Boatsinc2000

NRG Member-

Posts

108 -

Joined

-

Last visited

About Boatsinc2000

Profile Information

-

Gender

Not Telling

-

Location

Phoenix, Arizona

Recent Profile Visitors

-

Boatsinc2000 started following Boxwood Pricing , A downsizing sale - ALL ITEMS SOLD , HMS Winchelsea 1764 by glbarlow - 1:48 and 5 others

-

dvm27 reacted to a post in a topic:

Swan Masting Package 1:48

dvm27 reacted to a post in a topic:

Swan Masting Package 1:48

-

Saburo reacted to a post in a topic:

Swan Masting Package 1:48

Saburo reacted to a post in a topic:

Swan Masting Package 1:48

-

uss frolick reacted to a post in a topic:

Euryalus Framing Package 1:48

uss frolick reacted to a post in a topic:

Euryalus Framing Package 1:48

-

Canute reacted to a post in a topic:

Granado 1742 by DocBlake - FINISHED - 1:32 Scale - Bomb Vessel Cross-Section

Canute reacted to a post in a topic:

Granado 1742 by DocBlake - FINISHED - 1:32 Scale - Bomb Vessel Cross-Section

-

Boatsinc2000 reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - 1:48

Boatsinc2000 reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - 1:48

-

Boatsinc2000 reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - 1:48

Boatsinc2000 reacted to a post in a topic:

HMS Winchelsea 1764 by Trussben - 1:48

-

Boatsinc2000 reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

Boatsinc2000 reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

-

Boatsinc2000 reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

Boatsinc2000 reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

-

Boatsinc2000 reacted to a post in a topic:

USF Essex by Cookster - 1:48, 1814 Configuration, POB and POF (first scratchbuild)

Boatsinc2000 reacted to a post in a topic:

USF Essex by Cookster - 1:48, 1814 Configuration, POB and POF (first scratchbuild)

-

Boatsinc2000 reacted to a post in a topic:

USS Constitution by Boatsinc2000 (Jeff Hayes) - Model Shipways MS2040 + Hunt Practicum - 1:76 scale

Boatsinc2000 reacted to a post in a topic:

USS Constitution by Boatsinc2000 (Jeff Hayes) - Model Shipways MS2040 + Hunt Practicum - 1:76 scale

-

Boatsinc2000 reacted to a post in a topic:

USS Constitution by Boatsinc2000 (Jeff Hayes) - Model Shipways MS2040 + Hunt Practicum - 1:76 scale

Boatsinc2000 reacted to a post in a topic:

USS Constitution by Boatsinc2000 (Jeff Hayes) - Model Shipways MS2040 + Hunt Practicum - 1:76 scale

-

Boatsinc2000 reacted to a post in a topic:

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

Boatsinc2000 reacted to a post in a topic:

USS Constitution by JSGerson - Model Shipways Kit No. MS2040

-

Boatsinc2000 reacted to a post in a topic:

HM Cutter Cheerful 1806 by niwotwill - Syren Ship Model Company - scale 1:48

Boatsinc2000 reacted to a post in a topic:

HM Cutter Cheerful 1806 by niwotwill - Syren Ship Model Company - scale 1:48

-

Boatsinc2000 reacted to a post in a topic:

HM Cutter Cheerful 1806 by niwotwill - Syren Ship Model Company - scale 1:48

Boatsinc2000 reacted to a post in a topic:

HM Cutter Cheerful 1806 by niwotwill - Syren Ship Model Company - scale 1:48

-

Jon, I like the way that you setup your Dremel. I've struggled with the same issues making scrapers, but your setup gave me some ideas. Have same Dremel stand and XY table that I may be able to adapt. After a couple of those discs exploded I stopped trying and bought the AL scrapers but it's really limited.

-

Sorry if my comment came across poorly. You got a good deal. I was lamenting that I offered carving blocks for a long time and I don't believe that I ever sold one. Probably will regret getting rid of most of them. In those days not many builders had the tools that they have today nor the interest in carving. As to the question on Castello, the other boxwoods are smaller bush like trees and rarely produce pieces this large. Think 1-2" branches and its very expensive. Castello, which is not a true boxwood, comes in large boards typically 2"+ thick and 4-7" wide x 4-8 feet long. Castello comes from S. America. English boxwood is a little more yellow, but some of Gregory's pieces have excellent yellow color. Some of the color patterns are very typical of Castello, but that's the lesser distinctive feature. Castello makes an excellent modeling wood. I sold more Castello than all other woods combined.

-

Here are the details from the Swan Masting package based upon David & Greg's plans. Sorry, but the only format that I have for the dimensions is an excel spreadsheet. Hope that works for anyone who has an interest. Enjoy Swan Masting Package Insert.pdf HobbyMill Swan Masting Package Parts List.pdf Swan Class Masting Package List.xls Good Luck!

