-

Posts

1,398 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by DelF

-

-

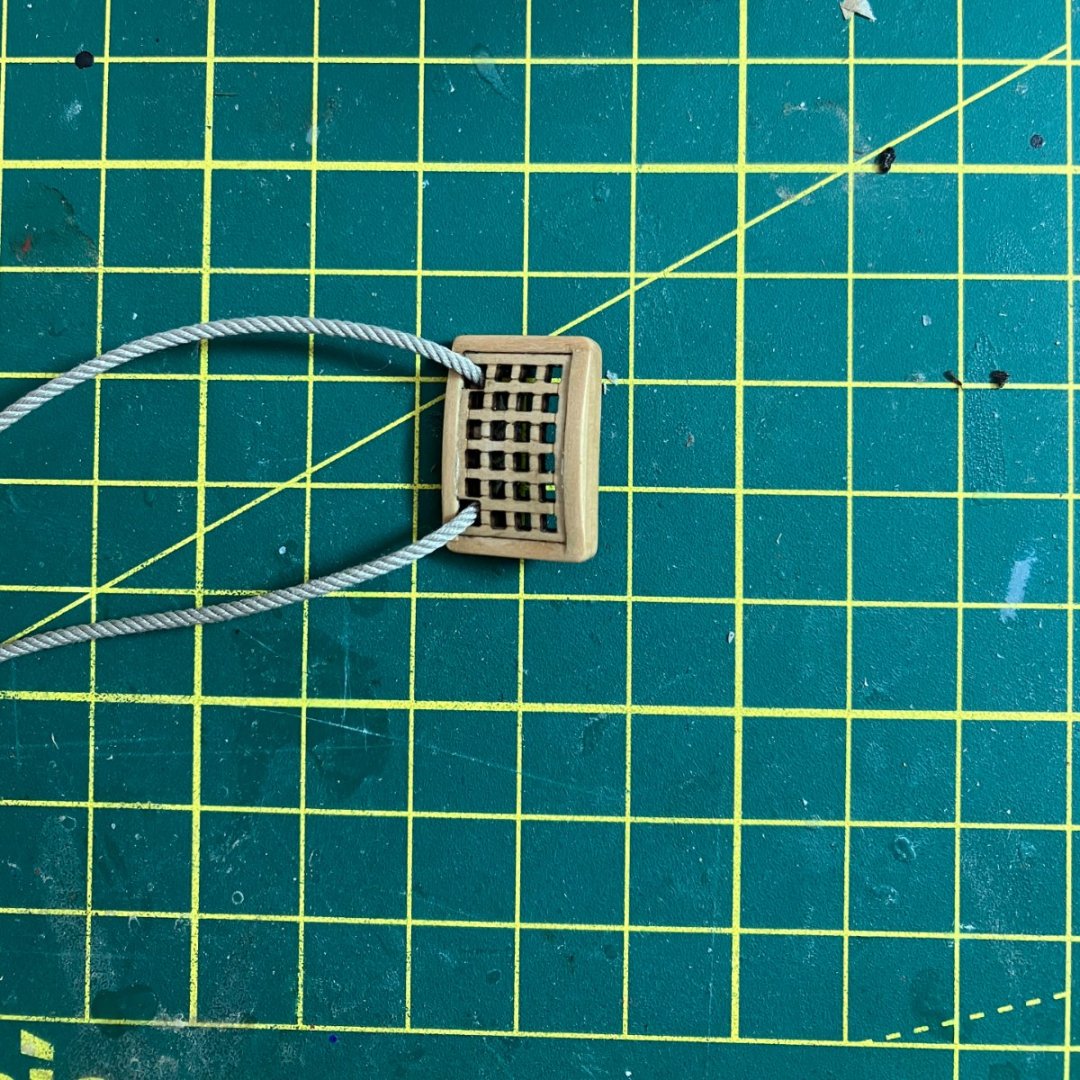

Crowsfeet

In my Speedy log I described fitting the crowsfeet in some detail so I'll just cover some changes I made rather than repeat everything here. Here's the link to the earlier description:

On Speedy I used DMC Cordonnet thread, run through a beeswax block to make it easier to thread through the holes in the tops and euphroe block. I used my thinnest thread, which I measured at about 0.15mm. In the real ship the crowsfeet line would have been very light - 0.75" circumference/<0.25" diameter, which equates to a fraction under 0.10mm at scale. As an aside I've yet to find commercially available 0.1mm rigging line that actually measures 0.1mm - it's often nearer 0.20mm - so I looked for alternatives.

