-

Posts

157 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Sailcat

-

-

-

Thanks for the kind words and encouragement once again

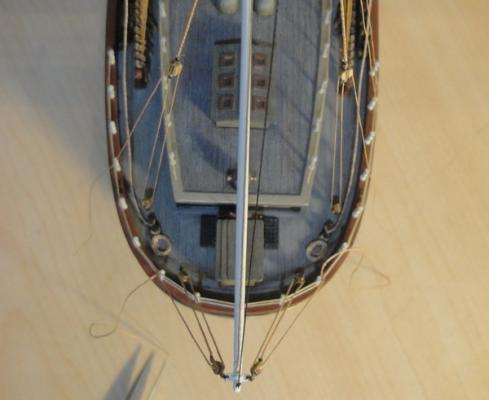

The display case is planned but I haven't really looked into it yet, soon though. And that's because this is my last post for this Build Log ... yes, it's finally 'done' in the sense that the work on the ship itself is as complete as planned. There's still the case as mentioned, plus little tweaks for the final appearance adjustments. But for now I'll just get on with the last photos.

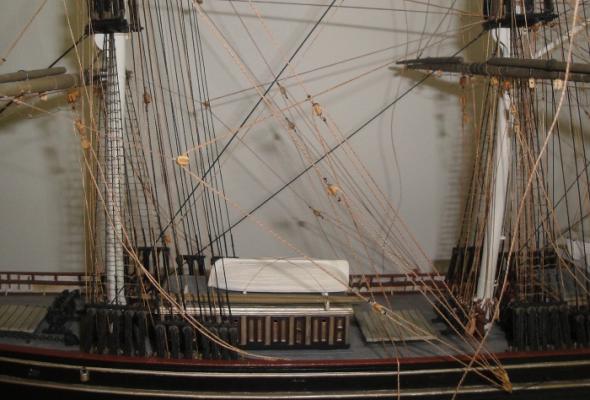

Fore Royal braces in place.

Fore Topgallant braces.

Fore Upper Tops'l braces.

Fore Lower Tops'l braces loose fit before tying off.

Fore Lower Tops'l braces tied off and Course braces loose fit.

Fore Course braces tied off.

The last of the decorative rope coils in place and the finish line is crossed.

The Dame Tisane.

And the rest I'll save for the Completed Model Ship thread. Many thanks to everyone who looked in and provided much needed advice and information. Special thanks to Jim, Dan, Popeye, Dafi and likely others who've slipped my mind, for helping me out repeatedly when I was struggling with stuff. It's because of you folk that I was able to get to this point

And as to what may come next - I've been feeling the itch to do other things hobby wise but I also can't stop thinking about the next nautical adventure. Perhaps the New Bedford whale boat, I really like that kit ...

-

A Big Thank You to all of you for your kind words and encouragement

And at the risk of sounding like a TV Commercial - It's All About Braces! Last post I ended with the beginnings of the mizzen braces being set up. Since that time I have been puttering away at it, a bit at a time, and remembering to take a few photos along the way. With that, here we go.

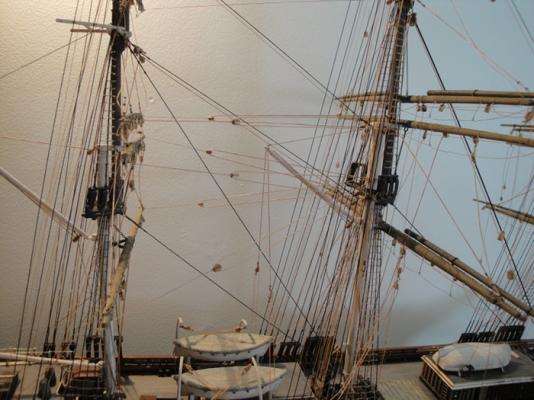

We start with the mizzen Royal and Topgallant braces in place - view is from starboard.

These next two are the start of the Mizzen Upper Topsail braces from both sides for perspective.

And now the Mizzen Lower Topsail braces.

Finally the Cro'jack (or Crossjack) braces.

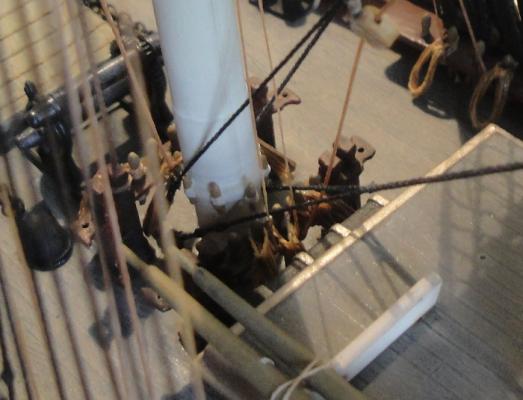

A view of the tie-off's for the braces - I'm going by the 'incorrect' kit instructions at this point because it's how the model is set up and the thought of trying to research and adapt to be more realistic is very, very, very intimidating, lol.

Do the next thing ... which in this case involves the Mainmast Skysail braces.

Followed by the Royal braces.

And the Topgallant braces - again all of this is as per kit instructions.

The Upper Tops'l braces being rigged - you can see the dangling line from the upper tops'l pendant.

The Upper Tops'l braces in place now.

The Lower Tops'l braces being rigged. Hard to see for all the rigging now but trust me, they're there.

And we end with the Lower Tops'l braces in place.

