-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Raleigh, NC

Recent Profile Visitors

-

Coyote_6 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Coyote_6 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Geowolf reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Geowolf reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Javelin reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Javelin reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

DavidG reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

DavidG reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

ccoyle reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

ccoyle reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Hello there, 10 weeks later, I've got some new pics to share as I make my way (slowly) through the San Juan Felucca. The superstructure details have been extraordinarily tedious and I can only stand to do about 90 minutes of work on the items at a time. Assembling and installing the cabin took about a week in total. I made one fairly large mistake...I installed the grating that the jolly boat will be lashed on to too close to the mainmast hole. I'll have to scoot the boat forward so that it doesn't impede the mast. There are some other aesthetic damages you can see as well. All the little eyehooks you have to install in preparation for the rigging has taken me quite a bit of time, and has been the biggest obstacle in progress. I've seen another build log that glued planking on to the ship's boats to give them a more authentic look, but with the time this has taken me, I am going to stick with the painted metal. Applying primer on those boats at the moment and will have them painted soon. The stairs to each deck were more difficult than I expected. I am desperate to begin the rigging, though I have never done it before, this being my first build. This phase seems the most interesting to me, but I may find it difficult.

- 21 replies

-

DavidG reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

DavidG reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

G'day to what few of you that may be following along with my first ever build, and it is quite obviously a first time build. I have struggled through every step, but we are pushing along and to an untrained eye (not that my eye could be considered "trained"), the San Juan is looking just fine. It has been three weeks, and since then I have installed the keel, stern post, stem, and shipped the rudder (she steers, huzzay!). The rudder gave me absolute fits. The provided hinges were very difficult to work with, especially as the stern post had very little depth with which to attach the hinges. It took several attempts at gluing them on, and the result looks shoddy with lots of dried glue residue surrounding the hinges. This would have been much easier had I glued the hinges to the pintles directly, causing the hinges to stay in place; however, I was determined to have the rudder be able to rotate. The model kit came with some paints, including some varnish, so I'm not applying the varnish to the decks and hull before I start working on the superstructure. We'll see how it turns out. Though I haven't gotten many responses in the past, I will keep posing my questions to the general public and doing searches within the forums. Curious how others have attached the rudders in their builds, and what feedback you might have. Cheers!

- 21 replies

-

Ken, a little late here, but congratulations on finishing the San Juan last summer. I am in the midst of building her currently as my maiden venture into modelling. I am curious about two things here: Did you do any staining/dying/painting of the San Juan? I am pondering trying to add a little color to the deck, but this being my first build I'm fairly unfamiliar with the process of applying any sort of finish. Curious if you did any sort of finishing to the Sapele second plank layer on the hull as well. Did you add the keel/stem/stern post before or after you finished planking the hull? I did them after, and I am wondering if I could have achieved a more exact and flush plank layer if I had attached the keel, stem, and stern post prior to the planks. Cheers, Will