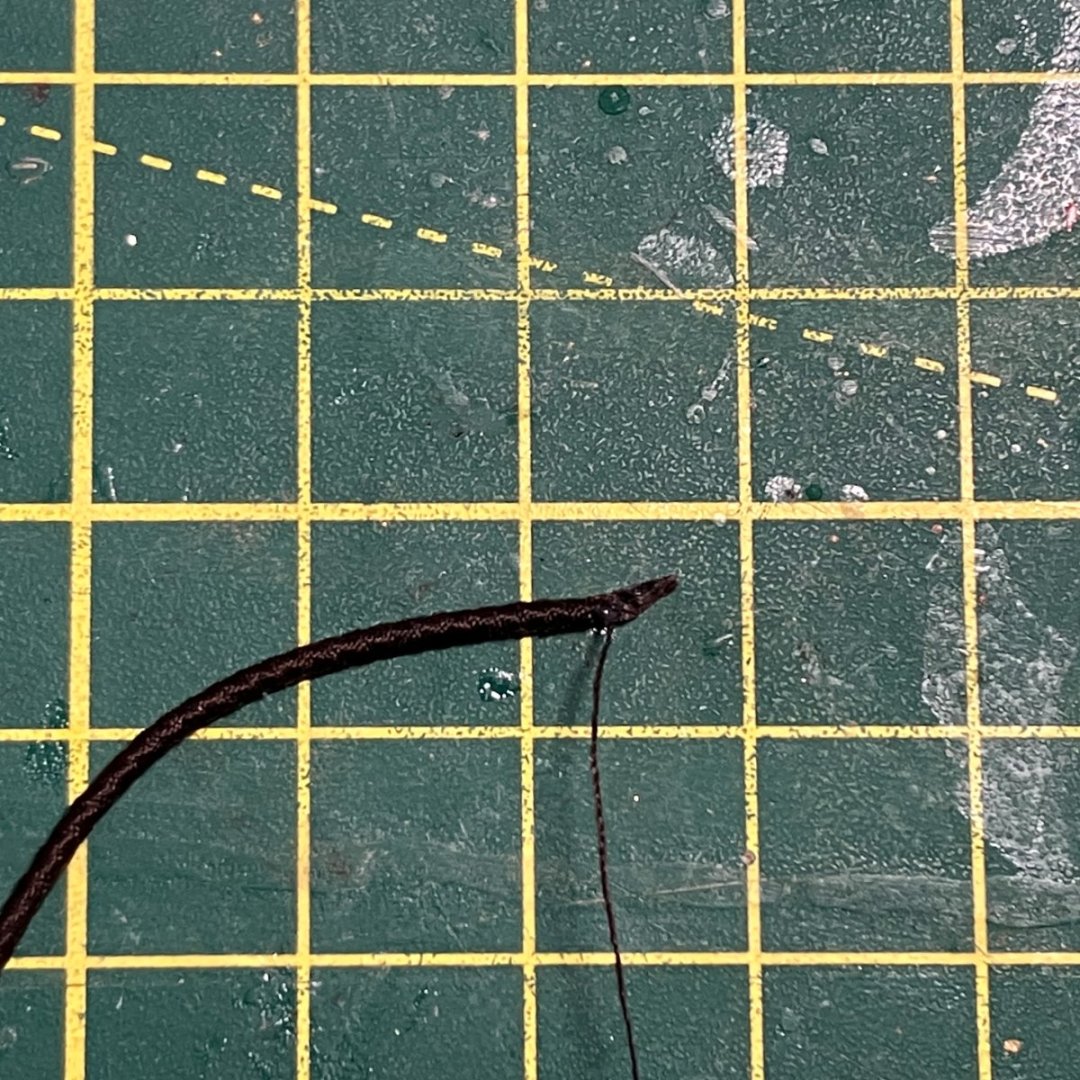

I checked in The Fully Framed Model by David Antscherl and he used 6/0 fly tying silk. I use thinner 18/0 fly thread for seizings, and it measures 0.04mm (human hair territory!) so I thought I'd give the thicker material a go. Not sure of colours, I ordered brown and beige:

On arrival I was pleased to find that my micrometer agreed with David's, measuring the line at 0.10mm.

The thread was a little tricky to rig to the euphroe block. I used 18/0 line for the seizing, and as both the line and the seizing were smooth silk they tended to slip apart. I found I had to leave the fly tying cement to set firmly before moving the line otherwise the seizing wouldn't hold. Once set, everything was fine. As with conventional thread I dipped the end in CA to harden it and facilitate threading through the tops.

As with Speedy, I rigged the crowsfeet according to the descriptions in Lees and Antscherl rather than the kit instructions, with a slight modification to allow for the even number of holes in the tops (the method I use requires an odd number of holes, namely twice the number of holes in the euphroe block plus 1). All this is covered in the Speedy log. I used the brown line as the beige just look too light.