What I haven't gone on about, nor shown, is the 'fun and joy' of the tying off of the braces to their respective pins on deck. I can say that I accomplished it with no breakage or snapping of lines in place - how I did this is a mystery to me though

So almost through with the Mainmast braces which will only leave the Foremast braces to complete. And at that point I will call this adventure over, which is probably why I have been procrastinating a bit. Funny and contradictory, but for these last 4 1/2 years all I could think about was the perceived impossibility of actually 'finishing' this re-build, yet now that the finish line is within reach, close enough that all I have to do is reach out and grab it, I find that I don't Want to, not really. Oh, there are always more things to do, like build the display case and find a home for her, but I am now getting the full realization of Why people put themselves through the seemingly Herculean effort of building and rigging these kinds of ship models - repeatedly.

Before now if I'd been asked if I'd ever do something like this again I might not have had an easy answer. Now though my answer would be, "Of course I will. The only questions are How Soon and What Kit."

And on that note I leave with the bittersweet certainty that this is the penultimate post in this Build Log - unless I find a way to draw it out even longer, lol.

-

I use two kind of liquid plastic cement, the regular and the super thin. For long seams like a hull I prepped the edges then clamped and ran the thin cement along the seam on Both sides (inside and out). After curing for 2 days I then ran a bead of 2 part long set epoxy along the inside seam for extra strength. Normally I don't take the extra step with the epoxy but my personal experience with plastic models has been, "The longer the seam the more likely the glue will fail eventually."

I used to use excess 'sprue' from the parts trees to add reinforcement but the epoxy bead provides more strength I found.

Hope this is of some help.

-

Thanks for all the kind words and thanks to Jim, Popeye and Sailor123 for your answers to my questions

Advancing forward now, dealing with the occasional bout of disbelief and trying not to get impatient had resulted in some more work, go figure, lol. Here we go with a batch of progress photos.

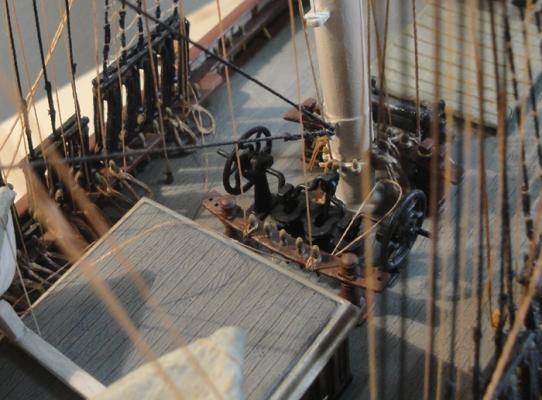

After all this time I have finally tied off the lines for the boat davits, which had been hanging loose. Here I applied the 'zero tension' strategy by dabbing diluted PVA into the blocks to lock the lines in such a way as to simulate tension.

I chose to simply hang the rope coils off the davit 'cleats' after perusing images on the Internet, it seemed like the common method.

Attaching the life rings onto the aft rails, just a dab of GS cement.

Bumkins (aka bumpkins aka boomkins) being affixed to the hull. At first I had planned to modify these but instead I left them as is in order to represent the kit origins - something I have done here and there through the build.

Hanging the anchors ... here is where I was applying weight to the forward end and then soaking the line in diluted/tinted PVA to give the illusion of weight tension.

The result with the anchor canted more realistically. The tint in the PVA is diluted black China ink, not a lot, to give the lines a dirty look when the glue dries.

A bow view shot of the anchors in place.

Attaching the 'chains' to the bumkins, some thin black nylon in this case. This is the midships bumkin.

And here's the aft bumkin.

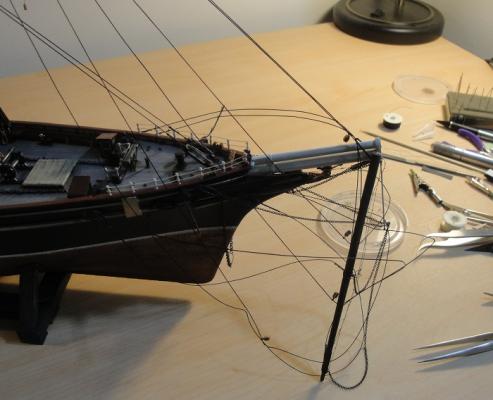

While I was attaching the blocks for the running rigging I consciously chose not to attach the blocks for the braces with the fear that I'd wind up getting confused and use the wrong ones. Sage forethought as I would have made more mistakes ... but now comes the time to attach all the rest of the blocks for the braces. A look at the mizzen mast with additional blocks in place.

Putting the blocks on the bumkins - this is the port aft bumkin.

And the port midships bumkin.

Here we go with the first brace, mizzen royal starboard, loosely in place.

Both mizzen royal braces in place with slight tension.

And a not too clear view of the mizzen royal braces tied off - additional detailing like rope coils yet to come.

So now there's just the rest of the braces to do ... just ...

This is the part that I never thought I'd get to in times past. Getting here fills me with mild disbelief and moderate elation, but also there is the growing concern of what happens when I tie off the last line and glue down the last rope coil. The question of who gets the Dame and where she will stay is still up in the air, thought I now have a place for her to reside temporarily while I figure this out. However, such concerns I am putting aside until such time as they become the primary ones, right now I just have to concentrate of making sure I do the braces correctly.

