-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by schooner

-

-

First of all let me say that you are doing a GREAT job on this build, very clean and sharp!

I've had my eye on this kit for a while because I don't have the room for a rigged ship of that size. I've done a fair number of wood kits but I was wondering if you used anything other than hand tools in your build? The only power tool I have is a Dremel that I use for sanding (I might buy a small disc or belt sander to help with the frames).

Thanks and keep up the great work!

- Mr Whippy, Jorge Hedges and mtaylor

-

3

3

-

-

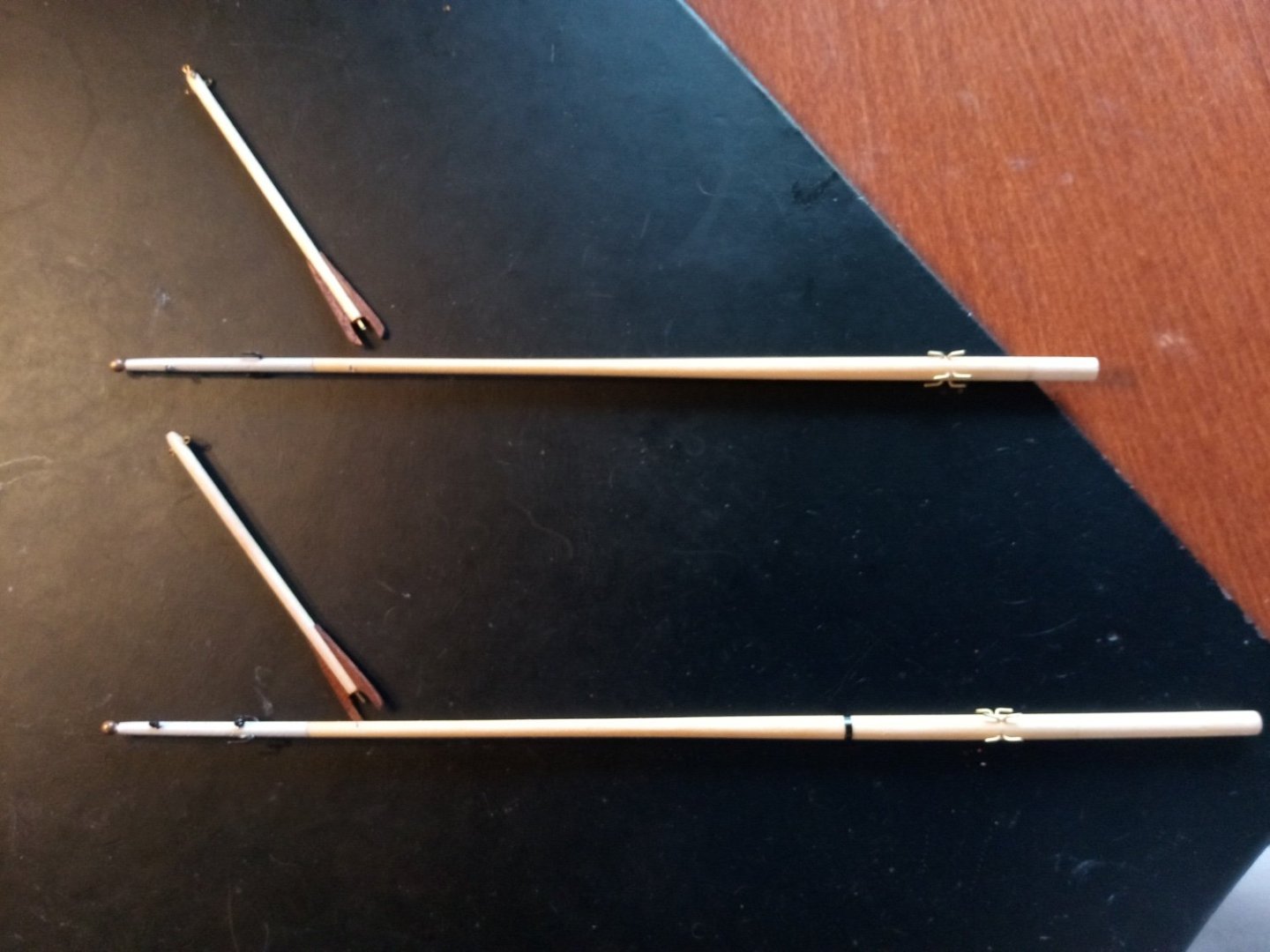

Topmasts and Top Gallant Masts

I’ve been fabricating the upper masts per the plans. The kit provides mast caps for the lower masts but not the upper ones so I ordered some small ones from BlueJacket.

I had some trouble getting the crosstrees right until I figured out that is was best to assemble them on the masts to ensure a proper fit around the different sections of the masts.

The Fore and main Top and Top Gallant masts are done (just dry fitted to the lower masts) and the Mizzen is ready for assembly. I’ve fitted brass pins in the masts where the yards will go:

Next up will be the yards.

- KurtH, ccoyle, Bill Morrison and 3 others

-

6

6

-

Back to the Shipyard

So, after a six month diversion into the world of radio control while building the SEGUIN, followed by an extended road trip out to the West Coast, it’s finally time to get going again with the ALFRED.

Before starting on the masting and rigging I wanted to do 2 things.