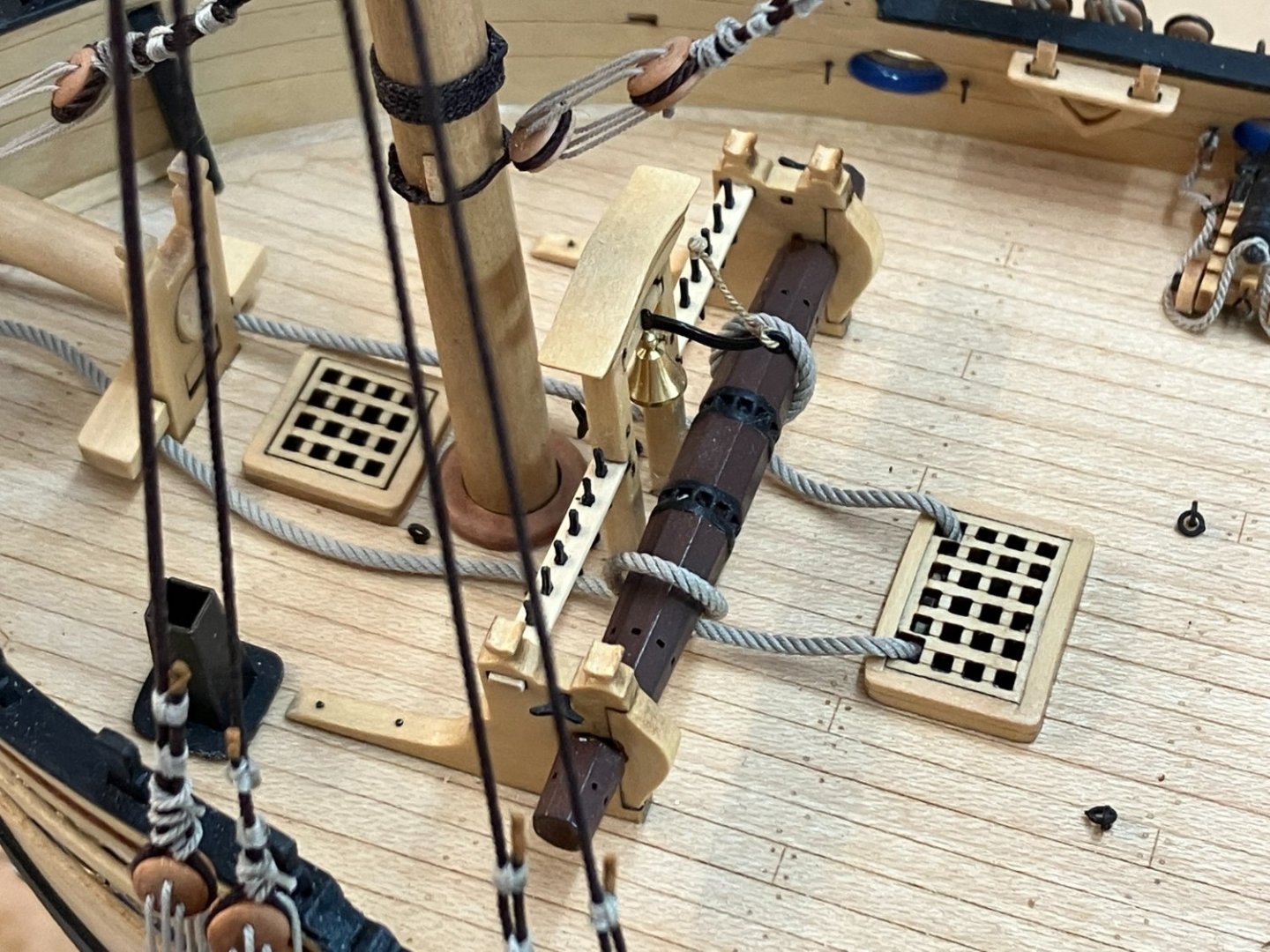

Here's the foremast crowsfeet. I've not tied the line off yet as I haven't finally decided I like the result yet:

...and a comparison with the same crowsfeet on Speedy:

I must say the 6/0 line on the left was a lot easier to rig. It was much easier to get the tension right, and the whole set up seemed to need less tension to get the line to sit straight, which in turn meant there was less tension on the stay which therefore wasn't pulled out of line too much. The lack of beeswax made the whole process less messy as well.

So, the question comes down to one of appearance. I think I'm happy with the way the 6/0 silk looks, but I'm going to give it a few days while I get on with other jobs before deciding whether or not to use it on all three masks.

I'd be interested in other folks' views.

Derek

- JpR62, Guyuti, Ryland Craze and 13 others

-

16

16

-

Topmast shrouds

Many thanks as always for the kind comments and 'likes'.

I'm really glad I rigged the shrouds before fitting the topmast caps and topgallants. Unlike Speedy where I had to seize the shrouds on the model, it was much easier to measure everything on the Duchess then complete the seizings and rig the deadeyes in comfort on the workbench.

I used 0.6mm line for the fore and main topmast shrouds and 0.5mm for the mizzen, 0.3mm for the lanyards and my thinnest Mara line (#150) for the ratlines and seizings. All the techniques were as per the lower shrouds.

