-

Posts

22 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Retired guy reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

Retired guy reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

Rik Thistle reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

Rik Thistle reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

Canute reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

Canute reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

Canute reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

Canute reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

-

FriedClams reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

FriedClams reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

thibaultron reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

thibaultron reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

mtaylor reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

mtaylor reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

-

mtaylor reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

mtaylor reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

-

mtaylor reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

mtaylor reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

Django reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

Django reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

Egilman reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

Egilman reacted to a post in a topic:

PM Research Milling Machine by Rik Thistle - FINISHED - late 1800s - 1:12 (est)

-

These posts make me nostalgic for the machines that I learned on. They weren’t powerful or fast, but they had style and a solid feel and you could depend on them once you knew their quirks. Your models are excellent. I hope that you keep them coming. After the reversing gear and governor for my fathers Stuart #7 and Unicorn, I am at a loss for my next build. My lathe can’t swing a Major Beam’s flywheel and the Reeves ME Beam has questionable casting quality. I was considering another Stuart Beam Engine, but going all out on scale details this time. I don’t think that I have enough time left for a Steam Traction Engine. As you know, it is a feeling of great satisfaction when they finally run.

-

Django reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

Django reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

-

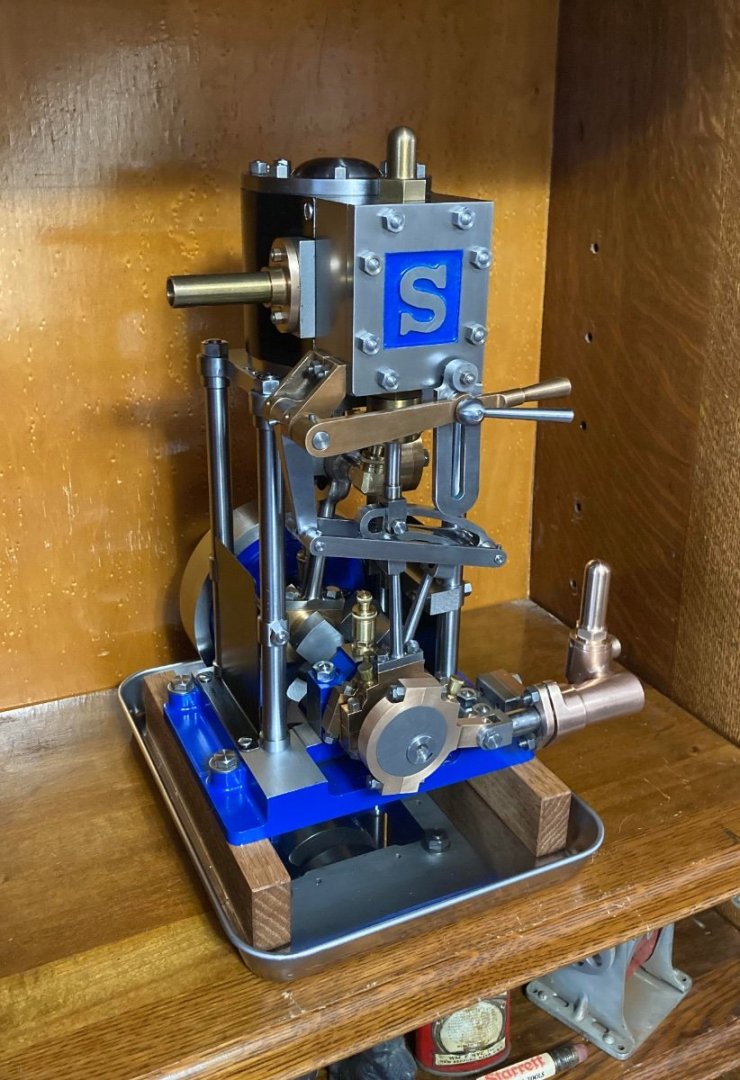

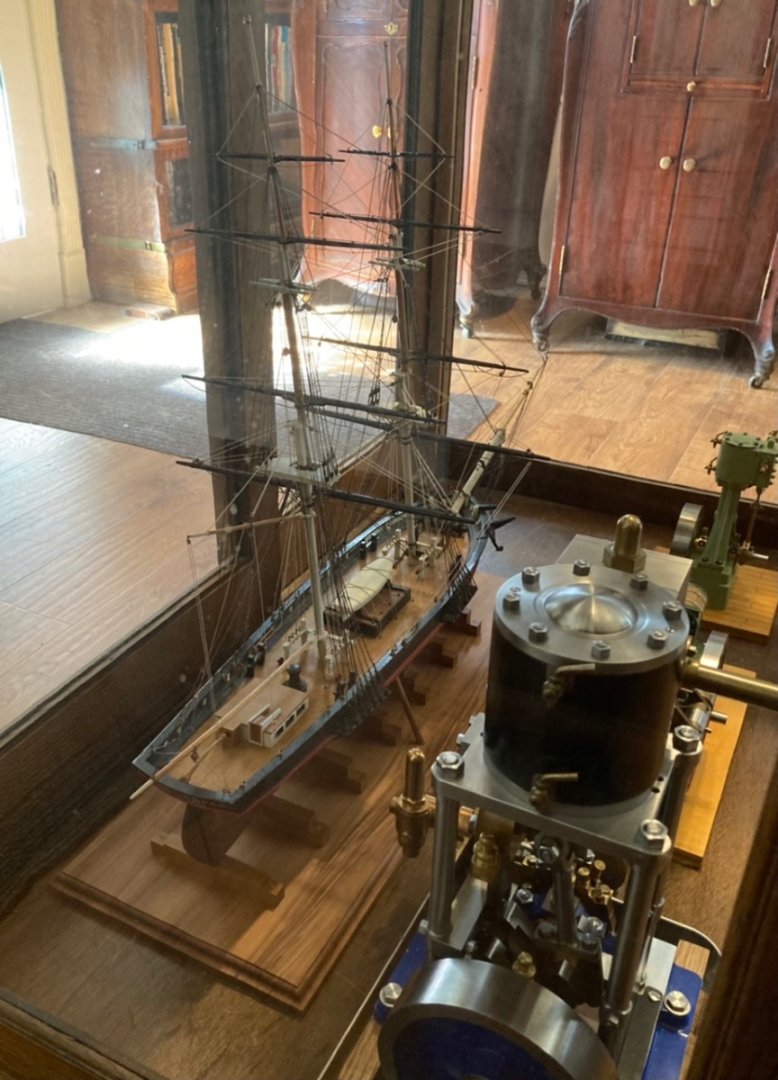

Thank you for the feedback. I looked through your model engineering posts and found them very enjoyable. The 10V with a disc flywheel and reversing gear is a marine engine, so it seems very relevant. Forms of beam engines were also used to power ships. Building model ships and model engines require a similar mindset. There seems to be much more interest in model engineering on your side of the pond, but fortunately, the internet makes the world feel smaller. My father built the Malek Adhel as a young man and I believe that it had big part in making him patient and detail orientated. You have to be clever to come up with setups for machining and for model ship building. The Stuart 5A that I have was primarily built by my father and he intended for it to power a small, full size steam boat. His 5A was extensively modified, but serious mistakes were made in the redesign and the execution, so he shelved it and passed it along to me. He wasn’t very hopeful that it would ever run, but after some redesign and a lot of rework and remaking of parts, it is now a complete and running engine, but I have no intention of building a boiler and putting it to work. Here is a closeup of the 5A marine engine, (like the Malek Adhel, another father to son project). The Unicorn and Stuart #7 engines were made by me father and the D10 is one that I built. I still need to make the governor for the Unicorn and the reversing gear for the #7. That will finish up the joint projects. I hope that you will continue to post your engine and machine builds.