-

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

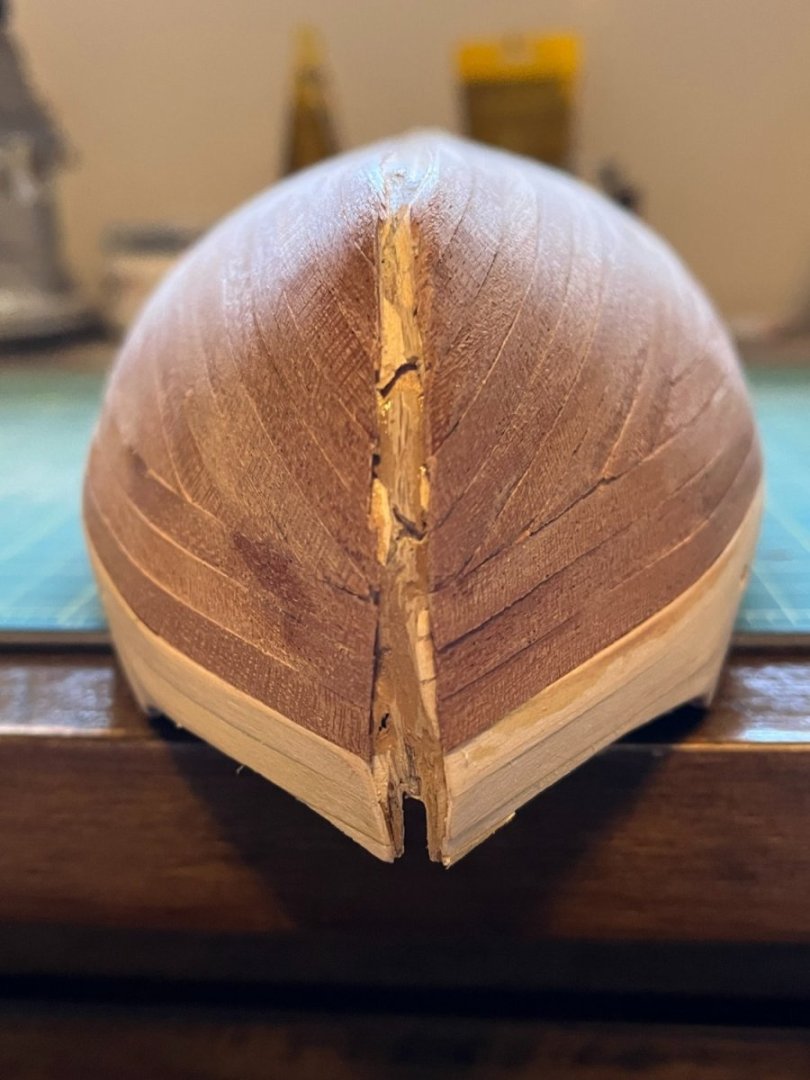

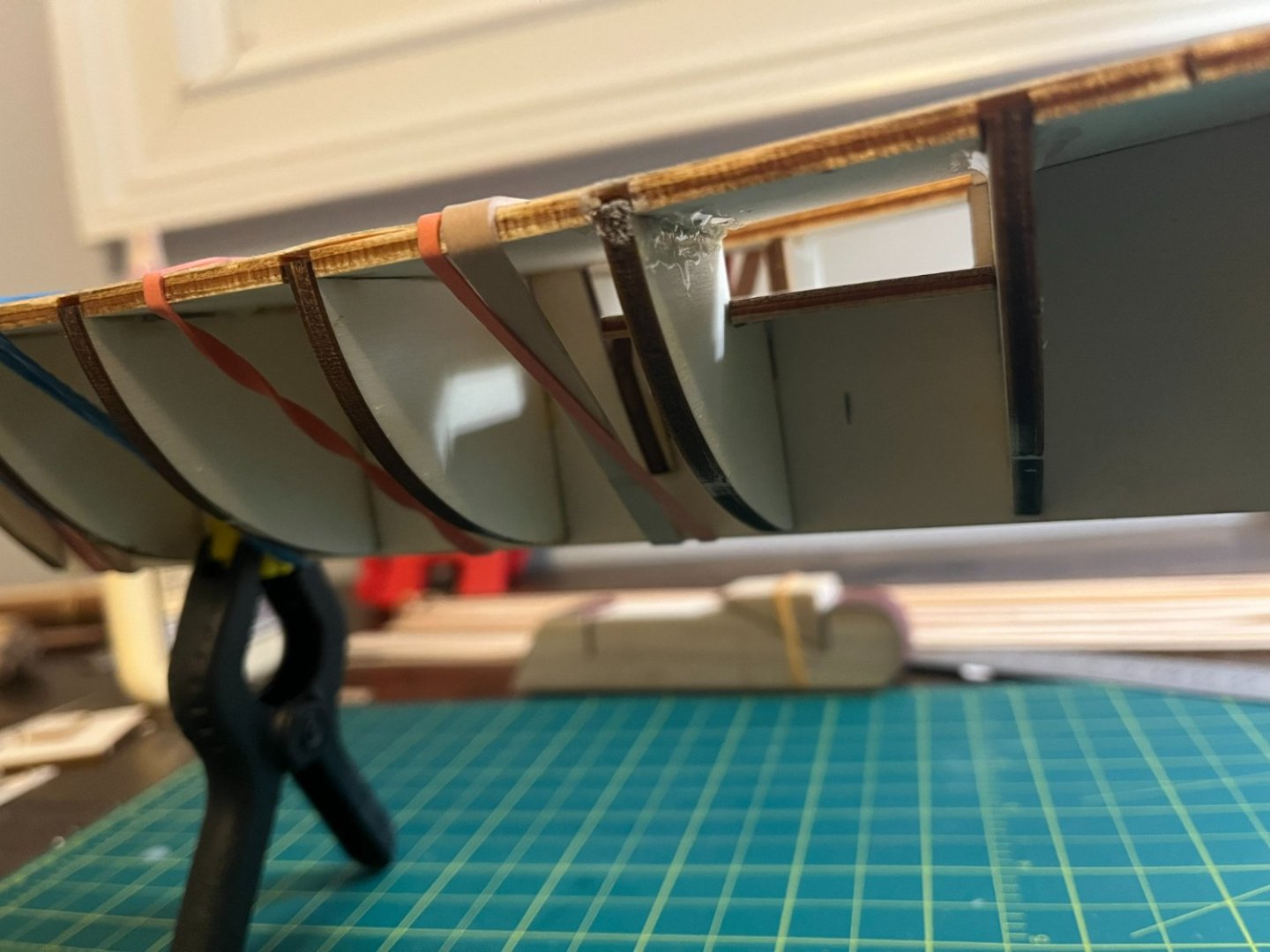

It's been almost 6 weeks since my last update! Time has been flying by and without much progress to show for it. Have been doing a fair amount of travelling recently, and random odds and ends have added up preventing me from spending much time on my San Juan build. I did manage to get the second layer of planks onto the hull - this lining uses sapelli wood. Again, my general planking method here is not too sound, and having to cut this wood into smaller pieces to fit the shape of the hull proved difficult for me. I had to scrap two or three planks due to incorrect/imprecise cuts. The biggest and most noticeable piece of shoddiness comes at the bow, where I found it very difficult to get my planks to line up flush together at the correct angle. I believe the majority of builds I've looked at (not for the San Juan specifically) seem to have the keel and, more specifically, the stem attached to the hull prior to planking. To me, this seems logical and would make planking easier in that you can easily line up the planks at the bow to lay flush against the stem. I am curious if anyone following this build has any recommendations as far as attaching the keel/stem prior to planking or afterwards. You can see what I mean in the photos I've included on how the bow looks pretty beat up. I also used contact cement for the gluing of this second lining, and I had some difficulty using that as well. Alas, we chug on in my first build and I continue to learn.