I also used #150 to serve the shrouds in the normal way, i.e. the full length of the first shroud each side on each mast and the middle quarter of each shroud pair. I always like the look of a gang of served shrouds stacked up on a masthead, even if it's only a few like this:

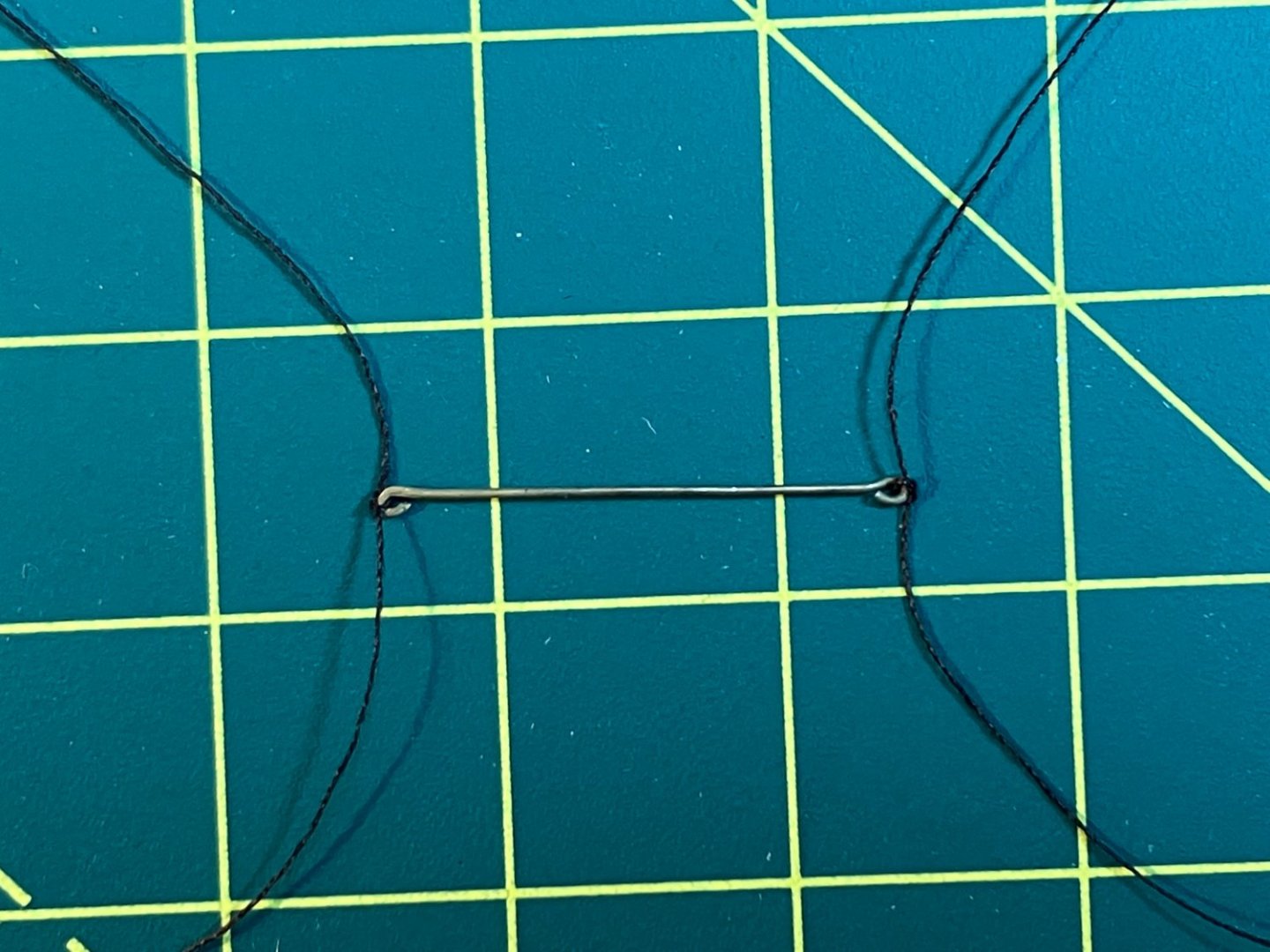

The futtock staves are short lengths of 0.5mm brass rod from the kit, seized with 18/0 fly tying silk. I used the Quadhands to hold the rod in place during seizing as described for the lower masts.

Unlike the lower masts, I didn't fit catharpins. They are shown in the kit, but according to Lees (The Masting & Rigging of English Ships of War) catharpins on topmasts did not appear on contemporary models until 1805, and that was an outlier. I was happy to leave these fiddly little items off.

As for the ratlines, I'm still trying to improve my technique. I mentioned in an earlier post experimenting with tying alternate clove hitches upside down to avoid the 'S' shape that tends to result if each knot is tied the same way:

For the first rung the result is a pleasing downward curve...,...but the next pair of knots results in an upward curve:

However, I actually found that on the model it was easier to persuade the latter curve into a better shape than it was to get an 'S' curve to conform.

I was quite pleased with the results, especially on the mizzen where there are only two shrouds!

Here's the whole model:

On next to one of my favourite rigging components, the crowsfeet.

Derek

-

On 10/27/2022 at 7:19 PM, Bob Cleek said:

I've never perceived any deterioration of the product over the passage of time

I've been using small amounts of pre-mixed shellac out of the same bottle for the last five years and it's still as good as new.