-

Django reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

Django reacted to a post in a topic:

Stuart Beam model steam engine c. 1770s onwards - Rik Thistle - FINISHED - 1:12 (est)

-

I joined this forum when I was restoring my father’s Malek Adhel model. I never searched for any model engineering’s posts. I like your personal touches. your engine looks great. I recently finished a Stuart Beam from a set of castings that I had tucked away since 2010. I believe that my set was cast in the 1960s. I drew outside the lines as well. How are the newer castings? I have a D10, 10H and 5A as well, but they were all made from old castings, (I believe that the newest is the 5A, and that was from 1982).

-

A little post-finish work. I made a base from a quarter sawed Oak plank that was laying around. It contains the original blueprints, Popular Science Magazines, spare fittings, line and tools along with Captain E. A. McCann’s 1926 book on model ship building. It raises the model up by 2 3-4” so the engines are less distracting. I will have a plaque made that identifies my father as the builder and will include the name of the ship and the years of the build. I also removed the cigar company graphics from the front glass of the cabinet, (kind of a shame).

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

Django reacted to a post in a topic:

Malek Adhel by Django - FINISHED - Captain E. Armitage McCann Brig Model - Restoration - 1938 Build

-

The Malek Adhel has returned to the safety of it’s display case. I plan to build a box that will raise the model approximately 6” and I will keep all of the documentation inside. I will also have a plaque made up at some time identifying the builder, the dates, (Feb. 1938-Feb. 1940), and the hours invested. I could see the light at the end of the tunnel yesterday, so I began work at 8:00 AM , took a dinner break at 7:00 PM and finished my day at 1:30 AM the next morning. The finishing touches were made this morning. It is nice to see it as I remember it from my childhood. It seemed like every time I got something done, something else would fail, so I ended up testing every line and replacing all the seemed frail, (most of them). Another thing that I inherited was a tremor. I am fortunate that mine hasn’t advanced much yet and I can usually keep my hands steady. I figured that it was now or never for this job. Thank you for the support and for not being judgmental regarding my baggage.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

Thank you for the encouragement. I have found it to be rewarding. I have tried to separate the baggage from the model and I have thought a lot about my father as a 20 to 22 year old filling his spare time with this ambitious project. The workmanship is amazing. I have replaced most of the rigging, (even rigging that was still enact). I want to preserve as much of my father’s work as possible while insuring that the model is once again sound and will last for more generations. The remaining original rigging are the shrouds and rat lines. All of the running rigging was made of a line that had become brittle, while most of the standing rigging had remained supple and quite strong. I did have to replace the stays. I will resume working on the bow sprit today. The third portion was broken off and the end was missing and the second portion was not made correctly so I made a new one. The only parts remaining from the original bowsprit are the first portion, the dolphin striker and two of the chains. The entire bowsprit will need to be re-rigged. I will feel much better when the model is safely stored and displayed in it’s case.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