Stay tuned for more ... but hopefully not a Lot more

- russ, avsjerome2003, Dimitris71 and 8 others

-

11

11

-

Thanks for the kind words and I'm still having a 'geek-gasm' over how quickly the old reflexes and data set have dropped back into their places.

I believe I mentioned before that this new arrangement makes 'on deck' rigging a lot easier in terms of angles, approach and access ... enough so that I can now proclaim, "The Fore And Aft Running Rigging Is Complete!!" (cue marching band, cheerleaders and confetti, lol)

But as with many things in life the completion of one stage leads to yet another, with the accompanying questions and pleas for advice - but that comes after the pictures

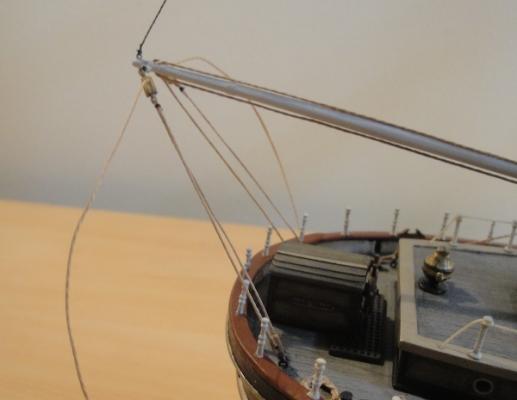

First of is the best shot I could get of the halliards and downhauls for the Fore Topmast Staysail and the Flying, Inner and Outer Jib sails. The set isn't as 'perfect' as I would like but the geometry here has been determined by the size of the blocks I used, which were too large for scale. I did manage to set them with almost no tension so the standing rigging still looks taut - that took some finicky finessing let me tell you, lol.

Here's where I admit that in my enthusiasm for progress I neglected to take as many photos as I usually do, but I did remember to take a few. This one's of halliard tie off's with rope coils emplaced. The rope coils I made for these were a bit smaller then the average as with the no-sails set up most of the halliard is run through almost to the bowsprit.

And finally the downhauls tied off and with thicker rope coils to reflect that there would be more line stowed here under these circumstances. Somehow I don't think I put enough coiled line here to properly reflect the 'real' situation, but that can be corrected easily enough - these coils are easy to get at unlike many of the others behind the deadeyes and such.

With a great sigh of relief I can now let go of the anxiety of leaving the fore and aft rigging for so long. This leaves one major final stage rigging adventure and that is the Braces and this is the final stage for me because I am not rigging for the stuns'ls. But before that can happen there must first be an accounting of all the little details which I have left incomplete for various reasons. One of these details is the placement of the bumkins which can now be fixed in place - I left them off until now on the advice of many who told me not to put them in place until I had to, sound advice which I'm glad I took.

As well are certain finishing touches which bring with them a foreshadowing of the completion. Finally setting and tying off the boat davits will be accomplished soon and I'm planning to simply make more on my rope coils and attach them as seems appropriate - Question Number One; Is this correct or is there a different way that these lines are coiled?

The anchors which I scratchbuilt so long ago can now be linked to their chains and stowed, which leads to - Question Number Two; can anyone give me a link or photo which shows how this is done? I know the basics but it's been so long since I thought about it that I do no want to depend on my flawed recall.

Life rings will be attached as well, I had considered omitting them but they add a nice touch to the look. I never did attempt to print out the ships name small enough to label the life rings ... and I doubt I will at this point, lol.

Holy wow ... it feels weird to be talking about the completion after all this time ...

-

Thanks again for the kind words and support, everyone. It certainly helps ease the struggle of trying to remember, recall and reinvigorate while trying to get the old brain to play along, lol.

Something that occurred to me during this return process is that though I've been away from the build for months at a time, in the olden days of wind sail that span would be considered a medium duration at best. Sometimes ships and crews wouldn't return for years and along with the uncertainty of if they would return at all family and friends would simply hope for the best, and this was the normal shape of things. These kinds of thoughts kept my chin up during the hiatus, not knowing if I'd ever be able to return to the shipyard is a downer to say the least. And with that preamble out of the way ...

SHE'S BACK!

What is mercifully not easy to see in these photos is the accumulated fine dust and thin cobwebs - you can see the little brush I was using for cleaning up process. That plus a modified 'foot' pump were enough to deal with the evidence of time sitting. And the next pic is after the meticulous go-over was completed.

When last I left off the Vangs, Boom Sheets and Signal ensign had been attached, awaiting finishing touches. Months later the loose ends have been clipped and rope coils have been placed for the boom sheets.

The Main Topmast Staysail halliard had been tied off but the downhaul was hanging loose. Finally got around to tying that off.

Here the ends of the signal ensign and the starboard vang have been clipped and rope coils placed ... hard to see but this is the best my camera can do.

One of the things I discovered immediately upon the return to the threadwork was that it was easier for me to accomplish the tying off to the on-deck portions. With that, and bolstered by enthusiasm and frantic energy, I set up, ran through and tied off the halliards and downhauls for the main topgallant and royal staysails. Here are the halliards tied off at the spider band and rope coils in place. It might look inaccurate because it is, yet another instance of doing the best I can with a kit rebuild.

Finally the downhauls tied off and rope coils in place, again hard to make out clearly and I probably could have left some details, like the rope coils, out and it wouldn't have been noticeable ... but I felt compelled. That let's me know that I'm finding the groove once more

- riverboat, Wintergreen, NenadM and 4 others

-

7

7

-

I just realized that I neglected to thank everyone for their kind messages and good wishes - so an extra big Thank You to everyone for your support.

