Metaspace

Members-

Posts

30 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

mtaylor reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

mtaylor reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

scrubbyj427 reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

scrubbyj427 reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Archi reacted to a post in a topic:

Papegojan 1623 by Metaspace (Roman Benesch) - Scale 1:26.6 - RADIO - wood, RC sailing, reefing, functional cannons

Archi reacted to a post in a topic:

Papegojan 1623 by Metaspace (Roman Benesch) - Scale 1:26.6 - RADIO - wood, RC sailing, reefing, functional cannons

-

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

Forlani daniel reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

Forlani daniel reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

mtaylor reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

mtaylor reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

BobG reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

BobG reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

Forlani daniel reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

Forlani daniel reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

Metaspace reacted to a post in a topic:

Chebece 1750 by Forlani Daniel - FINISHED - 1:48

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

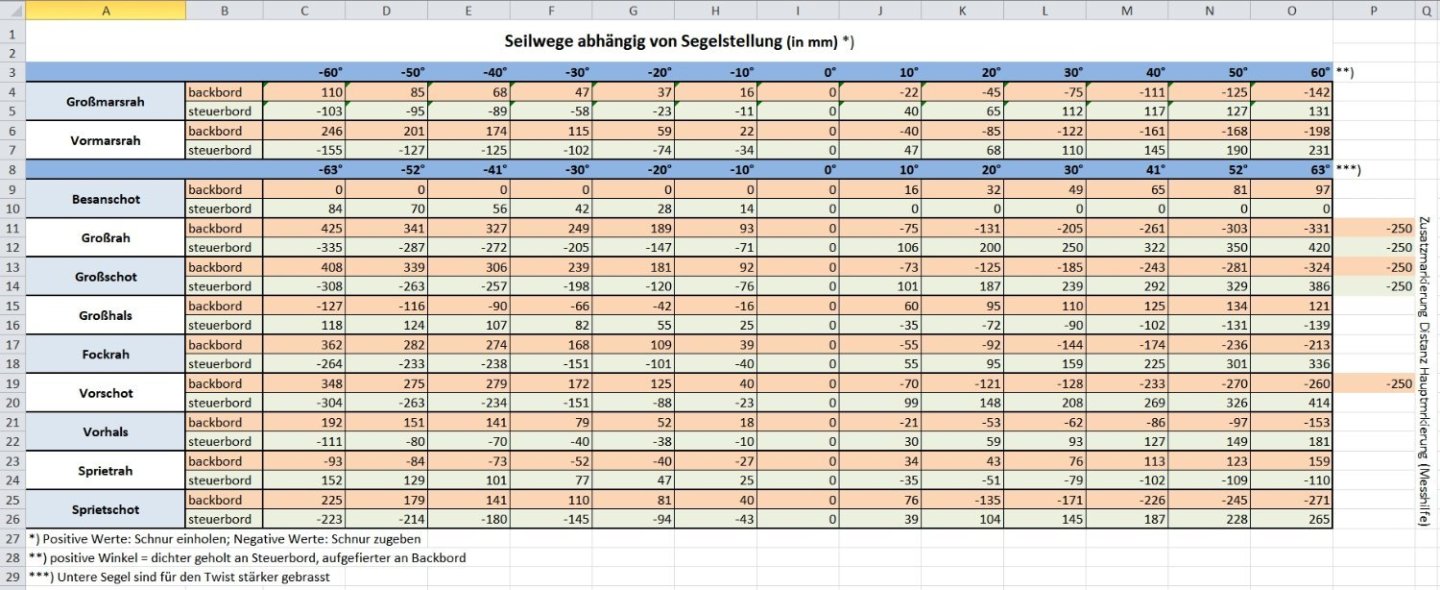

It's been a while! Which doesn't mean I wasn't working on the Zeta - just that I did not find as much time, due to some personal matters, and changing jobs. Also, admittedly, the current work on the ship isn't the most exciting, and quite tedious. In order to complete our sail steering unit, I had to measure the precise sheet rope movement distances for all sail bracing positions. This data is necessary to correctly dimension the bracing winches later. My measurement approach is as follows all sails were brought into default position (in right angle to keel; except mizzen sail, I'll discuss this later). sheet ropes are (temporarily) led out of the hull, to a reference point (in our case, the edge of the table on which the ship resides - the ship being secured against moving) sheet rope ends attached to weights, to assure ropes are taut ropes are marked at the reference point (sails in default positions; "zero-point") now, yards, outhauls are braced in 10° steps (and eased off respectively on the other side of the ship) made sure the ropes are all taut the difference between reference point and zero-point is measured For measuring the correct angles, I used cardboard half-discs with respective markings. Now I had to take the needed 286 measurements (22 sheet ropes, 9 sail positions) - and this takes a while! When I was done, it turned out that there were some discrepancies between starboard and portside, which were hard to explain by the slight imprecision of the hand-built rigging. Also, some measurement sequences of single sheet ropes from 0°, 10°, 20°, ..., 60°) were not harmonious for my taste. It took several attempts to eliminate (hopefully!) all measurements errors: The angle measurement half-discs need to fixed well, horizontally and vertically sheet ropes must not be confused - marking them, as well as their reference points, helps the weights for keeping the sheet ropes taut must not be too heavy - otherwise, they might draw additional rope out of the ship unnoticed before the measurement is taken (ropes with a pulley being especially susceptible) As our parrels mount the yard relatively loosely on the mast (to allow sufficient rotation of the yard, up to 60°, for remote controlled sailing), the correct, right angle between yard and mast must be assured As outhauls are controlled by sheet rope and tack, it must be