On 10/27/2022 at 7:19 PM, Bob Cleek said:I can't see what's not to like about the stuff.

Me neither.

Derek

-

-

3 hours ago, DaveBaxt said:

great to be back

Hi Dave - good to hear from you again, and thanks for your kind words (and no, I won't be adding sails!). In fact I suspect my next two models - Sphinx & Indefatigable from Vanguard - will be hull only. Although I enjoy rigging, Navy Board-style models take up much less space and that will be a consideration when we eventually downsize.

Best wishes

Derek

- SIDEWAYS SAM, VTHokiEE, DaveBaxt and 2 others

-

5

5

-

6 minutes ago, chris watton said:

For those that may ask, yes, the Indy will contain all parts for masts and rig

Looking forward to this with great anticipation having followed Jim's superb build log (though I haven't even started Sphinx yet!). I imagine you've been asked this before, but wouldn't it be possible to offer a slimmed down hull only version for those of us aiming for a Navy Board-style model? I suspect the answer will be that it would cause you more trouble than it would be worth, but I had to ask. I don't mind paying for the full kit, but it just seems a waste to have to send me material I won't need.

Derek

- Rustyj, CaptnBirdseye, chris watton and 4 others

-

7

7

-

Lower Catharpins & Futtock Shrouds, Topmasts

Over the last few days I've completed the standing rigging to the lower masts and fitted the topmasts:

I use the same methods for these elements of the rigging as I did for Speedy so in the interests of brevity here's a link to the relevant post in that log for the details.

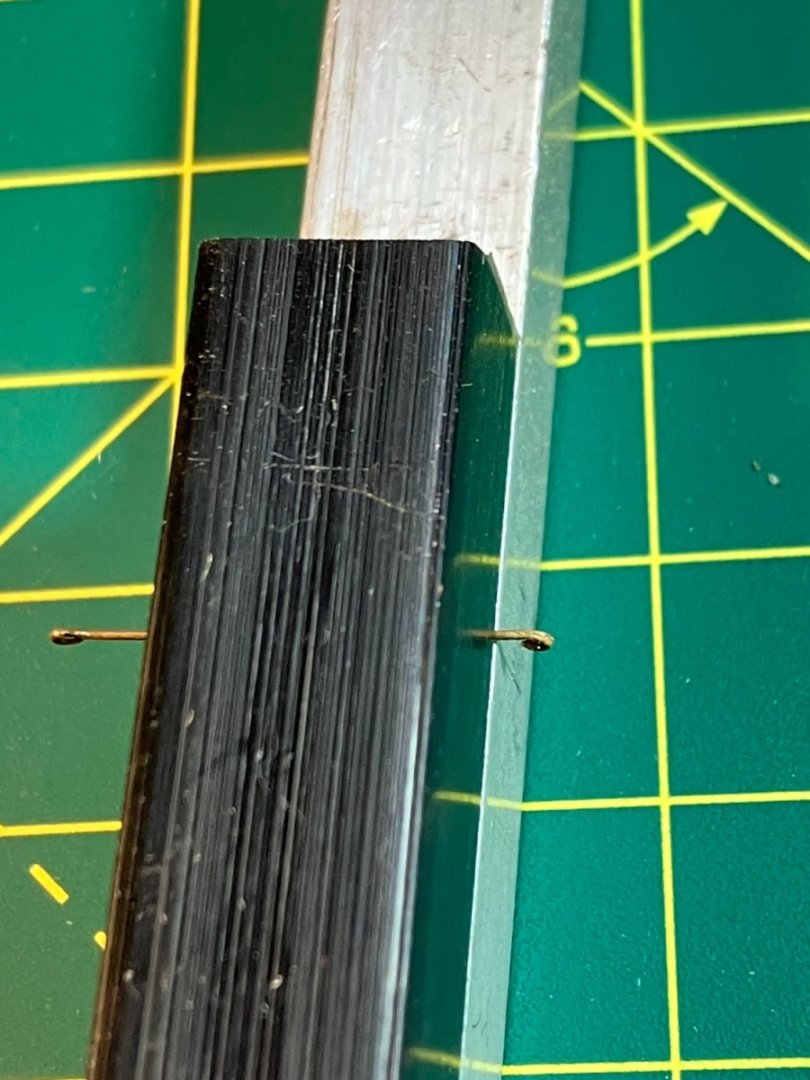

One minor point on the catharpins. I use wire for these as I find it too difficult to get even tension using rope. However by the time I've formed eyes in the end of a length of 0.5mm brass wire it usually ends up bent and difficult to straighten by hand. I usually straighten short lengths of brass wire by rolling them between two metal plates. With eyes on each end I couldn't use my usual plates but luckily I had a couple of pieces of square section that did the job nicely. I suspect hardwood might also work, but I find smooth metal works well for me:

Here's a closeup of the main top, showing the futtock shrouds in place.

Topmast shrouds next I think, then perhaps the crowsfeet.