When last we left I had completed the raised work area - this opens the door to the next bit of fun which is the rest of the big re-think of the workspace. The first bit of business was to move a shelf and re-purpose it. This was done at the Admiral's insistence, she didn't want the shelf where it was anymore so this worked for both of us.

The shelves were open slat design so I laid some shelf liner to protect the wood and to close the gaps.

Next up came the installation of wall shelves but in a new position from their previous layout.

Then the installation of a small stuff shelf to the right of the work area, similar to the one I had before but a little prettier. This is for stuff like glues, thinners and other regular use small items.

Then began the process of unpacking and arranging and re-arranging. Plus assessing what I have, where it is and trying to recall th einventory and so forth.

And of course the lighting. I'm using a couple of the old lamps plus an even older lamp which I had stored away for some future purpose. The where of placement will likely evolve as well but the set up as it is seems to work pretty well.

And here we come to another stop. Along with the re-think of the set up is also a re-think of how I store and array my working tools and supplies. I realized that I was utilizing old patterns from my previous set up working off the couch in my living room. Given that I am now in a truly different situation it's time for me to change things up, from where and how I store my brushes and paints all the way to the placement of the waste bin.

One of the ways in which I took the new set up for a test drive was to disassemble, repair and reassemble a little 3 tier wooden jewelry box I had once used for paint storage and is now returned to that task. As well I am in the process of fabricating a new brush holder and figuring out where I stored all the little bits and pieces of repurposed stuff, not just rigs and jigs but basics like my toothpick container and the 2 part epoxy, lol.

So things are going well. Once I have a bit more of the basics nailed down I hope to move the Dame back to her berth and then begins the process of figuring out not only where I was in the rigging but What It All Means once more ... after this much time away from it all my brain can process looking at the Dame is, "Holy cow, lookit all them threads ...."

- NenadM, riverboat, Wintergreen and 2 others

-

5

5

-

And so it begins ... (Long Post Warning

)

)After many weeks of thought, research, mulling and otherwise I have finally begun the process of converting the workspace into a form which is suitable for my altered physical requirements. I thought about posting this in another thread but the Build Log is my chronicle of my grand nautically related adventure and this is just another part of that, after all

So - lower back issues which prevent me from long periods of sitting or contorting myself whilst sitting required that I rethink where I do the work. Research into this issue provided a deluge of info - it seems that there are a Lot of folks out there with issues as far as long term sitting goes. I won't go into the details but if anyone out there is looking into this and doesn't want to spend a few thousand dollars on a manufactured variable height desk or work bench I suggest Googling the term "IKEA Bashing" as a great place to start. Very inspirational.

Before I chose how to do this I set out my parameters and thought them through repeatedly. The primary requirement was Variable Height but I didn't dwell on issues of fine calibration or the like as these complicated things way too much. Stability is also important but how much stability was something I had to redefine as I tend towards the extreme overcompensation school of thought. Size was easy enough to determine, limited to the footprint of the desk which remains the base, so to speak. And so, armed with a rough idea I went forth and procrastinated after buying the plank, eventually getting to today, well yesterday really but also today.

The wide shot of the Before look. All previous modifications (shelves and stuff) were removed when I painted the room recently.

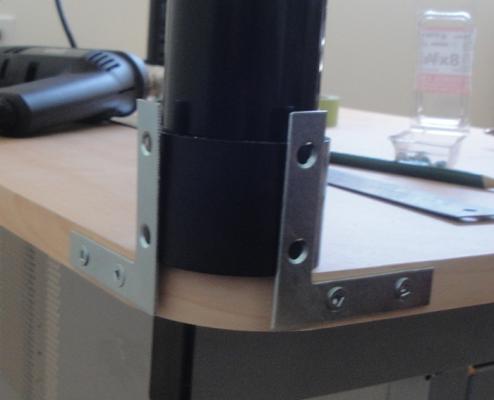

The Stuff. ABS pipes, caps and connectors for the legs (1 1/2" dia.) and a pre cut, factory sanded Pine plank that just happened to be the dimensions that I wanted for the workspace (36" x 20"), a case of lucky serendipity or something.

Drill two holes through the caps in order to affix them to the bottom of the plank.

Affix the caps thusly.

All caps affixed to corners.

The default height I had chosen was roughly 18 inches. Taking into account the thicknesses of the plank, cap and the connector which would act as the foot I cut the pipe into 16 inch lengths.

The previously mentioned connectors. Please note that one side has raised lettering on the rim so I was careful to make sure the flat side was down.

Putting it all together for view with the 18 inch metal ruler for reference, the workspace is 1/16" shy of 18" height, lol. Because plastic pipes of this nature can tend to self-weld I rubbed a bit of powdered graphite around the ends of the pipe. Next thing to do after I get things in the room set up is to get more 1 1/2" pipe and cut sets of legs at different lengths. Currently I want sets at 12 inches, 8 inches and 4 inches, but I'll wait to see what kind of height range I wind up needing.

Because the legs are wobbly from not being glued I thought to install anchor points (L brackets) on the base desk itself. This turned out to increase the stability quite a bit, though it's still wobbly both from the dry fit situation and the free fourth leg.

The rounded desk corner required 2 brackets.

For now I'm using zip tie's to secure the feet. Perhaps I'll change that up later.

