-

Posts

234 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

USA

Recent Profile Visitors

-

FrankWouts reacted to a post in a topic:

HMS Victory by PiperMat - Heller - 1:100 - PLASTIC - trials and tribulations

FrankWouts reacted to a post in a topic:

HMS Victory by PiperMat - Heller - 1:100 - PLASTIC - trials and tribulations

-

popeye the sailor reacted to a post in a topic:

Schnellboot Type 38 by svein erik - FINISHED - Italeri - 1/35 - PLASTIC - German WW2 torpedo boat

popeye the sailor reacted to a post in a topic:

Schnellboot Type 38 by svein erik - FINISHED - Italeri - 1/35 - PLASTIC - German WW2 torpedo boat

-

uncarina reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

uncarina reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

mtaylor reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

mtaylor reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

lmagna reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

lmagna reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

Old Collingwood reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

Old Collingwood reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

Canute reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

Canute reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

shipman reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

shipman reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

Jack12477 reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

Jack12477 reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

I wonder why Bismarck is so famous even now myself. She (yes Bismarck is a she, still not letting 'effing Nazis change nautical tradition! ) was a really attractive and impressive looking ship but she wasn't the unstoppable technological terror she was made out to be and is certainly more legend than reality these days. Maybe because the wreck has been explored and is recognizable, not a pile of twisted metal on the seabed like virtually every other large warship sunk in battle? Because of what she did to the Hood? Because Bismarck has moved into the realm of pop-culture? I don't know but honestly I'm glad the story of the Bismarck is still alive in this cancel-culture obsessed world. Real men fought and died for crazy things and the story of Bismarck (and WW2 itself for that matter) holds many important lessons to learn for today and future generations. For me, this kit has it's own meaning... I've been trying to do this model off and on since November of 2012 and it was only my second big battleship attempt since coming back to scale models as an adult after the Arizona. My "model career" online really began with this kit and it's only the second kit I attempted to go crazy on detail-wise. Even though I suck at actually finishing these things (only have the Nelson under my belt for 1/200 ships) I think I've come a long way in my abilities and it's fun for me to go back to the beginning of this thread vs where I am now and see how I've progressed. It's more than just a hobby to build the Bismarck for me anyway... it's a oddysey, an obsession... something I just *have* to do "because it's there" . Might even get a bit misty-eyed when it's done in another 10 years or so!

-

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

HMS Rodney by uncarina - Trumpeter - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

Not anymore but I put a couple pics on post #43 of this thread. Personally, I'd love to see a 1/200 King George V or HMS Vanguard... if we can get Neslon and Rodney, why not? Some smaller 1/200 ships would also be nice to add to the fleet.

-

channell reacted to a post in a topic:

Schnellboot Type 38 by svein erik - FINISHED - Italeri - 1/35 - PLASTIC - German WW2 torpedo boat

channell reacted to a post in a topic:

Schnellboot Type 38 by svein erik - FINISHED - Italeri - 1/35 - PLASTIC - German WW2 torpedo boat

-

I love the flawlessly clean look of your build so far... well done sir!

- 19 replies

-

- schnellboot type 38

- italeri

-

(and 2 more)

Tagged with:

-

channell reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

channell reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

-

channell reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

channell reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

-

I wish I had a magic pill or something that would restore my enthusiasm for working on these monsters when I get burned out on them... they make awesome models, especially when you throw the aftermarket stuff at them. They can get so overwhelming easy though! I did the Nelson, have a Rodney in the stash too. The world needs more models of the "Pair 'o Boots"... just really unusual and cool ships!