Derek

-

A welcome addition to your range Chris. Would these paints also be suitable for your 3d printed figures and furniture?

- thibaultron, Canute, mtaylor and 1 other

-

4

4

-

Congratulations on yet another splendid model, with a great log to match. Well done!

Derek

- hollowneck, mtaylor, Ryland Craze and 2 others

-

4

4

-

1

1

-

Well done Glenn - great model and a great log. I suspect you will have finished your next build (Indefatigable?) before I get round to starting Sphinx!

Derek

- Ryland Craze, mtaylor and Glenn-UK

-

2

2

-

1

1

-

I think you've made the right decision. For me, the cranes add yet another element of interesting detail. You are creating a truly beautiful model.

Derek

- Blue Ensign, chris watton, Dave_E and 4 others

-

7

7

-

-

2 hours ago, HardeeHarHar said:

Sorry to ask a lame question, but do you use half hitches on your ratlines? Can you share how you go about doing them, or point me in the direction of a good description.

That's not a lame question. In trying to rig decent ratlines I've tried half hitches, overhand knots and cow hitches but I always end up using clove hitches. I believe that's what was used on real ships, and most modellers do the same.

The best guide I've found is this youtube video:

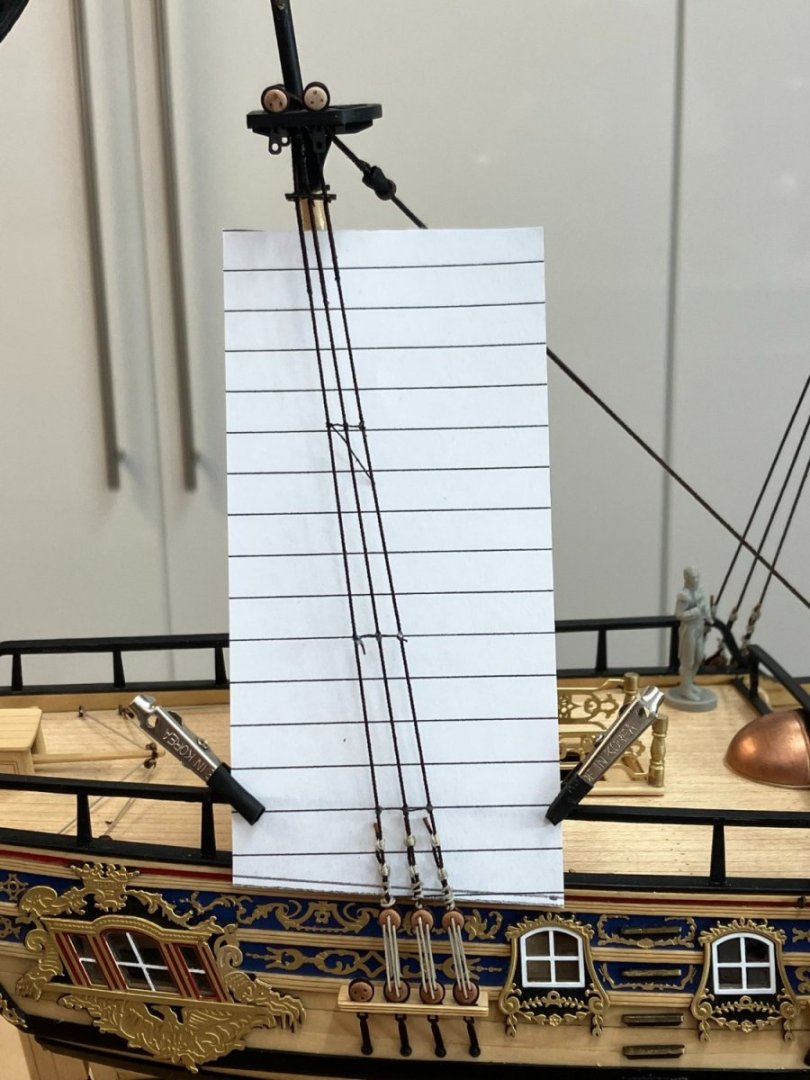

Couple of points to note. He's pinned some white card behind the shrouds which makes it much easier to see what you're doing. However he's using plain card whereas I prefer to use lined card to help me get the ratlines evenly spaced and parallel with the waterline. Here's an example:

Second, he starts with an overhand knot on the first shroud whereas I prefer to start as I mean to go on - with a clove hitch.

It's very easy to tighten the ratlines as you work your way up, producing an hourglass shape in the shrouds which just looks wrong. One way to help avoid this is to rig the every fifth or sixth shroud first, then fill in the gaps. Some people draw lines on the card to represent the shrouds and use these to try to keep the shrouds straight. I find that more difficult, but you might find it worth trying.

Couple of other points. I try to use the finest line I can for ratlines. In real life the lower ratlines would have been made from 1.5" line (that's circumference, ie less than 0.5" in diameter). On a model that's just under 0.20mm in diameter; any thicker looks too heavy, at least to my eye.