And here ends the first part of the conversion. I didn't get into the sealing of the plank but that was basically 2 coats of Varathane brand water based 'Diamond Finish' in semi-gloss. I prefer water based anything if it performs well and this stuff has served me well in the past for interior application. I may put a third coat on the plank given it's intended use, or I may not.

So in summary, this isn't a 'rock steady' workspace but rather a good, sturdy surface set at a level which won't compromise my injury. It can support more weight than I am ever likely to set upon it and is large enough for the stuff I do, anything bigger would require me to go outdoors anyway, lol. Keeping the base desk as clear as possible was also important, because when I go to change the height it would not do if the workspace was covered in all sorts of loose clutter so all that stuff needs a place to go. Next up are the other modifications and resets for the zone based on the new stand up version of things.

There's still a way to go before I can finalize the last little bits of the Dame but it feels good to be rolling on the track again, finally

-

Well, months go by and I suddenly realize I've been out of the loop and have not addressed my absence ...

Basically, I managed to re-injure myself near the end of August (at work) and the resulting rounds of exams and physio have revealed that I have some issues with the L4 and L5 vertebrae (the last two at the bottom of the stack) which prevent me from sitting for any length of time. Not only does this mean 'goodbye couch' for the time being but it also demands that I rethink my workspace - call it a paradigm shift.

Well, between recovery, therapy and life I've been very distracted. The 'almost complete' Dame Tisane sits on my mantle awaiting the workspace adjustment and the issue of the changing of the space has been consuming my thoughts and such. Plus I also painted the den where I work which is a combination of 'test run' to see if I'm physically capable and also allows for a reset of the area for the rethink and so on, lol. Pretty soon now (I hope) I will be 'back in the saddle' once again and posting but for now I'm still hammering out the details of what I want to do.

The Plan is to create a raised 'deck' where I can work in a standing position. I wanted to utilize my existing desk instead of spending a whole bunch of coin on a singular useage specialty desk and try to develop it in such a way to allow flexibility in set up so that it can become a hobby/art/craft/etc. arrangement. This has proven to be tricky as there isn't a lot out there for this sort of thing. But I believe I have a solution which is simple, inexpensive and requires only moderate building to accomplish - basically build a raised deck like a short table. As this develops I will be posting photos (in case anyone else out there with similar back issues needs some ideas of their own) and with any luck I will be able to complete the rigging on the Dame before the next Winter Olympics.

So, hope to return to the dry dock soon and spend some time catching up on all that I've missed. Best wishes to everyone and Happy Building!

- popeye the sailor, hexnut and mtaylor

-

3

3

-

-

I love the New Bedford whale boat and have been trying to keep up with the various versions here. I am also thinking that this will likely be my first 'serious' wood build (after I 'train' myself on a dinghy or something similarly simple). I am looking very forward to seeing what you do with yours.

Hmm ... we might need more popcorn ...

-

John, Anya, Michael, Danny, Popeye & Mark - Thanks for your kindness and support everyone. The Issue hasn't been resolved yet but I have begun developing options and I have determined that there is a 'home' for the Dame in a worst case scenario that the original intended recipients cannot take her. So, still some loose threads but not nearly as many, or as entangled, as I had first encountered.

Will - Popeye's suggestion is the best and simplest but if that fails then my suggestion would be to scratch build what you need. If you go through the Dame's Build Log you will see that I have done that with the windlass pump and many of the stanchion posts ... along with too many other parts to remember. The thought of scratch building might 'seem' intimidating but once you try and fail and try again and succeed it becomes clear that it's not so much 'talent' as practice that matters in such things. And always keep in mind when you're scratch building that the point is Not to get it right the first time but simply to eventually get it right, or as Dory says in Finding Nemo, "Just keep swimming."

Well I'm back at it after yet another hiatus. The stoppage was partially due to my realization that I kind of pushed myself to get started again (my back is still recovering, much better now but there are those minor issues which keep cropping up). This impatience led to the snapping of the bowsprit and so I stepped back and let myself, and the Dame, heal and rest some more. Then, once I felt ready to get back at 'er, Life threw me curve balls in the form of unseasonably hot weather, changes in the work I do at work in the heat, the opportunity to paint the interior of our place and so forth. But today I got back to it in a small way, just a taste in order to dip my toes. And speaking of 'so forth' I thought I'd start this photo posting off with an image of one of the distractions ...

For anyone interested the band is Rush and the song they are playing is Caravan.

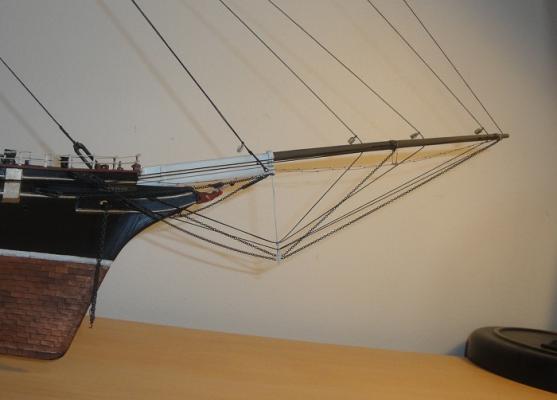

And now here we have the repaired bowsprit - and I just noticed my photo has that weird 'bending' thing where it looks like the bowsprit is bent but rest assured that to the eye is looks straight.

Here I finally attach the upper 'rail' along the aft posts, or stanchions.