- 21 replies

-

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

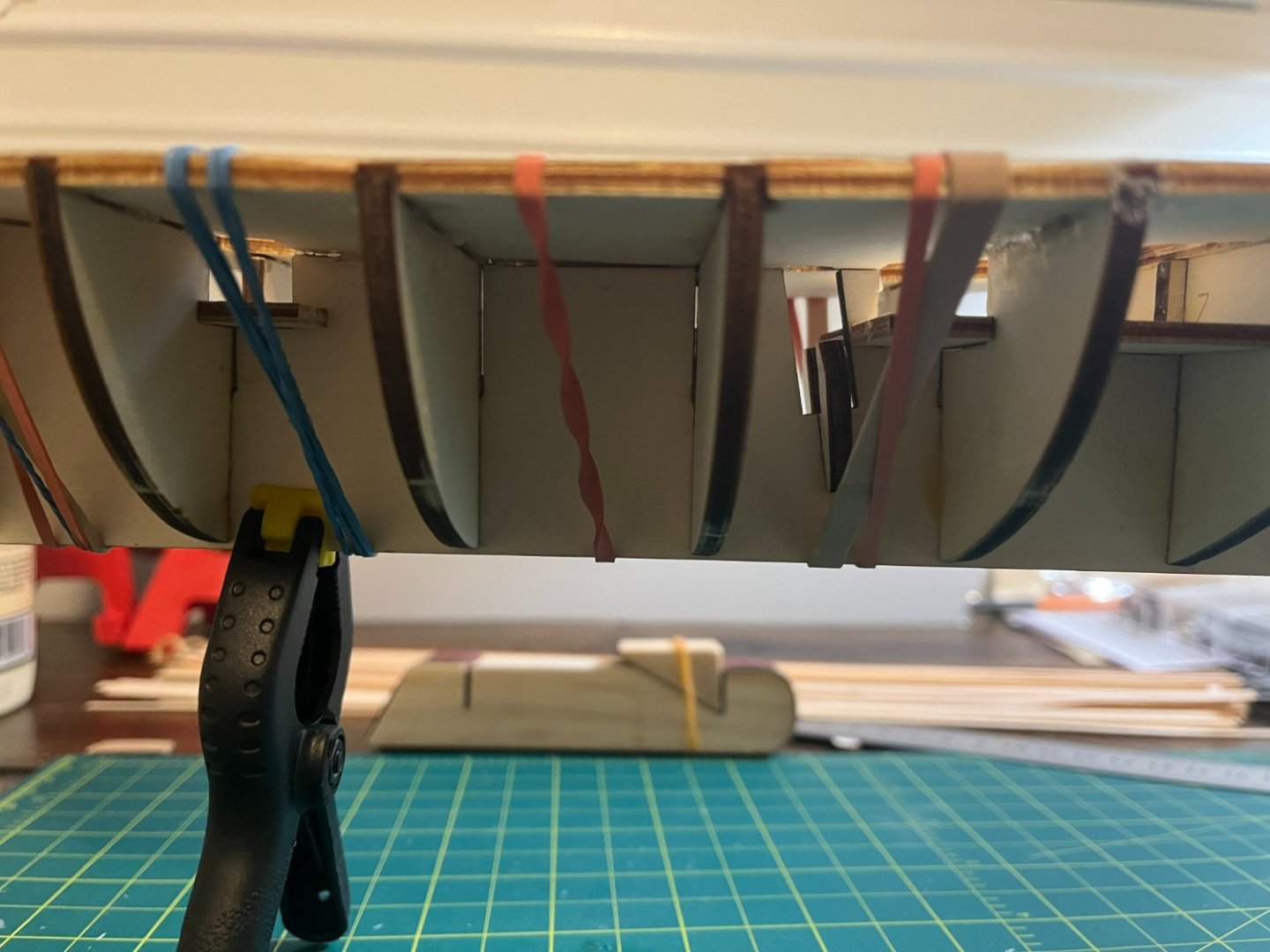

Lots of work in the yard this weekend made for less recreational time than I would have hoped. Note sure how those of you with a full family have time for this hobby! Sanding down the hull is taking up much more time than I planned for, especially as it's somewhat physically taxing as well. I finished the first plank layer and coated it in wood filler to plug some of the gaps, so now I'm sanding it all down. I have a little foam handheld sanding tool that you can attach sanding strips to with velcro. I like it because it's flexible and can bend with the shape of the hull, but you do have to apply a good bit of pressure when using it, and my arm starts to hurt after going at it for 10 minutes. Anyway, pics of progress included below!

- 21 replies

-

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

Prowler901 reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

ccoyle reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

ccoyle reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Quick update on my first hull plank layer. Going better than I would have anticipated, and for a first build I am mostly pleased with how the strakes are turning out. I have learned quite a bit from this "trial-and-error" build and for the next one I hope to follow more conventional planking methods. I should have this first layer complete by the end of this week and can move on to the second layer this weekend.