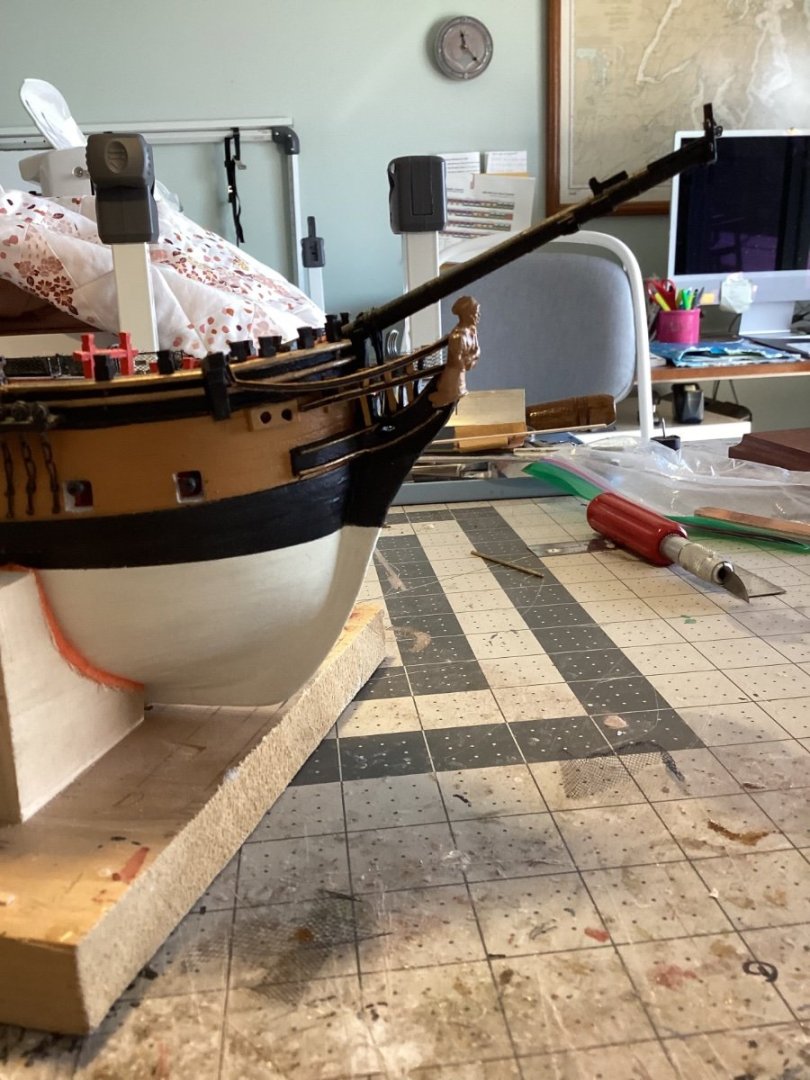

First up was fixing the upper head rails. My first attempt left them pretty straight without any of the “swoop” normally seen on the headrails of period ships (swoop being my term for vertical curvature):

So I removed them (the lower headrails had to be left alone since they conform to the outer edge of the PE grating) and replaced them with the same mix of Brittania metal from BlueJacket faced with plastic channel pieces from Stripstyrene; I’m much happier with the re-do:

The other thing I wanted to do was to mount the model on its pedestals and display board because it would be a real nightmare trying to do it with all the masts and rigging in place. Since the masting and rigging should not require placing any serious pressure on the hull I think now is the time to do it:

Now I can put the hull on the shelf and work on the upper masts.

- CiscoH, mort stoll, chuckthedragon and 8 others

-

11

11

-

-

Hi Tom,

I just came across your log and have spent a lot of time looking at the rigging. I'm getting ready to start masting and rigging my ALFRED from BlueJacket and your techniques and rigging sequence have caused me to rethink my plans. Your explanations are lucid and your photos are sharp. Thanks for taking the time to post.

Quick question: You have referred to "Ultra rope" as great stuff. Could you point me to the manufacturer or website - I have had no luck on my searches.

Thanks and keep up the good work.

-

Rod,

I just got back from a long road trip so I missed the finish to this build. Great job!!! I had no idea this kit was so detailed, and complicated, but you really did her justice.

Maybe you could bring all of your model ship building skills to bear and make your TV cabinet look like the bow of a planked boat!

-

Wonderful work! Very clean and neat.

Are you going to build or buy the case?

- Keith Black, mtaylor, Canute and 1 other

-

4

4

-

-

21. Ship’s Boat and Final Rigging

The Boat

The instructions call for carving a provided block of wood into a boat shape -that's beyond my skills so I ordered a 3 3/16" britannia boat from blue jacket and covered the top with tracing paper to simulate a canvas covering.

Standing Rigging

For the shrouds and stays I followed the recommendation in the instruction book for the RC option and used black stretch cord (.5mm) that I bought online. To secure them I used .015 inch crimping tubes.

Previous build logs, as confirmed by the plans, reported that the after boat davit is completely blocked by the shrouds on the port side of the aft mast so I moved both davits 1/2” forward. Several build logs reported a problem with the shrouds impinging on the deck house roof. I found that if I anchored them on the inboard side of the cap rail that there was no problem.

The stretch cords, set to be about 1 inch short of their pre-stretched final length, hold the deckhouse firmly in place but are easy to lift off of the hooks on the mast so the house can be removed.

Running Rigging and the flags

The model comes with a gaff boom on each mast. I assumed they were there as part of an emergency “get home” sailing rig. If so, the rigging on the plans did not make much sense to me so I copied the gaff rigging used on my model of the USS Olympia (built at the same time as the Seguin) and added double blocks to the gaff vangs and changed the rigging of the gaffs themselves.

The paper flags are from the kit. I rubber-cemented a piece of aluminum foil onto the back of one half of the flag, leaving a border around it for paper to paper gluing. When dry I placed the halyard in the fold crease and then folded and glued the flag halves together. Two different size dowels were used to impart alternating curved folds. Although the dowels could just as well be used to make the flags hang limply I wanted the Seguin to look as if she is headed down the Kennebec River under a full head of steam to pick up a schooner to tow into Bath for an extortionate fee.

The only thing left to do now is to design and fabricate a launch/recovery/carrying cradle, probably from PVC piping and then conduct the maiden voyage, but that will have to wait until Nov when we get back from a road trip out to the West Coast.

-

-

Paul,

Thanks for clearing up a mystery for me. Searching for the tug's namesake I googled and googled "Seguin" but all I could find was a hero of the war of Texas Independence who died shortly before the Seguin was built. Even though during the Mexican War he fought against the US, Texas didn't hold a grudge against him and named Seguin Texas after him. I thought it was strange and unlikely that Seguin’s owners would go so far afield for a name but now I know there is a Maine connection.

So much for leaving this model to the Seguin, TX public library in my will.

-

20. Upper Deck Details

I did one more bathtub float test, this time with the motor running to make sure there would not be any leakage in the stern tube with the shaft rotating - everything was fine.

