MrBeanCar

Members-

Posts

7 -

Joined

-

Last visited

-

I am getting close with my 1851. I am working on the lines on the front, and there are a couple of pieces which I can't figure out. They are part number 631 (4 of them), they are called "redancia", which would be "thimble" in English. It looks like that setup should allow for adjustment of tension to the jib boom, and so should be blocks with the tensioning end routed through a hole in the hull. But that is not shown. Regards

-

Canute reacted to a post in a topic:

Mamoli materials list-codes

Canute reacted to a post in a topic:

Mamoli materials list-codes

-

mtaylor reacted to a post in a topic:

Mamoli materials list-codes

mtaylor reacted to a post in a topic:

Mamoli materials list-codes

-

Yes that is perfect. Thanks Regards and Happy Holidays

-

mtaylor reacted to a post in a topic:

How do you get a smooth finish?

mtaylor reacted to a post in a topic:

How do you get a smooth finish?

-

Canute reacted to a post in a topic:

How do you get a smooth finish?

Canute reacted to a post in a topic:

How do you get a smooth finish?

-

I was building a small J Class model, and wanting a smooth finish. It was a white finish, white is notoriously difficult to get coverage without lots of coats. Not sure how many I ended up with; but it was a LOT. All of the paint was acrylic. What I ended up doing was: I hand brushed the model with a cheap, indoor acrylic. It was very rough. I think I put on 3 coats. I then sanded that until it was smooth. This left a few spots bare; but not to worry. I then air brushed enough coats until I had very good coverage, it all looked white Then I sanded it, starting fairly fine, as the finish was pretty smooth. Just not "really smooth". I started with 600 And progressed to 12,000. I really did not see much effect past 4,000 and since then I rarely use 12,000 anymore, I usually only go to 2,000 or maybe 4,000. Interestingly, for some reason I thought I should shoot another thin coat after the final 12,000. The surface repelled the paint like it was coated with oil. I suspect that, even after it dried, there would have been little to no adhesion. Since then, I've adopted the following for smooth finishes over wood 1) Sand surface to at least 2000 grit 2) Two coats of wood sealer 3) Sand with 1000 to 2000 4) Paint; airbrush; at least 3 coats 5) Sand with 1000 6) Clear coat. Either gloss or matte, whatever the final effect is that I'm looking for 7) Sand with 1000, to 4000 I'm still fine tuning this. I don't think I need to go to 2000 in steps 1 and 3, but that is yet to be proven Regards

-

I'm building a Mamoli America 1851, and I'm not familiar with their material codes. For some of the items, it would help me to know what it is made of in order to find it. Some I can figure out: MET is metal; LN is wood of a particular color/type (think it's legno in Italian). But what are OTN CO NO Regards

-

I am also missing part 525 from my kit. How did you make your replacement part? I looks like you used an extra/spare 504 and added a tubular attachment for the jib boom Regards

-

catopower reacted to a post in a topic:

Mamoli America Bulkhead questions

catopower reacted to a post in a topic:

Mamoli America Bulkhead questions

-

Gregory reacted to a post in a topic:

Mamoli America Bulkhead questions

Gregory reacted to a post in a topic:

Mamoli America Bulkhead questions

-

mtaylor reacted to a post in a topic:

Mamoli America Bulkhead questions

mtaylor reacted to a post in a topic:

Mamoli America Bulkhead questions

-

Well just by accident I was looking along the length of the frames and noticed the profiles did not look right. I thought the frames were in order, on the sheet that they are cut from. They aren't. So I had mixed up frames in the wrong slots. I matched them to the profiles on one of the plans, and this solved the problem I had. Regards

- 1 reply

-

- fitting bulkheads

- america 1851

-

(and 1 more)

Tagged with:

-

MrBeanCar started following Mamoli America Bulkhead questions

-

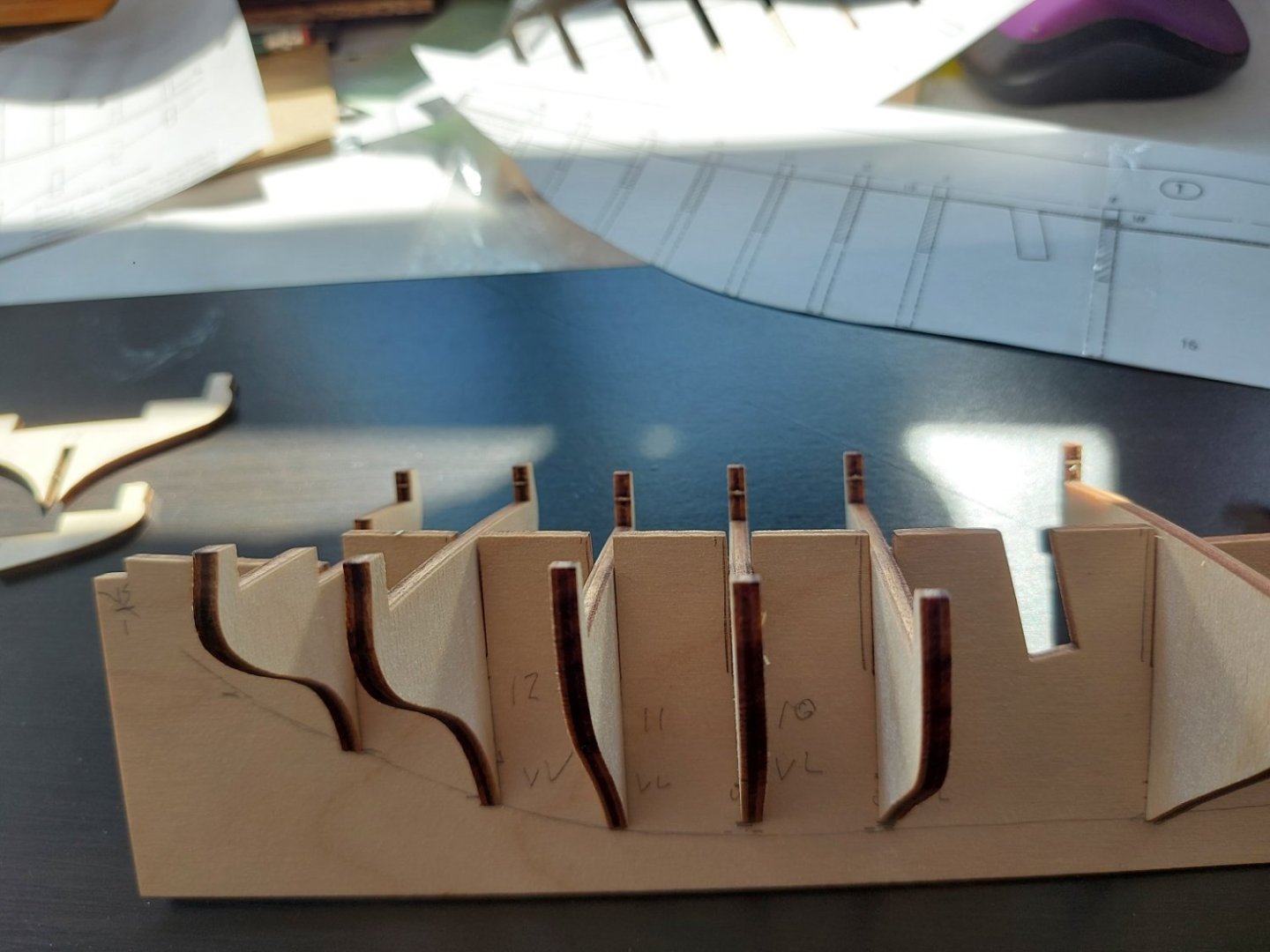

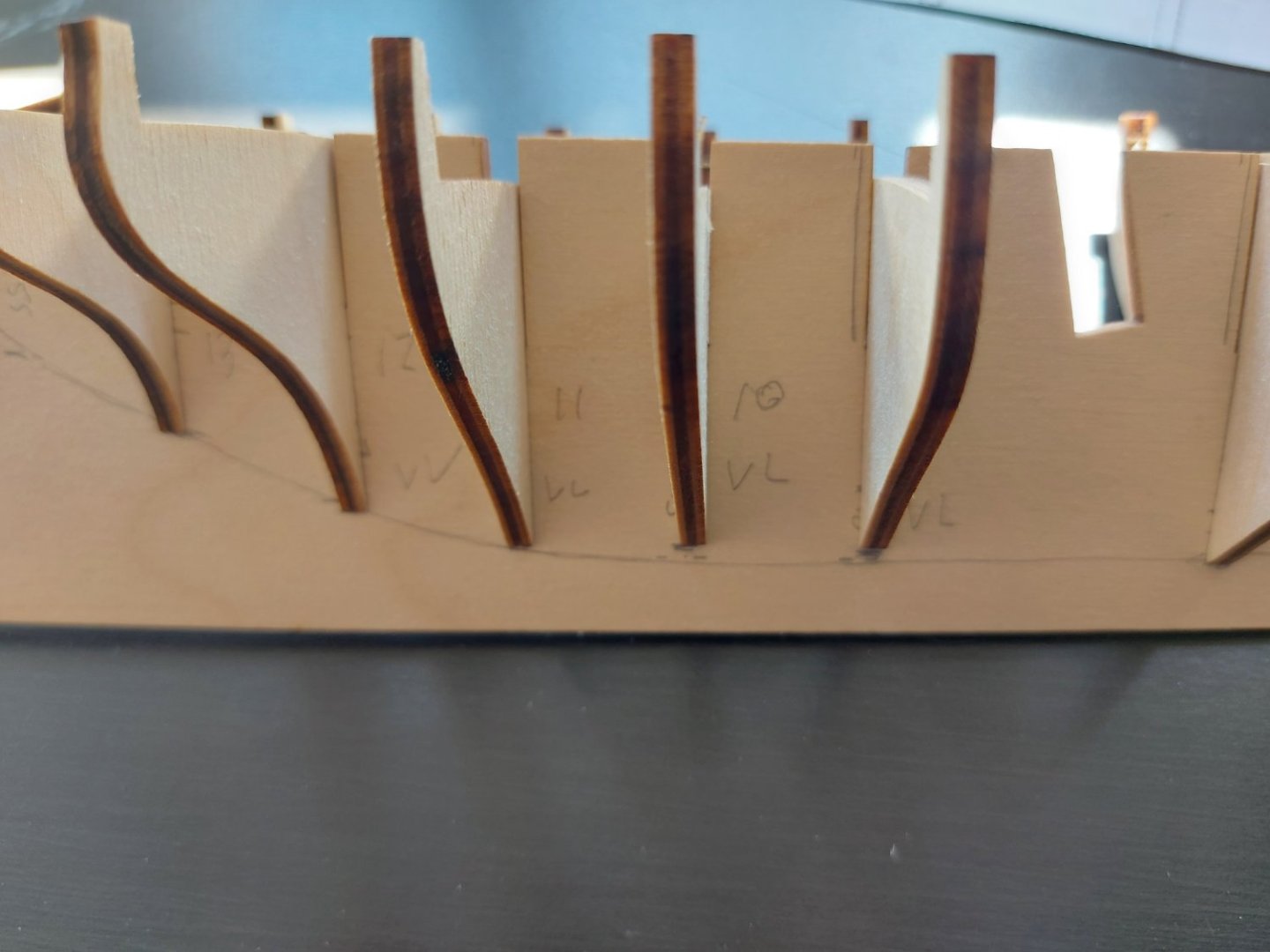

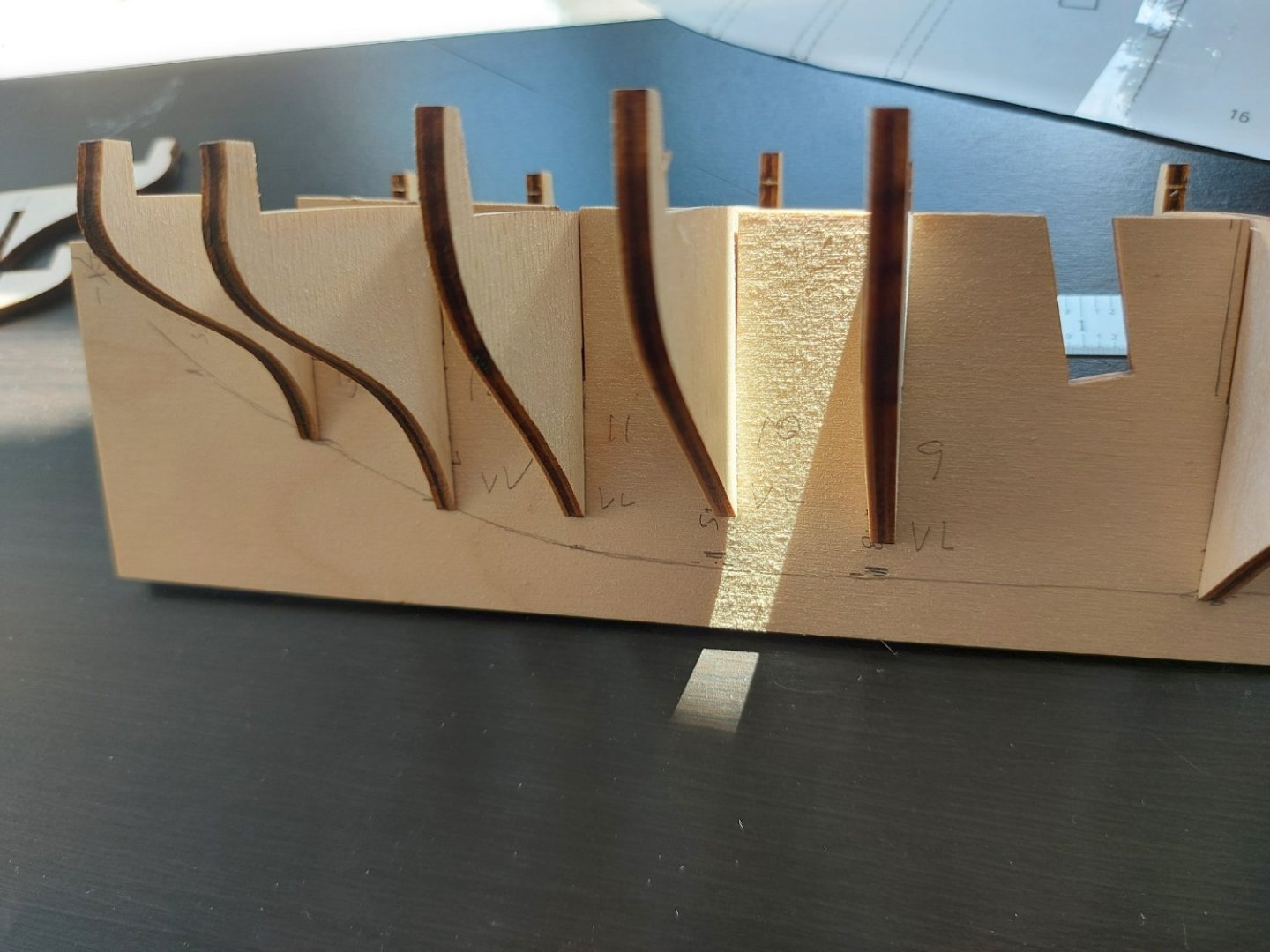

I’m starting the 1/66 Mamoli America; and I’ve read what build logs I could find. My primary source at this time is Hamilton’s from 2015. Glad I looked at that as the openings in the keel for the bulkheads are quite off, similar to his experience. I’ll be adjusting for that. I’ve found something else that seems a bit out of kilter (described below). Input requested. My thoughts are that I should make the bottoms align as well as possible and not worry about what happens up top. Exposition The top surfaces of bulkheads 9-10-11 end up well below the top of the keel (Part 16) ; ¼” for 10 and 11, and 5/32” at 11. I’m not concerned so much about where the bulkhead ends up at the top, however, I’m concerned more about where the bottom edge of the bulkhead ends up at. Using a copy of the plan, I drew a smooth line connecting the bottoms of the bulkheads and matched that to where the bottom of the bulkhead meets the keel. 1) If I raise up 9-10-11 so that the top of these bulkheads meet the top of the keel, the bottoms of the bulkhead don’t come close to matching a continuous line 2) It actually looks like I need to lower bulkheads 9 and 10 further down, to create a smooth line I attach 3 fotos. Foto 1 shows how low the bulkheads are compared to the top of the keel; Foto 2 shows how the bulkheads meet the keel, and the need to lower 9 and 10 a bit (matching comment 2 above) Foto 3 shows what happens should I move the bulkheads up to match the top of the keels; this doesn’t look right at all

- 1 reply

-

- fitting bulkheads

- america 1851

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.