- 21 replies

-

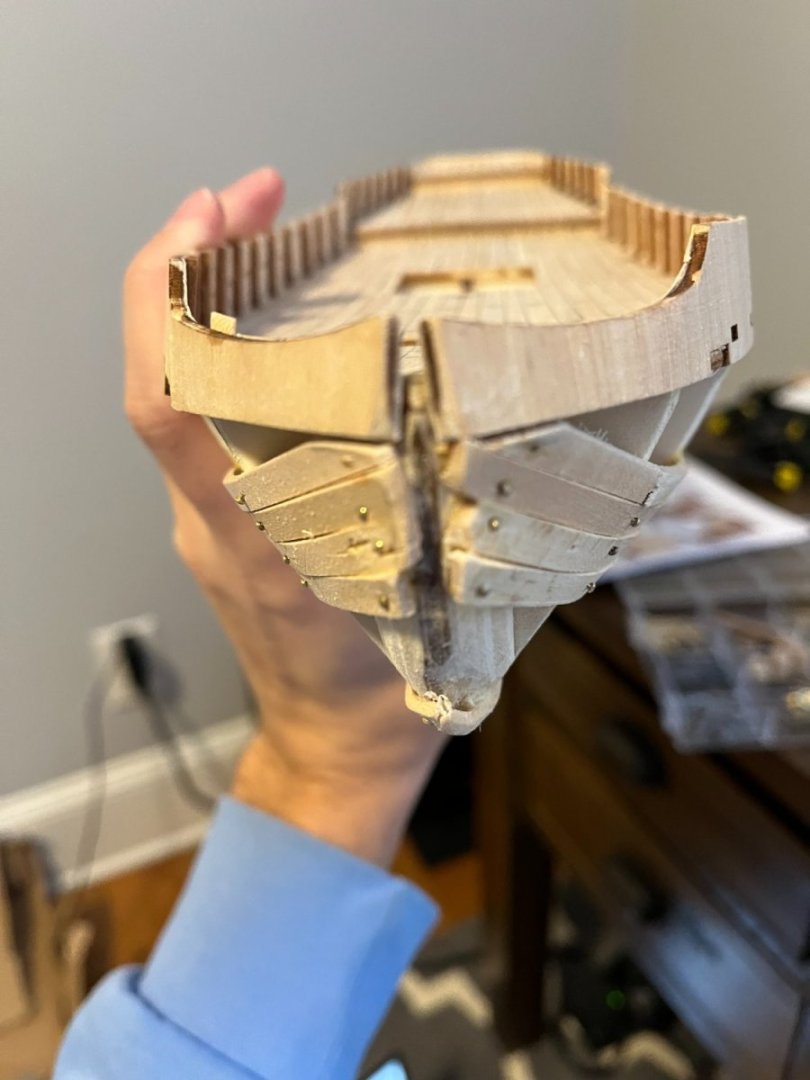

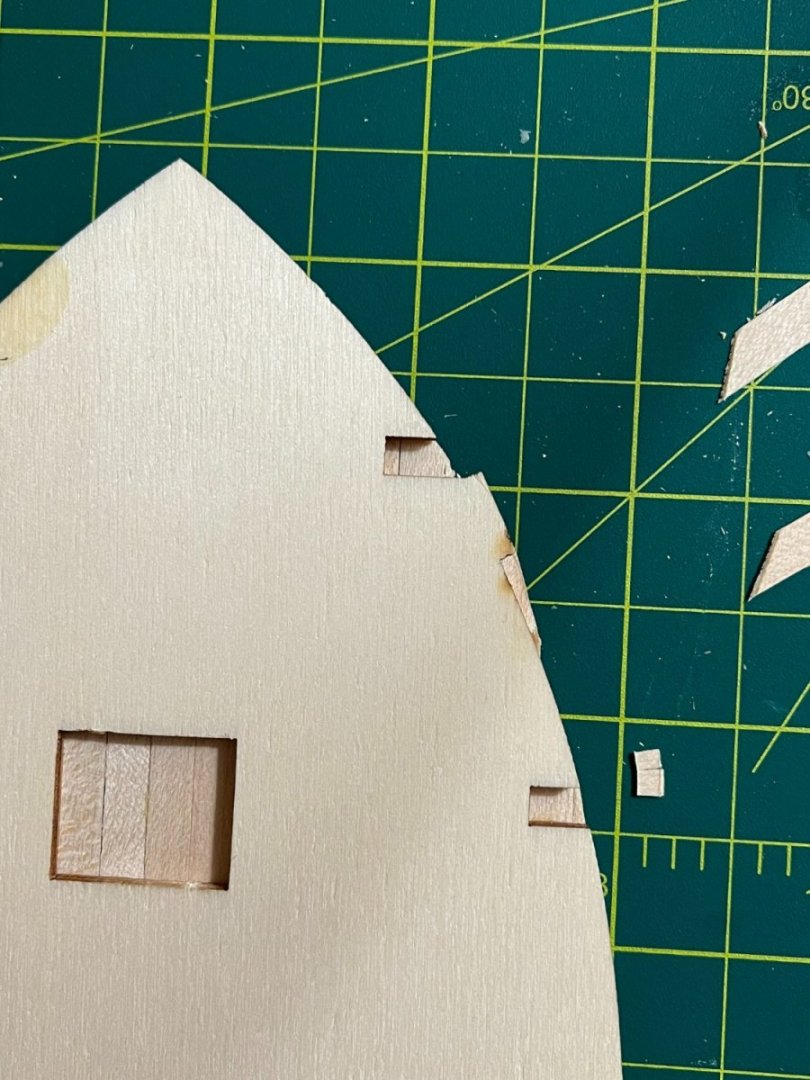

Well, I attempted to lay the garboard strakes this afternoon. I believe I would have had an easier time with things had I started at the very top, just under the bulwarks rather than laying the first plank in the middle of the bulkhead frames. Nearly every video and guide I've looked at, the modeler seems to have started from the top (under the wale/bulwark) and worked down from there. It also seems that most of the models I've seen in demonstrations have the stem already attached to the bow as well as the sternpost already in place. I don't know if it's atypical to plank the hull prior to attaching those items, but the kit instructions have it laid out that way. The garboard strakes were extremely difficult to lay, especially at the bow where I was unsure how they were supposed to lay (see photos - it looks pretty shoddy). I do not have a bow rabbet to "lock" my planks into place as I have seen in several videos. I am just going to continue on planking how I have seen in a specific video related to this particular kit - it will not end up looking quality, but I believe I can manage to make it look halfway decent, especially once I am able to go over it with the second plank layer.

- 21 replies

-

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Allan - thank you for your continued input and discussion, you have been tremendously helpful. I will absolutely dig into Chuck's video demonstrations. As for the pre-bending of the provided planks, I did this with a couple of them before I glued them in place. I will plan to continue with this method. Pre-cutting the tapering of the planks is a little more difficult for me and something that I haven't quite gotten the hang of/figured out yet.

- 21 replies

-

I have spent a good part of this morning reviewing these documents and other general guides/threads on planking. While there are several useful bits of information in those guides (using string to divide the hull up into separate "bands" to plank, information on cutting each plank to shape prior to bending), some of these techniques are seemingly a bit harder to employ with the kit I am working with as I am limited to the wood planks that were provided in the kit itself. An important step seems to be the "spiling" of the planks - however, with the pre-cut kit-included planks, I'm not sure if I am really able to spile the planks in the desired manner to get a perfect fit onto the hull. As I understand it, spiling is cutting a plank to fit directly onto the hull, including the potential widening/tapering of the plank to fit into the bow/stern, by using a piece of softer board to understand how the plank should be positioned and then using that outline to cut the plank. I don't fully understand the "stealer" and "drop strake" concept, or rather how to understand where they need to go. I often struggle to translate text into actual application...Video demonstrations are more helpful to me. Part of the reason I am just chugging on ahead with the planking is to do it so that I have a frame of reference to compare with these text-based guides. This is very much a trial-and-error build for me, and note that this is a double-planked model so in theory I should be able to hide the shoddiness of the initial plank layer. The things I have learned in my initial planking session, where I laid three strakes per side: I did not sand the frames enough in order to get the strakes to lie flat against them. I have a better understanding of how they need to be sanded at an angle in order for the strakes to lie flat. Because of this, the nails have been helpful in keeping them in place. The steps I took to bend the strakes into place on the hull frames before gluing down are very helpful and maybe necessary, particularly to allow them to shrink as they dry so that I don't end up with gaps. I employed thumbtacks for this, but maybe with some smaller clips I can use clips alone so I don't have to puncture the strakes themselves. Going to keep researching as I go!! Thanks everyone for your input and commentary!

- 21 replies

-

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

PostCaptainAubrey reacted to a post in a topic:

San Juan Felucca by PostCaptainAubrey - OcCre - 1:70 - First Build!

-

Thanks for the note, Allan! I have sifted through the guides you mention. I went ahead and began the planking of the hull, and have laid three strakes on either side of the boat. Now that I've gone through the process, I'm going to re-review some of these files as I believe they will make a little more sense to me now that I can understand the application. Provided some photos of what I accomplished so far. I feel like I did an OK job. Getting the nails in were a pain as they kept skewing off to the left or right rather than going straight in. Again, the first plank was supposed to go into the center of the each hull frame. Attempted to measure the midpoint of each frame with a tailor's measuring tape, marking the halfway point on each frame. After soaking the planks for 30-45 minutes, I laid the first one in place over each halfway point marking on the frames. I fixed it in place with thumb tacks, attempting to let the plank dry and have the bended shape set in before I glued/nailed. I did this with one other plank below this initial one, on each side. Once those had dried, I detached them from the frames, and then glued and nailed them in. I was a little unsure on how the plank was supposed to line up at the bow of the ship - should I be measuring these out into an exact point and conjoining the two opposite planks at the bow? The video I was referencing, the builder essentially is just able to lay them approximately and then sand the tips at the bow into a point. You can also see in the picture of the front-on bow view that the planks don't exactly line up oppositely. One area to improve on next time.

- 21 replies

-

Well, I have spent the last couple days watching all kinds of videos on planking the hull. Alas, my plank bending tool from Model Expo has not come it yet, and I feel as if I will need this to do the job, so my big plans for today are scrapped. The instructions will have me laying the initial plank in the center of the hull and building out from there. Do planking methods vary from model to model? I suppose it doesn't always make sense to just start at the top and work your way down?