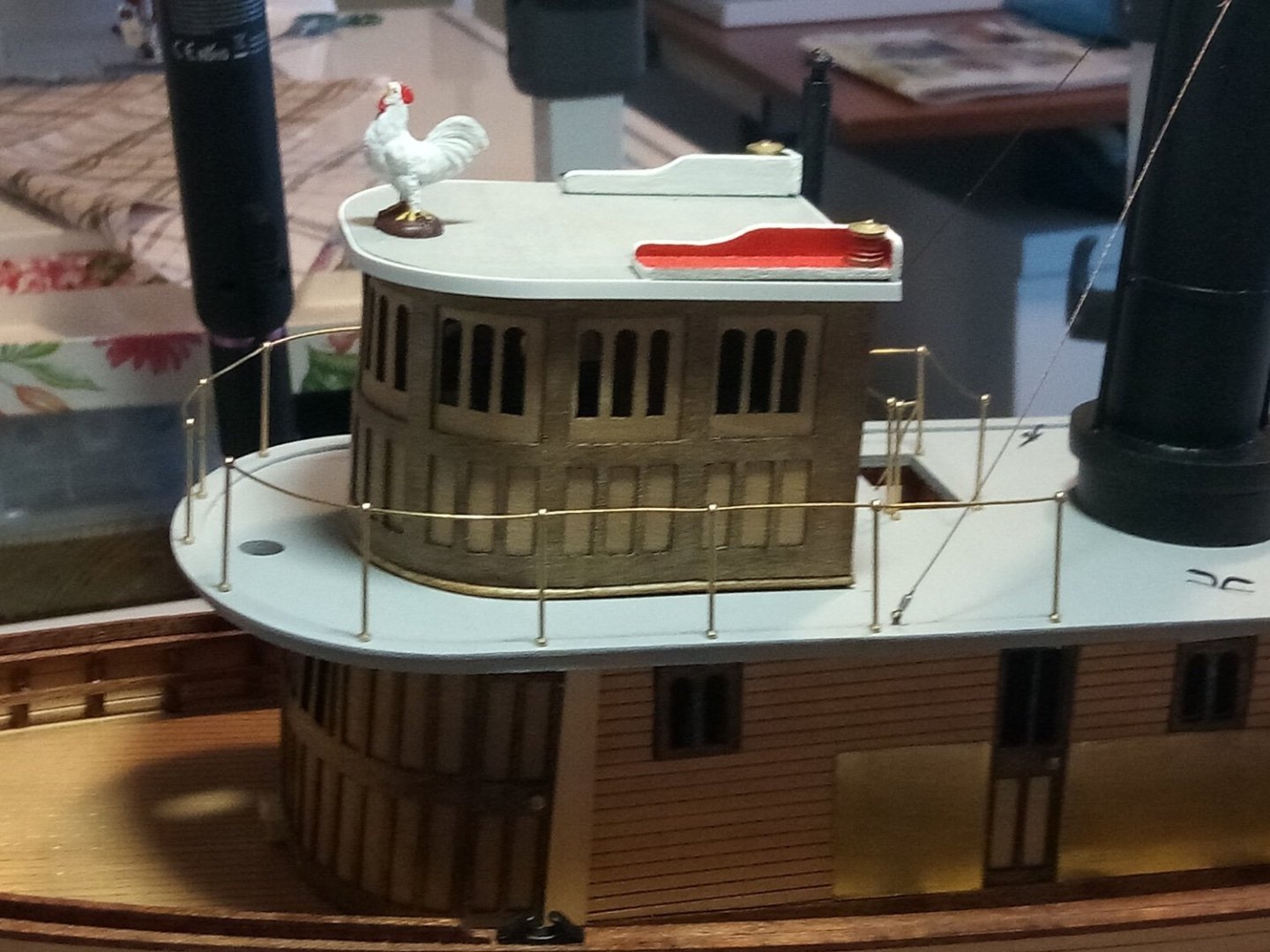

I placed the pilothouse in place after setting up the brass railings.

I got a lead on some very nice brass stanchions from RVICHMA’s SEGUIN build log. I bought 2 packs of 10 from the Age of Sail website. 24 gage brass wire fits snugly in the stanchion holes.

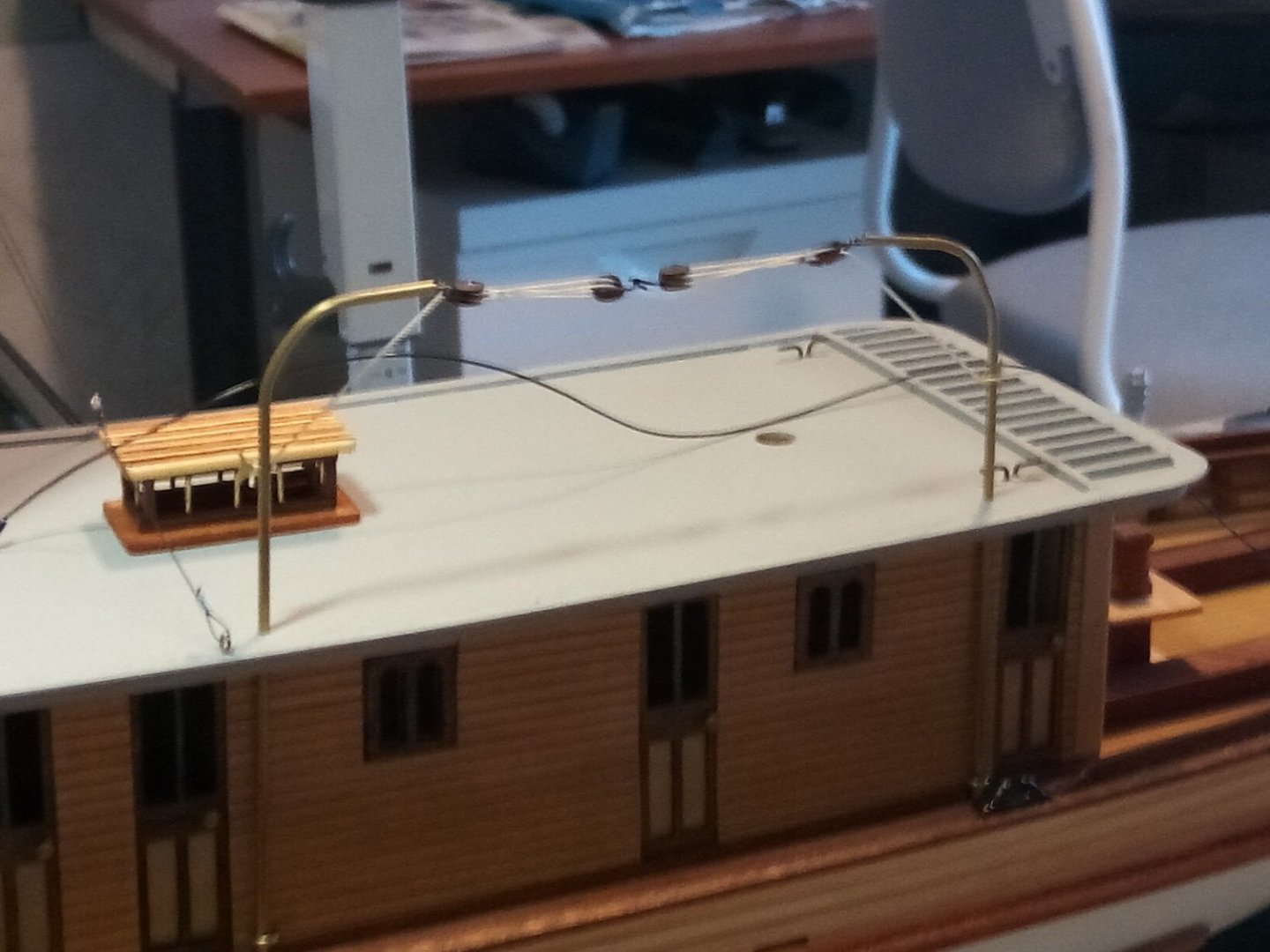

The stack is pinned in place and the guy wires use the kit-provided copper wire with crimping tubes to fasten them:

The skylight and the boat davits were easy additions:

This build is almost done with just the masts, rigging and ship’s boat to go.

