-

Posts

324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bluto 1790

-

WELL DONE, TOM! . . . CONGRATULATIONS! She's looking superb, with the sails filled with all the available wind! When I look at mine now it almost looks unfinished - - - the sails make a big difference. And 4 1/2 years? . . . mine took me 9 years although there were a few lengthy lay-off periods.

-

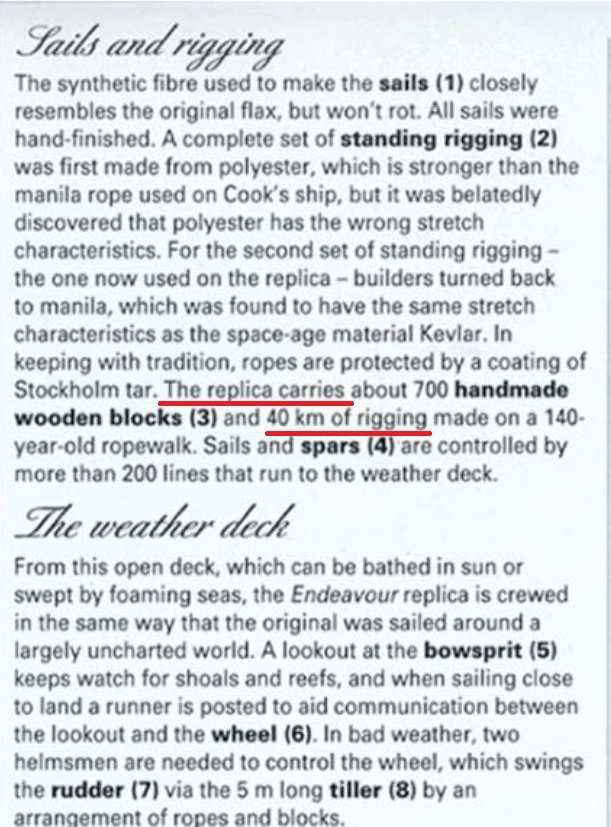

Hi Tom, Your progress is looking amazing on your Leopard! I hate to dis-illusion you ~ but I think you've been undersold on the info you read about the length of all the rigging ropes on one of these sailing ships! I have read (and yes - for the moment I can't find the source!) that the length of rigging on the 1988 replica of HMB Endeavour was around 14 miles. I've just been searching Google for the info and saw 30Km (approx 18.75 miles) quoted in one place, and on another site - this one > HM Bark Endeavour. Australian National Maritime Museum, Sydney - Travel To Eat it stated the length of rigging as 40 Km (approx 25 miles). Here's a screenshot from part of that webpage > Since Endeavour was considerably smaller than one of these 50 gun ships it would seem logical that the latter would carry even more (longer total length) rigging ropes.

-

You say "slow but steady" ~ well, the way the wind is filling those sails already that ship will be zipping across them waves! Looking great!

-

Hi Tom, That sail is looking great! . . . and what a lot of work just in one sail. How did you get the 'wind in that sail'?

-

Such luxurious cabins !!! I want to sail on this ship when she is finished! When I see work of this standard I feel I should cancel my membership of the forum. A-M-A-Z-I-N-G !

- 589 replies

-

- le gros ventre

- cargo

-

(and 2 more)

Tagged with:

-

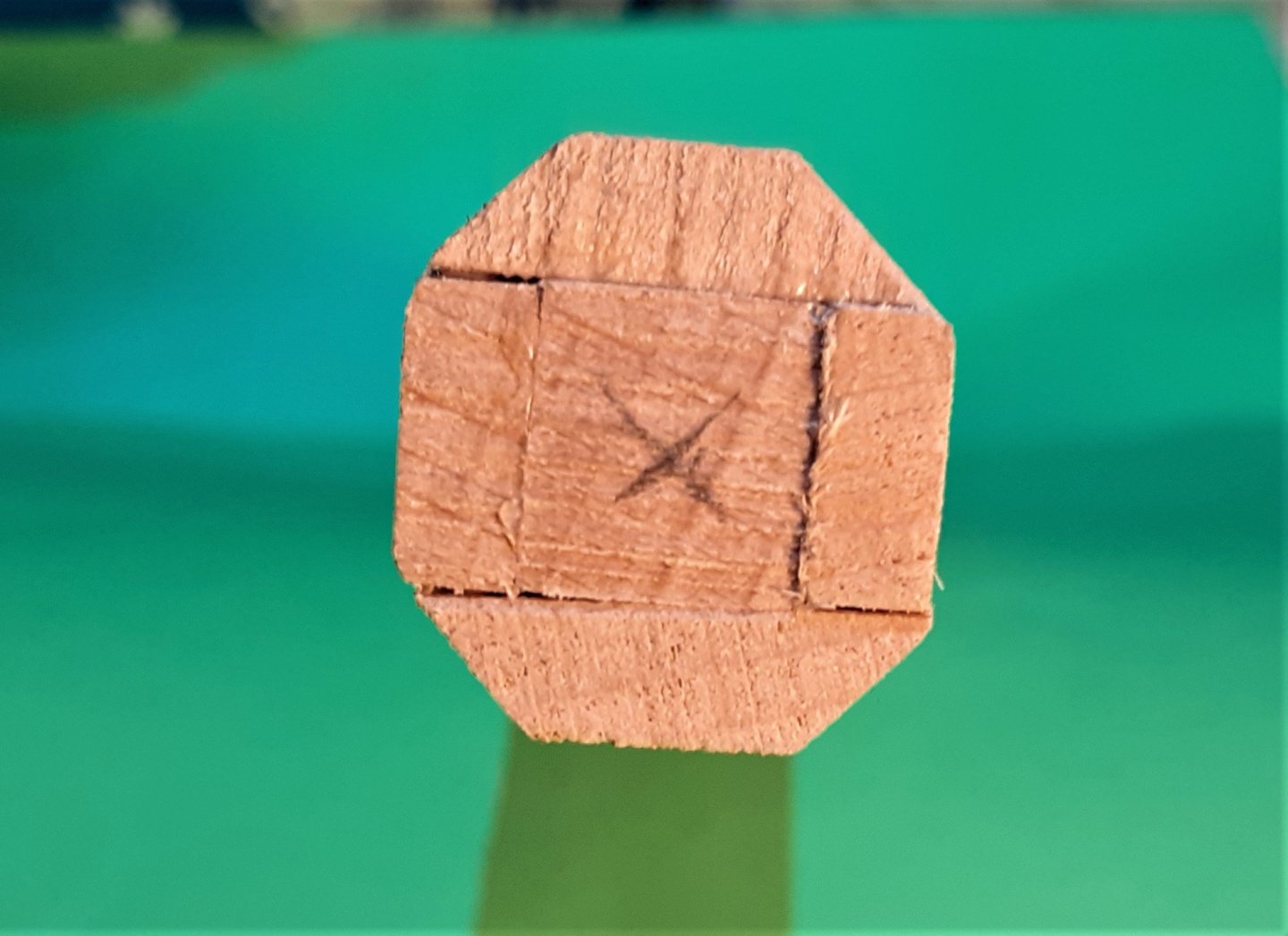

Thanks Bruce, Gregory and Druxey for your comments. In view of your comments and having looked at the 'item' again, I feel I have to believe the wooden part was in fact the sheave out of a block and that someone has indeed 'decorated' it with some 'old rope'. In its present appearance I can't imagine it would have any practical use ~~~ and that's why I asked the question . . . as I couldn't imagine how it would be used!

-

Bruce, it was on today's edition of "Bargain Hunt". He didn't actually say it had been under water for over 200 years but he did say something like 'it was his prized possession from the wreck of HMS Invincible', so I assumed that it had been salvaged after having been 'down there' for some time. The site of the wreck was discovered in 1979.

-

Watching an antiques program on TV this item was described as having been salvaged from the wreck of HMS Invincible. (Captured from the French Navy 1747 and sunk 1758) The item was described as a "pulley". I would expect a pulley to have been fitted with a rolling sheave but this item appears as a flat circular piece of wood with just a round hole at its centre ~~~ so, for what would it have been used, and HOW would it have been used?

-

HI Tom, "Splicing the main brace" is an expression in very common usage but I reckon that more than 99% of people using it don't know its origin and original meaning -- just like so many other old expressions, so don't feel silly! . . . and milestones! . . . that's the thing about this ship building -- there are so many milestones and it's great when we get to each one and tick it off! Once you get the yards on and rigged it's going to look complete but if you're adding sails it's going to be even 'more completer'!

-

Thanks for the comments and likes. Michael, there are quite a few items in my build that have been copied from other builders, but if there is anything that you (or anyone else) wants to copy from my 'stuff' then I'm well flattered! Tom, about the only 'fancy machine' I have is my mill. The mill and the bandsaw are the 2 most used machines in the build, with an occasional use of the drill press for larger diameter holes. The mill is also used as a drill press for small holes from around 3mm down to 0.5mm. Oh, almost forgot the drill powered lathe/jig I use to make 'round things'.