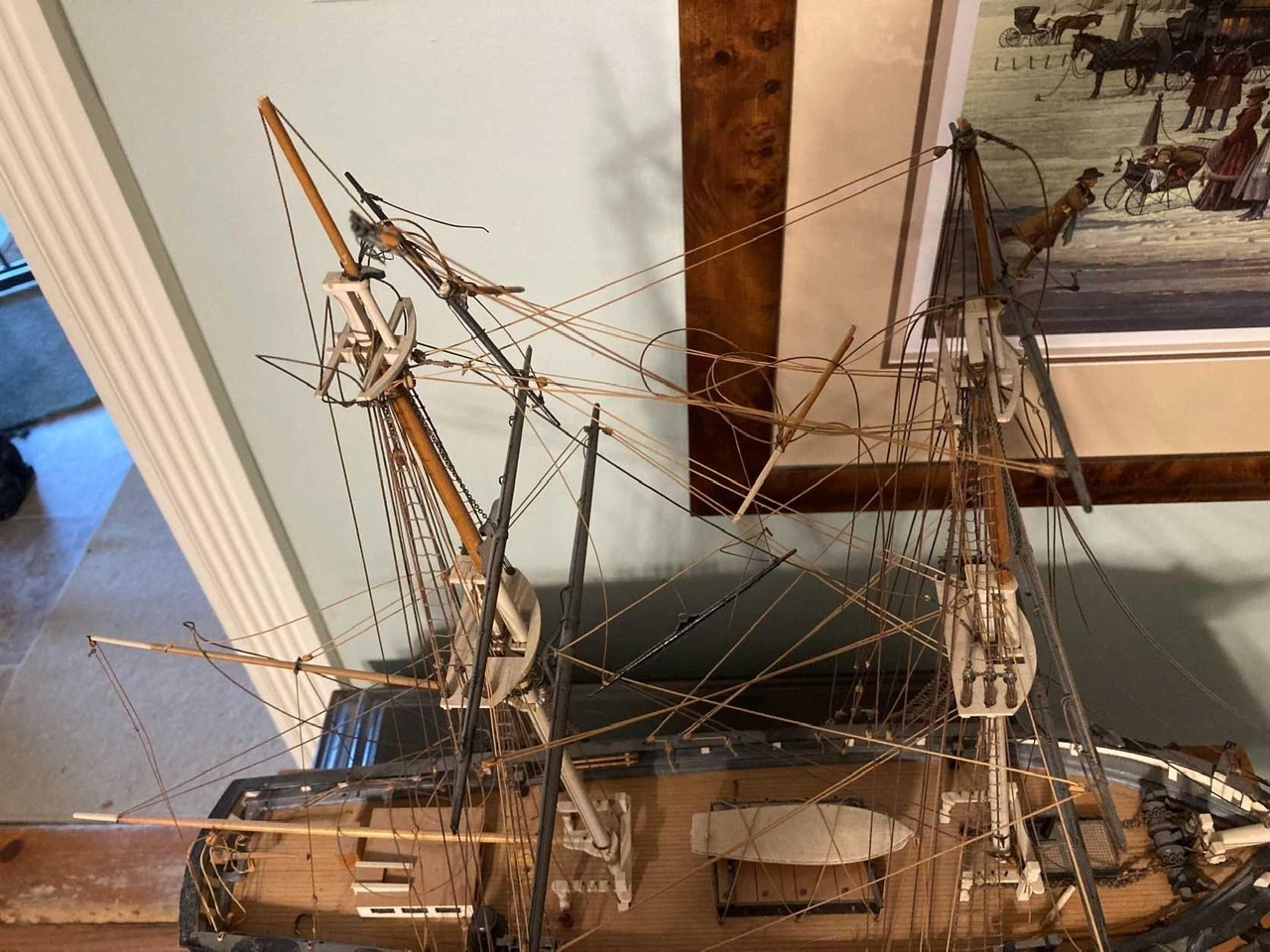

I wanted to add a couple pictures of the model as I received it. The base board was warped and the edges were left plain. The top masts and the end of the bowsprit were broken off. Most of the rigging needed replacing. Some belaying pins, bullseyes and deadeyes needed to be duplicated. One of the yards was falling apart and had to be rebuilt. Some Brass fittings had corroded as well. The last picture was taken this mornin. Everything aft of the fore mast is done. The refitting the bowsprit and lashing down the anchor chains is all that is left.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

Making some slow progress with an improved attitude. I have been removing and replacing any fraying or fragile rigging. A replacement section of the bow sprit has been lashed in place, (I will lash on the last section after the rest of the rigging is up to avoid breaking it as I move the model around on my small bench. The top masts are in position. The balls on top are real Gold beads, (the letters on the stern were hand cut from a sheet of Gold using a jewelers saw). My grandfather was a fine jeweler, but lost everything during the depression. My father mentioned the lettering to him and he took out a sheet of gold and his tools and cut the lettering at the kitchen table. The “W” of New York has been missing for all of my 67 years. I replaced it today with a “W” that I cut, but the “W” is not made of Gold. My grandfather was very talented. As I work on the model I am amazed at the workmanship. My father had no mentor, no forum or internet to refer to. All he had was his ingenuity, patience and probably the public library and his experience sailing. The gaff and driver boom have been re-rigged, the yards repaired and the chains have on the lower yards have been reattached to the masts. The rudder post has also been repaired and I repaired the front cradle for the pulling boat, painted the pulling boat and lashed it back down. I have also untangled a lot of the rigging and I have been doing some cleaning as I go. I will not move to the midship and work my way up. Some of the stays will have to be done at the same time. I am finding the project satisfying.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