- 21 replies

-

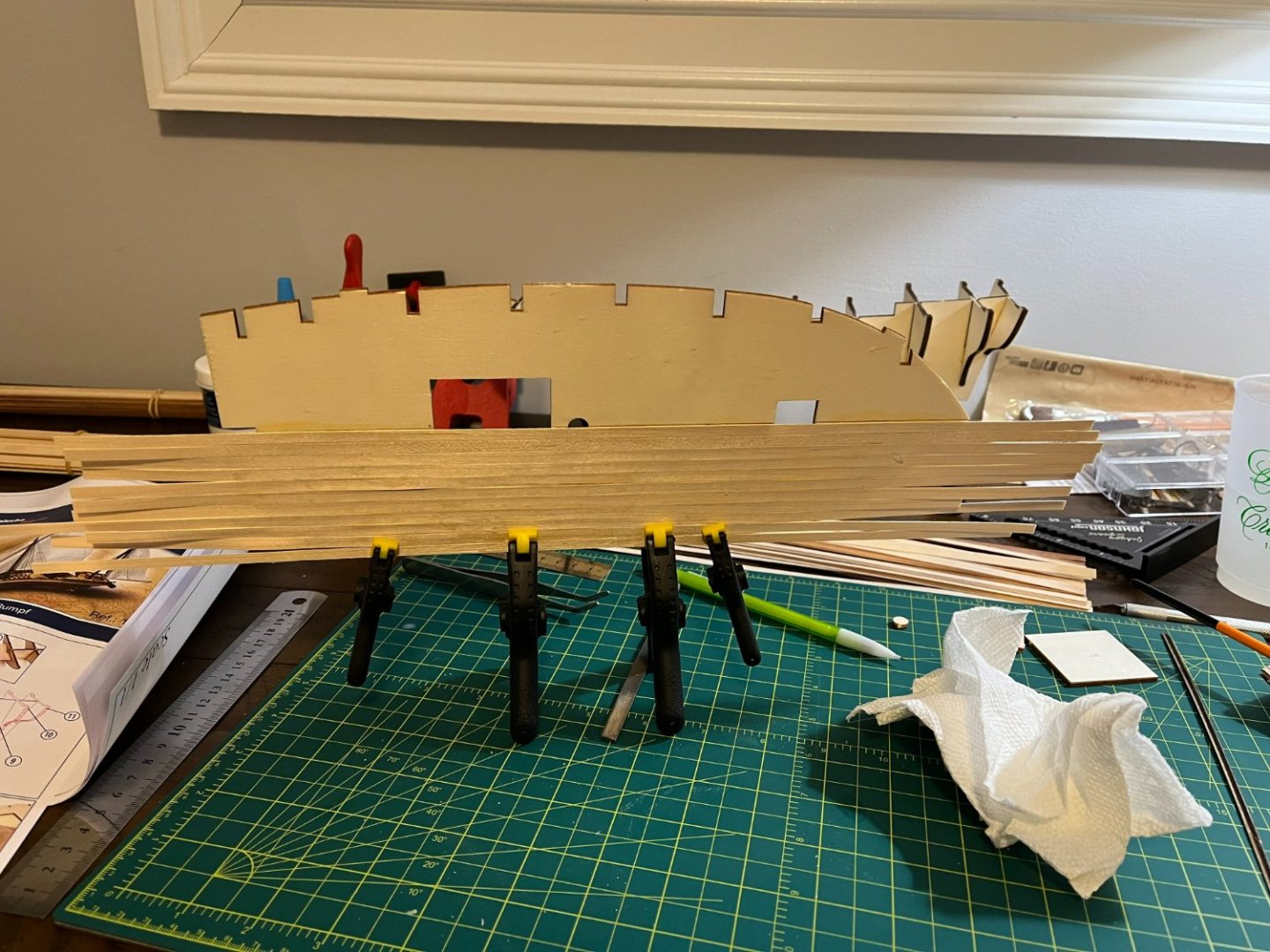

Happy New Years everyone. It's been a few weeks since I've posted anything on my build log here as I've spent a lot of time working on things that don't have as much obvious visual change. I added in supports to the hull to assist in laying the strakes I believe, and spent quite a bit of time sanding everything down, especially the bulkhead at the bow. I bought a Dremel, a great investment. I've found myself needing some different size/shaped files, so I just ordered a set today that should arrive this weekend. My biggest step has been attaching the gunwales (unsure of correct terminology). I soaked the pieces in water for about 15 minutes in order to get the desired bend to attach them. There was mostly no issue attaching them, though you can see in one of the photos below the starboard gunwale towards the bow did have a little structural damage, but nothing catastrophic by any means. Planking the gunwales (planks face inward) was a disaster, and soaking them in water loosened the white glue I used so that some planks came loose (you can see in one picture). I couldn't get them to lay straight and ended up having to play jigsaw puzzle trying to fit different shaped planks into odd spaces. I guess I will run into this when laying the hull strakes as there will be planks that have to be shaved down to fit different angles. What is the best method for getting an exact angle on the plank before shaving it down? I saw a video of someone using a piece of cardboard and cutting the cardboard to match the desired shape needed then applying that same cut to one of the strakes. I believe I'll begin planking the hull this weekend. Nervous but excited about it.