-

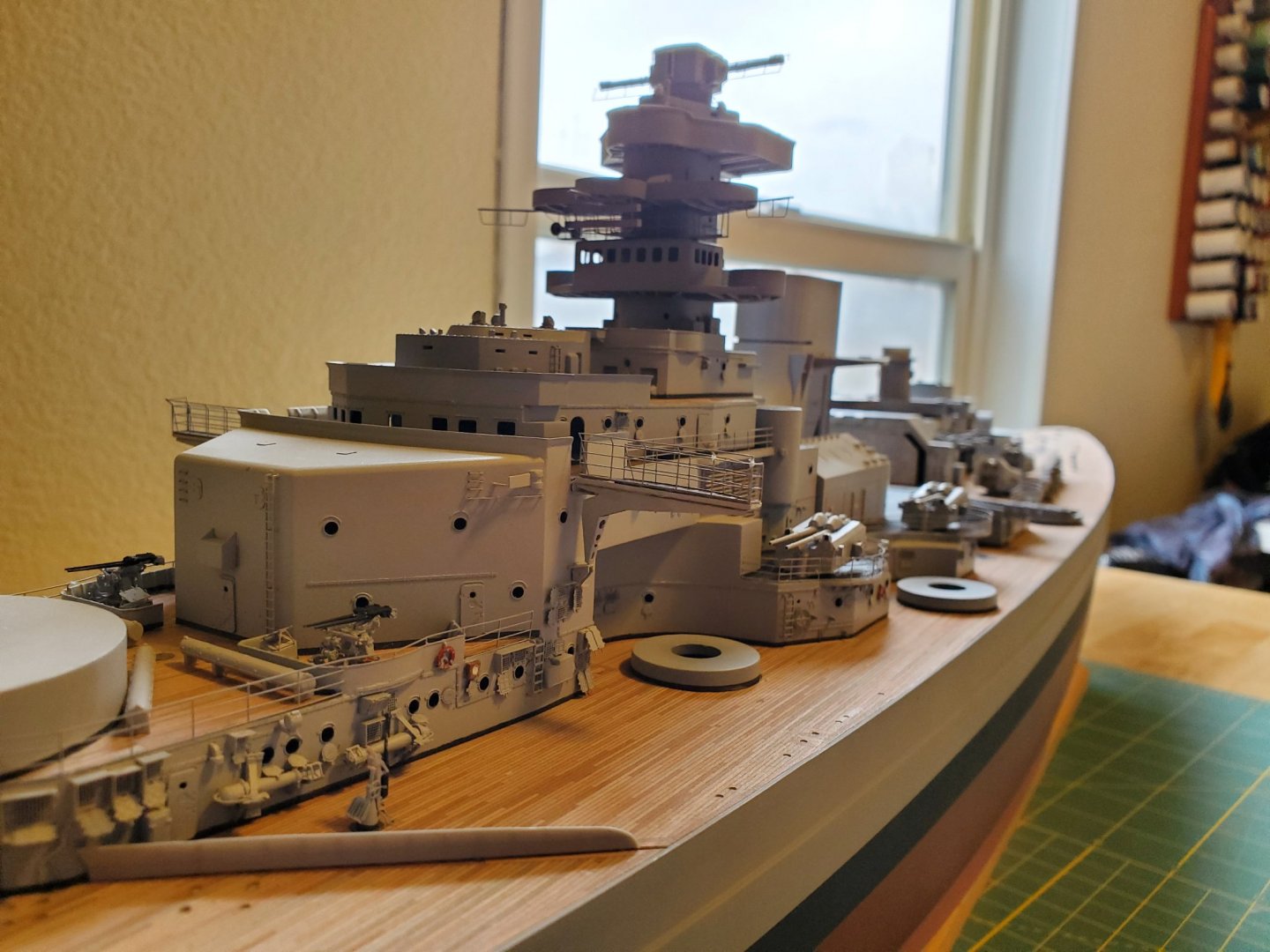

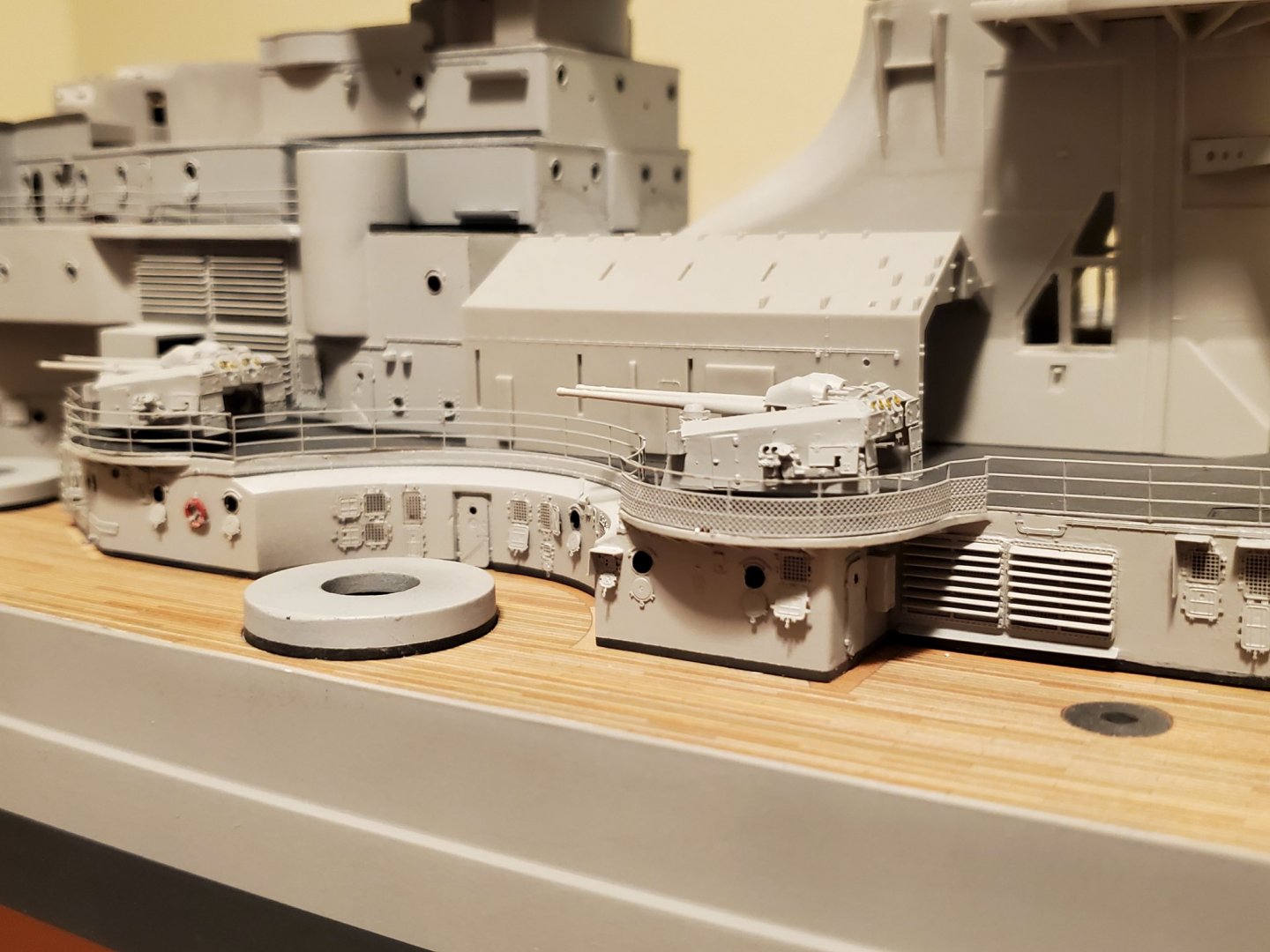

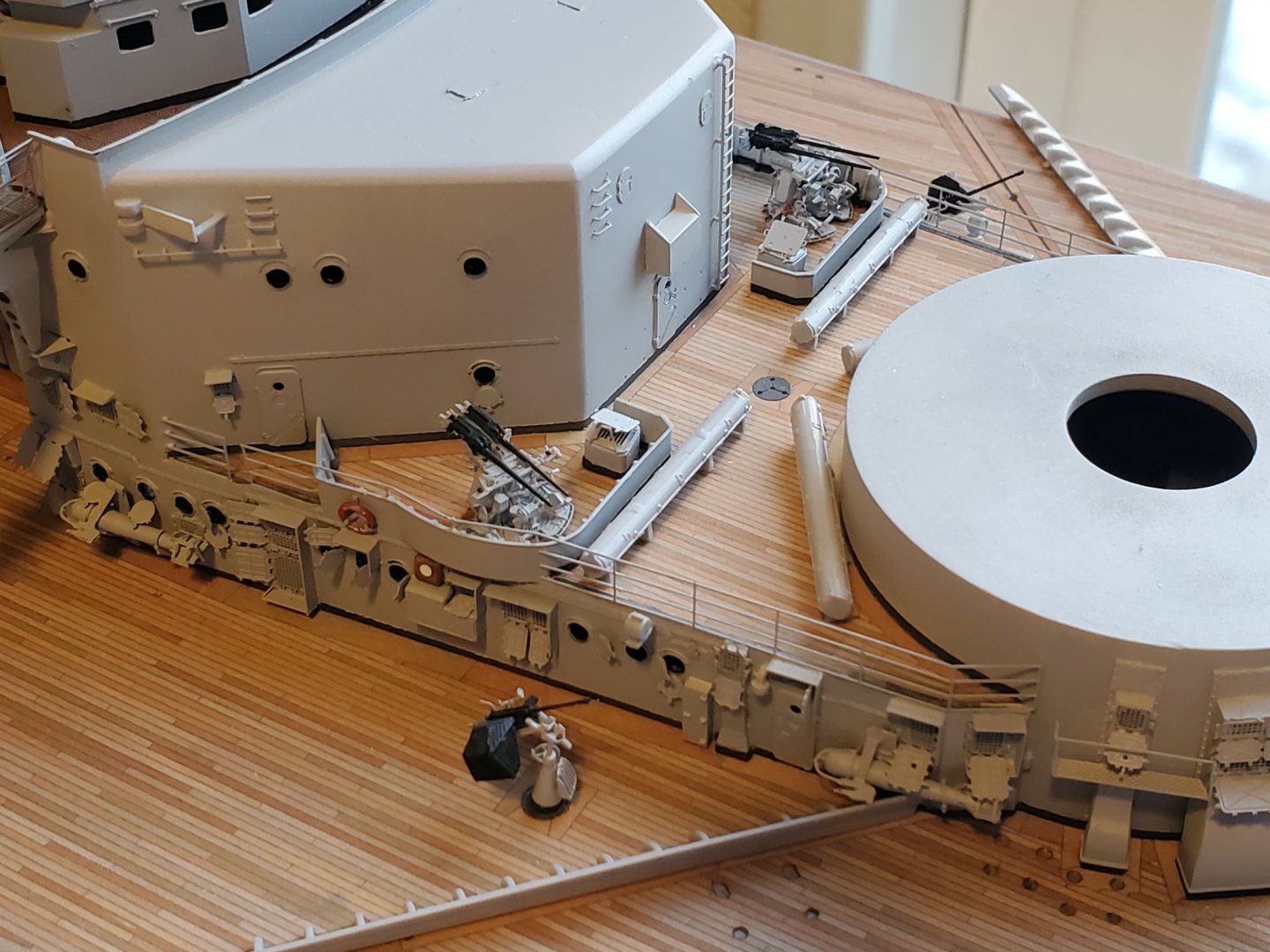

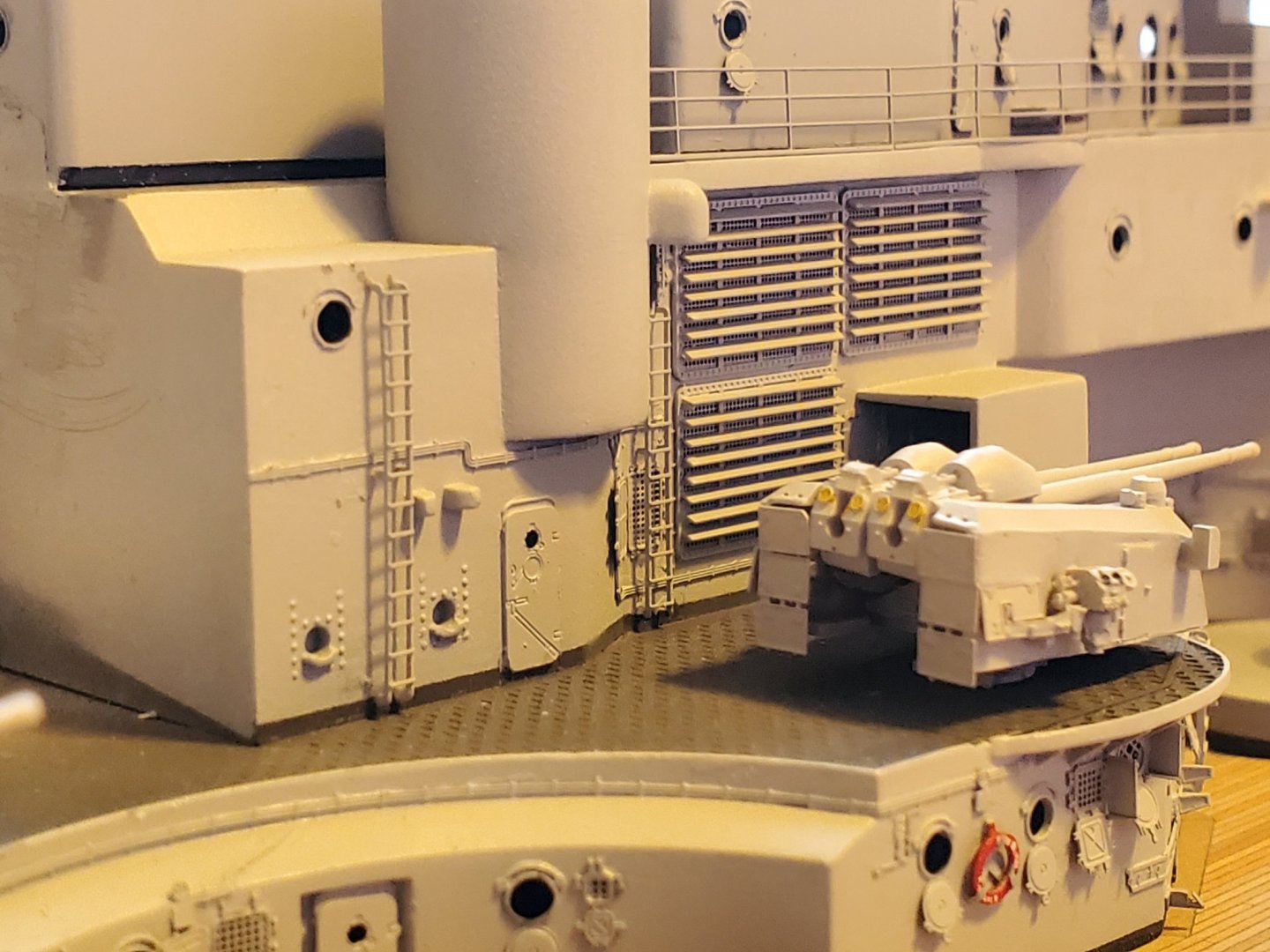

Made some good progress over the weekend... got the conning tower set up complete with scratched out open "safe doors" (something I wanted to do after seeing it on the wreck) as well as getting quite a bit done on the Admiral's Bridge. Still tons of detail to go on the Admiral's bridge but at least the main modifications are done. I also had to throw in an eye candy shot of those Veteran Model Flak guns... so cool looking!

-

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

channell reacted to a post in a topic:

Bismarck by Channell - Trumpeter - 1/200 - PLASTIC

-

Thanks everyone! Working on this thing has been (and continues to be) an odyssey, that's for sure. No way I'm adding up how much I paid for all the stuff in this thread... I think it might drive me to tears. At least it's all paid for, provided I don't buy anything else for it (which seems unlikely) .