Also, I find the knots can slacken quite easily, so I usually put a dab of glue (I use dilute pva or shellac) on each knot as I finish each line.

Finally, if you tie each clove hitch the same way there's a danger that you'll end up with 'S' shaped 'rungs' in your ratlines. Here's a photo where I've tied some rope to a pair of door handles to illustrate the point:

You need to try to tweak each knot as you tie it to minimise this effect.

Just out of interest, I tried tying alternate knots upside down which works for the first rung, producing a nice downward curve...

...unfortunately the next rung slopes up and looks worse than an S-bend!

I hope this is of some help. I suggest you look at the video then try practicing some knots. Practice really is the answer although I've been practicing for years and still can't do it to my own satisfaction!

Derek

-

-

Thanks Tim, much appreciated.

9 hours ago, VTHokiEE said:- did you use the PVA mix with synthetic rope? I thought you switched to gutermann Mara thread.

You're right, I use Mara for all my rope now. This link to an earlier post describes how I made the anchor cable from Mara #70. I haven't looked back since I started using Mara, and I certainly don't miss all the dyeing I had to do with the threads I previously used for rope making!

Derek

-

-

Well done Rusty - superb model!

-

-

Like B.E., I ran out of superlatives to describe your Winchelsea some time ago. I'm not sure the bar you're setting could get much higher.

Derek

- Ryland Craze, Edwardkenway, Dave_E and 3 others

-

6

6

-

Anchor cables and lower ratlines

After a considerable break occasioned by holidays, visitors and other distractions I'm finally back in the workshop.

As mentioned in my last update, I brushed some dilute (50:50) PVA on the anchor ropes and held them to the deck with small weights while they dried. I think the result has them lying more naturally:

Next, it was on to the lower ratlines. The less said about these the better. This is the fifth fully rigged model I've tackled and I would have hoped to improve my ratlines over that series. To my critical eye the Duchess is marginally better than my first model, but no better than the other three. In fact in some ways it's worse, as I found it very difficult to span the very wide gaps in the fore and main shrouds neatly.

Using Mara #100 line I started off rigging every fifth 'rung' as well as I could...

...but then found it impossible to maintain this level of neatness as I filled in the gaps:

I just hope the ratlines won't catch the eye quite as much when the rest of the rigging is in place.

One of these days I'll get it right - as the song says, "Things can only get better"! Despite being somewhat disappointed with the ratlines, I'm enjoying getting back to the workshop.

Derek

-

45 minutes ago, glbarlow said:

We’re going on an Alaskan cruise starting from Vancouver in September, let me know how it goes. I hope you both have a great trip!

Thanks Glenn!

46 minutes ago, glbarlow said:Don’t forget the hard shell golf bag carrier to fill with the Alaskan Yellow Cedar 😂

Unfortunately I don't play golf. I'll try and persuade Karen to ditch half her clothes on the way back - that should give me room for about 20 or 30 pounds of timber 😁

- hollowneck and CiscoH

-

2

2

-

Anchor cable

This will be my last post for a while as we fly to Vancouver tomorrow for the start of our Alaska cruise - subject to Covid testing, which is still a requirement for cruise passengers.