And now I can finally 'tie off' the ensign halliards, vangs and sheets for the Spanker set up. In order to prevent 'bowing' as I was using nylon line for the rail I stiffened the portions where the ties were going with dabs of 'super thin' CA.

And ending with a top down view, I was trying to show off the symmetry but I could not get the correct camera angle for that effect, so this image is slightly 'oblique' as they say.

Now onto the remaining fore and aft rigging and after that the braces ... the sense of impending completion is starting to make me grin randomly. Back soon with more - I promise

-

Popeye, John, Anja, Marc and Mark (I hope I got that right) - Thanks for the kind words, humour and support - it did turn out ok, but ...

... after an unexpected hiatus due to 'Everything Else Besides Model Ship Building' popping up I thought I'd drop a quick post to let everyone know I'm not in hiding or abandoning the Dame ... I'm just busy and the odd bits of spare time I have seem to occur when I can't see straight from fatigue - not the best time to get into rigging, lol.

This is also why I haven't been lurking as much - I'd like to comment more on other threads but the mental fatigue also takes a toll. I'd rather not 'say' anything instead of babbling incoherently (which is a change from my younger days, for sure, lol).

But the itch is there and she sits patiently.

However, for those who have been following this saga I have some troubling developments as to her eventual home. The tea shop (and owners) to whom I was going to give the 'cased' Dame as a gift have been doing very well for themselves, so much so that their store is now quite crowded and all available space has been committed to their business. There are fewer and fewer 'decorative' zones and even those are shrinking. I'm not about to ask them to sacrifice valuable space in order to display a purely decorative item.

Hopefully there will be a way for me to get the Dame to the owners, if not in their store then in their home, but a casual conversation revealed that they are in the process of 'clearing house' themselves (think; decades of collecting stuff from their travels) ... and so the fate of the Dame is now kind of 'in limbo.' It's sad to consider at this point but it seems likely that I may not be able to fulfill my original intent

And there is nowhere I can 'display' it in my own home, lol. One of my old email signatures comes to mind (I got it off a t-shirt), "This would be funny if it weren't happening to me."

Anyway - as further developments arise I will of course make more posts. Hopefully of the build, with photos

-

John - thanks for the info yet again

Popeye - Thanks for the kind words of warning ... I wish I had been paying closer attention because ...

Popeye - Thanks for the kind words of warning ... I wish I had been paying closer attention because ...Nautical Disaster Time

I have been very fortunate in that I have not had to report much in the way of 'oops' factor as far as breakages during this build. That all changed today, though.

But before I get into that there are a few more photos of business as usual, starting with the 'fixed tensioning' of the Spanker gaff vangs. To do this I simply attach little clips with enough mass to pull on the lines without too much force, then I 'lock' things into place by dabbing a bit of diluted PVA on the line where it passes through the blocks. This way when I tie off the ends to the rails they won't 'pull' as much.

The Spencer gaff outhaul line being put in place.

Applying the 'fixed tension' method to the Spanker boom sheets.

Emplacing the lower 'rail' along the posts using white nylon line - same as fore and the little details on deck. If I had this to do over again I would have likely made the posts and rails out of brass wire ... next time ...

So there I was, carefully turning the ship to cut the loose ends of the lower rail when suddenly I hard a pop and the next thing I knew ...

I'm still not really sure what happened exactly, but after a five to ten minute hiatus while I tried to slow my heart rate to under 200 bpm I went back and assessed the damage. Luckily the only broken part was the bowsprit boom where it seats. So I carefully untangled the lines and chains, straightened out the one cathead whisker which got bent and reset the whole affair. This photo I took right after the dry fit ... before I glued it back into place.

So I can report that I might have to tweak a forestay to regain the 'tensioned' look but my 'zero tension' rigging proved to be advantageous in this case. If this has been a more sturdy model with more tension on the lines I doubt I'd have been able to just slip it back into place as I did. After some careful re-alignment I used 'super thin' CA applied with a sharpened toothpick to the crack and it seems to be holding just fine. Once I did that I walked out of the room and kept my distance - Superstitious me takes this sort of thing as an omen and besides, I'm still getting over the adrenaline hit several hours later. Best to leave it for now, give it a day or two, then get back to it ... MUCH more carefully, lol.

-

Pardon me for falling into my youth but ... Dude! That is SO COOL!

Keep listening to the little voices in your head - they make take you down unplanned avenues but from what you've shown us, the detour is well worth the effort!

-

Are you thinking about a Rotary Saw-type drill bit? These kind of look like regular drill bits but are made out of harder metal to allow sideways cutting instead of just 'in line' drilling.

I believe Dremel actually has a range of these bits - a friend of mine used his Dremel to cut straight lines through wall tile using what looked like a thick drill bit. But they're probably way more expensive and might not be available in the size you need.

And failing this, have you considered doing it by hand? It's slower but there a lot more control over the situation, carving wise.

Good luck with finding what you need

-

Arrrgh, just wrote a bunch of stuff and lost it with an accidental 'page back' hit ... time to start previewing at the end of each sentence, lol.

Ok, let's try this again. What I have discovered in my limited experience with waxing lines for rigging is as follows;

Thicker lines - best if the wax is melted into it as the run through method won't infuse the 'core' of the line with wax, thus the 'stiffening effect' won't be as pronounced. By melting the wax into the core of the line (and squeeging the excess as much as possible) it becomes 'stiffer' so that you can achieve the 'taut line' effect without having to put a lot of tension on the line.

