reason is that we recently got one at my workplace. It is a different type of design to the ones I was looking at, but more suitable for the things I need it for. Most relevant is that the type I am now considering use a commercially available router for the cutting spindle (Dewalt or Makita) That then comes with a 1/4 chuck so is a lot more flexible with regard to tools it will accept and is also made to specifically resist some side loading. So is capable of milling in wood across 3 axis. This is the design I am considering, and is the one we have at work, there are a couple of alternative suppliers: Prices are more but still keeping me interested. This type including router, milling kit, controller and software is circa £1300 for 750mm x 500mm bed with 140mm Z axis. I intend to get to know the one at work a little first then probably go for it. The other thing that I like is that the ones I am looking at are UK or US made. The two that look best to me are https://www.robotshop.com/uk/carbide3d-shapeoko-3-robust-cnc-router-kit-us.html and http://ooznest.co.uk/3D-Printer-CNC-Kits-Bundles/OX-CNC-Machine/OX-CNC-Full-Kit Nick -

I use a very similar thing but it is rechargeable. If you search for manicurist drill you should find a few around. Most have a poor chucking arrangement but I found one with an 1/8 collet so my smaller drills and tools fit well. Nick

-

Hi Jim Sorry I missed your reply a while ago. But thanks for the picture. I should recognise it certainly, I worked for a while in Priddy's Hard, Gosport side as you say 'at the back' of Portsmouth Harbour. My window looked out directly onto the redundant ships, up for sale or waiting scrap, mostly RFA's and the like. Certainly brightened our day when the SBS used them to train in ship assaults, air-borne and sea-borne. Also the Vanguard trying to get a last pint in the Still & West reminds me of the photo still hanging in the pub. I'm still enjoying seeing your work immensely, and your work rate is staggering. all the best Nick

-

Wonderful work Jim, I could look at these for hours. Especially nice seeing settings I know. You should be congratulated on not just the quality but also the quantity by the sounds of it. Nick

-

If you only want it for small drills and other rotary jobs then a 'Dremel' is most people's default.

-

The evolution of a workshop, love it Helmut. It's funny how a lot of us seem to get as much enjoyment in organising our tools as we do modelling. Nick

-

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

Indeed Wefalck. The company was Zmorph and tools was Zmorph VX Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

A few days ago I visited a trade fair for 3D printing / Additive Manufacturing as part of my day job. I noticed a great little filament machine that was boasting multiple interchangeable heads. That included a router head and a laser cutter head as well as a few different printing heads. The laser was limited to paper and card really but the router head was cutting and carving some pretty nice details in wood to about an inch depth. -

Ship holder

pompey2 replied to zappto's topic in Building, Framing, Planking and plating a ships hull and deck

Hi zappto While you are designing and making your base board it would be a good time to consider a couple of things so that you can incorporate some features. You will want to mount your bulkheads nice and square to the spine and the base so maybe think about features to locate a jig to held hold them square. Also you might want to be attaching things to the model later in the build, so some feature to hook or attach clamps, elastic bands etc might be helpful, could just be a simple lip along the edges. Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

Hi Jolly Roger Just took a look at the router you are buying. It looks pretty good, quite sturdy. Sizes are maybe a bit limited but price is good. Maybe you could give us some feedback once you have had a chance to run it through it's paces? Thanks Nick -

Desktop CNC Router, Engraver, Mill

pompey2 replied to pompey2's topic in Modeling tools and Workshop Equipment

Hi hjx Thanks for the feedback. That is some very nice work you have been doing there. I use 3D CAD in my day job so that side is OK. I would need to find a translation into the Router machine code though. Nick -

Hi All I have been getting very interested in these little machines recently. Only really for fine wood milling. You see a lot of them across ebay and Amazon, pretty much all of the home market ones seem to come from China. They are three axis, USB linked, approx. A4 table size and come with a software package. And the prices are very good. But that is as far as I have got, in a lot of respects they seem too good to be true. Has anybody got any experience of using one? Or even seen one in action. I would like to understand a lot more - build quality, spares availability, ease of programming, reliability etc etc Nick

-

For models created in SolidWorks there is very good, free viewer - eDrawings. You get pretty much full 3D viewing functionality - pull apart assemblies, section, measure, rotate, zoom etc. Visit the solidWorks web site to download a copy. It will also view some other formats like ACAD. You can use it to view native Solidworks files, or the creator can save a native file as an eDrawing file to help protect their IP. Nick

-

Hi Newt They are belaying points associated with the P&S Knightheads, you can see a bit in the attached. Nick

-

Lovely Job Robert, your planking is looking real fine. Keep up the good work Nick

- 521 replies

-

- caldercraft

- victory

-

(and 1 more)

Tagged with:

-

Help reading plan

pompey2 replied to Rick01's topic in Building, Framing, Planking and plating a ships hull and deck

Sounds like an idea from Don, actually the same hole rising at a steep angle. -

Hi Graham I have recently done just that (see confed log) I used Admiralty Dull Black, I thinned it with water, probably about 50/50 but thinned it to a water-like consistency whilst retaining some degree of colour. I then sprayed many coats, many coats! about 20 in all. If you do very light coats, which is a must to avoid runs then they dry in less than an hour, at least enough to do a further coat. But as I mentioned in my log I am leaning towards a brush rather than an air brush in future. The multiple tinned coats works pretty well when brushing and using the gun is a lot of extra faff. Best of luck Nick

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.