- 66 replies

-

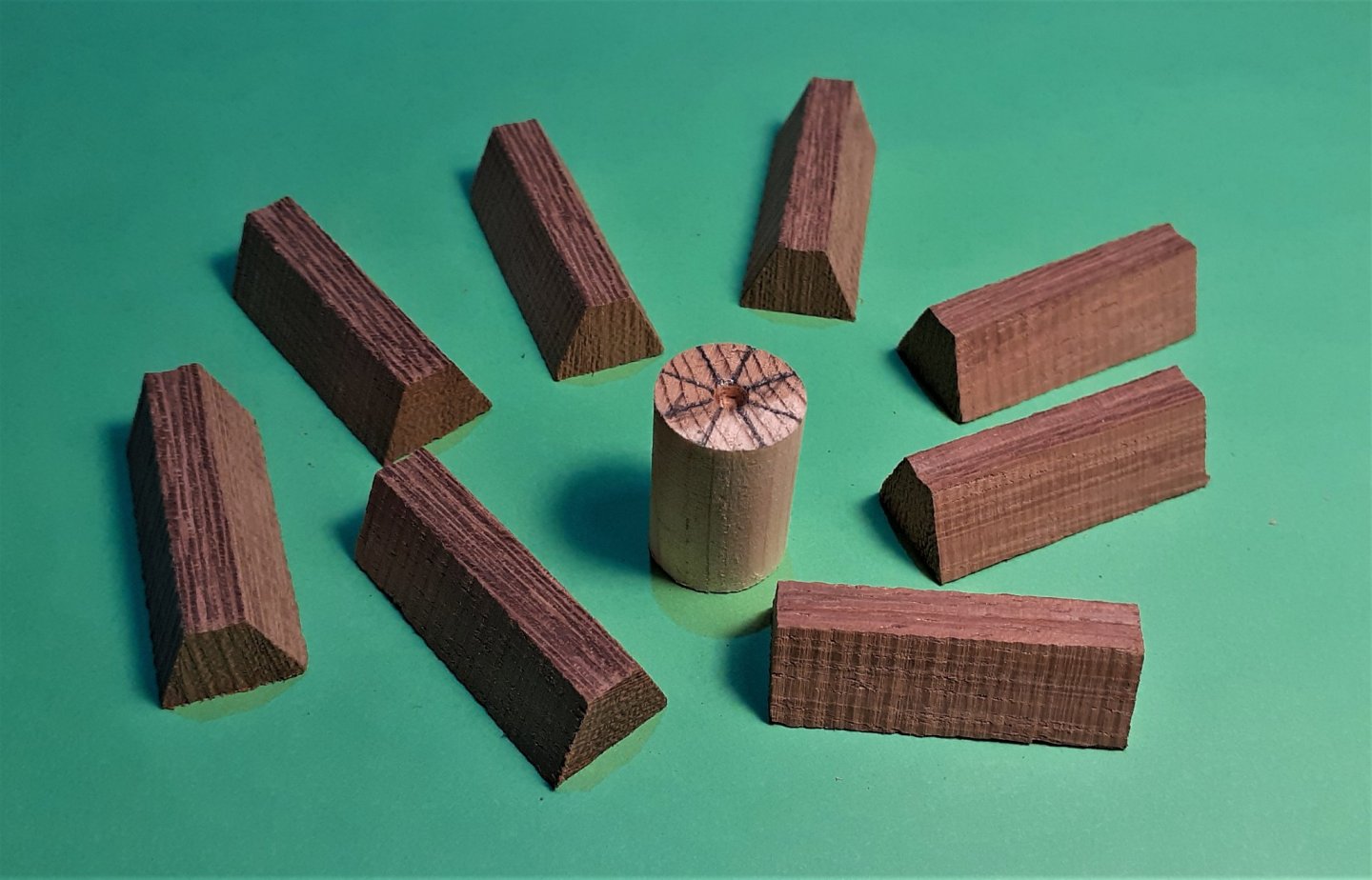

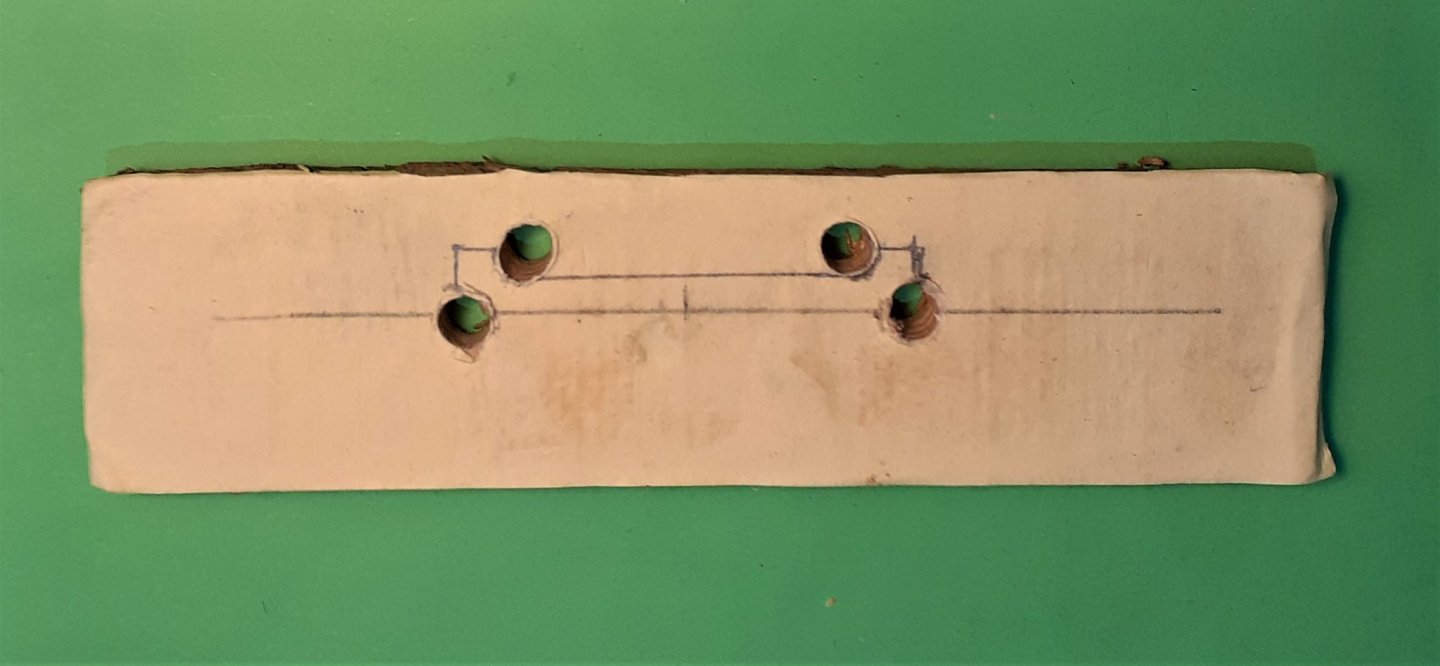

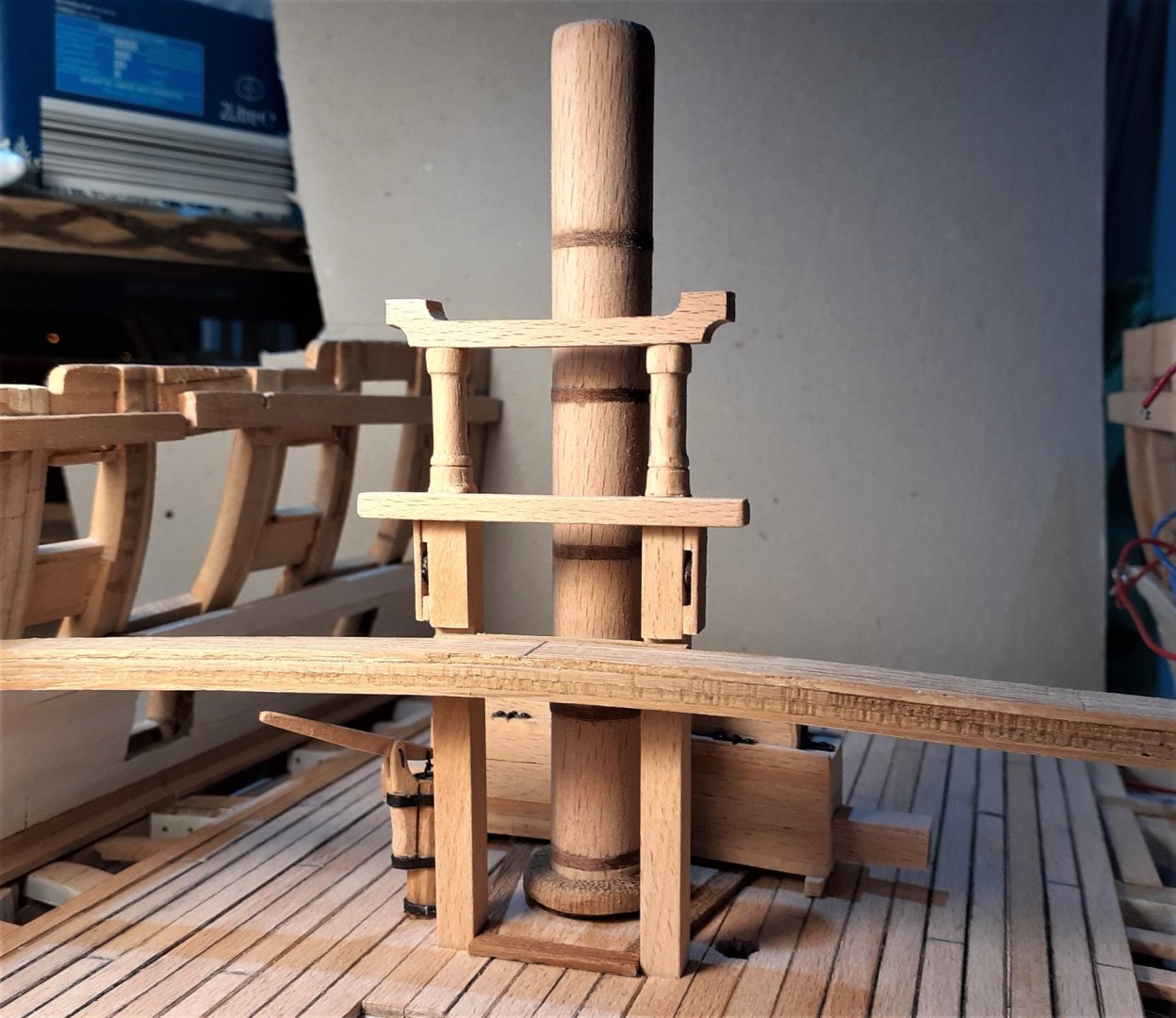

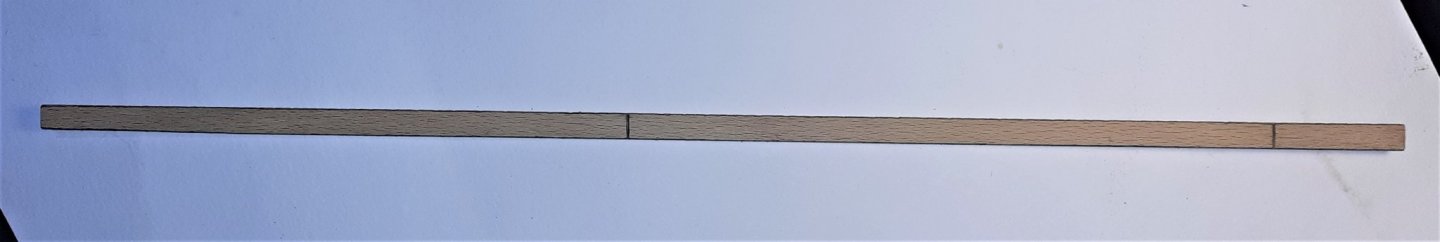

Thanks for the thumbs ups and the visits. Making the mast was reasonably straightforward -- making the mast wedges had me thinking for a while. As I don't have a 'proper lathe' just a drill in an attachment and only having a standard drill chuck I couldn't create the wedges in the way I've seen them done here on the forum. So I turned a short length of softwood down to the same diameter as the mast at lower deck level. I tried to calculate the size of wedges that would be required for 8 wedges. These wedges were glued on around the 'dummy mast' leaving an unglued section > With all 8 glued on there was a small gap of about 1.5mm > With the gap filled the inside diameter was just a hair too tight for the mast so that small sanding drum did enough to make it a snug fit > With some work on the bandsaw and with a little bit of invention, I was able to finish it off on the lathe; Right way up > Upside down > and in position > With the mast > The sheet bitts still needed the top cross piece. I drew it to scale on paper and glued that onto a piece of beech. For the 4 quadrant curves I drilled 4 holes with a 6mm drill bit at the drill press. That was the first attempt -- a couple of the holes weren't exactly where they should have been but the second one came out OK. A couple of pieces of brass wire helped hold it in position while the glue dried > and with the 2 sheaves attached > and just to see how it all looks >

- 66 replies

-

Hi Tom, Is that very fine mirror a prototype for one you're going to model for Leopard!!! Looking at your layout plans for your pins looks scary! I just did the standing rigging on mine and even that required a LOT of belaying points ~ rigging the sails will sure need a lot more. I'm really looking forward to seeing it with all sails flying!

-

Hi Tom, I have to confess that I cheated a little when I made the yards on my other build! I didn't try for 'octagonalism' the way you did ~ on the mid section of the yards I glued on 4 thin pieces of timber at regular places around the yard. After a light sanding with a sanding stick that mid section was having the appearance of being octagonal - - - and up there on the masts, with all the rigging going on around them it's not very obvious that they're not perfect! Now, seein' as I'm on here I'll post a few other pics. Did the mast foot tenon and here is the mast, together with the other 'stuff' having a dry test fit > Some of the above photos reveal that the mid section of that deck has been planked. I can confess that I cheated a little with that planking ~ I used full lengths for each full plank fitted so far. At the points where 2 planks would butt against each other I used a craft knife to cut a groove deep enough to mark with a black pencil lead to simulate the joints. For the 'caulking' between the plank edges I also used the black pencil but I didn't just mark the planks along their edges. I ran the knife along the top edges at around a 45° angle, creating an almost imperceptible chamfer, then ran the pencil along these chamfers. The black edges and joints are almost visible in this photo! > Before fitting any of these items around the main mast area I wanted to get the inner hull planking done as I imagined it could be very tricky trying to drill into the hull sides for the gun tackle eyebolts if the deck isn't clear of mast and pumps etc. There's still enough space at that level to be able to get a cordless drill in there >