- 21 replies

-

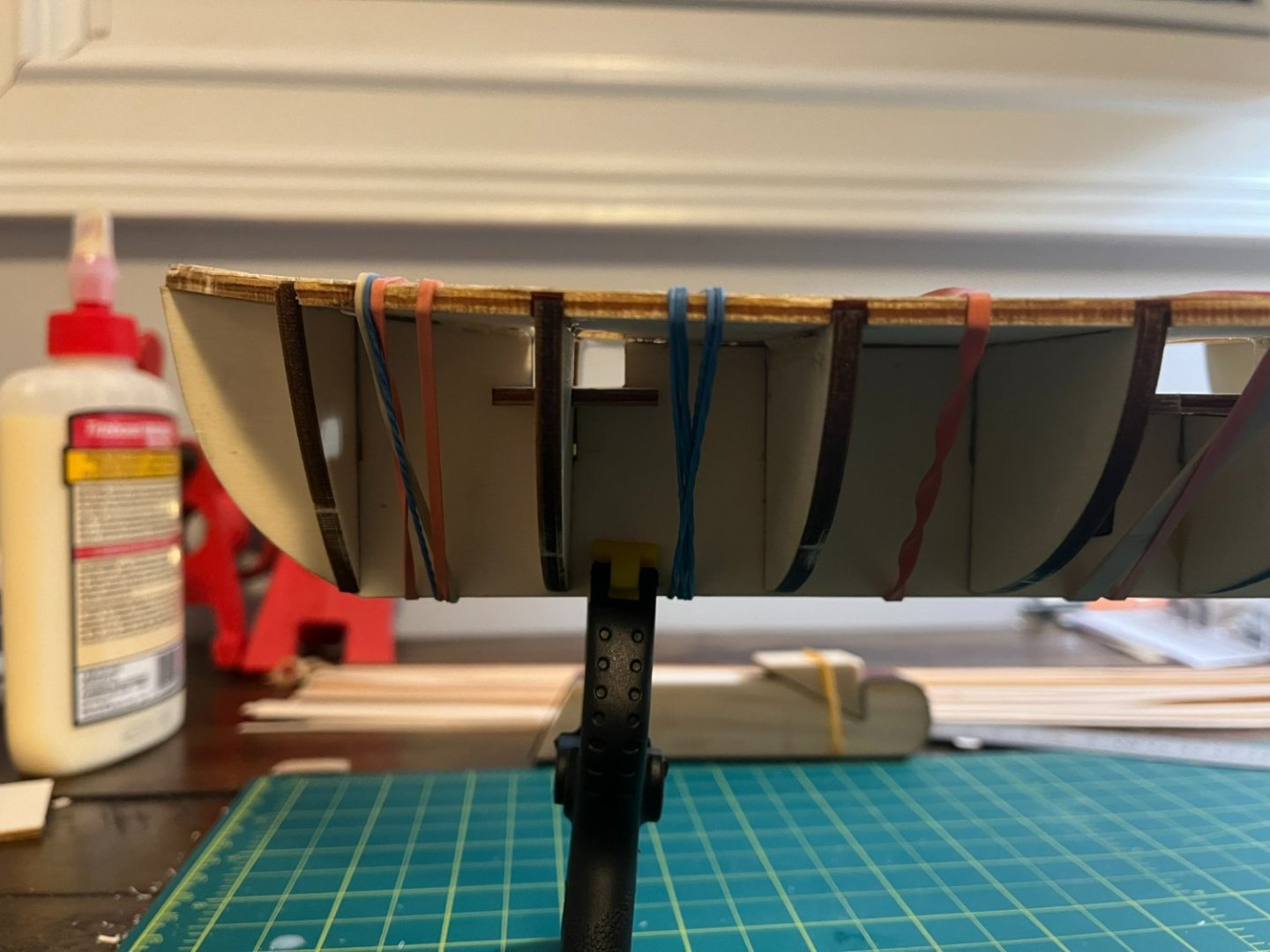

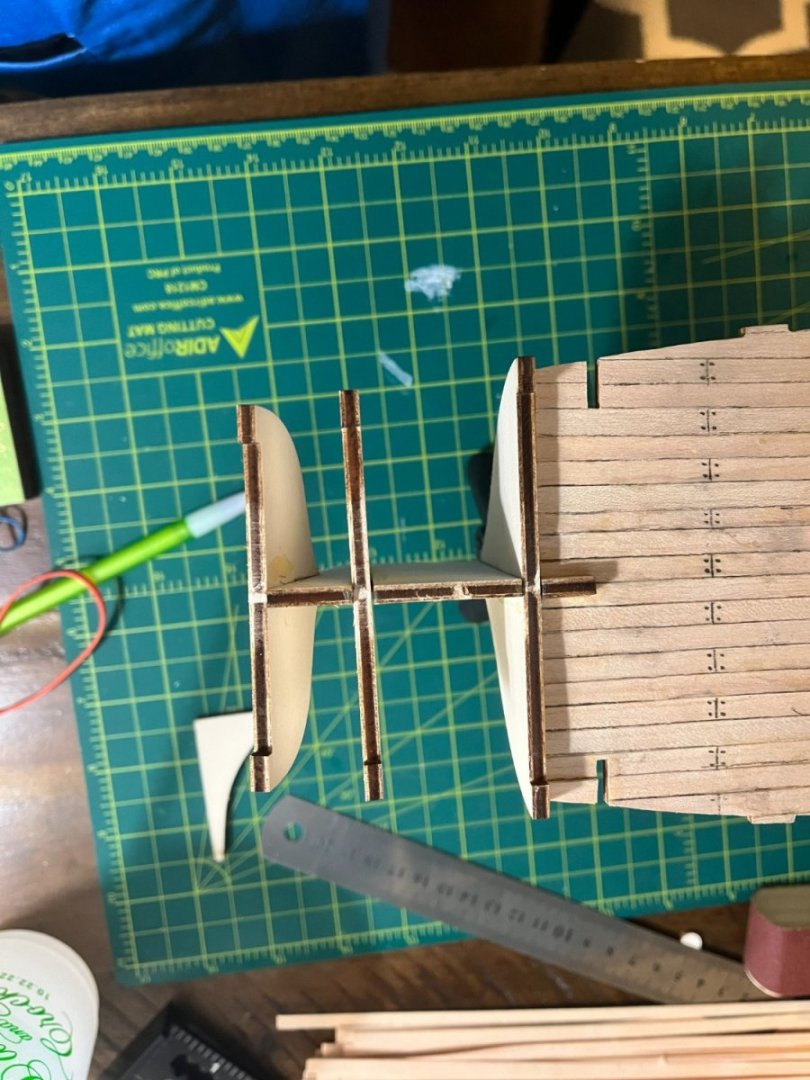

Well, decided to get some work in on the San Juan before taking off for Christmas holidays. Goal was to get the deck attached to the hull, and whew, it was much more difficult than anticipated. Before I began gluing, I drew in the caulking of the deck planks with a pencil. I have read of other people using different methods here to enhance the look, but I am just keeping it simple with my first build (would love to hear how y'all like to approach the caulking, however!). One step I found myself wanting to go back and be a little more aggressive with was the sanding of the strakes after I finished trimming the excess wood. There was still quite a bit of texture that I ran into while drawing in the caulking. Once I completed the drawings, I got a bucket of tepid water to soak the deck piece in so that I could bend it to the hull. Tried to avoid getting the top half of the deck wet so that it wouldn't affect the planking. Unfortunately, my fingers ended up smudging some of the drawn on caulking - will probably have to go back and touch that up. I used regular white glue in the attempt to secure the deck, and I don't think I used enough glue. It was very difficult to get the deck slats lined up with the bulkheads but once I got a couple secure the others started to fall into place. However, because I didn't use enough glue I found myself essentially having to hold down the deck with my hands while the glue started to dry, causing some mild hand cramps. I've seen the rubber band method used here and attempted that but don't think my rubber bands had enough pressure to keep the deck in place. I had to go in and touch up several areas of the space between bulkheads and deck with super glue (any preferred brand of quick-dry glue? I just picked up some standard Gorilla Glue Super Glue) to try and get them attached. Got a bit of the super glue on my fingers in the process...The primary areas where I was having to reinforce with super glue came on the bow bulkheads - no real issue with any of the further aft bulkheads as the deck was flush against those with little handling. You can see in some of my photos below where there is still space between the keel/bulkheads and the deck. Once the everything finishes drying I'm hoping to go touch those up with additional super glue so that everything is flush. I also noticed that one of the bulkheads which I believe will support the quarterdeck is not squared to the keel like I thought...will have to address that at some point I imagine (can see in one of the photos below).

- 21 replies

-

Thanks. I looked up a video on a pin vise drill and see how it works now. I haven't gotten to a point where I need to use it yet.