-

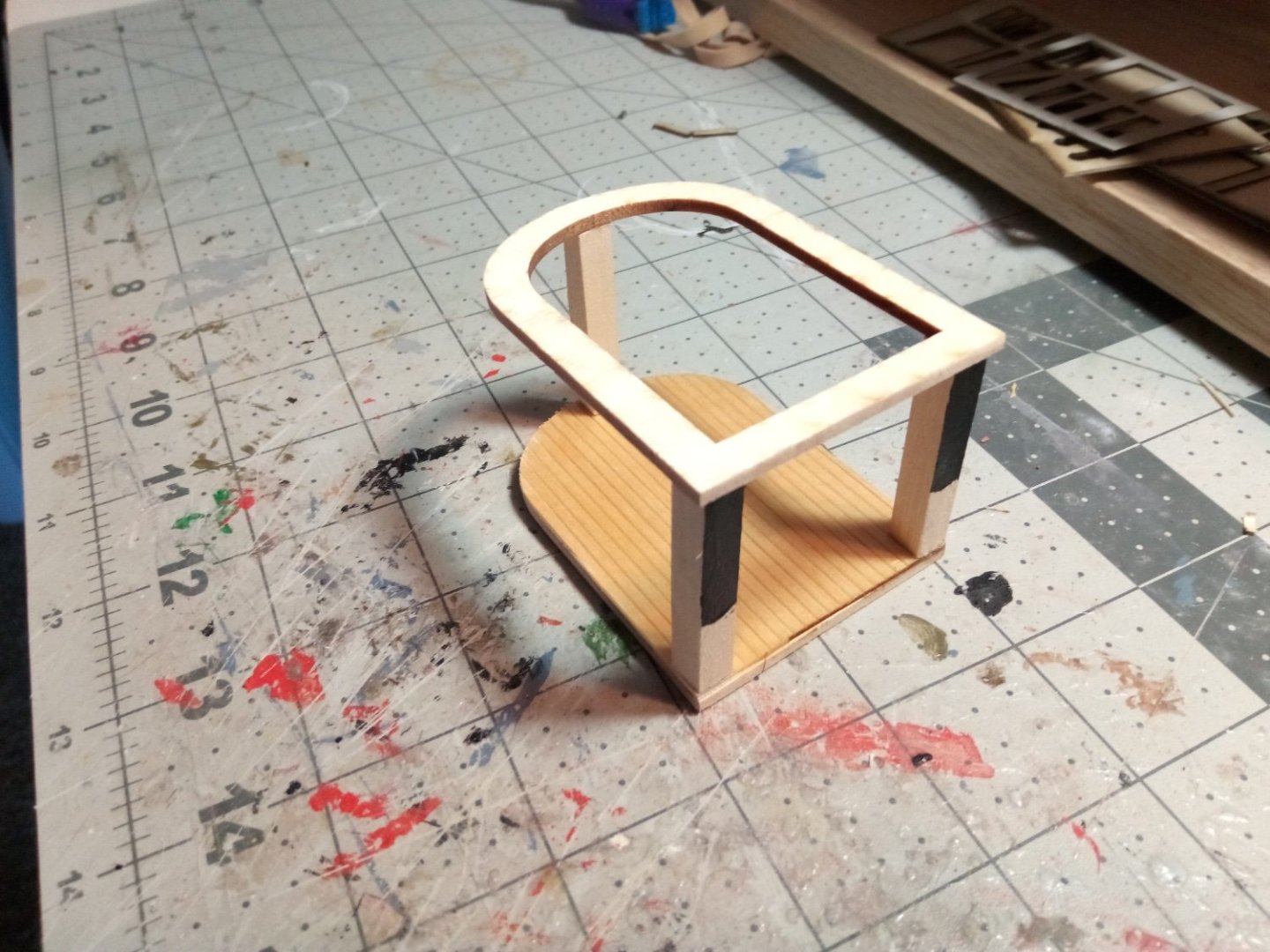

19. Pilot House and Masts

The frame for the pilothouse consists of laser cut base and roof outline, joined by 3 pieces of 1/4” square stock. I added some scrap decking material to the floor.

The 2 aft support columns show thru the window and door so I painted part of them black to make them less obvious. Although the instructions call for 1/4” square stock the plans show 1/8” square stock - I’m glad I went with the 1/4” , it is very sturdy which helped when it came time to bend the sheathing around the frame while glueing.

To shape the 2 laminated pieces I found a spray can with the same radius as the front of the pilot house. After soaking them in hot water and ammonia I rubber- banded them in place and left them overnight:

The steering wheel is britannia metal, its stand is made up of strip wood per the plans. The plans show a chart table and bench, I added a voice tube and engine order telegraph:

Here is the furniture in place:

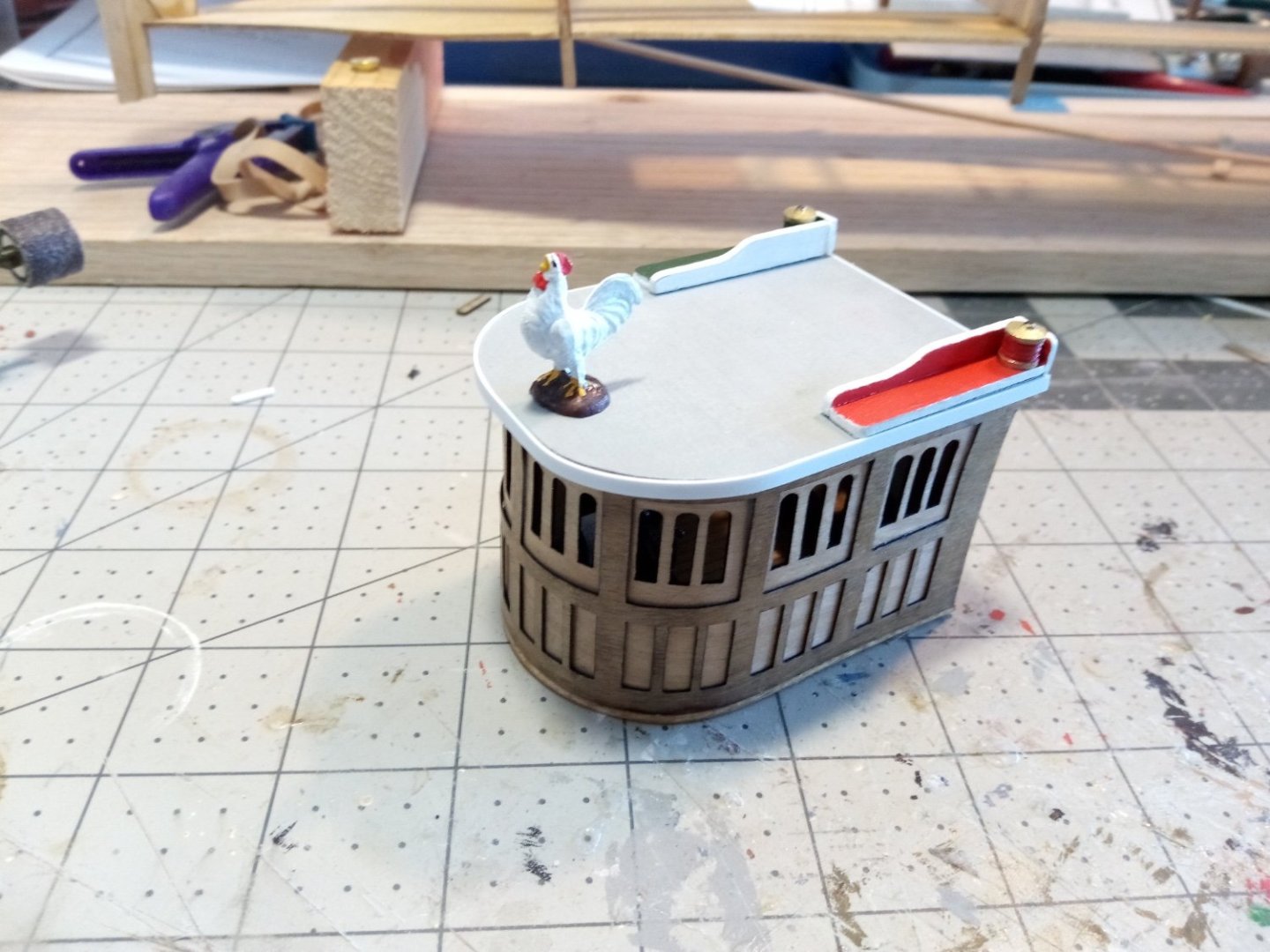

And here is the completed pilothouse with the roof (and rooster) in place:

As it turned out, almost all the interior details are not visible. It’s pretty dark in there and the sight lines thru the windows block everything but the top of the steering wheel, the voice tube and the bench.

This would be a perfect place for putting acetate in the windows but I left them out for the sake of consistency - I had to forgo glazing the doors and windows on the lower deckhouse so that the heat from the motor and ESC would have a way to vent.

The masts have been tapered and the metal work attached:

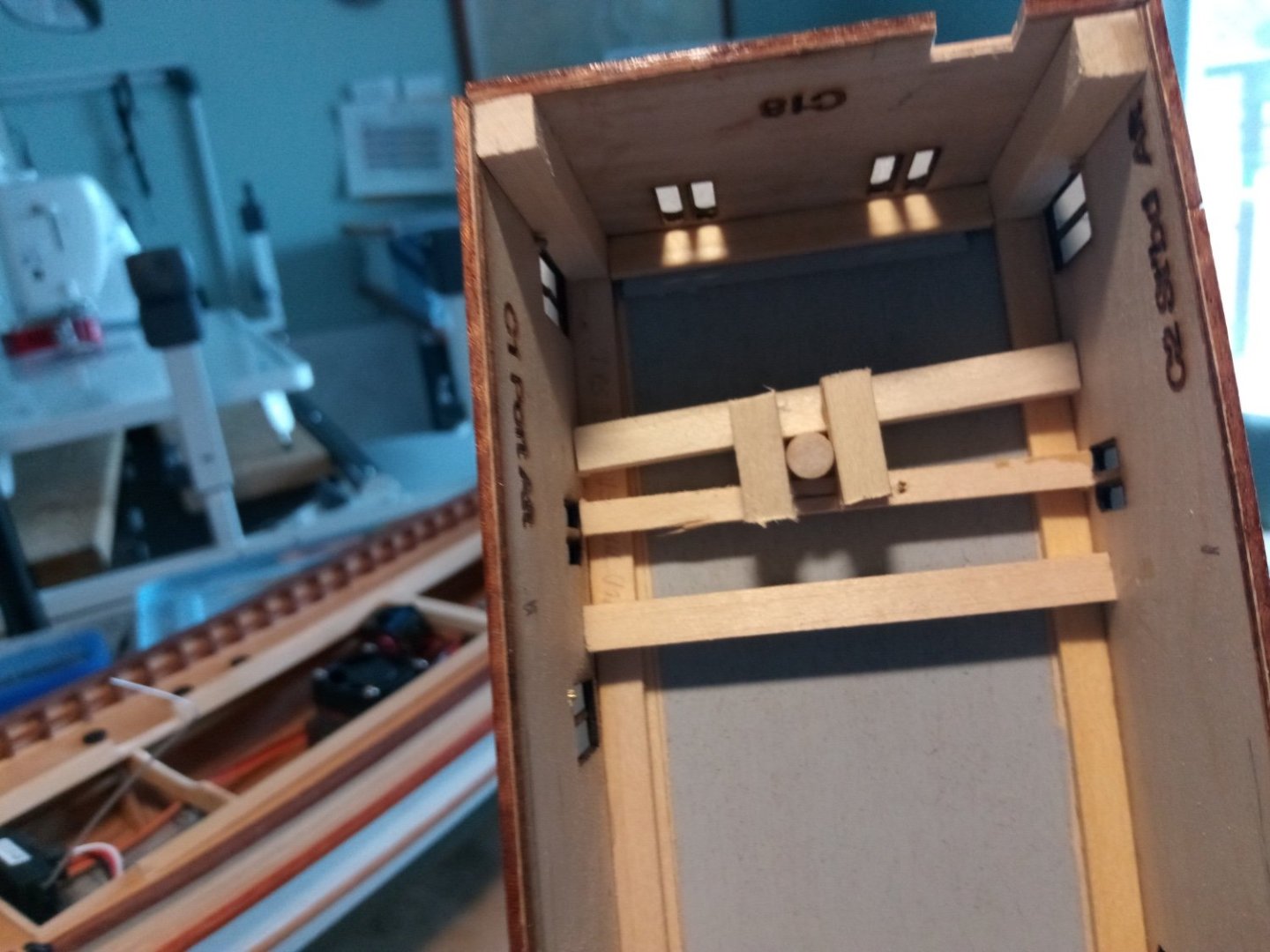

The instructions call for attaching the foremast by glueing the bottom to the deck which would work fine for a static model but since this deckhouse needs to be removable I changed the attachment point to a spacer that is glued to the front of the deckhouse and will sit on the deck between the water barrel and the ice box - the mast will be glued and pinned to the spacer which is set at a width that will place the mast at the designed rake:

The aft mast needs a little help securing it. The instructions call for glueing it to the hole in the roof but even for a static model that will not provide much strength when it’s time to tension the rigging since the bottom of the mast is just hanging in the air inside the deckhouse. I put a framework on the underside of the deck that will provide a good glueing surface and that also sets the mast plumb and with the proper rake:

-

Nice rigging work! I'm at a loss figuring out what purpose the preventer serves, although the photo below shows one on each side. Any idea?

