Bill Hudson

Members-

Posts

146 -

Joined

-

Last visited

About Bill Hudson

- Birthday 01/21/1932

Profile Information

-

Gender

Male

Recent Profile Visitors

-

mtaylor reacted to a post in a topic:

Position at BlueJacket available

mtaylor reacted to a post in a topic:

Position at BlueJacket available

-

ferretmary1 reacted to a post in a topic:

Position at BlueJacket available

ferretmary1 reacted to a post in a topic:

Position at BlueJacket available

-

davyboy reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

davyboy reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

GrandpaPhil reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

GrandpaPhil reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

mtaylor reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

mtaylor reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

John Fox III reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

A break away from the ship momently. Trying to airbrush has been a problem. Only had a very noisy compressor out in the garage. It is not at all compatible in my little shop off the dining room. I looked on the internet and found several about 4"x4"I was reluctant to order from the unknown source but discovered a similar on in the Micro-Mark catalog that is rated at 25psi. . I ordered it but the hose connections do not fit my Passche airbrush. I contacted the MM tech department and got Dave. He sent me an adapter free of charge which works. Has a nice flow of air although I haven't tried any paint through it.

-

Making lifeboat small mast for 1:200 Yamato

Bill Hudson replied to Olaf's topic in Metal Work, Soldering and Metal Fittings

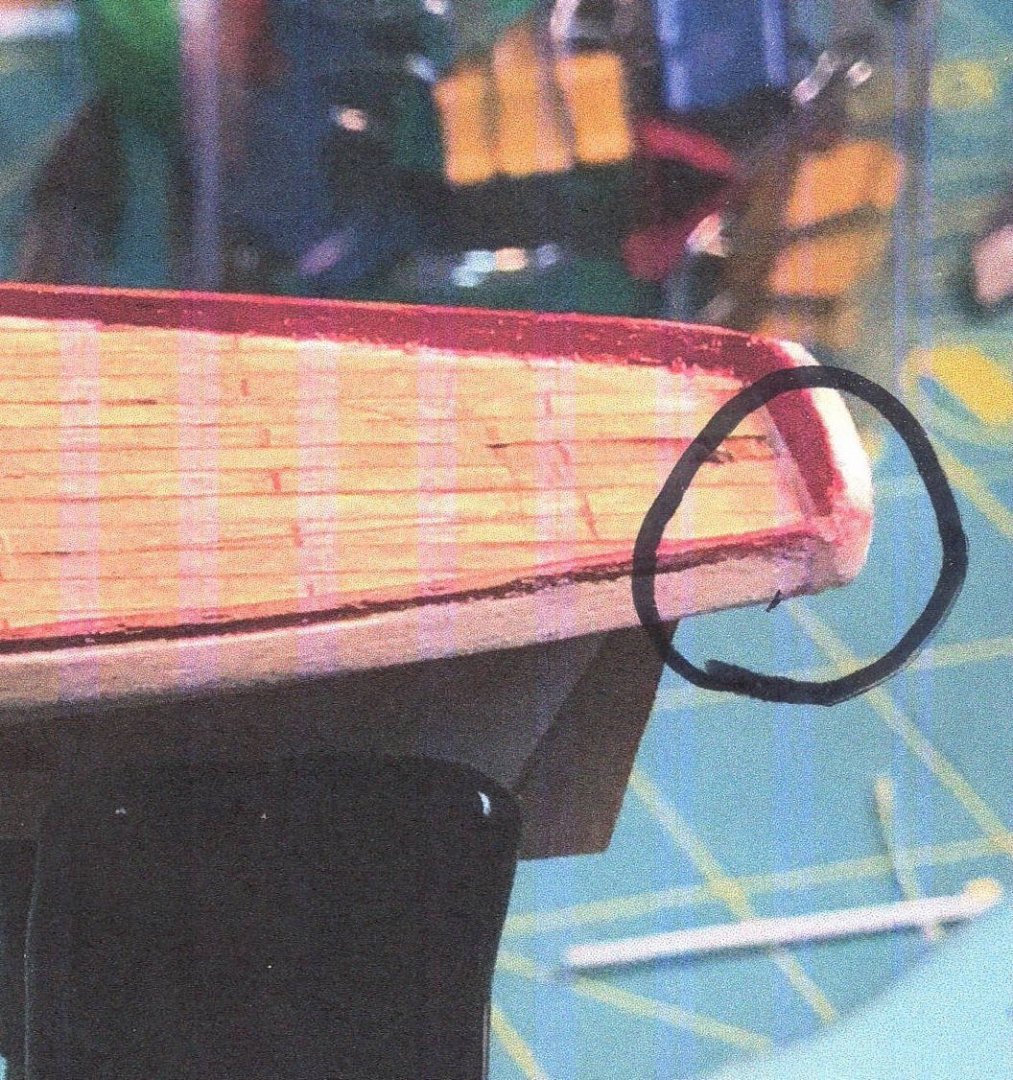

Still at it. Progress slow yet. This time I added walnut gunnel trim. Nothing like photos to show the screwups. Eventually it will clean up nicely. Looking ahead; what do I do for blocks? I have not calculated it out but at best guess 1/16" diameter on average. Same for cannon balls. Probably next stepwise to primer the hull to protect it from damage. Bill -

Making lifeboat small mast for 1:200 Yamato

Bill Hudson replied to Olaf's topic in Metal Work, Soldering and Metal Fittings

I use >020 brass wire in a spool. Unwind the length you need and clamp one end in a vise and pull the pull the other end with pliers stretching it out some. It will straighten and harden the wire at the same time. Bill -

Still going. Thank you all for the feedback and suggestions for hull and painting. Despite the setbacks of age and tremors I have decided not to give up just because my work now is not any near what it used to be. Ths model keeps my active an d helps me mentally. I have built a hatch. I used fine strips painted black on sides as I would for decking. Nothing like photograph to shoe you al the flaws however I think that once i finish with ll the deck furniture I can give it final primer and fine sanding. Thank you ll for your indulgence and good feed back. Bill

-

Bill Hudson reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

Bill Hudson reacted to a post in a topic:

Mini Revenue Cutter 1829 by Bill Hudson

-

Mini self contained airbrush

Bill Hudson replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

I ran across an add where one was used to decorate a cake. It looked easy, no contortions of fingers. Was somewhat noisy though. I was watching a U tube segment when it came up as An add. -

Mini self contained airbrush

Bill Hudson replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

Yes I have. I have found them not to be a dependable source for airbrush as the pressure is not constant even with a regulator. I have used Co2 with a regulator for years but found it damages the ozone layer. -

Mini self contained airbrush

Bill Hudson replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

Bob I agree with you about being awkward to hold and operate. Best I can tell is that you would need to hold the brush at 45º or so sideways in your hand to put the finger in a position to operate the trigger. Sorry about your peripheral neuropathy. I have been fighting that for many years and at times I have thought of using it as an excuse to quit modeling. But modeling is so much a part of me that I can't give it up even though I am now pushing 92 years of age. Hang in there and keep your mind on the project rather the pain. You can do it. As for the self contained airbrush I can not see ant advantage. I do not have room in my tiny studio for a noisy compressor and air brush but there are some very small compressors for limited use time. Presently I am using CO2. Not the best environmentally. -

Mini self contained airbrush

Bill Hudson replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

I only posted this to see if any one has used one. There are several type of similar design. Several have onboard compressors. As far as precision is concerned; there are many people out there who can do some of the finest work with crude equipment. It is all about the talent. -

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.