- 21 replies

-

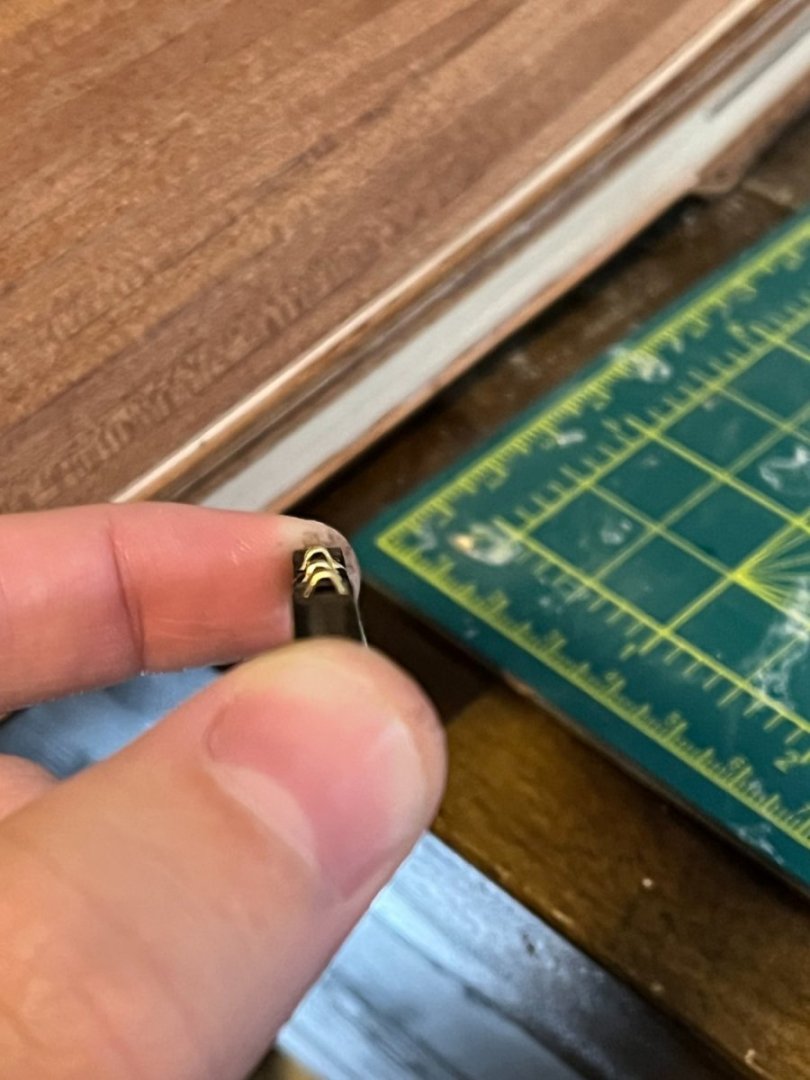

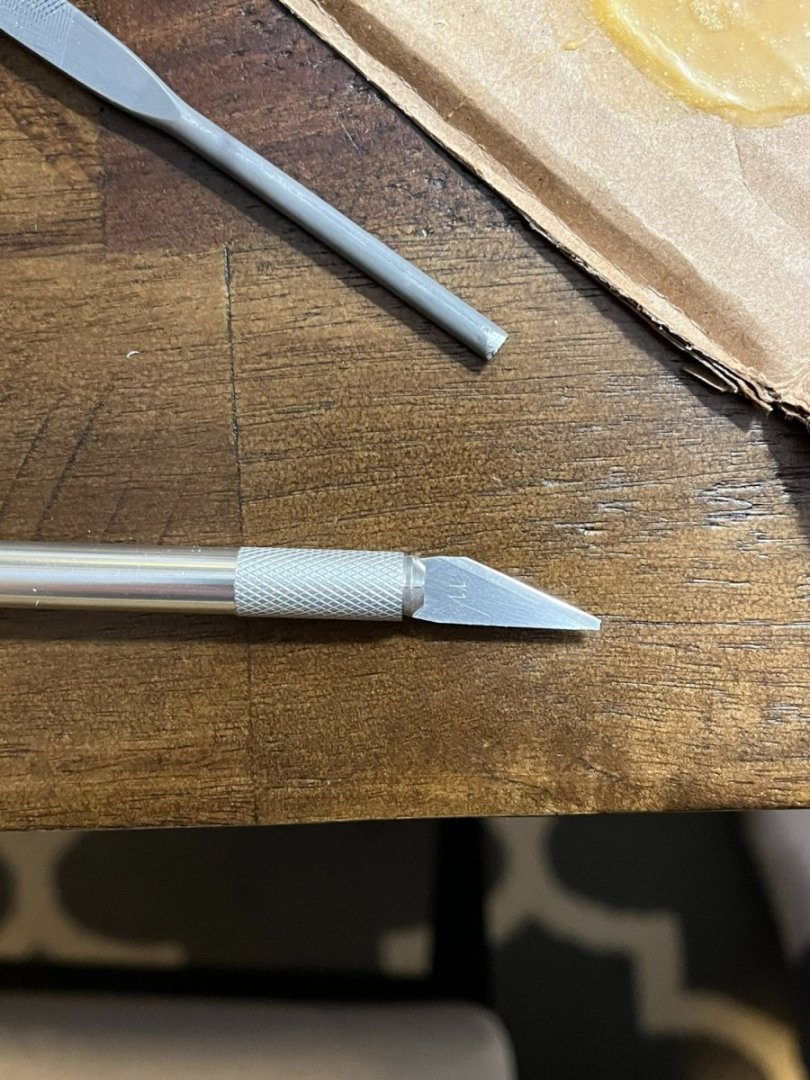

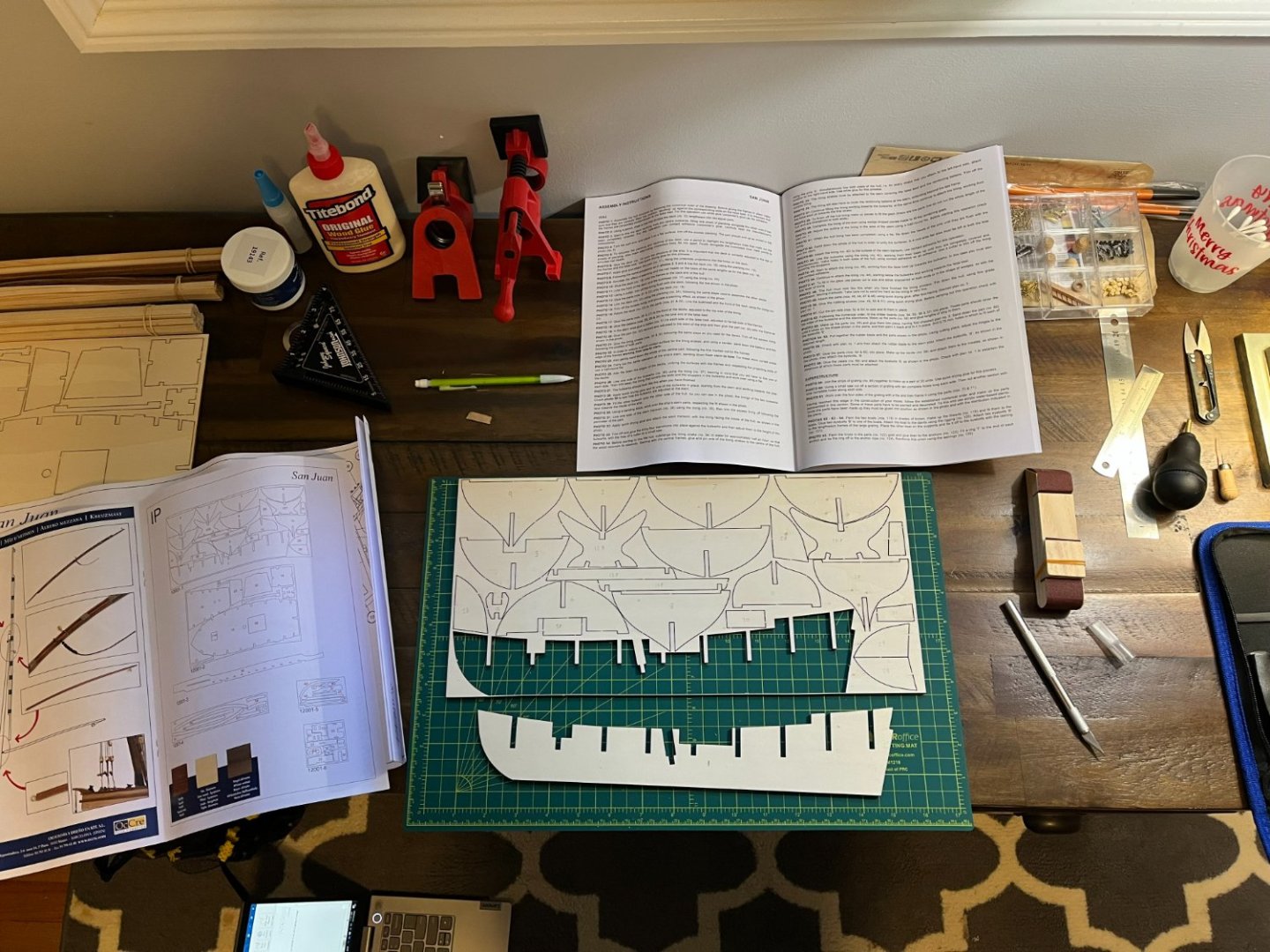

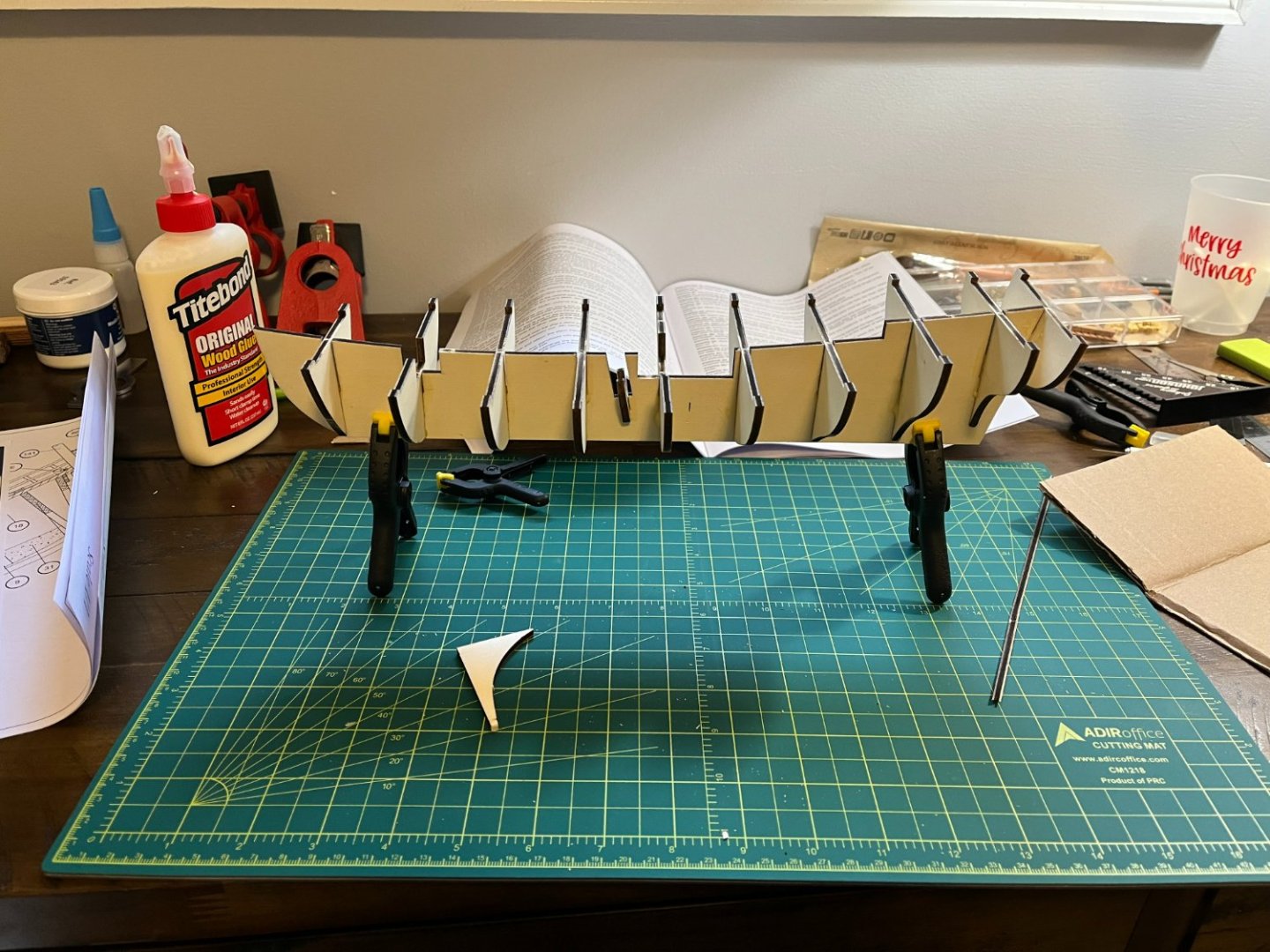

Hello Everyone! I've laid the keel on my first venture into model wooden shipbuilding - the San Juan from OcCre. I'm going to have about two months off this coming summer as I make a transition in my career, so I thought this would be a great way to fill my time. I wanted to go ahead and order a beginner's kit to start now in the hopes that I could build some skills and ultimately tackle a ship somewhat more profound this summer during my time off. We shall see how I handle the San Juan build, however! Being a novice, I plan to stay exactly on plan, barring any unforeseen circumstances. There don't seem to be many build logs for this specific kit, though it is supposed to be geared towards beginners, so that may be why. VictorBXM has some great videos in his build log, and am grateful for the first 4 videos and their guidance they've provided so far. As I build, I will probably type up my questions on best practices, etc. Any feedback is appreciated with thanks. On to the actual build: My workspace is a converted at-home office with a decently sized desk. The desk itself is very uneven...I ordered a cutting board to assist with this. Gotta start somewhere! I ordered some tools off the OcCre website, but so far they have proven somewhat mediocre. Cutting the pieces out of the balsa framework was much more difficult than I would have thought, and can only assume the difficulty was due to the knife from the toolset. In the process, I broke the tip of the knife off (I have ordered a new set of knives which I think will be higher quality). You can see some photos of the tools below, including the chipped knife. One item I was unsure of, but I believe to be