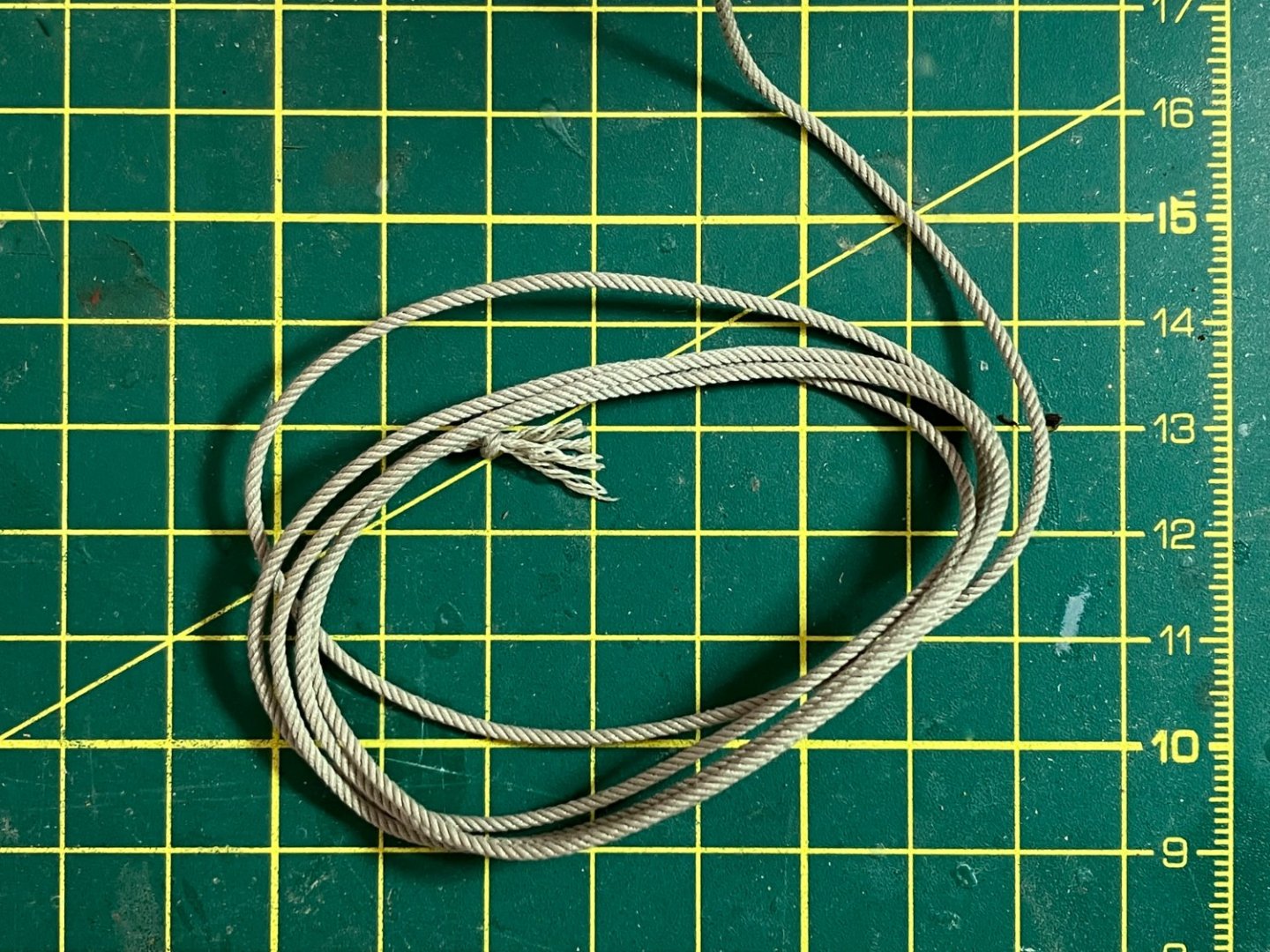

As a last little job before departure I managed to find some more displacement activity to avoid ratlines until our return. I wanted to fit the anchor cables before the deck became too cluttered so I set up the Rope Rocket to make my own. I felt the kit line was too heavy at 2mm. According to the usual references the circumference of a ship's bower anchor cable was 0.62 times the diameter of the main mast. So with an 8mm main mast the cable would be 4.96mm round and therefore 1.58mm in diameter. After some trial and error I made a length of 4-strand rope, each strand consisting of five lengths of Mara #70, given a final diameter of 1.50mm which I felt was close enough. I always prefer to go under rather than over-scale. I should add that I only set the ropewalk up to produce one metre of rope - no point wasting material!

Here's the result, and a comparison with the kit rope:

I threaded the cable through the hatch, then dry-fitted it to the deck to check it looked OK and would thread through the hawse holes:

I'm quite happy with that, so on return I'll dampen the cable down with some very dilute pva and hold it down with small weights while it dries.

I'm off to pack that saw so I cut smuggle some of that Alaskan Yellow Cedar 😁.

Derek

- Blue Ensign, ccoyle, David Lester and 11 others

-

14

14

-

Yes, I use a heat gun to ‘set’ the rope and stop it tending to unravel. Some people bake their rope in an oven but I find the heat gun works fine for small quantities. When I cut it from the rope walk I knot each end to stop it unravelling, wind it into a hank, put the hank in the bottom of a glass jar to stop it blowing away then blast it for about a minute.

I should stress that I use a crafter’s hot air gun, not the really powerful type used for stripping paint!

After heat treatment the rope is no different, except it won’t unravel.

Making your own rope is easy and satisfying, as the stuff you make yourself will be better than most kit material. I used to dye my rope as well but that was time consuming, messy and a bit hit and miss, at least for me. I’m glad I got onto Gutermann Mara thanks to Chuck’s post.

Derek

-

Hi Jonathan

I use Gutermann Mara thread for all my rope, having read Chuck Passaro's description of it (see here for more information). Chuck's Syren Rope Rocket is great for running up your own rope, and like you I use the Syren machine for serving. For the latter I use the thinnest Mara thread I could find - #150. You can use black if you wish but personally I prefer very dark brown, partly for realism (the Stockholm tar used on standing rigging was not black) and partly because pure black looks too stark to my eye. Details of the colours I use are in the link.

Here's some pictures of the serving line in use, to illustrate how it can create an eye:

Hope this helps

Derek

HMS Sphinx 1775 by Hollowneck - FINISHED - Vanguard Models - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

Great work Ron. I've had my Sphinx sitting on a shelf in my workshop for a year now and I'd always intended her as a Navy Board-style model, partly because I've always wanted to do one and partly because it would take up much less space. Until I saw your Camilla that is. The splendid job you're making of her rigging and sails is making me think again. I'll blame you when my wife berates me for "filling the house with yet another huge model"!

Derek