BTW, if you ever get down to Maryland and DC the Maine's damaged foremast is on the seawall on the grounds of the Naval Academy in Annapolis and the main mast is at Arlington National Cemetery. Photos of both are easily Googled.

Keep up the good work, I've enjoyed watching this come together.

- mtaylor, Canute, Ryland Craze and 1 other

-

4

4

-

18. Steering Gear & Deck Furniture

The push rod between the servo and the rudder needs small brass rod at the ends to fit into the small holes on both arms but such thin rod may bend under pressure so I used an idea I found on a RC website and used a wooden dowel for the majority of it. This model is a little unusual in that the pushrod will remain above the deck but it will not be visible since it will be inside a 3-sided box, 2 of which sat on the fantail of the real SEGUIN to protect the steering ropes. The box hiding the pushrod and the fantail grating will be spot glued with white glue so I can remove them if needed.

The deck furniture is done, with the exception of the boat. The fore and aft bitts, the ice chest, the stack and the skylight are per the plans. The kit provides a resin piece for the water barrel but I’ve had several wooden ones from Model Expo in my stash since my first build, as it turns out they are a perfect match for the plans so I used one.

Next up will be the Pilothouse.

-

-

Hi Ian,

Yes it is a mini-servo on the rudder, I got a pack of 10 of them online for about $20, hopefully it will work because a larger one I have won't fit in that spot. If it does burn out after a while at least I have plenty of spares.

As far as the motor goes I don't know if it is brushed (I threw the box out and I'm a total RC newbie), it is geared.

The Washburn does look like a nice kit, there is a decent build log for it over at https://www.rcgroups.com/forums/showthread.php?1558895-Building-the-George-W-Washburn

-

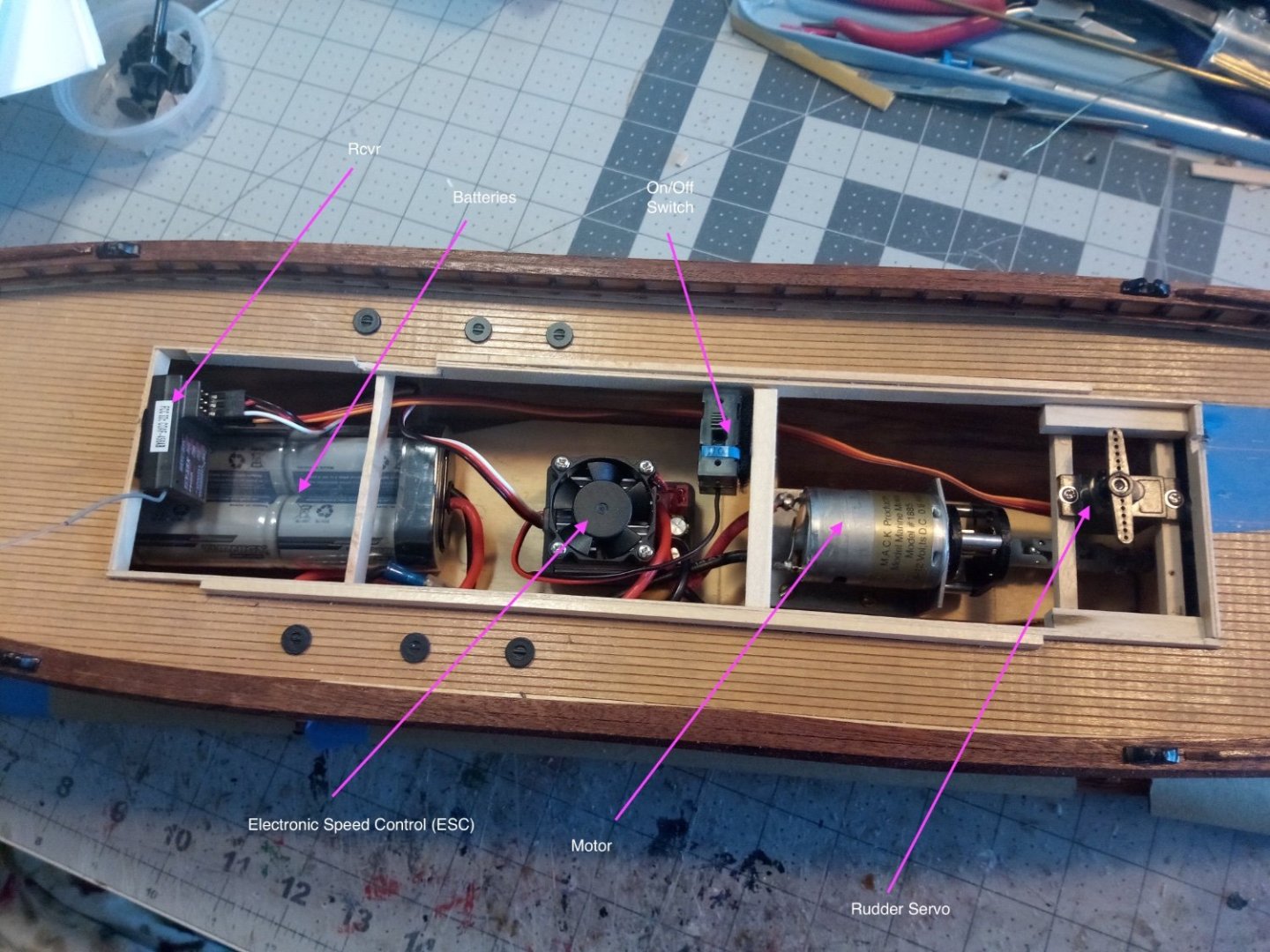

17. Installing Ballast and the RC Gear

Bedford posted a reply a little ways back recommending that I ballast down the model to its waterline and let it float in the tub for a few hours to make sure there are no leaks. It was a good suggestion so I followed it.