a sort of drill, you can see included in the picture of the kit. If I am correct that it is a drill, there doesn't seem to be a way to rotate the drill head that I've been able to figure out. Eventually I was able to get the keel cut out as well as the bulkheads. The slots in the hull for the bulkheads seemed a little loose-fitting, which made gluing the bulkheads in somewhat difficult. There seemed to be some gap space in between the hull and the bulkheads after I glued them down - I got something called "gap filler" in the OcCre set. Is this what that might be used for? I have finished laying the strakes on the main deck, and am almost finished trimming the excess wood. A few of the wood planks that I used were a little warped, which made setting them on deck difficult. I had to employ use of several clamps here to clamp some of the warped planks down in order to set properly - I probably could have soaked these planks to correct the warpage. Once the glue finished drying, I began to trim away the excess wood from the planks. That process was hampered by my chipped knife. There are some close-quarters cuts where you don't have much room to operate and having a sharp point would have been very helpful. You can see what I mean in the closeup photo of the deck where this is a small corner to carve. Overall, the deck strakes look like they were laid by a beginner, which I am totally fine with. This is as far as I've progressed. I need to trim out the planking from the spaces on deck where the mast, cabin, and grating will go up next before attaching the deck to the hull. I believe I'll have to soak the deck in order to bend it to the hull...I'll be posting updates as I continue the build, and of course would really appreciate any and all feedback! Thanks for tuning in, Will

- 21 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)