-

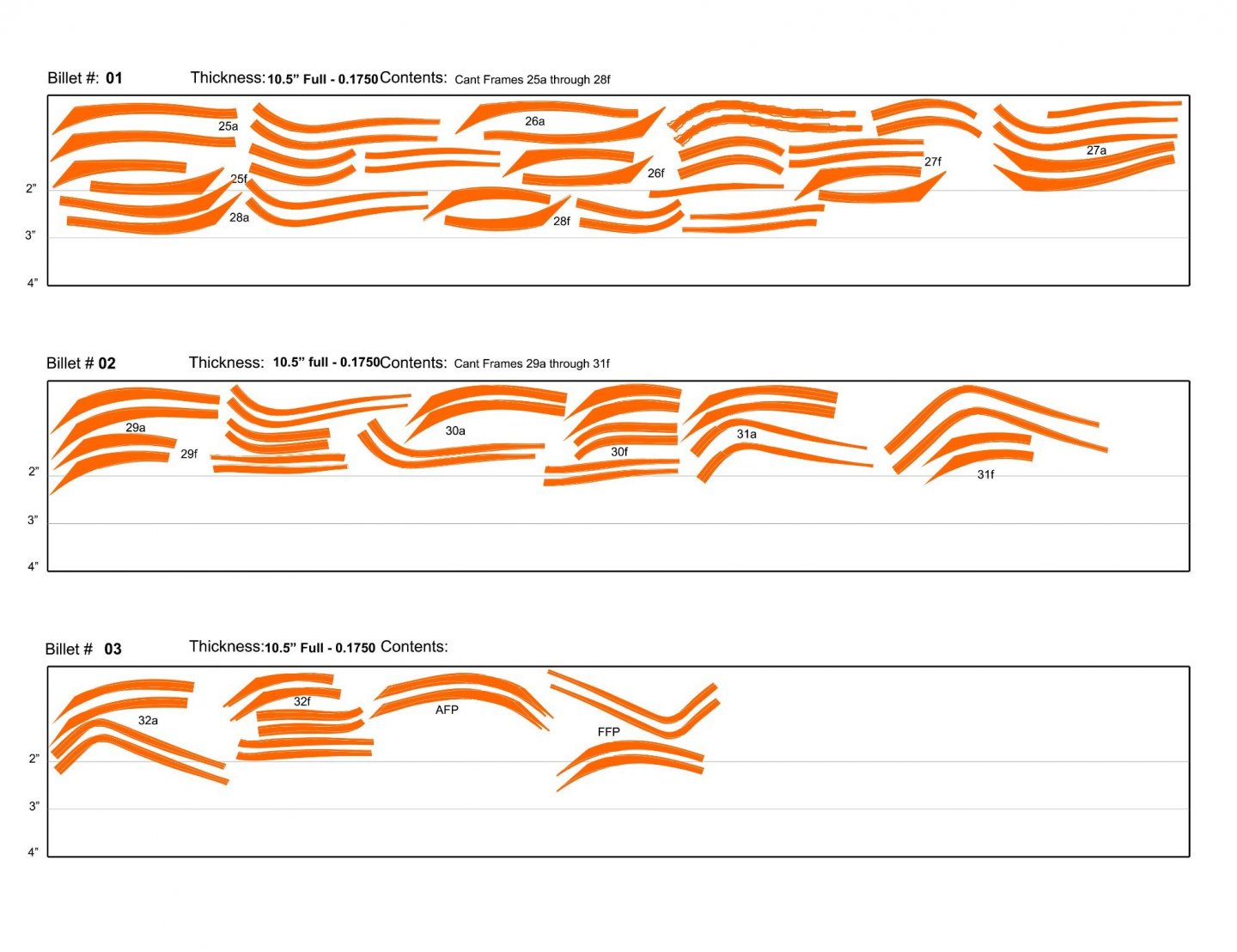

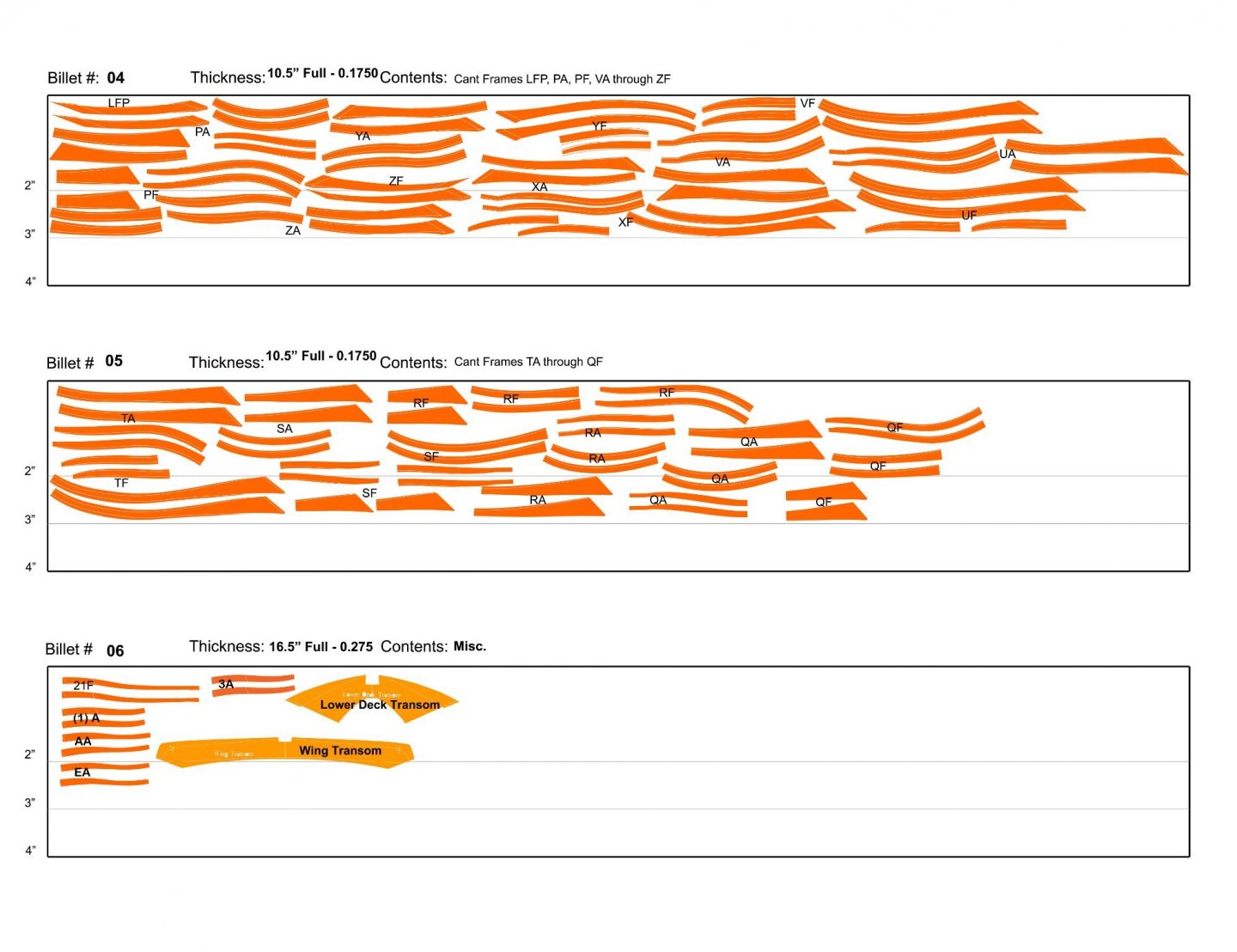

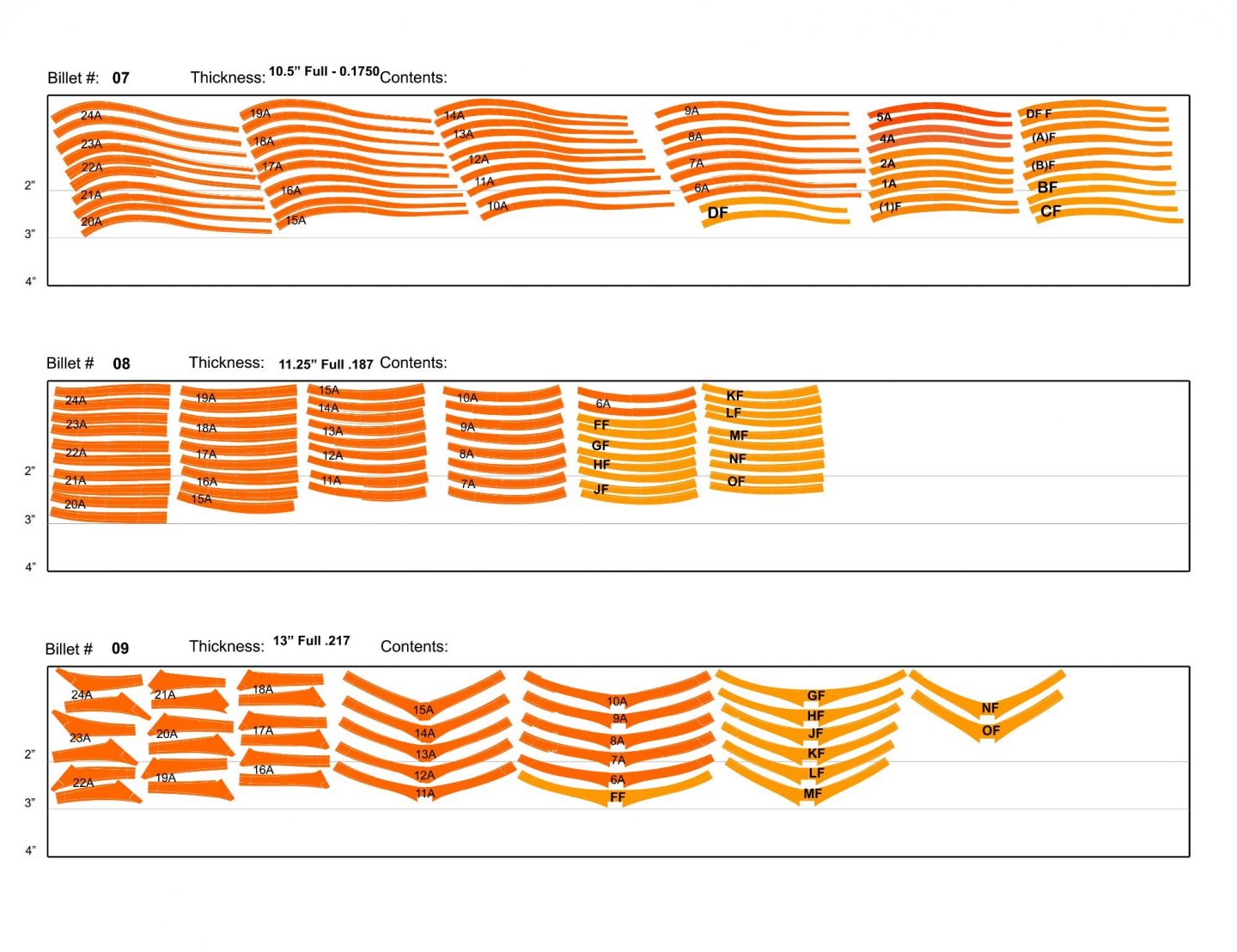

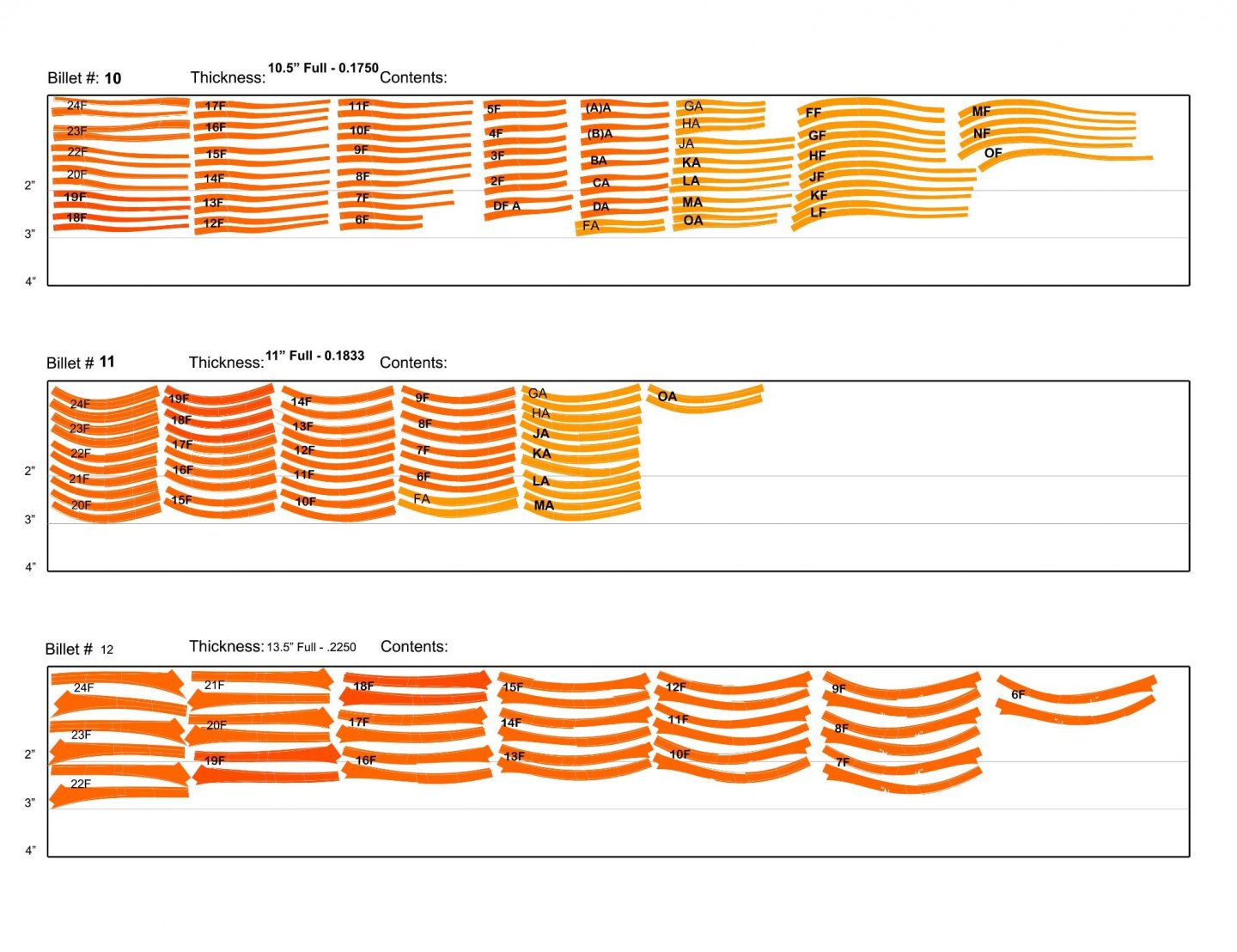

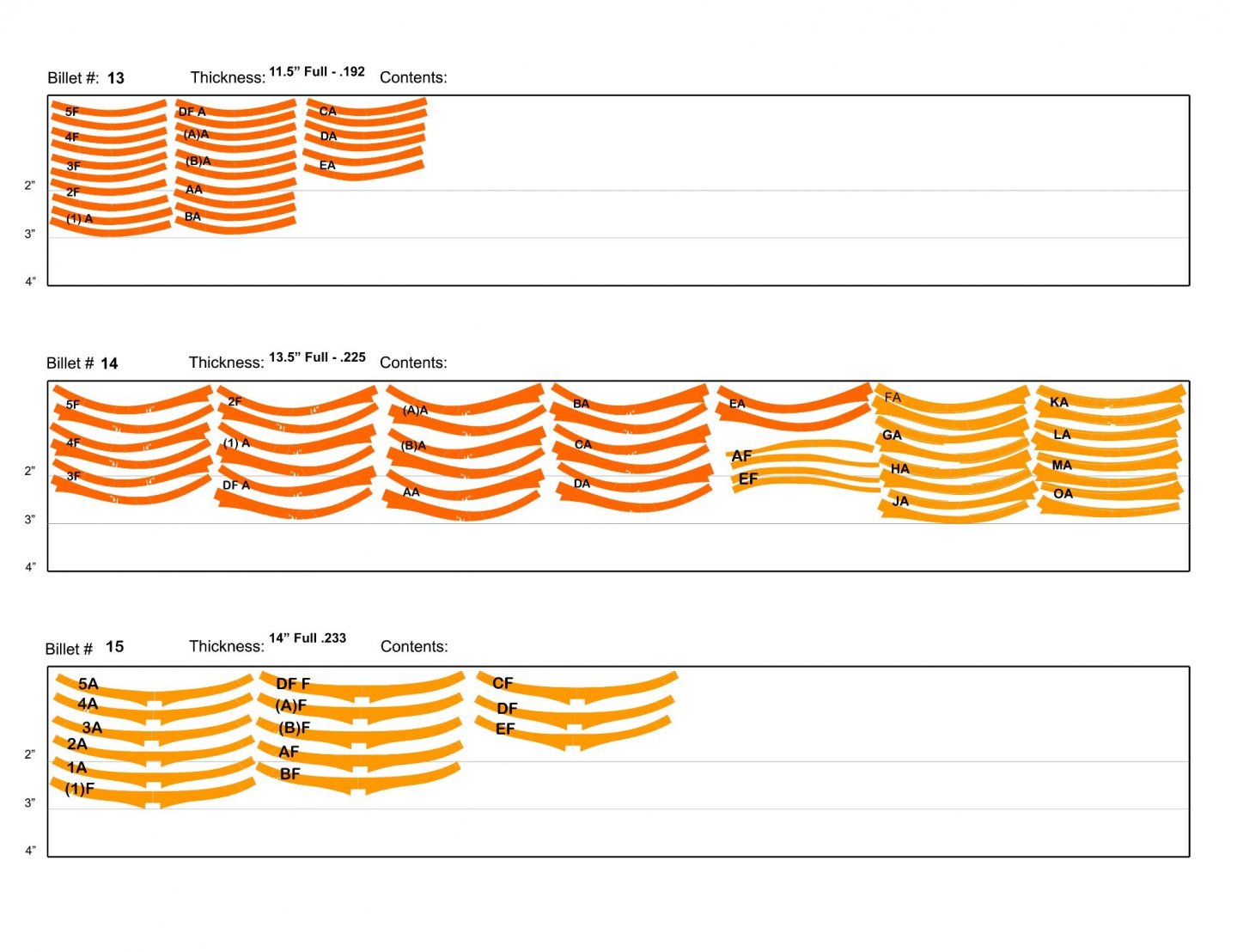

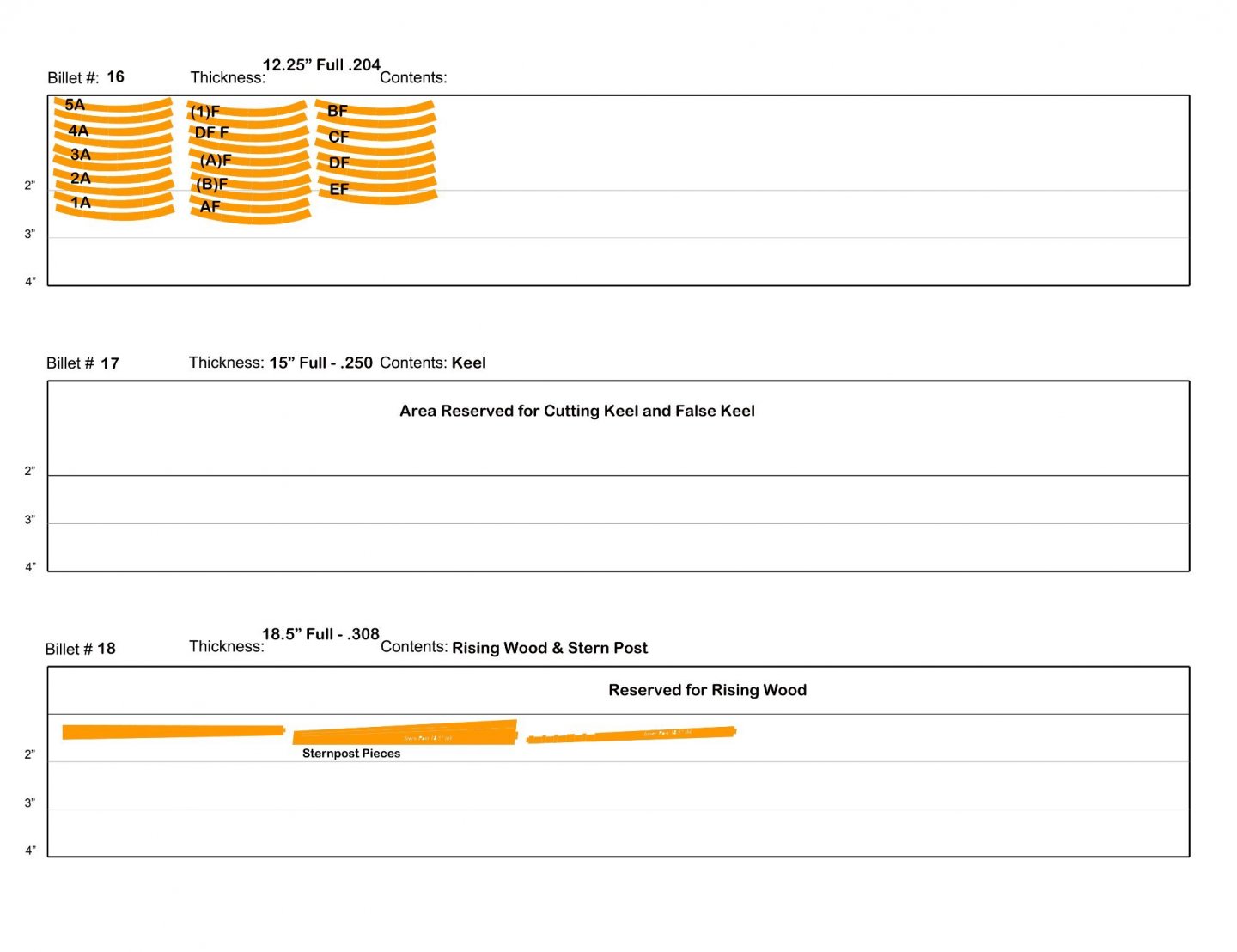

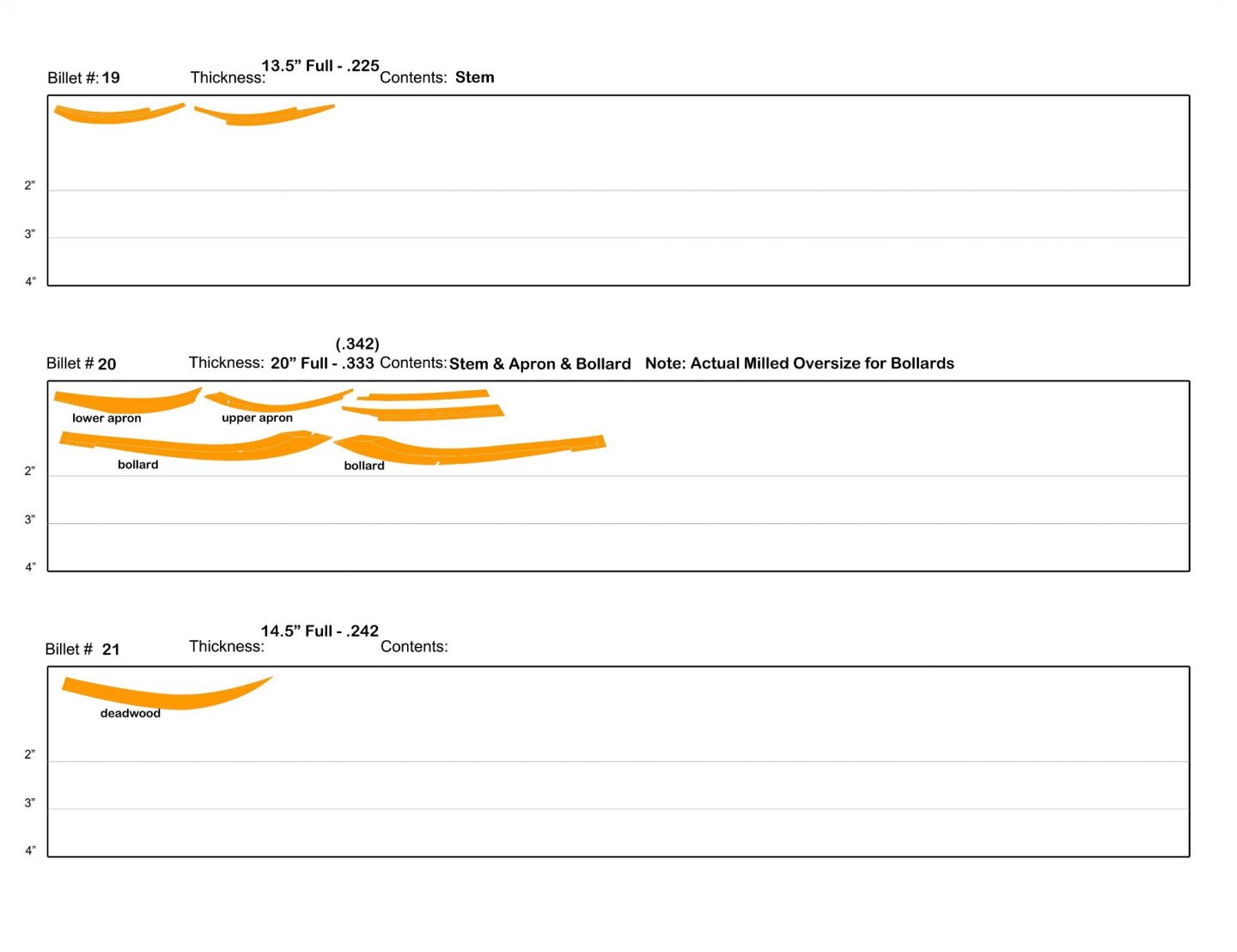

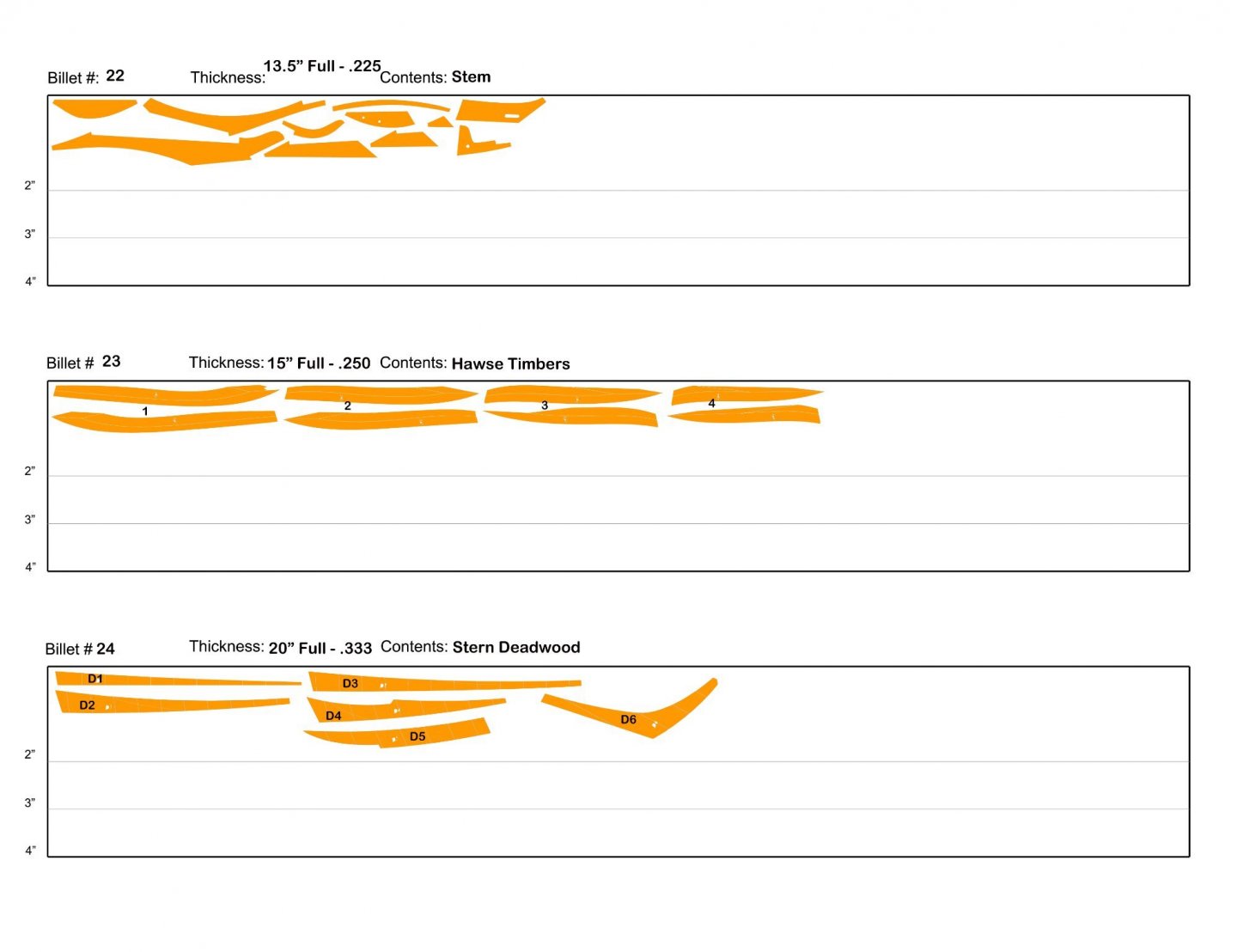

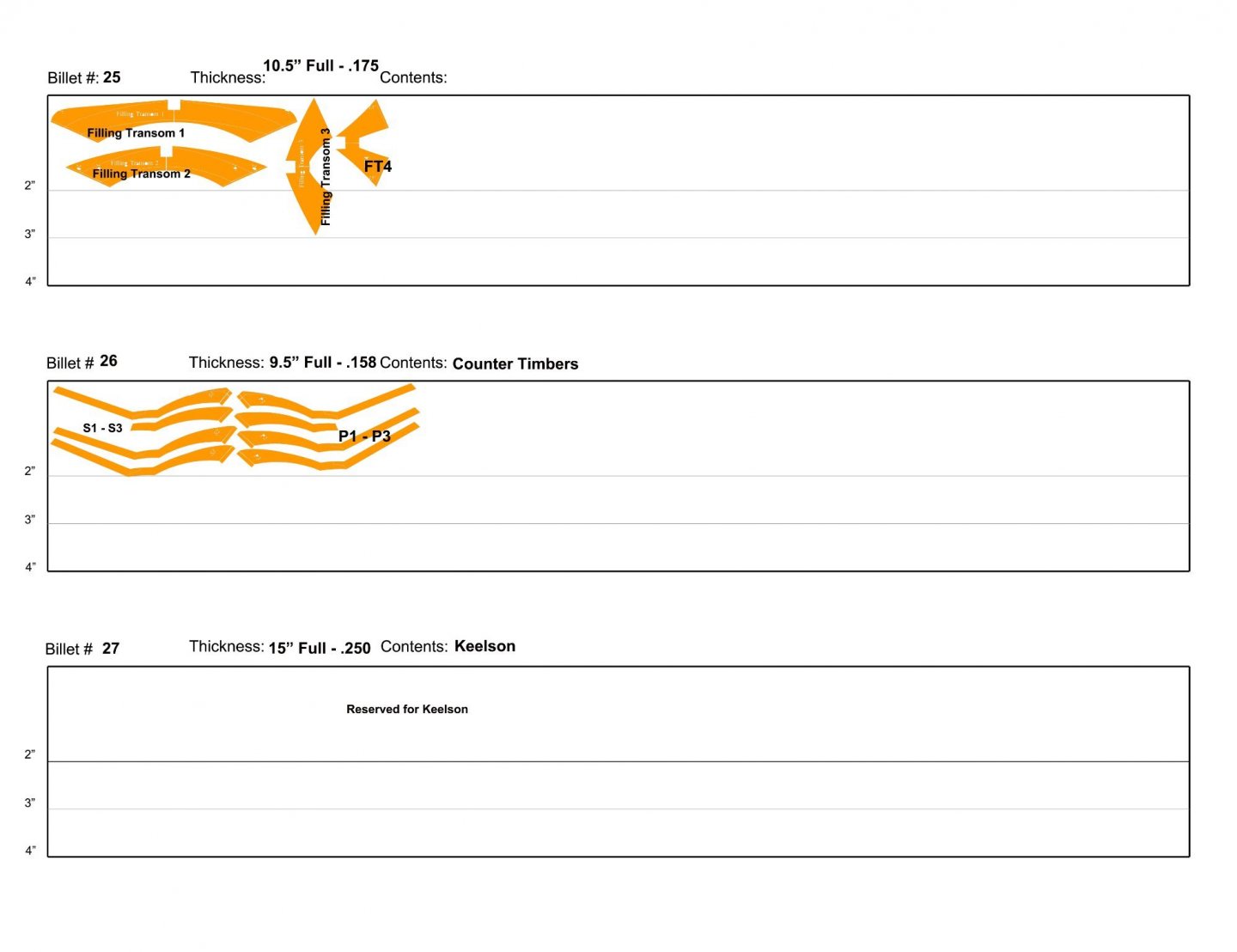

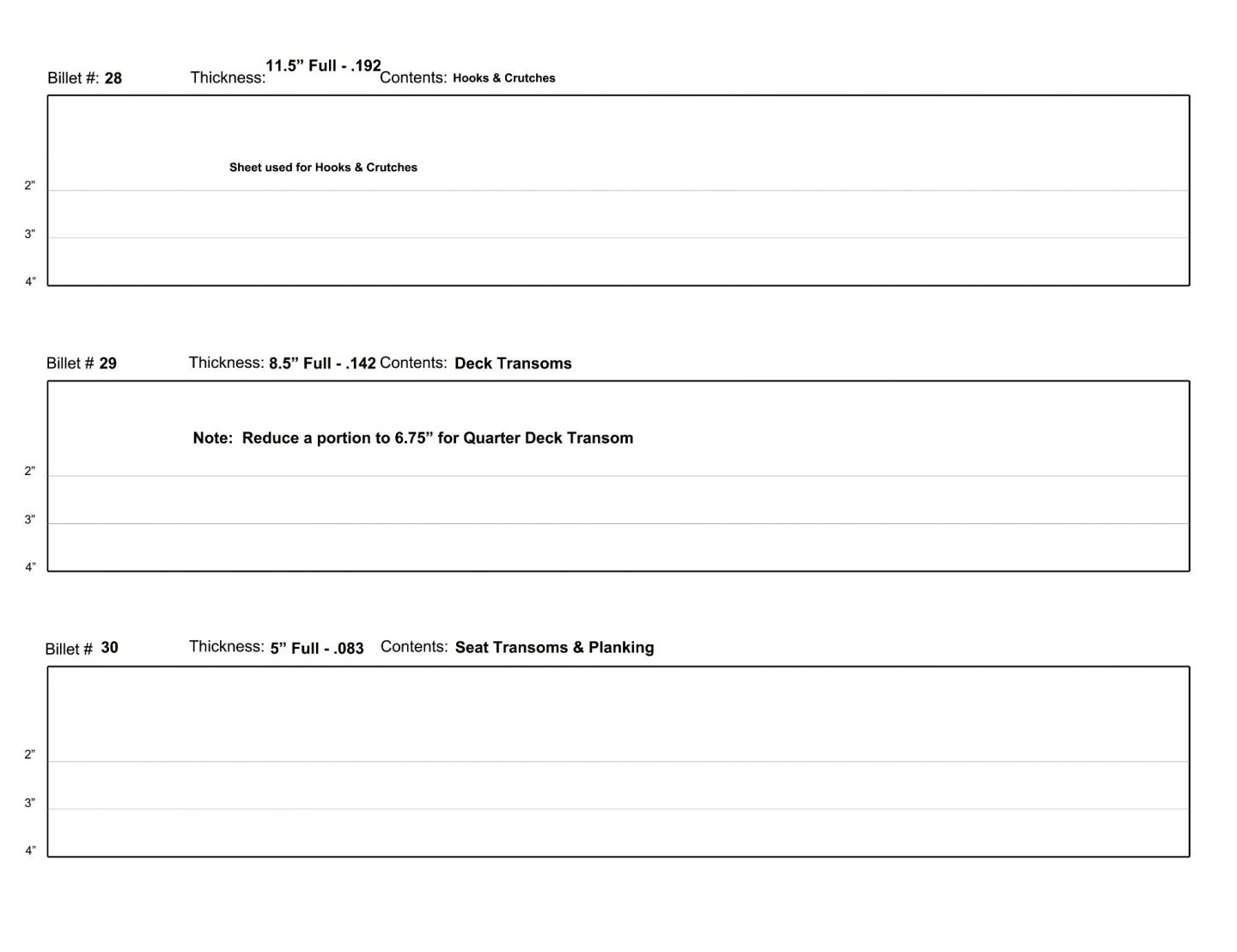

Here is a copy of my Naiad framing package wood list based upon Ed's books. Just like the Euryalus, each frame was broken down into the individual futtocks and placed on a template of the corresponding thickness. I have also included pictures of how the futtocks were laid out from a