- 66 replies

-

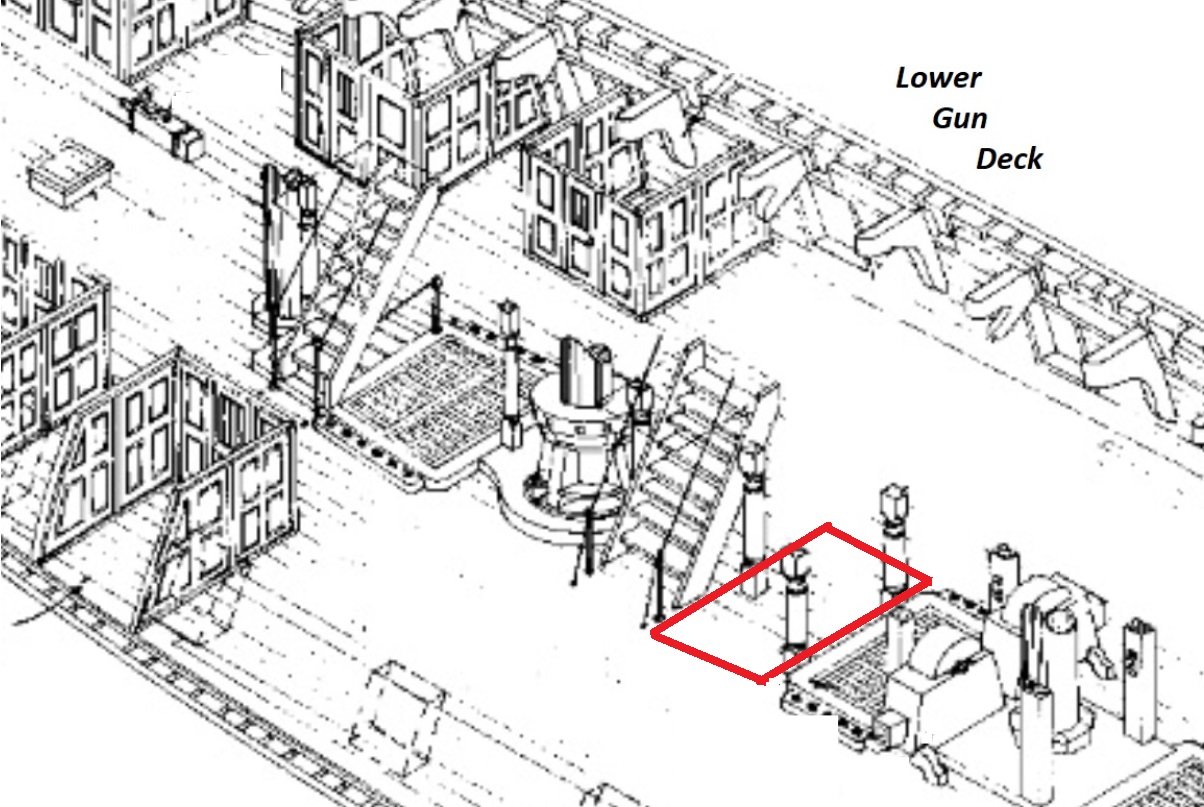

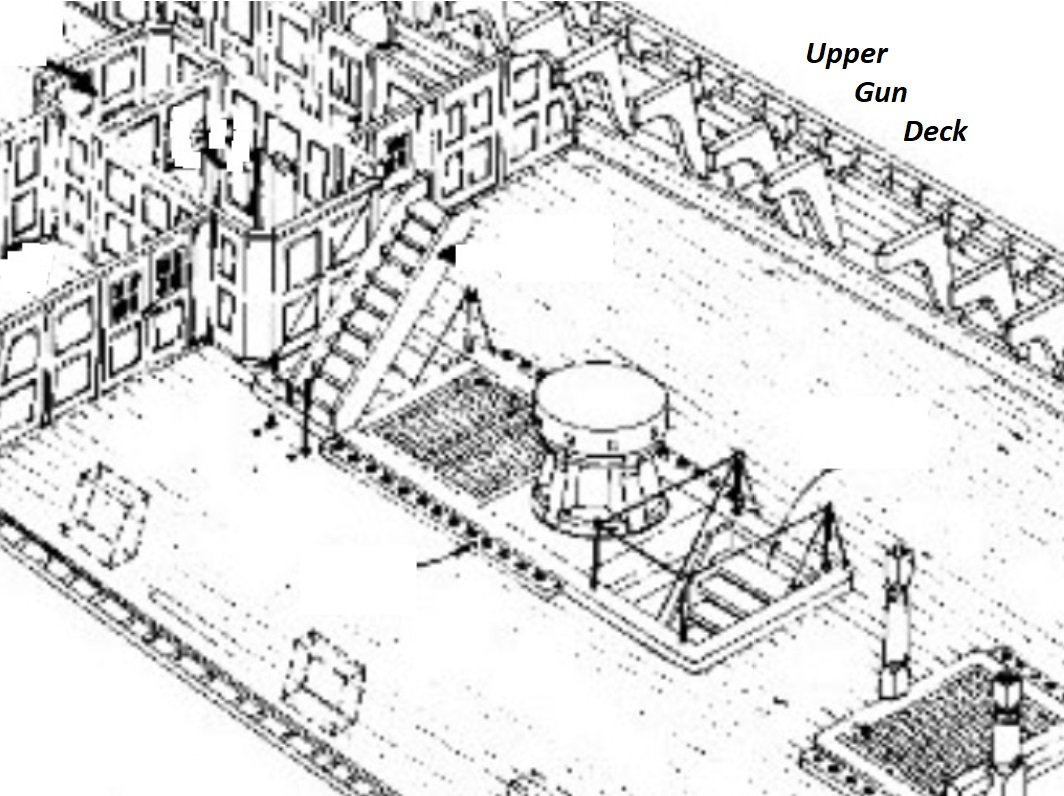

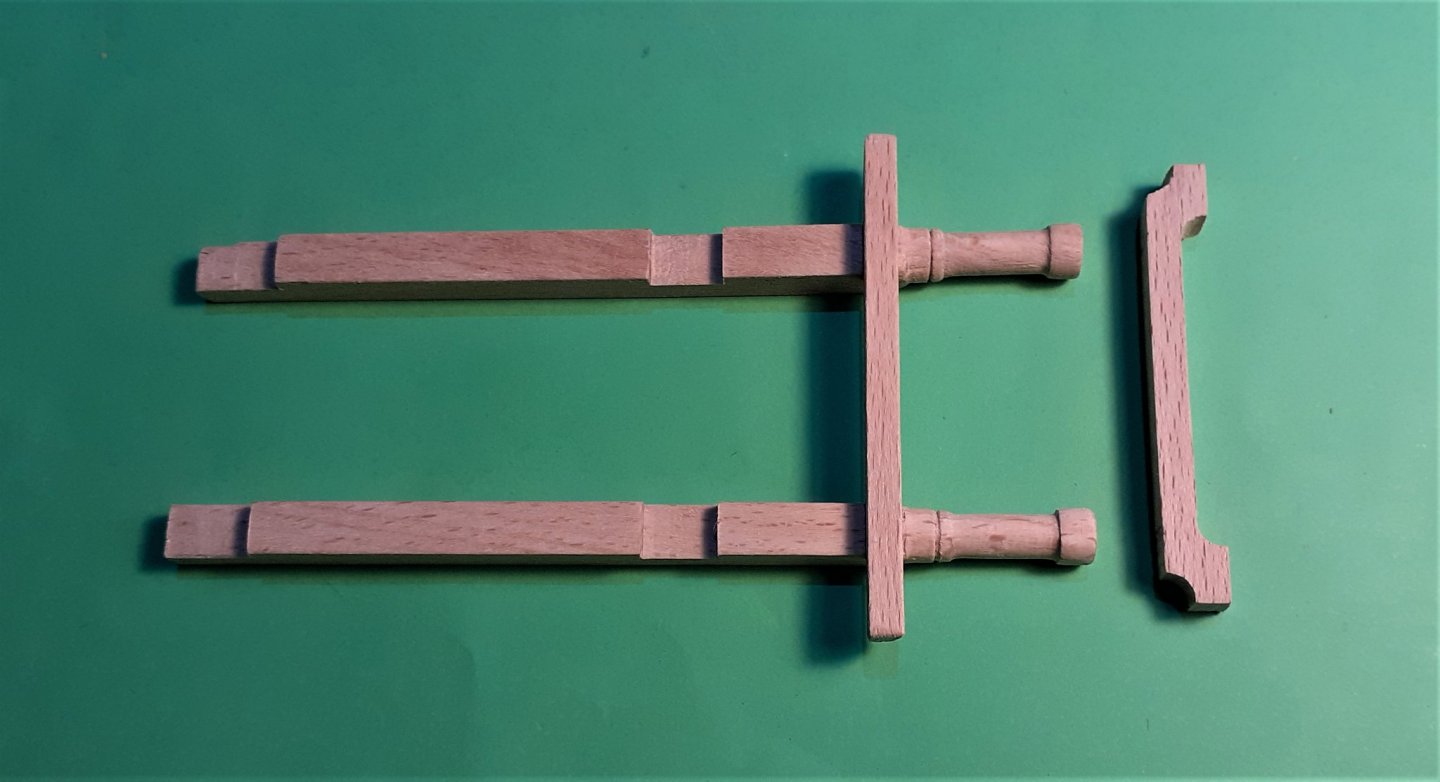

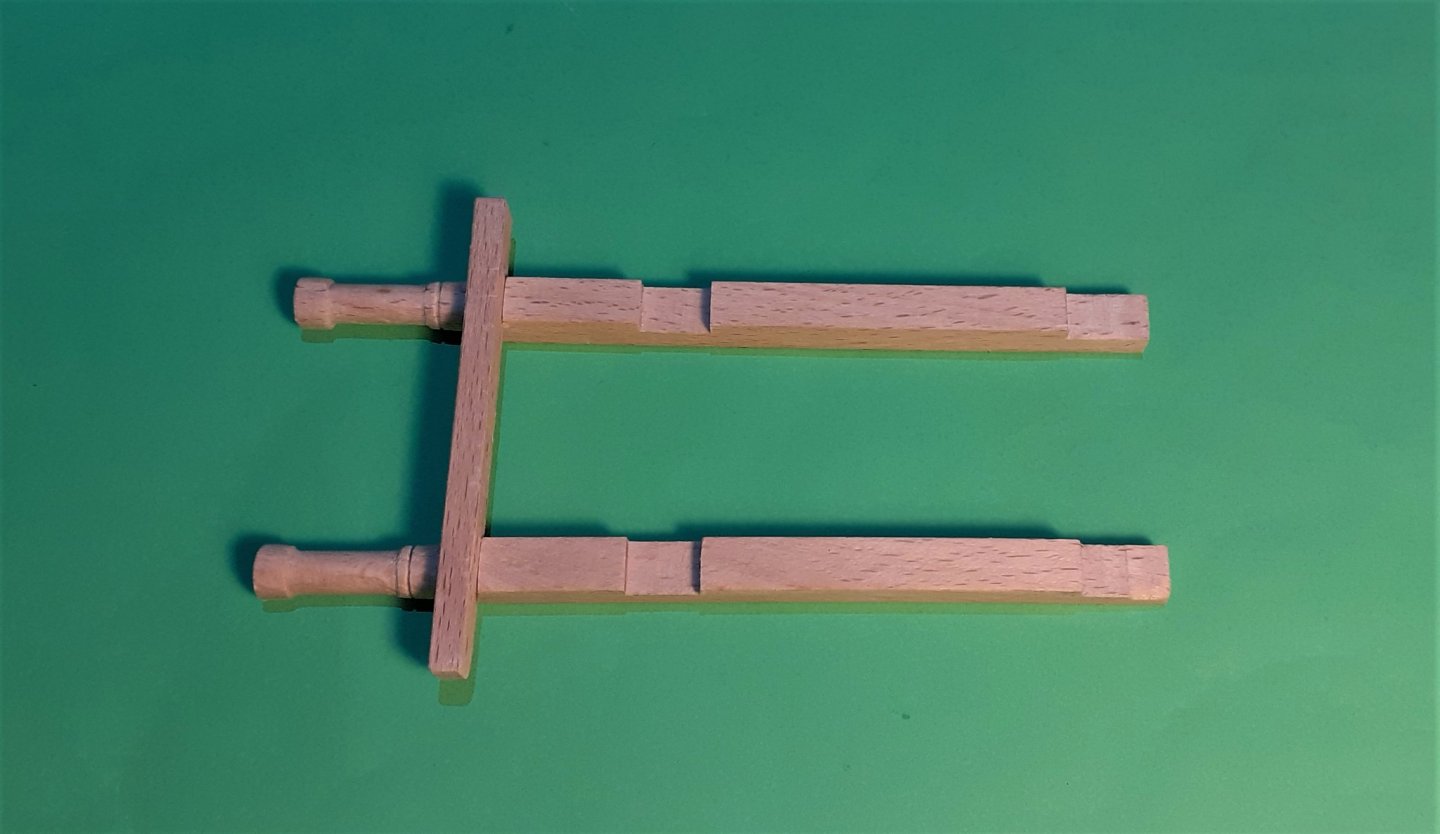

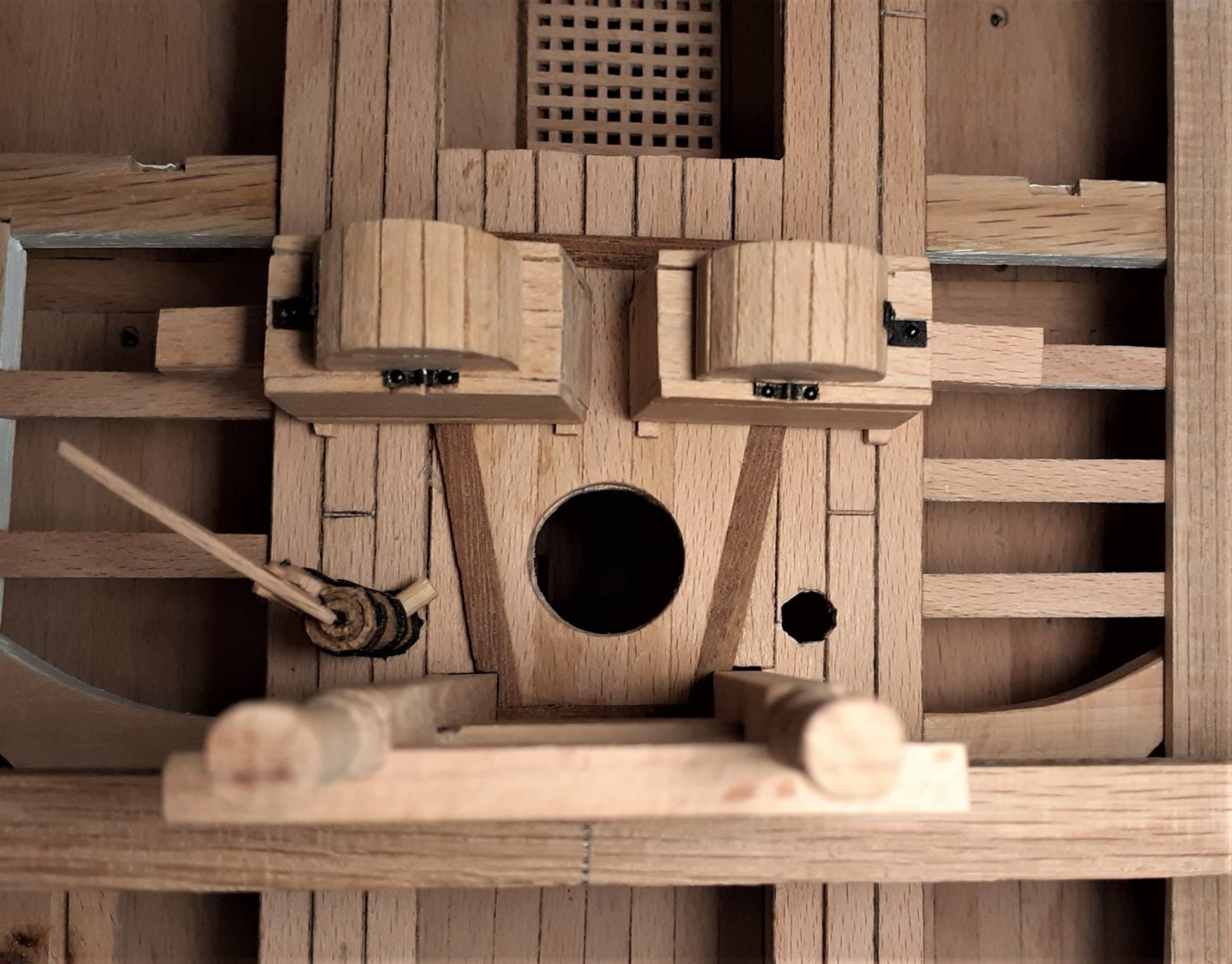

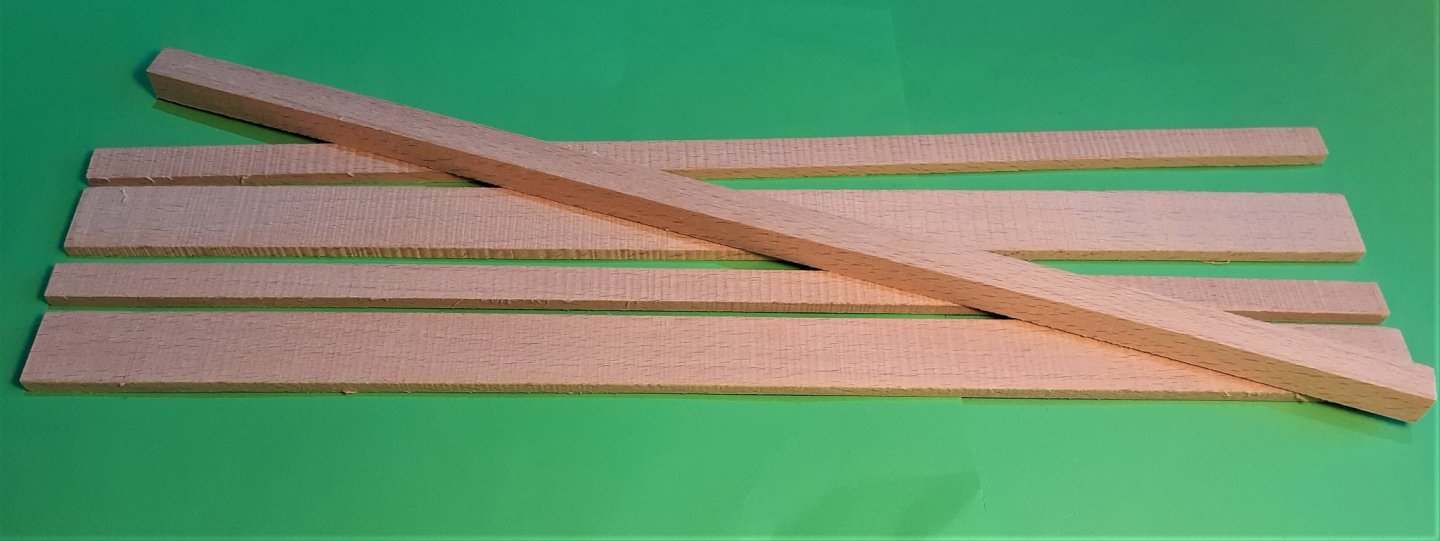

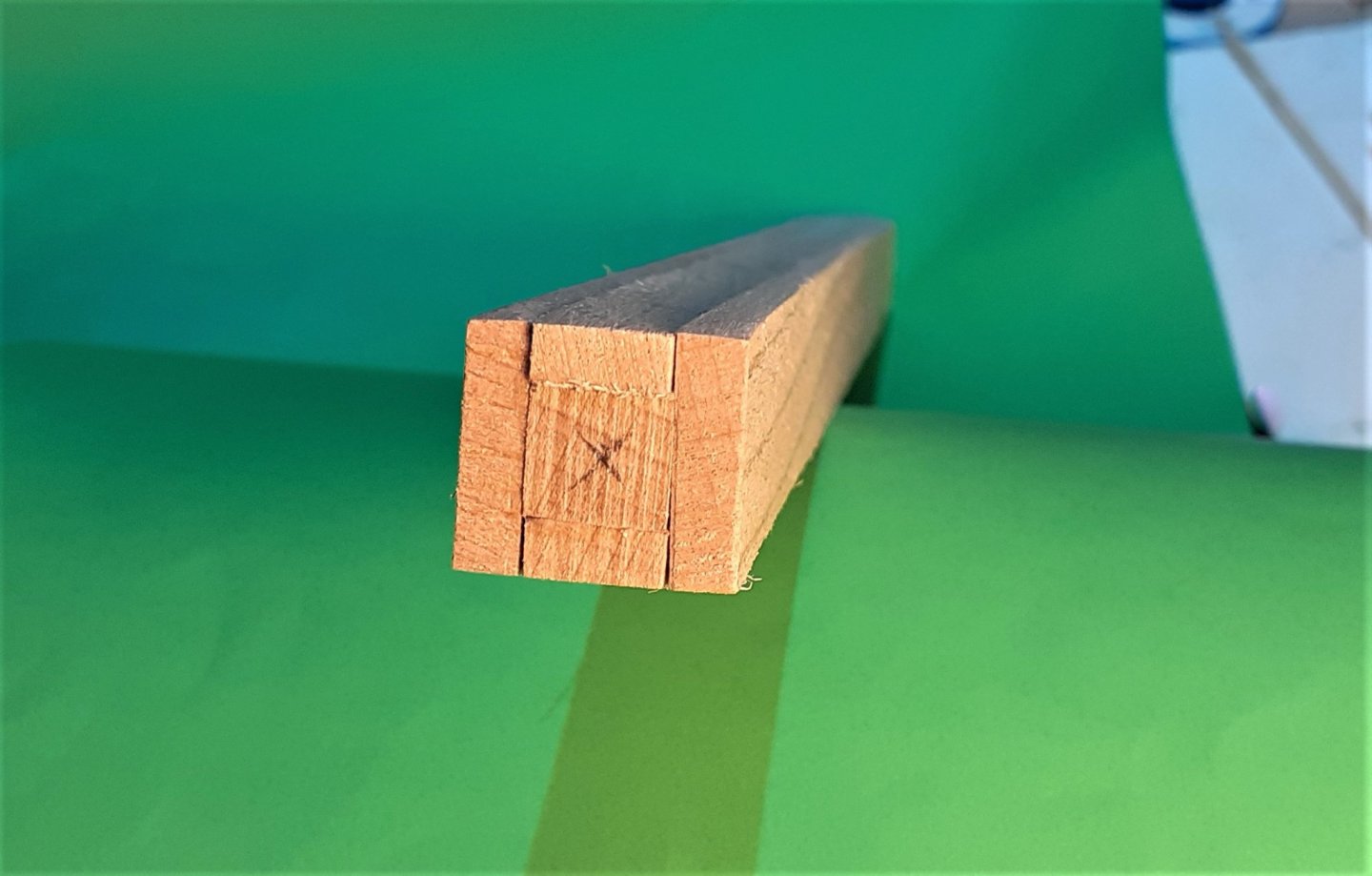

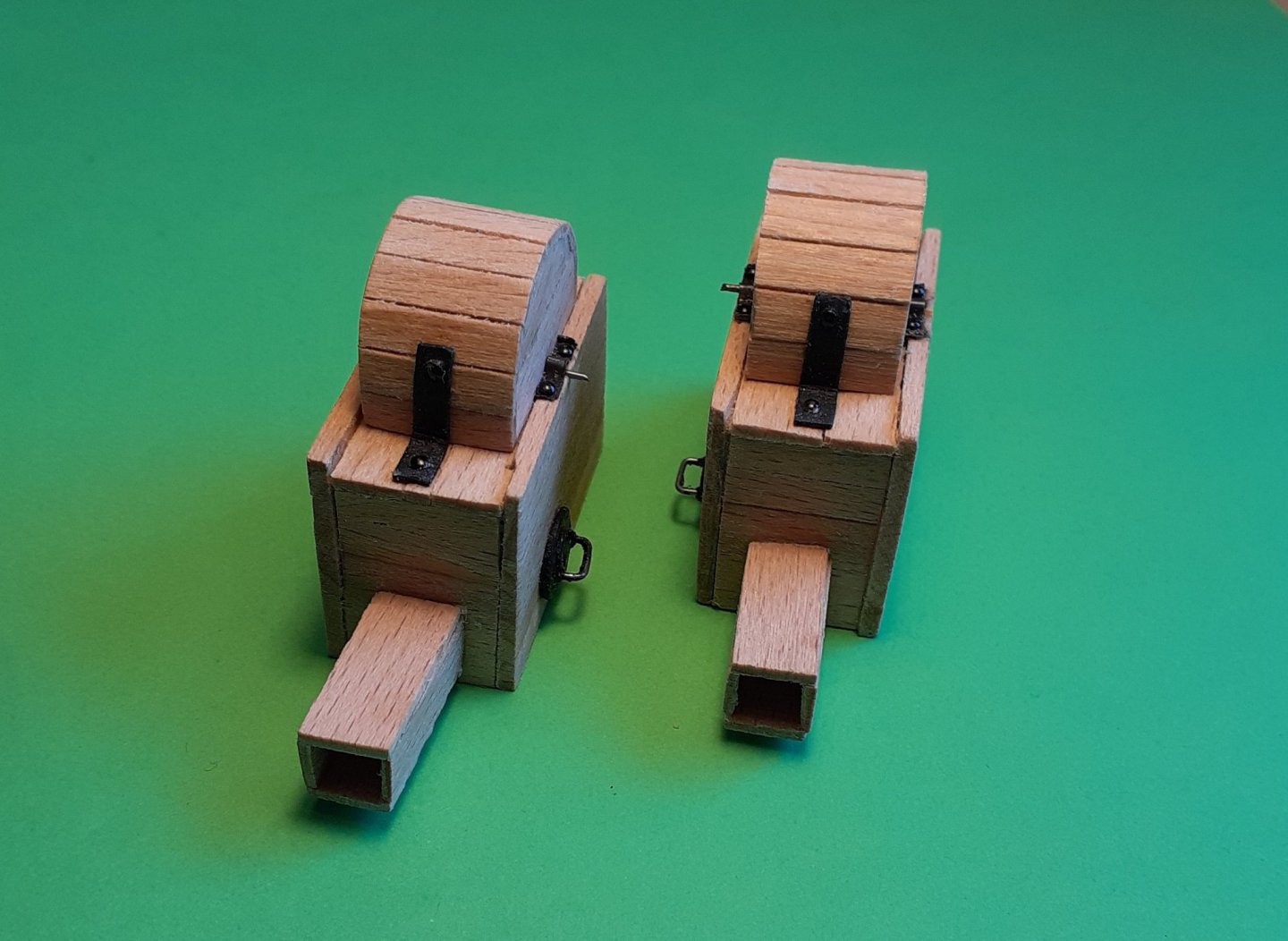

Thanks for the comment, Tom, and the others for the thumbs-ups. I wanted to be getting all the 'stuff' done for that central area around the main mast. Although the 'business end' of the topsail sheet bitts will be on the upper gun deck, the lower end of the posts originate down in the lower gun deck. These are the posts after turning the top parts and morticing for fitting to the lower gun deck and also for receiving the lower cross piece. (At this point they still had to be morticed to fit the upper deck beam.) Then morticed for the upper beam and with the lower cross piece fitted. (The morticing was done on the trusty mill.) Finished the lower brake pump head > For the pump dale I used a short piece of bamboo skewer with a hole drilled up into its centre. A test fit for the chain pump cisterns, that brake pump and the sheet bitts with a dummy blank for the upper deck beam. (Still have to make the top cross piece and the side mounted sheaves for the sheet bitts.) Now, that big hole in the centre needs something to fill it. On my other model at 1:80 I had the 'luxury' of just using shop bought dowels ~ the 'fattest' dowel I needed for that was less than 12mm (0.5 inch). The main lower for this section needs to be around 17mm. Rather than just turn a single solid piece of timber I opted for a 'made mast'. Here are the five components parts for the mast. A single square section piece for the centre and four rectangular sections (two of them wider than the other two) > The first stage of the glue-up > . . . and the second stage > In order to reduce the amount of wood that would have to be taken off at the lathe I tilted the table on the bandsaw to 45° and knocked off the corners > Just out of the lathe. While in the lathe I cut five shallow grooves to accommodate the bandings that will go there. (Using the lathe ensured that the grooves are at the same level all the way round and saves having to measure and mark later.) Still to cut the square tenon at the mast foot.