Thin lines - work well with the run through method. You can also use the melted wax method but here is where getting rid of the excess becomes more important as thin lines show the excess more (flakiness, lumps, etc.). One technique I borrowed from Batik is to have an iron set to low and a bunch of newsprint sheets. Run the line between newsprint sheets under the iron, the weight of the iron should be enough to squeeze excess meltwax from the line and it soaks into the newsprint to prevent it from 'reapplying' itself to the line.

Synthetic lines - I've used both methods on nylon lines and found that the same principles apply, the thicker the line the better to use the meltwax method. Another thing I did with the thin lines to 'seal' the wax was run the waxed line through a cloth pad but I applied more force and ran it fast to generate friction heat.

The type of wax is important too. I avoid Parrafin wax (basic candle wax) because it has a low melt point, is very 'grainy' when cooled and is usually mixed in huge industrial vats with all kinds of chemicals added. Often with cheap Parrafin you're find a high glycerin content or the traces of perfumes from a previous batch.

Beeswax is my preferred fave because of it's 'natural' origins (not Organic, if anyone tries to sell you 'Organic' honey or beeswax at a marked up price laugh at them ... bees don't create 'organic' stuff by definition). Beeswax also has a higher melting temperature and is finely grained, which makes it more supple when cool. Plus it smells good (aromatherapy) and it has a nice colour which tints white lines ever so slightly.

Microcrystalline wax (a.k.a. Jeweller's wax) is also a preferred one for me. It comes in white or dark blue - Don't use the dark blue stuff as it is formulated for sculpting jewellery 'castings'. Microcrystalline wax has a high melting point, is (as the name implies) very fine grained and it's supple when cool, like beeswax. This kind of wax is often used in very fine Batik work.

So to summarize, I used both methods and found them to be good - once I figured out the specifics.

Hope this is of some help.

- lamarvalley, egkb and Dida

-

3

3

-

Hey Borge, just checked in and learned of your elbow issue. I'm just getting back into the swing of it myself (lower back problem) so not only can I sympathize but I can also support

Take care and take it easy - this is one of those things that requires patience but it does pay off in the end! You'll be back at it before you know it

-

John - Thanks for that tidbit about the jib and staysail sheets. I'd been wondering about them and in the back of my mind there was some commotion as I'd probably gotten this information previously (from you most likely) and forgotten it in the process. Any rate, a few less details to worry about ..

And so we continue with rigging - this first shot is the uphaul and downhaul for the mizzen Topmast Staysail, with the 'thimbles' tied together and run down close to the mainmast.

Heres the Spanker gaff and boom with the outhauls led back in as if there were inhauls in place.

The uphaul and downhaul for the mizzen Topgallant Staysail rigged the same as the Topmast Staysail.

The Spencer gaff vangs in place.

The Spanker boom sheets in place - awaiting the 'rails' for the ends to tie off to.

The Spanker gaff vangs in place - also awaiting the rails to tie off to.

The mizzen mast spider band getting crowded.

And a couple of questions for perusal ... in the case of the Spanker boon there is a cleat which is utilized for tying off the inhaul and outhaul lines but I am unsure as to the method of stowing the extra line there. This same question is on my mind for the extra line from the Spanker boom sheets and gaff vangs - as these are tied off to the rails how would the excess be stowed?

At this pace I hope to tie on the 'rails' on the rear stanchions over the weekend and maybe get started on the rigging lines for the Main staysails ... but I am also trying very hard to avoid stressing out my almost-but-not-quite healed back so I'll have to see how it goes

-

... you'll no doubt have to modify the rigging a bit to fit in with the confines of the kit structure ...

Oh how true this is, lol. After some consideration my old reflexes are slowly dusting themselves off ... namely, figuring out how to 'cheat, fake and deceive' my way through the rigging in situations like this.

I'll have some questions about how to deal with jib sheets in a bit ... but as these questions are still quarks firing off randomly in a fog of proto-mnemonic potentials I'll hold off for now.

As it stands, I have decided to simply 'run back' the existing outhauls on the Spanker gaff and boom to mimic the effect of tying the ends to the inhauls as would be the case if the inhauls were actually there. Same with the Spencer gaff as well. I'm not going to try and work in the necessary hardware to properly rig the inhauls and sundry at this late stage - that's just a way for me to invite Disaster and his sister, Calamity, over for dinner

Having further reviewed the rigging of the jib sails I can tell that a lot more compromising is ahead ... but that can wait until I run face first into the issue.

By the way, thanks again for the help. It is definitely helping me navigate my way through this

-

John - thanks for the promptness of your reply

*Discussion* - having re-re-re-reviewed Underhill's Masting and Rigging and the kit instructions I have determined that (to the best of my knowledge) there are only outhauls accounted for in the kit. Thus my incorrect references to upper and lower sheets should actually read head and foot outhauls. The boom sheets are present and accounted for in the build.

Having established that, the Inhauls, brails, and guys aren't accounted for with the Spanker set up. Underhill's book makes no detailed mention of the Spencer at all. And you would not believe the kind of stuff the 'Net threw at me when I googled Spanker

Anyway ... I'll break this down into segments. The following deals with the kit situation.

The Spanker set up as per the kit and instructions accounts for the standing rigging as you described, I think they're called the peak span and boom topping span. There is also a line tied to the gaff a bit inward from the signal halliard block - this line passes through a block attached at the mast cap and down the mast to be belayed on the mizzen mast spider band. I tried looking this up but I can't find a clear reference for it - possibly a kit inaccuracy.