drawing package. When I was milling I included copies of these pics with the package as a guide so that you can gage how much wood that you will need. They are deliberately not to scale and it gives you a sense of what is involved in planning to mill such a package. Enjoy! Naiad Framing Package Insert.pdf

-

Hi Wes, I remembered you right away as soon as I saw your user name. Thanks for stopping by. Just hoped over to see both your Conny and Essex builds. Great job on both of them. Looks like you learned a great deal about milling wood. I know what you mean about putting the Conny away for a while. It's a long and arduous build. Not sure if after your Essex build that you will have the interest to resume your Conny as they are so different builds. I've got all of Bob's kits along with a Naiad package waiting for me and my plan is to work through the Conny before I start the others. Hope I make it. Been working on the bow rails and trailboards for the past few weeks and hope to post an update soon. Seems as though each portion brings on a host of new challenges. I'm almost looking forward to coppering...but I know better. Cheers,

-

Hi Dave, Great to hear of your interest. I've retired from the wood milling business and it takes a lot of time to break down each frame and lay them out on the corresponding sheets, so that's why I posted the content here in case anyone would like to start the build. Suggest that you contact Modeler's Sawmill or one of the other wood milling services with this content list and see if they can mill it for you. Best of Luck!

-

Shame on me! For a long time I was Gilmer's largest customer for this wood when I was operating HobbyMill. While I spent a lot of time milling it, I never really used it other than to make sheet and strip stock. Now that I'm doing some modeling, I just switched away from basswood to using some of my boxwood stock for the cheek and other rails on my Conny build. Can't believe how easy it is to work with...harder than basswood yet pretty easy to cut with any knife or chisel, homogeneous so none of the graininess or fuzzies of basswood and really