- 66 replies

-

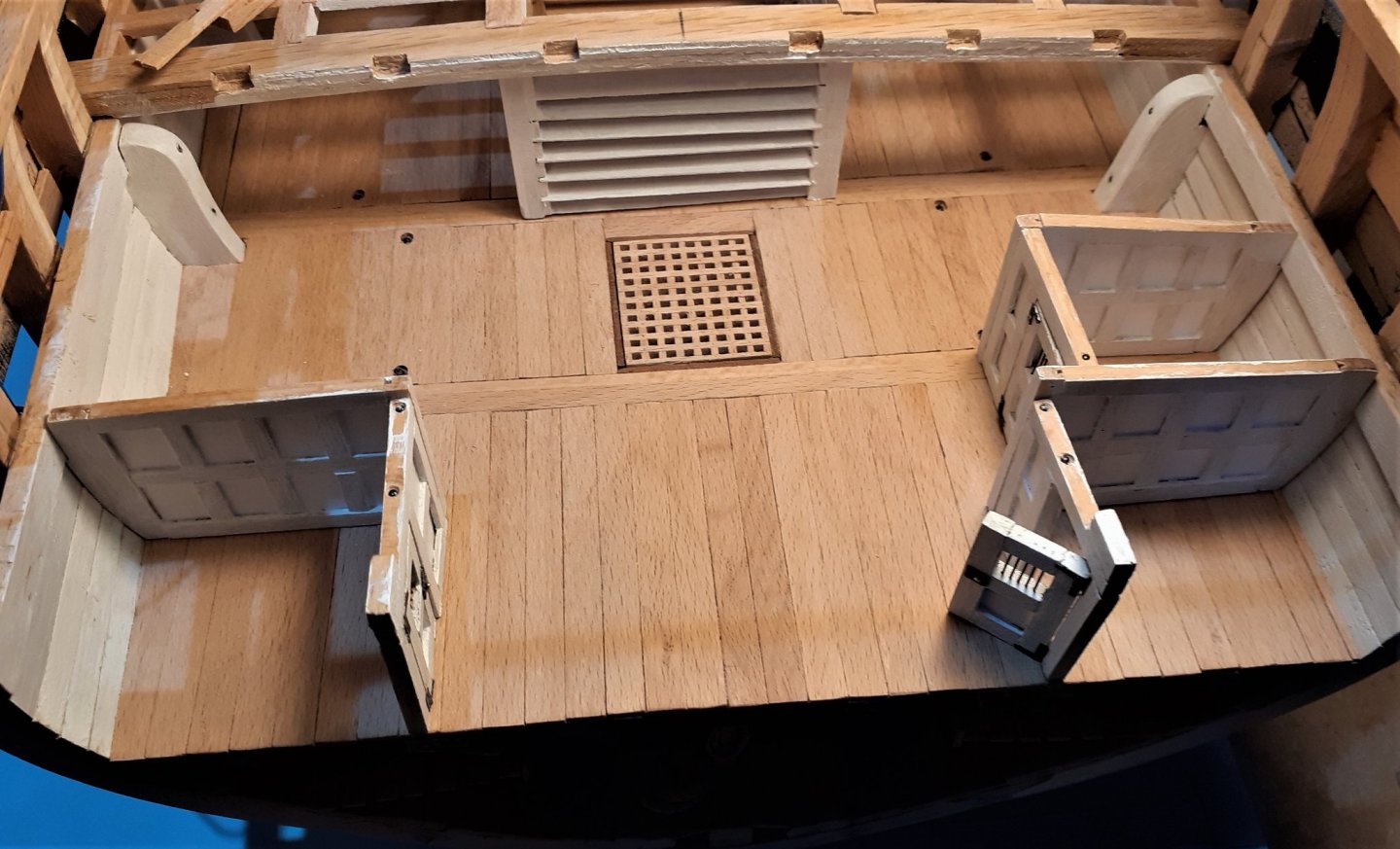

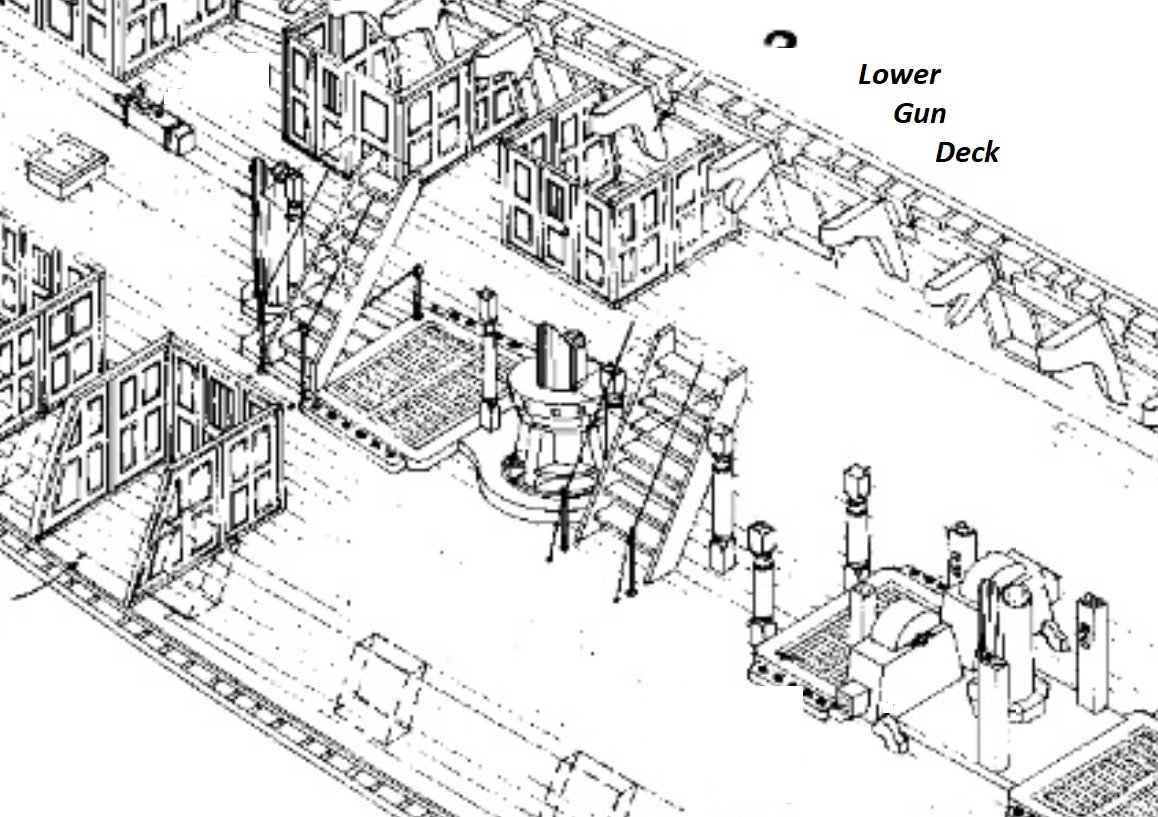

With the orlop deck more or less finished, time to move up to the lower gundeck. A whole lot of planking would have to be milled, but although quite time consuming, was fairly straightforward, while creating the profile of the waterways was something that caused a deal of frustration for me. I've never before tried using a scraper to create a moulding and it took some time before I was 'getting the hang of it'. At first I was trying to remove the required amount from a solid length of timber ~~ and that Beech is real hard stuff! It just wasn't happening for me. This is the scraper I used > That was made from a utility knife blade. As it was proving too hard to scrape the profile from the 'solid' wood, I ran it over my table saw blade to remove most of the material > Then finalised the profile with the scraper, then trimmed it down to it's final shape on the bandsaw > With these waterways done I could 'relax' and get on with doing the easy deck planking. In that central area all around the main mast it's going to be quite busy with the mast, the lower ends of the posts of the topsail sheet bitts, two brake (Elm tree) pumps, four tubes for the chain pumps along with the heads of the chain pumps. I thought "I'll just get on and make the chain pumps cistern heads." Four days later they still weren't finished! Most of the main components > . . . and glued up > The brackets at the spindles and on the top are blackened brass but the "plugs" on the sides are card painted black with wire handles. At this time the central area of the deck is planked as I want to be getting all that 'busy' stuff sorted. I also made a dummy upper deck beam so that I could gauge the approximate lengths of the brake pump tubes. The lengths of the four chain pump tubes isn't critical as they'll be covered and out of sight by the pump head cisterns. The brake pump tubes are different lengths as the one on the left of the photo (starboard side) serves the lower gun deck and the port side will serve the upper deck. I've seen drawings of 3 deckers with one brake pump on lower deck and the other one two decks above on the upper gun deck. The bottom ends of the topsail sheet bitts will be accommodated in the 2 square 'holes' ahead of the brake pumps.

- 66 replies

-

Hi Tom, Looking great! I can see you're closing in on that 'front end'. When you look at the bowsprit it DOES look a little bewildering (I say that as if the rest of the rigging isn't bewildering!) but just as you say ~~ taking one line at a time and it all comes together eventually. I remember when I first got Petersson's rigging book, I thumbed through it and thought I'd never be able to get that done, but one step at a time . . . . .

