-

Posts

14 -

Joined

-

Last visited

-

Chris, Thanks for merging my accidentally duplicated posts. But I still seem to see the two entries when I go on my log. I do have difficulty working on this site at the moment, but I'll learn .... I hope!

-

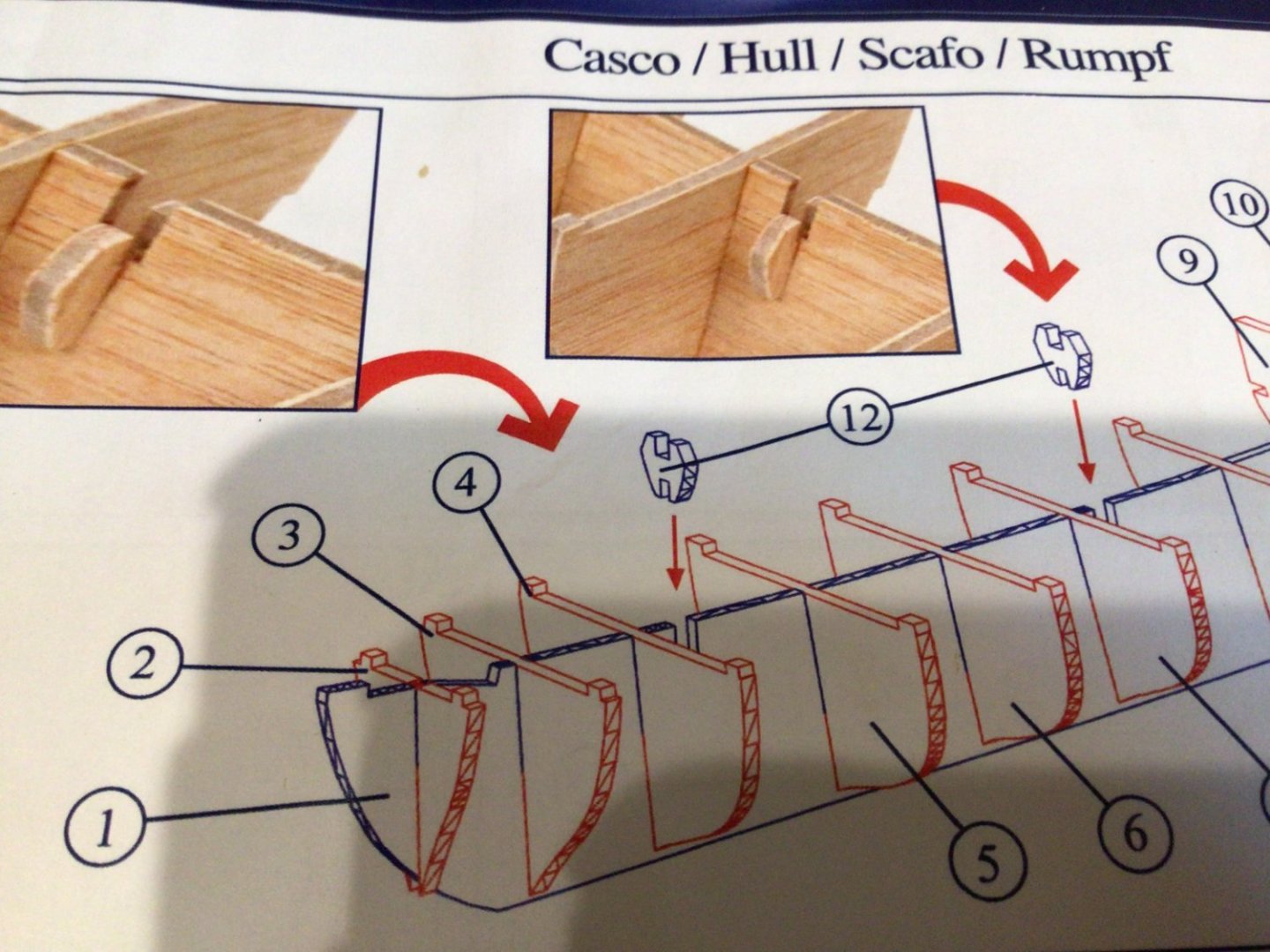

Getting ahead of myself, but not soon enough. I decided to check the matter of masting, partly because I hadn't received the correct parts in the kit for the masts. I wish I had done this before I planked the hull, in which case I would have rebuilt the mast steps. As it is now, when I feed a mast down through the deck the foot of it is sitting somewhat precariously on the edge of the false keel, and the little parts that are supposed to be the steps, which you glue onto the false keel early in the game, well they don't seem to be holding the foot of the masts at all well. I can't see what is happening because I'm all planked, but the mast ends will slip off on one side or the other and on first thought it seems that you will only be able to keep them straight with the rigging, when you get that far.

What I have decided to do is, with squares and protractors, to carefully set up each mast squarely (port & stbd) and with the rake I want (probably about 8°), then extract the masts without altering whatever method I am using to keep them properly set up, put a big glob of glue on the foot of the mast and feed it back down. If any error creeps in, then it should be small enough to correct either with mast wedges at the deck, or with the rigging later.

Going back to the matter of mast steps. If you still have access, I would make little blocks of wood for the mast steps. Make a fore and aft groove in the bottom so it will sit accurately on the false keel, and drill a quarter inch hole about a half inch deep in the middle of the block on top. You will have the deck on at this point, so feed a piece of dowel through and down to check that all is fine.

-

Today I completed the exterior lining of the bulwarks and what I think we used to call the counter; that is to say, the view shown in this photo of the aft end, specifically the curved, raked back part.

I am sorry to have to report that there are discrepancies in my kit from OcCre. The dowels received are 4 pcs 0f 3.8mm dia. (5/32") and 2pcs of 4.8mm (3/16"). So I am OK for spars, but there should have been 2 pieces of quarter inch for the masts. No problem, because I have some ¼" in stock, and of course there's lots of that at the hardware store anyway.

I received far more than I needed of the 2x5x400mm (sycamore I think), which is used for the first "underplanking" of the hull, (as shown in the lower hull here). I have a bundle of 15 pieces of that left over, enough to plank another half a hull. Strange.

.thumb.jpg.b62b14ade032ff5c06b8c204fea9cd29.jpg)