great edges. Takes paint exceptionally well too. Been thinking the past few weeks while I've been working on the bow structure why all of the experienced builders flock to this wood and how stupid I've been to stay with basswood. Thought that it would be harder to work with than basswood, but the opposite is true! So, if you've never tried it, suggest that you pick up some from Gilmer or one of our wood milling sponsors and try a few sheets. If you are purchasing in bulk from Gilmer, suggest that you keep track of the moisture content. It varies all over the map. My first experience was that I cut down some longer pieces into 24" lengths and they all checked due to the higher moisture. After that I always checked the moisture content of each board and coated the ends with shellac whenever I started to cut the stock into 24" lengths. Typically I always had a year's supply stickered in a controlled environment waiting for the moisture content to come down. Also sometimes Gilmer would be out of stock for several months at a time until the next container arrived. If you are buying some of their precut turning stock then the moisture should be OK.

-

At one time I produced this framing package based upon Allan and Wayne's book. Since I've retired from the milling business I thought that it might be helpful to post the contents of that wood package for anyone who might be interested in the build or milling this package. The package was created by taking each frame apart into individual futtocks and laying them out on the corresponding frame thickness sheet. Hopefully I left enough room between futtocks for the average scroll saw user; however, I did allow for extra material. The attached pdf file was the package insert from the framing package. Happy milling! Wasn't sure where to post this, so please move if better located under another topic. If there is an interest in any of my other wood packages, just let me know and I'll be more than happy to post their contents as well. Jeff Hayes HobbyMill HMS Euryalus 1803 HobbyMill Framing Package.pdf

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.