-

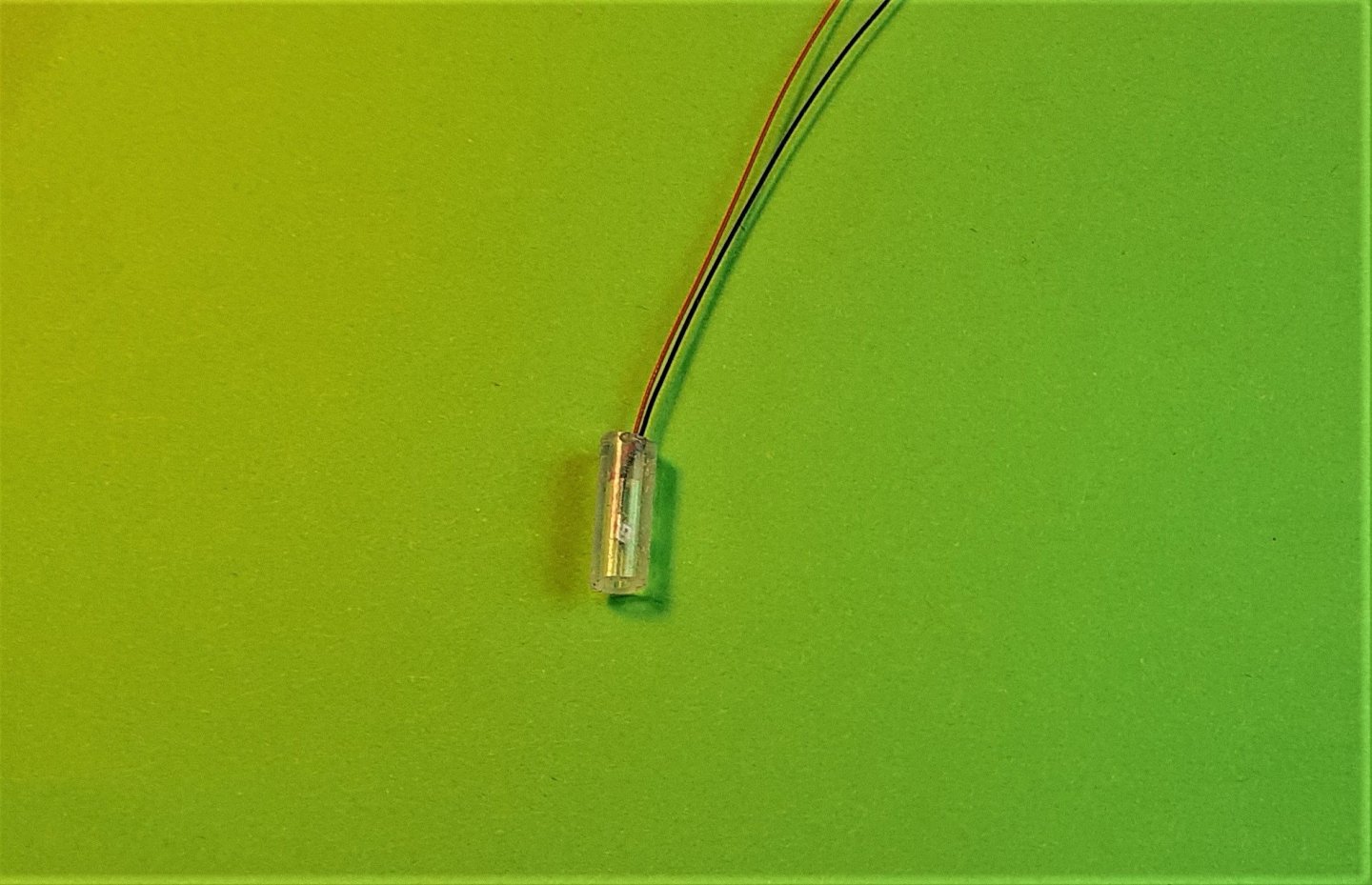

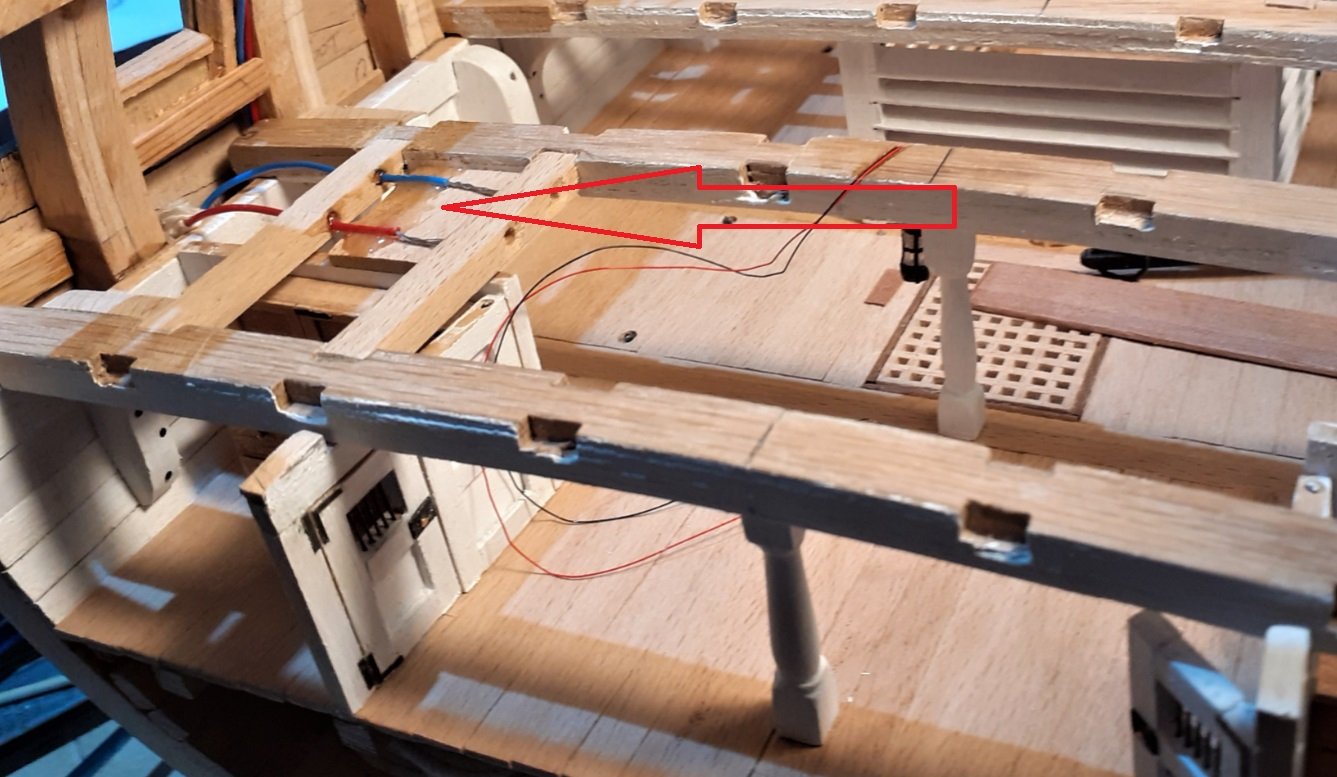

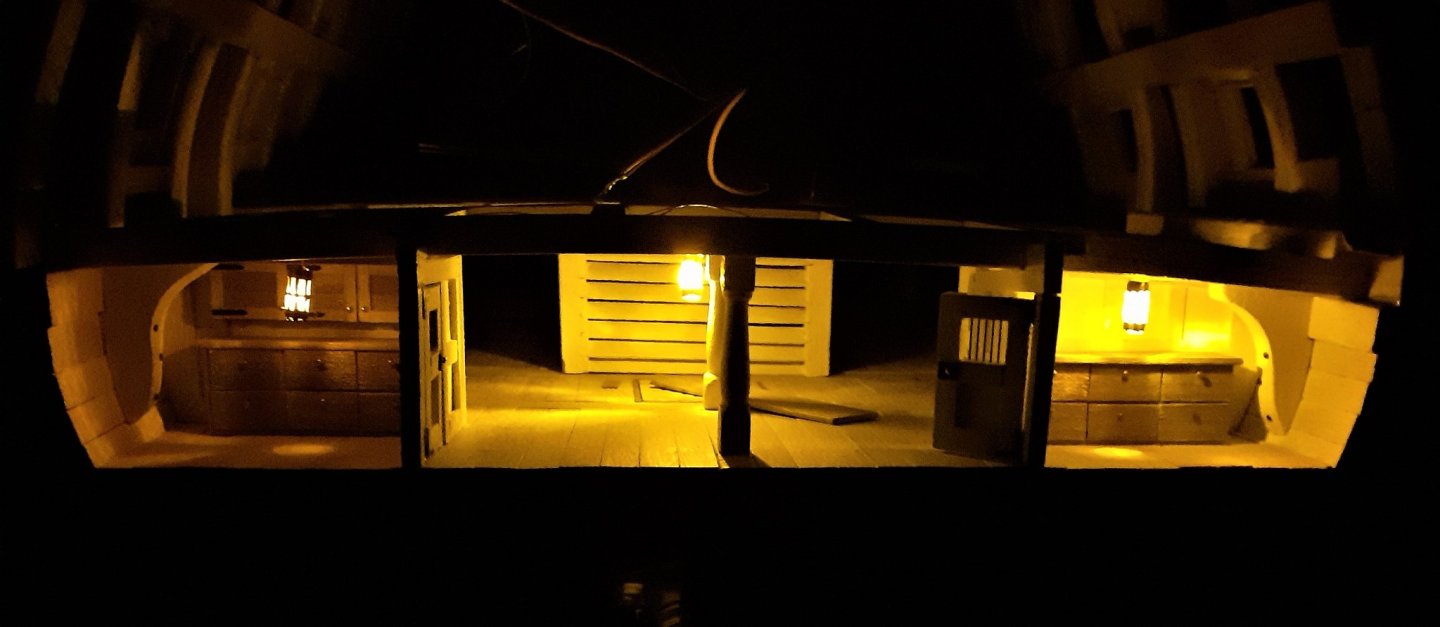

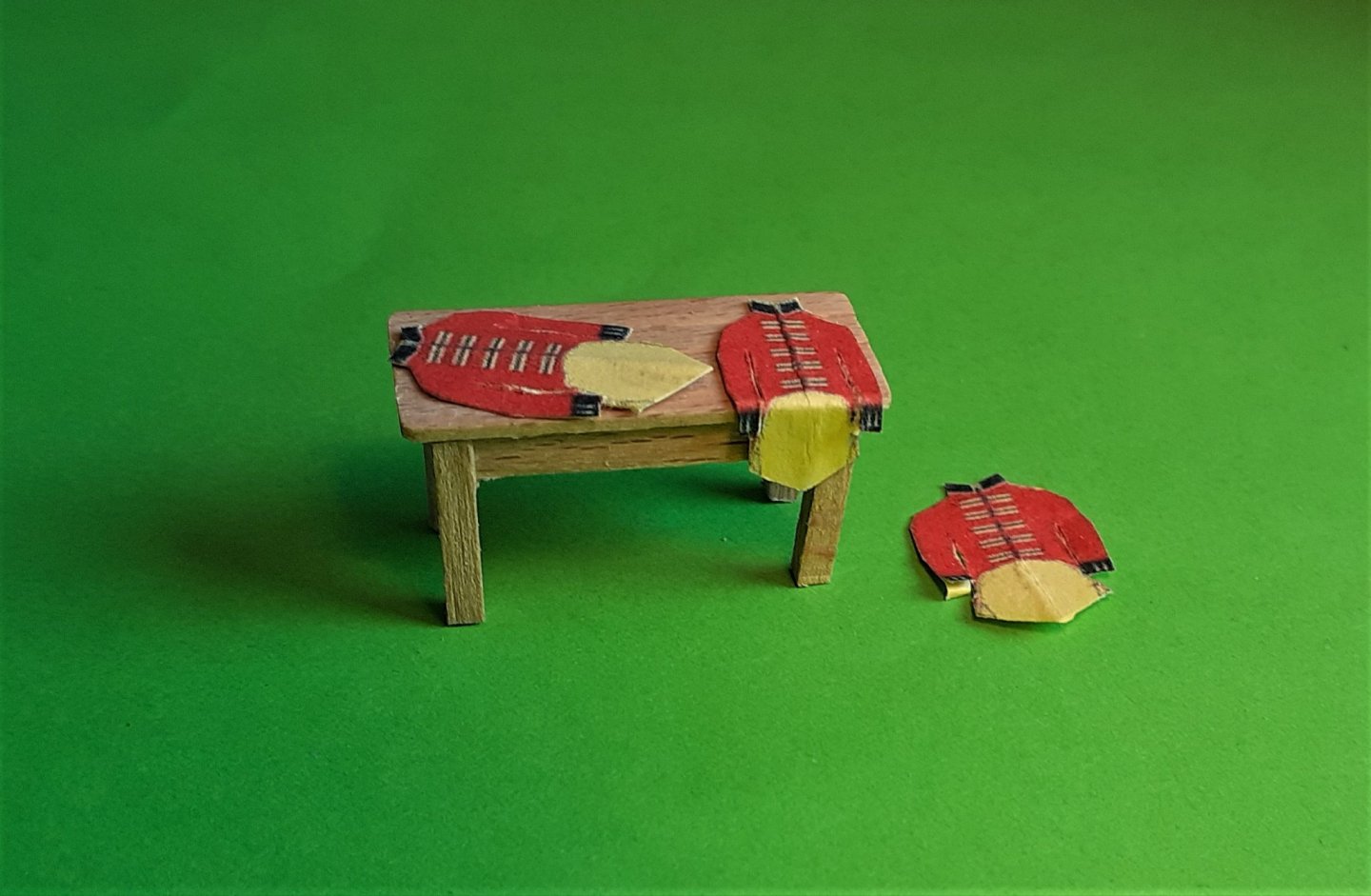

Thanks Michael for the comment and the others for the visits and likes. Not a lot of apparent progress to report even though what I've done has taken considerable time. Before I progress any further on that lower gun deck I wanted to get the lanterns and their wiring installed. As the wiring for these lanterns goes through some carlings and even some deck beams, and especially at the aft end the wires go in several directions, I'm going to omit the ledges in these areas. (The deck will be completely planked anyway, so 'what's missing' won't be seen.) Before doing any more wiring in the ship I took some time to get ahead of myself a little and created 12 of the lanterns. Doing what is seen above is fairly easy and quick. I just cut the tube to length, insert the LED (Pico size), lock it in position with a small drop of epoxy resin and allow the glue to dry ~~ then the 'fun' begins. Getting all the parts of the framework on to each lantern is what is time-consuming, and after a few lanterns, becomes a little tedious. (Although not in the same 'tedium league' as doing 1000s of ratlines!) When I did the wiring for the hold I soldered the wires together in 'mid-air' -- without any kind of platform. This time I made a platform between 2 carlings and that made it much easier to solder these hair like micro wires. The aft platform is arrowed below > The 2 rooms at the aft end got a lantern each and I hung one near the centre in the open area of the orlop deck > . . . and at first 'switch on' > and at the fore end, illuminating the cable tiers and upper well > Shortly after the above photos were taken, the lantern in the Marine clothing room mysteriously became very dim, so I got one of the Marines to hang another lantern in there > I have to apologise for the condition of that Marine clothing room ~ some tunics have been left lying on the table and another one hangs from a nail driven into a hanging knee. (Now I know why they're called 'hanging knees'!)

- 66 replies

-

Thanks for the comment, Tom, and to the others for the likes and visits. Tom, you've just sparked another interest for me - - - I'm now considering enrolling on a cobbler's course at a night school somewhere! So, right now, I don't have any scale shoes to display - - - however >>> and since I've been able to upload that photo above I'll have another try at uploading the failures from last night >

- 66 replies

-

Attempting to create another post here -- BUT am still unable to upload any more photos - - - keep getting an error message. *€!#**!!!£%$!!!