I went to my local Bass Pro outlet and bought a selection of different sizes of lead fishing weights. I ended up using about 3/4 lb of the weights, all of them in the aft 1/3 of the hull since there is a pronounced “squat” on this hull - the waterline and the keel are no where near parallel. Just like on modern tugs, they wanted to get the prop as deep as possible to generate thrust, not bubbles. I ended up with just under 1/2 lb of weight in the aftermost section near the rudder tube and the rest went under where the motor will sit. I could only fit one of the two NiMh battery packs I ordered but even if there was room for the second pack there is not enough reserve buoyancy to support it - just one pack took care of bringing the bow and midships area down to the waterline.

The bathtub test worked fine - thank goodness. With that out of the way it’s time to start installing the RC gear.

The first thing I had to do was something I did not want to do. The biggest threat to running this model on my lake will not be wakes from real boats but one of these guys (the fish not the geezer - that's not me BTW):

There are a ton of Largemouth Bass in my lake, including a few big ones under my dock. They weigh 3-5 lbs, move fast and strike vertically at prey on the surface, including baby ducks (all together now “Oh No!! Not baby ducks!!) One of the most effective lures for catching them (bass, not ducks) uses brass blades that rotate as you retrieve it so it looks almost identical to what this beauty would look like while running:

So after sanding off the protective coating and adding spray paint my prop is now a boring black:

The motor was mounted to its pad with screws. Aligning the motor shaft with the prop shaft was easy to do visually athwartship but vertically took a combination of a small mirror and my finger to check for alignment as I turned the screw.

The battery pack is velcroed to its pad so it can be removed if needed but I plan on recharging it in place.

The ESC is also velcroed so it can be removed if I need to remove the battery pack (for a relatively large model there really isn’t all the much space to work with inside the hull).

Since the rudder servo will also experience torque it’s mounted with screws. The servo is placed so that its arm and the arm on the rudder stock align fore and aft.

The last item to add was the receiver - I placed it as far forward as possible to minimize electro-magnetic interference from the motor and ESC. Placing it there also allows the 3 inch antenna to project vertically up into the deck house for (hopefully) better reception.

Next up will be installing the pushrod between the servo and the rudder.

-

Thanks for all the kind words everyone - it has been "a real trip" to use a term from my youth.

Double-planking would be a good idea.

-

16. Lower Deckhouse (cont)

The instructions call for removing the tops of frames 2 and 3 but I left them on to avoid any spring back from affecting the hull seams - I think I can work around them installing the RC gear.

The instructions also call for installing a coaming around the deck opening “3/8” wide out of 1/16” basswood”. I did not understand why they needed to be so large so I made mine about 1/4” high with about 1/8” above the deck:

The pieces of the deck house went together without a problem. In addition to the 1/4” square stock added to the aft corners to brace them I also added them to the forward corners. 1/16” by 1/4” stiffeners have been added to the top edges, they also serve to increase the glueing area for attaching the roof. I marked where the door opening will be have to cut out on the starboard (far) side for the stairwell:

The waterway along the edge of the roof is a piece of laser-cut thin wood. The roof attached to the deckhouse without any need of soaking - despite the sheer of the deckhouse.

The instructions call for making the stairs out of strip wood fitted into slots. That would look great but I don’t have the tools or the skills to pull that off so I used a piece of 3/8” by 5/8” strip wood cut into lengths, each 1/4” longer that the previous one and then glued the them in a stack and used the scribed decking material to make the sides of the stairwell:

When I fitted the completed deckhouse to the deck the coaming provided a snug fit fore and aft but there was little contact on the sides so I tried various thicknesses of strip wood to increase the width of the coamings until I got a good fit all around - good enough that when I turn the hull upside down the deckhouse stays in place.

I was pleasantly surprised at how well the laser cut sides match the sheer of the deck - it is a great fit that does not need any additional strips along the bottom to hide any gaps.