The running rigging consists of a head outhaul, a foot outhaul, boom sheets, vangs and an ensign halliard.

The head outhaul passes through a sheave at the end of the gaff, passes down to a block affixed to the base of the gaff and from there goes down and belays on the mizzen mast spider band.

The foot outhaul passes through a sheave at the end of the boom, but instead of running to a block it is tied off at the 'boom cleat' near the base of the boom.

The boom sheets consists of a line tied to a single block which is itself attached to the boom, run through a block attached to the deck, back once more, through and tied to the rail.

The vangs are similar to the boom sheets, line tied to a block on the end of the vang pendant, down to deck, through block, back to pendant block, through and then down and tied to rail.

The ensign halliard is simply a line tied to the rail at both ends, passing through a single block affixed to the gaff.

So - as much of the running rigging has been omitted in the kit is there a 'proper' way I can set up the head and foot outhauls to at least appear 'proper' for a no-sails situation or is this a case of having to creatively disguise it? The option of going back and trying to incorporate the missing aspects is a bit daunting to say the least.

The Spencer gaff does not appear to have standing rigging. As previously mentioned the line which seems to act in that fashion runs through a block attached to the mast top, from there down where it belays at the fife rail just forward of the main mast.

As far as running rigging goes, the Spencer also has only an outhaul which passes through a sheave at the end of the gaff, through a single block attached at the base of the gaff and down to belay at the spider band.

The vangs are similar to the Spanker vangs, except that the blocks on deck are tied to pins instead of ringbolts and the line belays to a pin instead of being tied to a rail.

I guess the question here is similar, what to do with the loose end of the outhaul for the no sails set up.

And having processed all this into a form fit for public communication I can confidently state that I have likely broken my brain, lol.

Any suggestions and/or advice would be, as always, greatly appreciated.

-

John & Danny - Thanks for your kind words

And ... yeah, there's a Lot more to do, lol.

And ... yeah, there's a Lot more to do, lol.But not as much as it would be if it were not for the fact that I am choosing to omit much of the rigging in favour of my own lack of experience and (secondly) the kit limitations.

Speaking of rigging ... here we go with the next steps. At this point I am a bit at sea as the level of detailed information available in Underhill's tome is not as comprehensive for the Spanker and Spencer assemblies. What information there is has given me enough to go forth ... albeit with a lack of specifics but what is one to do. And given that, any and all technical inaccuracies henceforth are due to my inexperience.

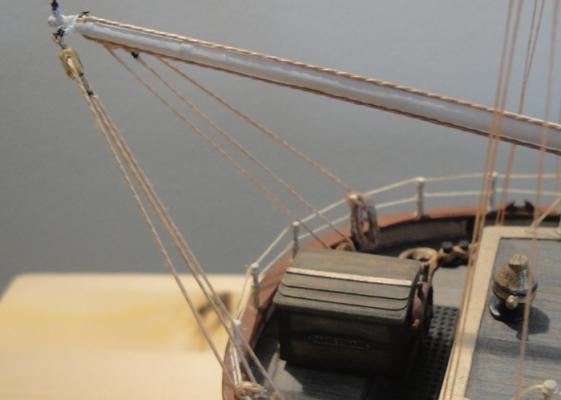

Spanker boom and gaff in place. Vang pendants and the lower sheet in place.

Spencer boom in place. Vang pendants at the ready as well.

Block for the Spencer vangs in place - this wasn't easy but old reflexes can be restored given patience ... lots of patience, lol.

Underhill was not clear as to if these are Lifts or Spans ... regardless, he does mention they are made of steel cable and I happened to have some thin black nylon of a slightly smaller gauge than the upper stays so the scale is maintained.

Spencer boom lift or span - here I am guessing that it is made from rope as it is passed through a block and down to a fife rail to be belayed.

And for the Spanker I think this would qualify as a lift - tied around the gaff, passed through a block to the spider band about the mizzenmast. I considered affixing another ring bolt but I've been trying to leave bits of the kit origin visible here and there.

And the Sheets for the Spanker - I tied 'eyes' into the ends (like 'thimbles' I hope) and then used guesswork and intuitive thought to run them to where I think they'd go when the sails were removed. So the 'upper' sheet runs through the sheave at the end of the gaff and back, the 'lower' sheet is attached at the 'thimbles' and the pair are tied loosely at the block. This is probably wrong so I'm not going to finalize yet ...

If anyone knows if this is approximate to reality or if I have it wrong I'd appreciate being informed as I have been unable to find definitive information on this aspect.

Back to rigging for this landsman and it feels good ... and confusing

-

A thought that occurred to me after I posted was that you should also determine how your copper was weathered in terms of 'dry' or 'wet.'

If it weathered in water then it will be black or dark grey. If it weathered in air (like in dry dock) then you will get the green patina look.

Copper does not 'go green' in water.

Best of luck with this and remember that 'the good stuff' takes longer but is ultimately worth it

Thread Sizes - Where to buy? - moved and retitled by moderator

in Masting, rigging and sails

Posted

When I was searching for threads of various sizes I had good luck at jewellery/craft stores - not pre-made jewellery but the 'make your own' places. They are also called Bead Shops as well. Couldn't always find the correct colour but that just meant some home modification.

Hope this is of some help.