assured that the sail hangs vertically to the ground, fully stretched, to allow correct measurements. Since the sails warp easily, and normally are not taut, I had to build temporary wooden frames for sails with outhauls (all except topsails), and attach them to the sails to assure the correct shape, and thus, outhaul positioning The above learnings came at a stiff price - I ended up with taking all measurements 2.5 times. Each time, it means adjusting 8 ropes, cheking tautness, angels, re-adjusting until everything fits properly, and then measuring and taking down the numbers. Only after the last pass I'm fairly confident on the numbers 🙂 The topsail yards were especially tricky - the ropes controlling them come from below in a quite steep angle - getting the yard position right, without deforming the relatively thin yard was challenging. I was quite happy that sails, yards can be well rotated from -60° to +60°, and also the friction of the ropes in their piping is pleasantly low. Here a few pictures from the measurement process: The mizzen sail is handled differently. For this, we only control its outhaul - for the mizzen rod, we forgot to lay piping back in the days. But that is not too bad, as the mizzen sail has very limited movement, and is not really relevant for powering the ship. According to the experts, it was used to create rudder pressure, as well as (together with the spritsail) trim the ship. Under wind from abaft, the mizzen sail will be allowed to take one of two positions - the rear end of the mizzen rod may be fully veered to either portside or starboard (depending on the previous maneuver). When the ship luffs, the mizzen sail outhaul is braced more and more, until it's fully tight. On the lee side, we do not want to further add sheet rope, i.e., veer, as this rope is in fully veered state already. This means, the pair of brace winches for the respective side of the ship will pull in rope for the windward side, while adding as little as possible for the leeward side, i.e., that winch will not consist of more than the axle itself. And here the measurements:

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

Metaspace reacted to a post in a topic:

„Święty Jerzy” („Sankt Georg”) 1627 – reconstructing an opponent of „Vasa”

-

Amazing work! I'm a bit surprised to see the gun ports of the aft cannos seemingly to be smaller then the rest. Do the guns have a smaller calibre? With the Papegojan of the same period, with assumedly a similar setup of aft cannons being used either in the rear, or to add to the broadside, were of the biggest cailbre, slightly larger than the rest of the main gun deck. As I am confident you have done thorough research, would you have an explanation for this? Or am I simply mistaken because of the angle of the drawing?

-

Hard to say, the sailing control unit with its 24 bracing winches, plus 24 gear transmission winches will take some time - then the cannons have to be fitted, the mechanism to open the gun ports and deploy them, retract them will be another major effort! Smaller things will be creating the lead ballast, and the Arduino cannon firing software. Next year is likely the earliest manageable 🙂

-

I have added the flags - bought at http://www.schiffsmodellflaggen.de. I'm quite happy with the quality, waterproof (this being a remote controlled model), and a thin fabric, which flows even with light winds. Instructions came with the flags how to cut them out, and glue them - had been quite a while, since I had a pressing iron in my hand 😄 The flags come in different sizes, not for all flagpoles was I able to get the precise historic size to scale - this is due to our unusual scale of 1:26.67, I assume. Still, I'm happy with the results!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.