-

-

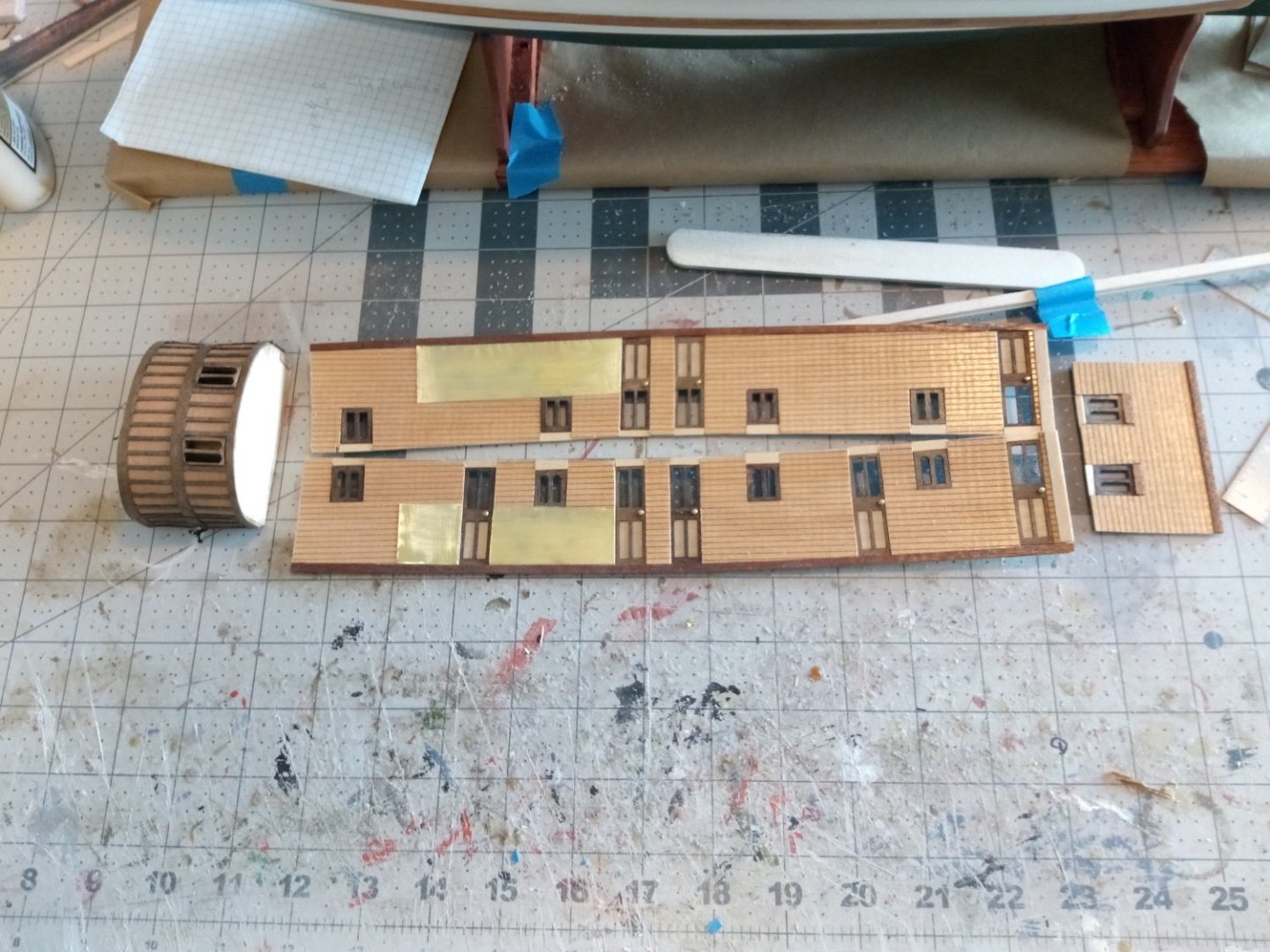

Post 15 Lower Deckhouse

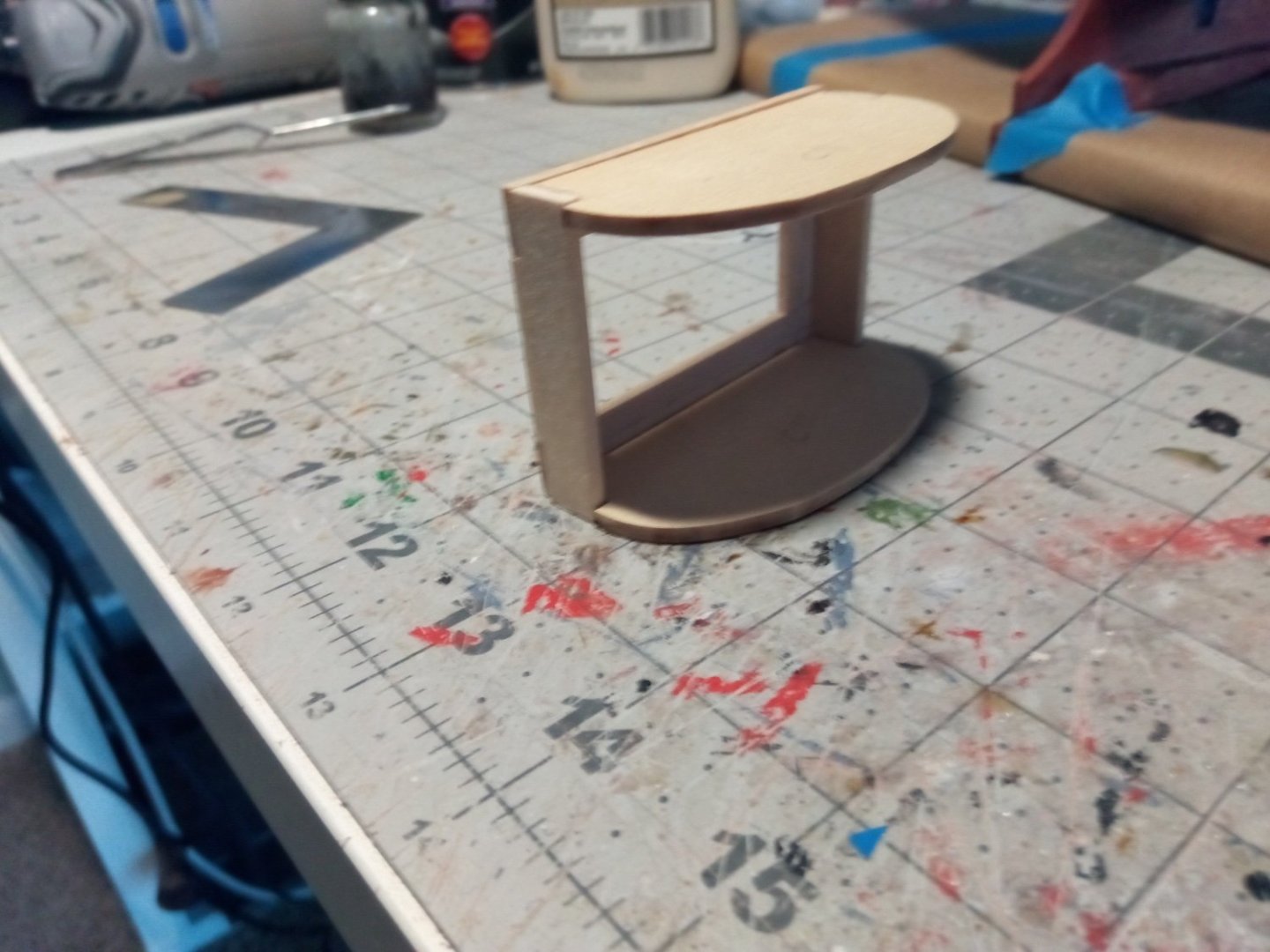

The kit provides laser cut sides, rear bulkhead and roof. The semi-circular front is made up of strip wood covered with 2 laminate pieces.

There are 12 windows in the deckhouse and the kit provides 20 window frames. Since the 2 forward windows do not get frames that leaves enough for 2 frames per window, which is good, because if 2 of them are stacked they look better when surrounded by the scribed sheeting.

A minor point that could be easily missed: There is a door on each side of the curved front piece, both at the aft edges. The only way to know that is to notice the door knobs on the plans. I added door knobs to all the doors using the heads of some brass finishing nails.

The frame for the front went together well but I had trouble bending the inner piece - not so much bending it as getting the bend to remain after the soaked wood had dried out - it returned to a basically flat condition. I think the problem was due to the wood provided being plywood so I used it as a template to make another piece out of 1/32” sheet basswood. The basswood bent easily and retained its shape after soaking. The top piece bent without a problem.

The instructions call for assembling the deckhouse sides into a box and then adding the scribed wood sheeting and brass (shielding near the coaling scuttles) but I thought it would be easier to measure and fit those while the pieces were laying flat.

The built-in curvature to the top and bottom of the sides in order to fit the shape of the deck is readily apparent (and welcome).

The brass does not look good in a photo but in “real life” it looks fine:

-

Your photo reminds me of something unexpected I recently learned - the MinWax stains you show in the lower right of your photo match what I've encountered coming straight out of the can but if I stirred them (not shaken) the colors change dramatically, e.g the Ipswich Pine goes from the light transparent yellow to a solid dark-medium brown. The can directions make no mention of either stirring or not stirring it prior to use.

I've decided to leave well enough alone- that way I know that I'll get something that looks like the color on the label.

Keep up the good (and fast) work - she is coming along great!

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Your post on the makeup and purpose of all the blocks on a yard is great! It is a clear explanation of how to rig them but also a tutorial as to their purpose (many of which have always been less than clear to me).

Thanks for taking the time and effort to explain it all, it will be a great help as I am about to start setting up my yards.