I posted this in my build log as well: Please ignore the post above. After an attitude adjustment I have decided that I will continue with and complete the restoration. It’s a beautiful model and I can’t allow 2500 hours of my father’s life to be wasted. Sorry for the pity party. There is a lot of emotion that comes back when working on something of my father’s. He was a POW at Stalag Luft IV and his PTSD was never treated, (through no fault of his own). That aside, he was a fine craftsman and I am amazed that he build this at such a young age.

-

Please ignore the post above. After an attitude adjustment I have decided that I will continue with and complete the restoration. It’s a beautiful model and I can’t allow 2500 hours of my father’s life to be wasted. Sorry for the pity party. There is a lot of emotion that comes back when working on something of my father’s. He was a POW at Stalag Luft IV and his PTSD was never treated, (through no fault of his own). That aside, he was a fine craftsman and I am amazed that he build this at such a young age.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

I am not sure where or how to post this. I have decided not to go forward with the restoration of the rigging. I had hoped to preserve as much of the rigging as possible, but most of it is too fragile and really needs to be replaced. My relationship with my father was not good, and I hate to say that I am not willing to put the time into the boat. It is a finely built and historical model and it should beproperly restored, but I can’t do it with my father’s ghost hanging over my shoulder. The model is approximately 33” LOA and 23” tall on the base. If anyone is interested in re-rigging this historic model, they are welcome to have it along with the originalplane and Popular Science magazines that featured it. I live in Claremont NH and would be willing to deliver it within a day’s drive or meet someone part way. The pictures below are as it is presently.

-

I am not sure where or how to post this. I have decided not to go forward with the restoration of the rigging. I had hoped to preserve as much of the rigging as possible, but most of it is too fragile and really needs to be replaced. My relationship with my father was not good, and I hate to say that I am not willing to put the time into the boat. It is a finely built and historical model and it should be properly restored, but I can’t do it with my father’s ghost hanging over my shoulder. The model is approximately 33” LOA and 23” tall on the base. If anyone is interested in re-rigging this historic model, they are welcome to have it along with the original plane and Popular Science magazines that featured it. I live in Claremont NH and would be willing to deliver it within a day’s drive or meet someone part way. The pictures below are as it is presently. Thanks

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

I have started working on my father’s ship again. It was one of those “the more I do the further behind I get” days. I had to replace the top masts and the jib boom, (I had already completed that). I had noticed that the end of the jib boom was offset approximately 30 degrees. I thought that was odd and referred back to the drawings. It was a mistake from the original build and the jib boom was supposed to be centered. The jib boom cap has a square opening that aligns the jib boom , so the best option was to replace the bow sprit. Fortunately, the old glue joints are not very strong and after some gentle persuasion, I was able to completely dismantle the bow sprit. All parts are made now and two coats of amber shellac and white paint have been applied. I will apply some shellac over the paint to match the rest of the white on the model. I am fortunate to have a good Harding Toolroom Lathe, so the tapered spars came out nice. Tomorrow I will turn up the small pins that act as stops. I hope to reinstall the bow sprit, jib boom and mast tops tomorrow.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

-

Django changed their profile photo

-

Very nice. One of my all time favorite boats. I’ve never sailed a 12 1/2, but I have fond memories of sailing Bullseye Sloops, (same hull form but with a Marconi rig, fiberglass hull and cuddly cabin). I do love a gaff rig and I miss my old Beetle Cat, (maybe Bluejacket will introduce a Beetle Cat model).

- 23 replies

-

- Herreshoff 12 1/2

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Work has come to a stop for the next few days while I wait on come tools and supplies. I also want to do some more studying and neaten up and organize my work area. The Malek Adhel is safely back in the case for now.

- 32 replies

-

- Malek Adhel

- Restoration

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.