- 66 replies

-

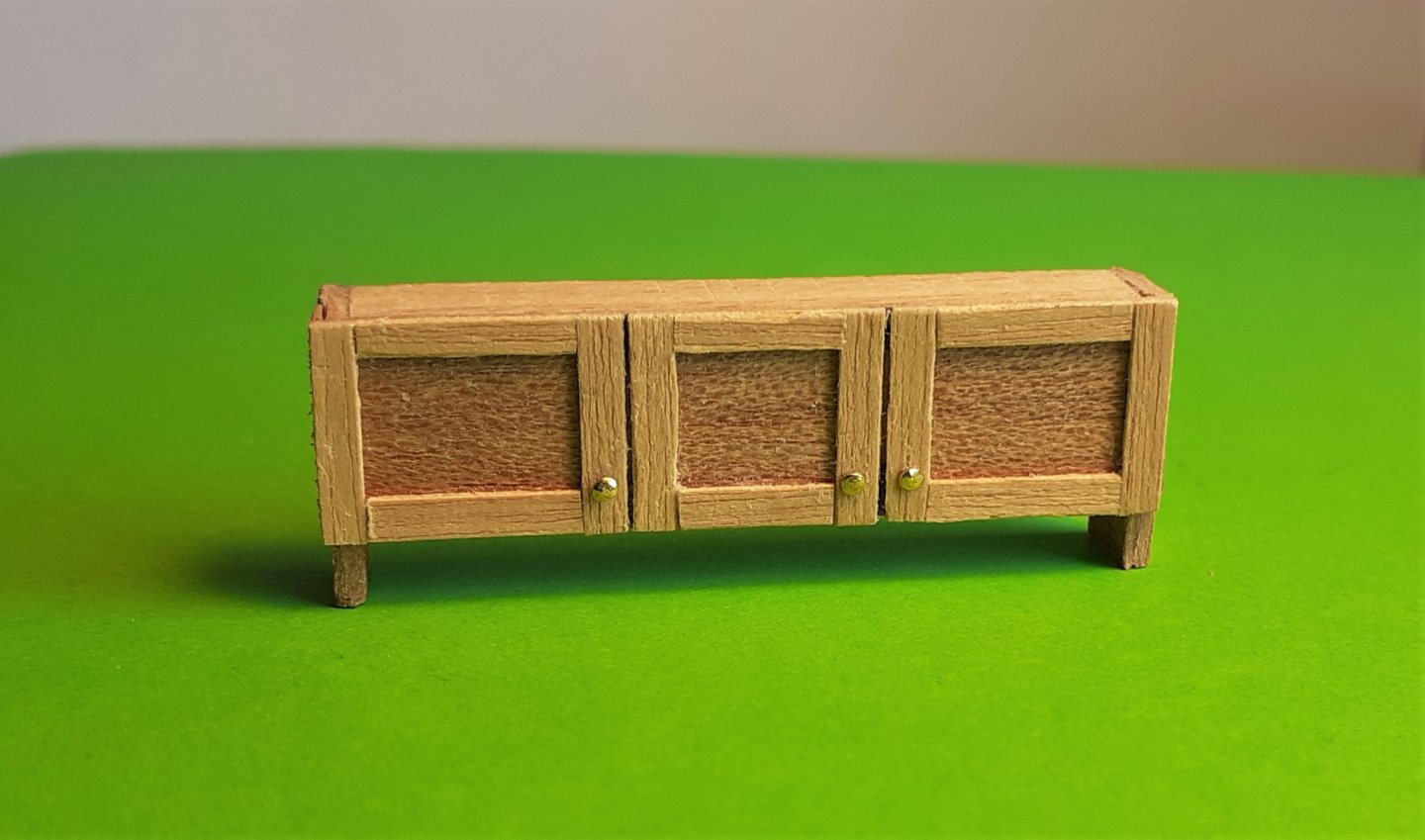

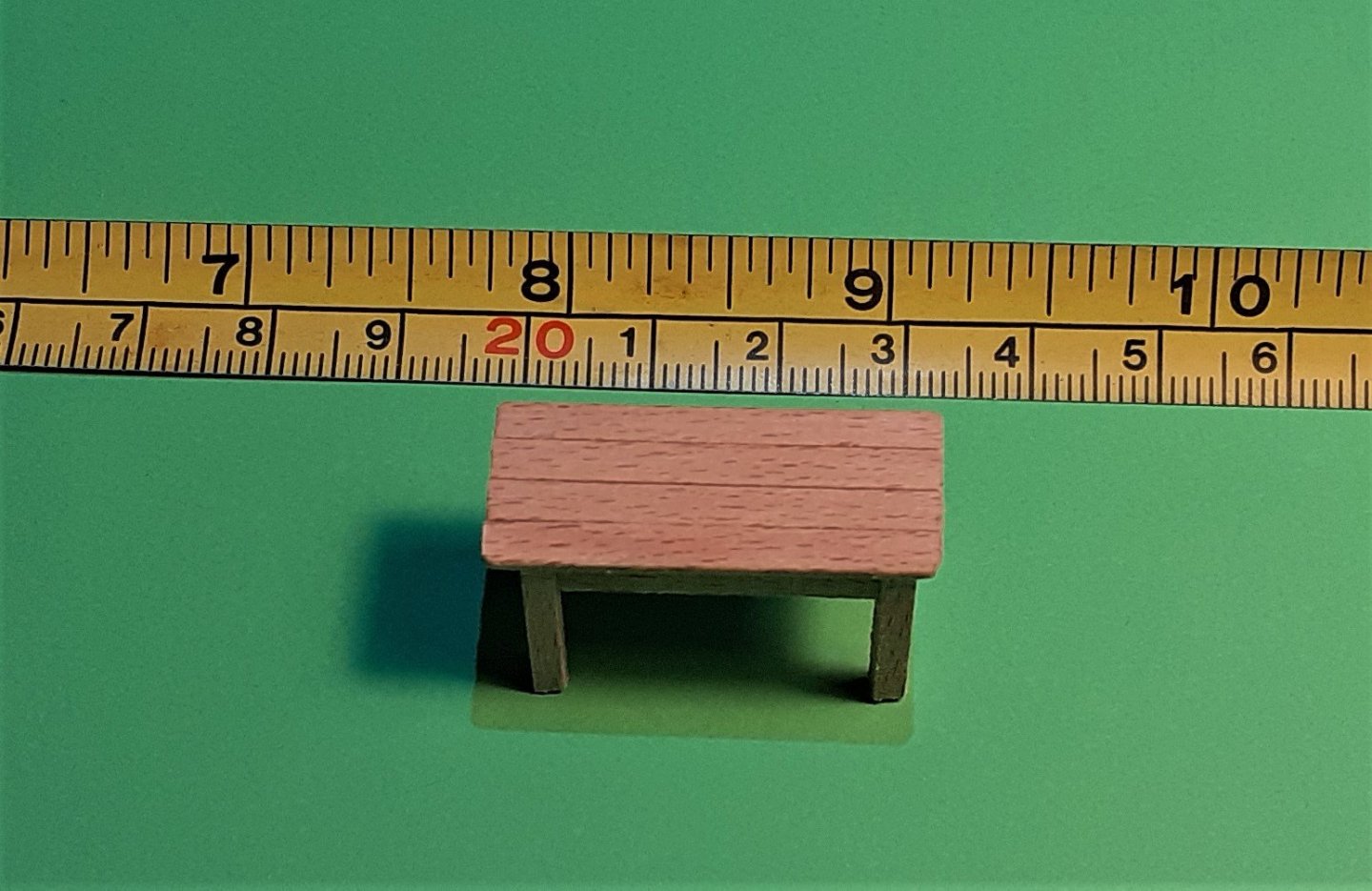

Finding information on what kind of 'furniture' occupied these rooms wasn't easy and I resorted to watching a few 'walk-thru' videos of HMS Victory on youtube to get some ideas. Decided to make a couple of base units with 6 drawers in each -- one unit each for the Marine clothing and Captain's storage rooms. and in position where they'll live > These last 2 deck beams needed fitting so, fitting these, and fitting the hanging knees came before finally gluing in these drawer units . It took a couple of days before I noticed that I had omitted the central deck beam pillars! ~ that was annoying! . . . they were already turned and painted and in the box waiting their turn to be fitted at the same time as the beams. I like to attach them up into the beam and down into the floor with some wire but this time just had to be content with squeezing them into position with a little PVA, top and bottom. Base units now permanent fixtures > The Marine clothing room possibly had some wall cupboards, so > As above, drilled for handles; below, with handles made from snipped-off heads of some brass nail, as had already been used for the handles on the drawers > Handles fitted > I felt these doors were a little too modern looking, 1990s maybe? . . . so I gave them some fake hinges > On the wall > A table may have been a useful item in that room so > *** AT THIS POINT I'VE TRIED UPLOADING MORE PHOTOS BUT KEEP GETTING AN ERROR MESSAGE SAYING "UPLOAD FAILED"*** WILL TRY ADDING A COUPLE OF PHOTOS IN THE NEXT POST . . . . .

- 66 replies

-

Thanks Bruce for the comment and the others for the likes and visits. Bruce ~ welcome aboard! . . . there's plenty room on this 50 gun ship!

- 66 replies

-

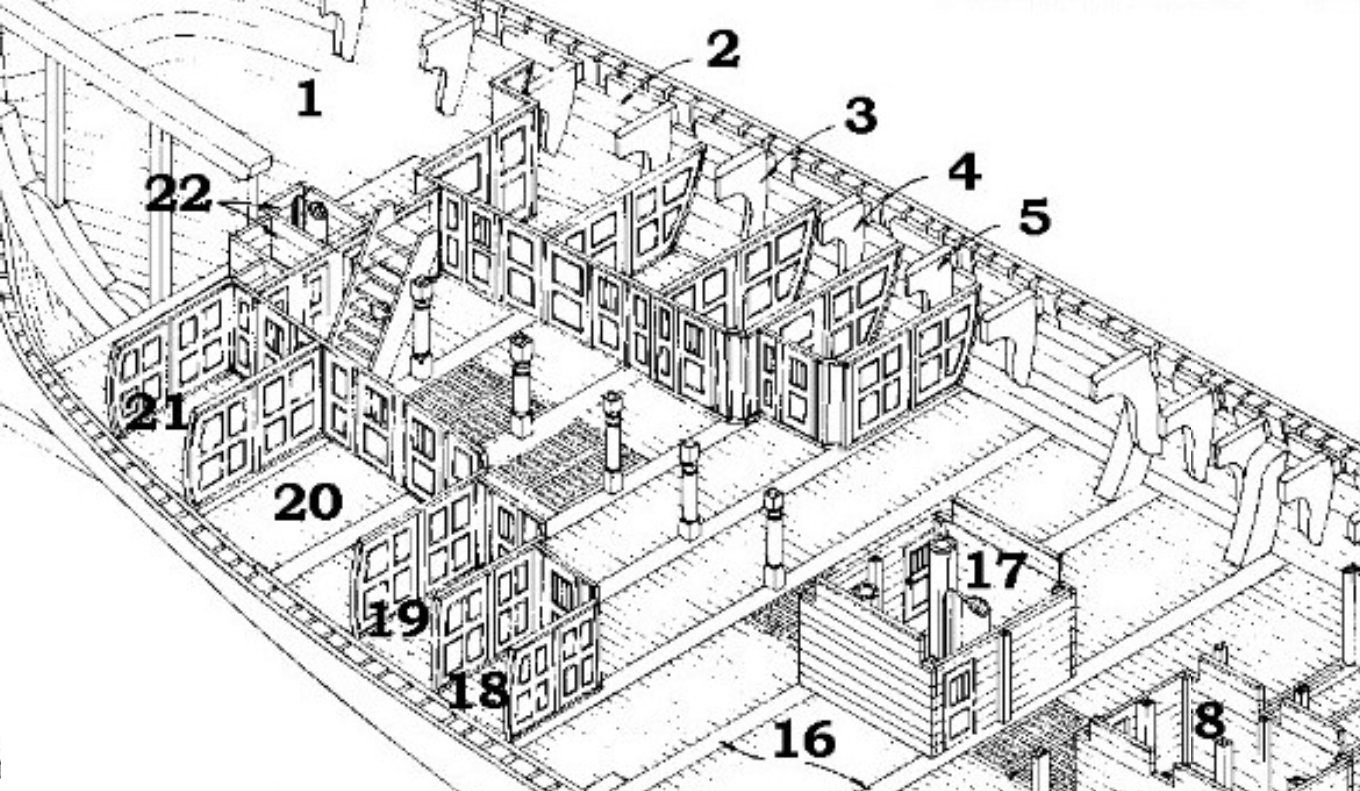

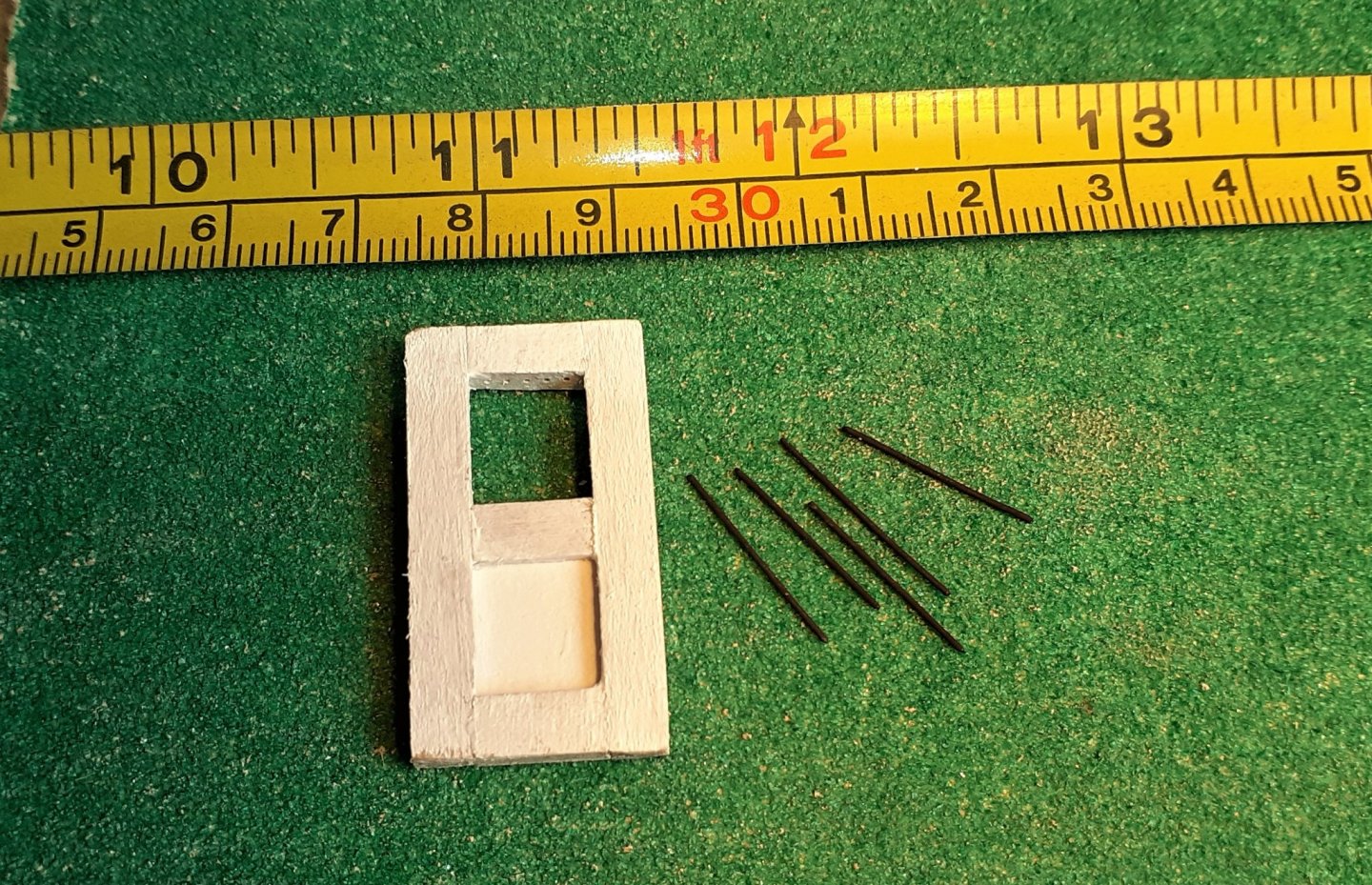

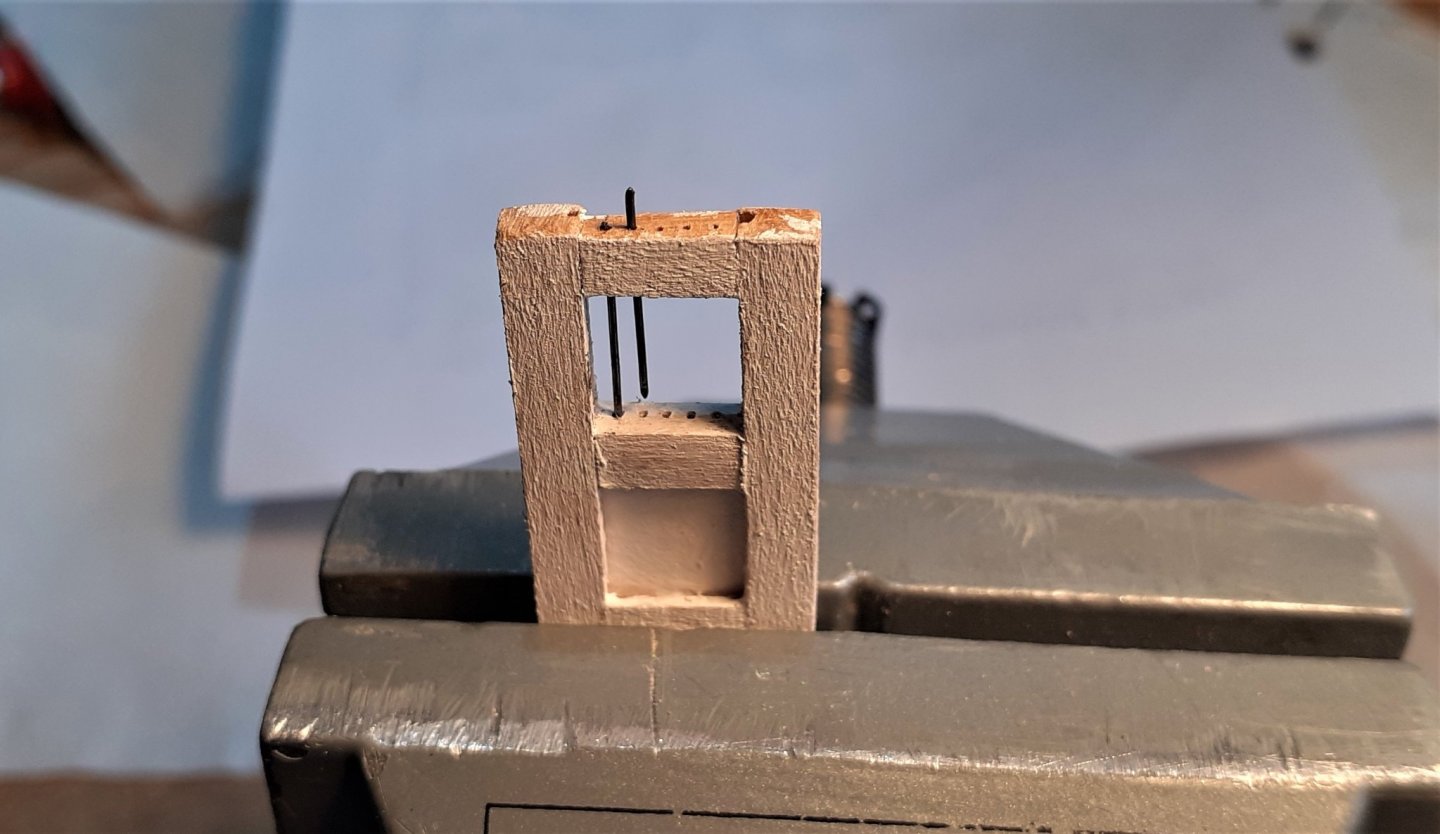

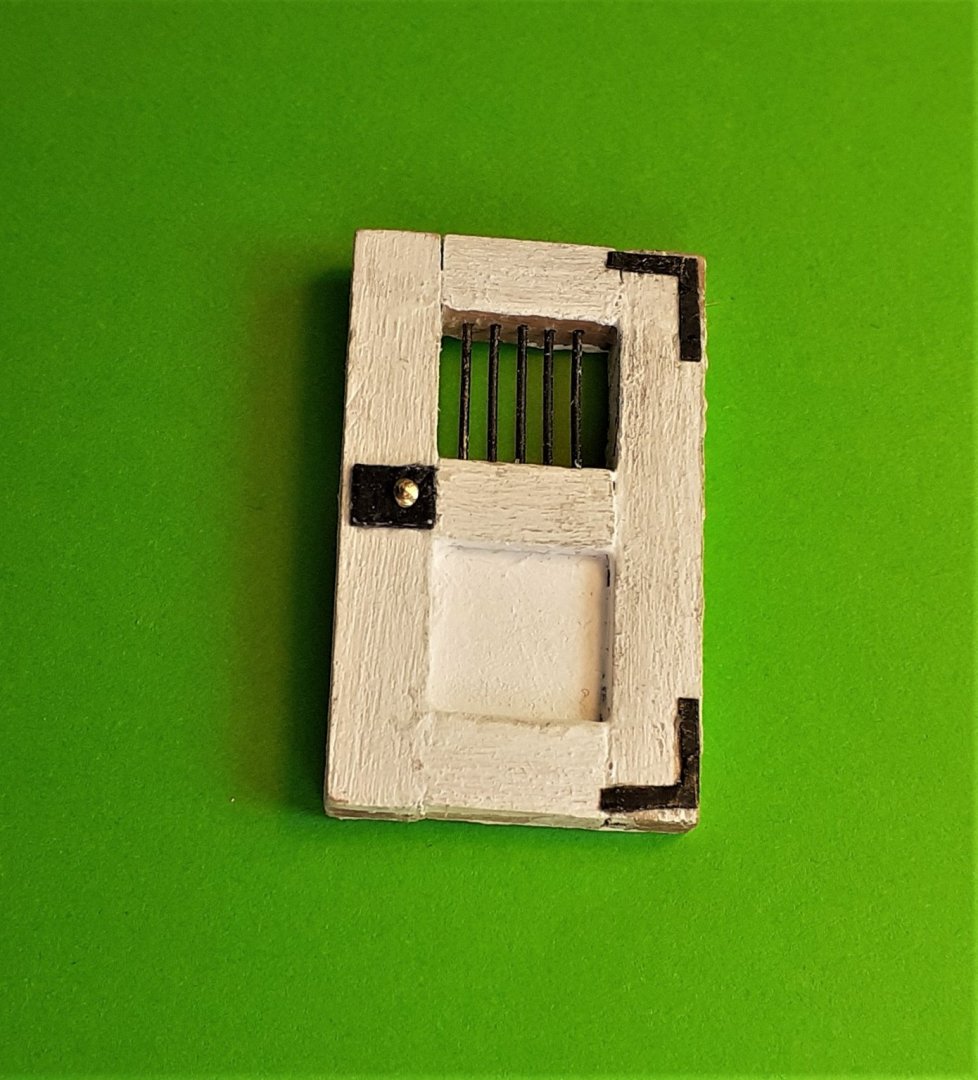

The two aftmost deck beams were still to be fitted but some work on the orlop rooms in that area was still to be done. Three rooms would be accommodated there -- Marine Clothing, #5 in the drawing below; the Lieutenant's Store Room, #18, and the Captain's Store Room, #19 >>> Being further inside, room #18 was tackled first. First was the forward paneled wall which I made with wooden top, bottom and side spars, but for the panels a single section of card was used. That card 'panel' was further sub-divided into 8 smaller panels by gluing on more wooden straps on each side. Just using one large piece of card for the whole wall made it easier to keep everything flat. With the wooden straps fitted > and dry-fitted where it will live > I quite liked the look of the wooden framework with the white panels, but as almost everything down there on the orlop deck was painted white, a white paint job it would be. Here with a few other components for these orlop rooms > The "L" shaped section above is the Lieutenant's store room and the sections lying flat are the Captains store room still to be assembled. (The 2 wedge shaped pieces glued to the inside face of the door standard/post above will be mentioned later.) The doors, although small, were no small project! Created using a similar method as for the paneled walls but leaving the upper 'panel' empty for the bars. At first I attempted assembling the doors by leaving off the top beam, fitting the bars into the middle beam then trying to lower the top beam down into position while trying to get these 5 bars located in the top beam -- it wasn't working !!! So, I glued-in the top beam, clamped the door in the vice, and inserted each bar in turn down through the top beam and into position in the middle beam. That seemed to be a much easier way of doing it. > The "L" shaped hinges and the door lock are blackened brass, as are the 5 bars > and the door knobs/handles are the heads snipped off a few brass nails > The 3 rooms positioned on the deck. (As for the wedges mentioned above ~ these were to allow me to position the door in a half open position on the Captain's store room -- I think the Captain had to rush off in a big hurry to the heads, but I'm sure he'll be back soon to lock that door.) Dry positioned along with the as yet 'un-morticed' deck beams >

- 66 replies

-

Thanks Allan, Mark and Henry for the further comments. Allan, as Henry said "Weighing and raising the anchor is a several hours long process and involved a great number of the crew." I know these bars were very long, although I didn't know their proportions in relation to the ship's beam. I know that on HMS Victory the capstans could accommodate up to 256 men at one time. Back in 2003 I sailed on HM Bark Endeavour for 5 days and only on one occasion did we lie at anchor. Compared to a ship of the line, or even a 50 gun ship, Endeavour is quite small but raising that anchor was one mighty task. It was done on the ship's windlass and not the capstan but raising that 'smallish' anchor probably took us the thick end of an hour ~ and if my memory serves me correctly (which at this age doesn't always work!) we were helped a little by the ship's electrics.

-

Thanks guys for the responses. As I said in my first post above, I knew that pillars could be moved but didn't think that companionway stairs would have been moved -- but on that score I consider myself re-educated! Maybe there was a reason (although not one that I can think of) for that stairway to have been positioned exactly there, when, from the drawings it looks like it could have been positioned just ahead making use of that capstan much easier with a lot less 'stuff' to be moved. If the stairway had been first installed in the position that I've indicated on this drawing it may have been more 'convenient'? >>>

-

Every time I look at the drawing of the lower gun deck of the 50 gun ship I'm working on I'm a little puzzled at the placement of the companionway coming down from the upper deck as it's right beside the lower capstan. I can't imagine an efficient use of the bars on that capstan with such a big obstruction placed there. I know that some pillars could either be removed, or hinged up to facilitate use of the capstan bars, but I can't imagine a whole companionway being removed or hinged up. Here's the drawing of the lower deck > The upper capstan appears to be reasonably accessible > Would it be the case that most of the man power would be employed on the upper capstan and the lower capstan would be more of a 'slave capstan'? However, the drawing creates another problem in my mind -- as it was the lower capstan that had the messenger cable turned around it, and when raising a two ton anchor there would have been extreme load and tension on that messenger ---- I can only imagine that the messenger would have wrecked the stanchions for the hand ropes if not the companionway as well the first time the anchor was weighed ???

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.e44aa2433412e991acd4e277bb00f1d7.jpg)