-

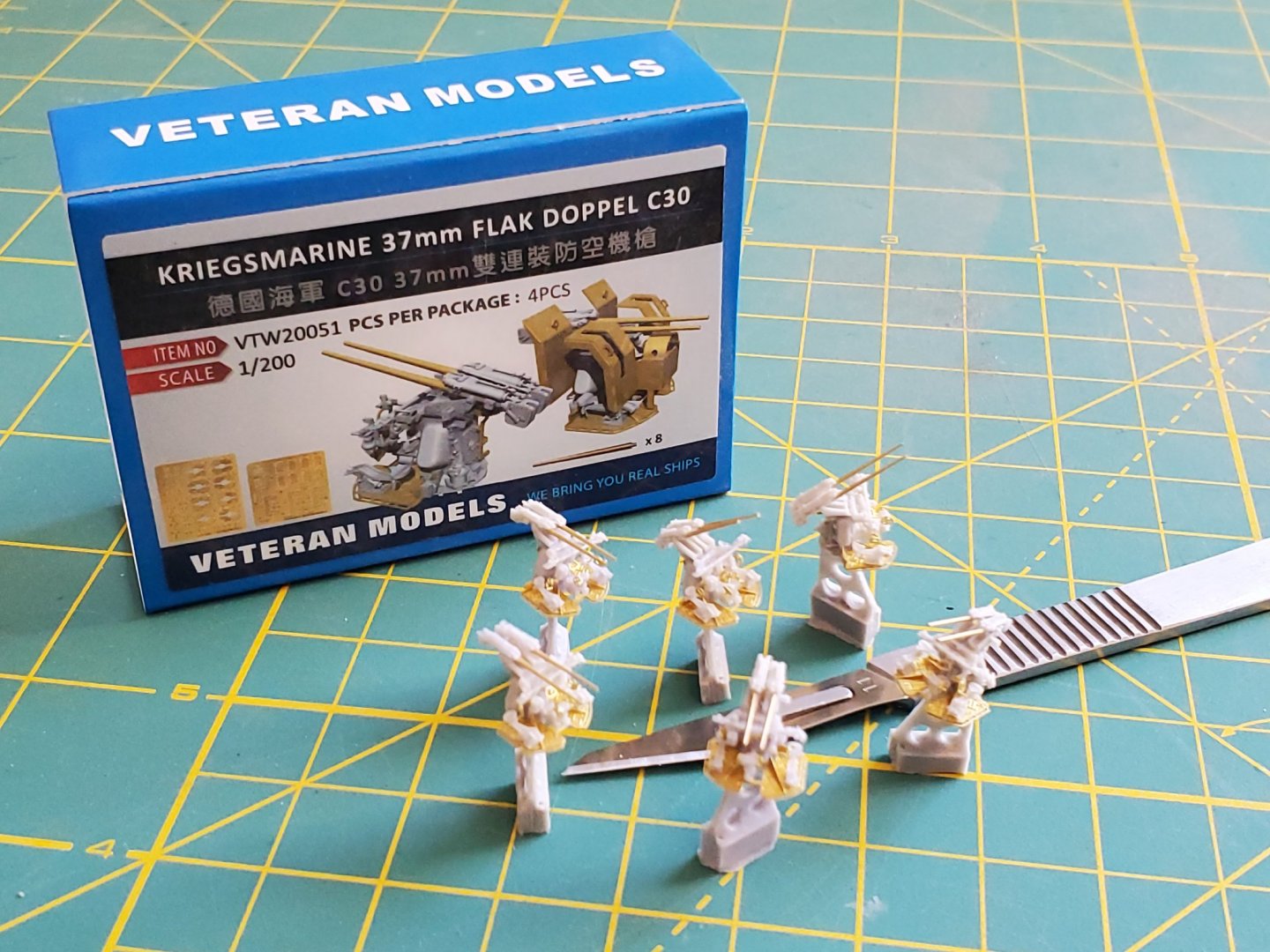

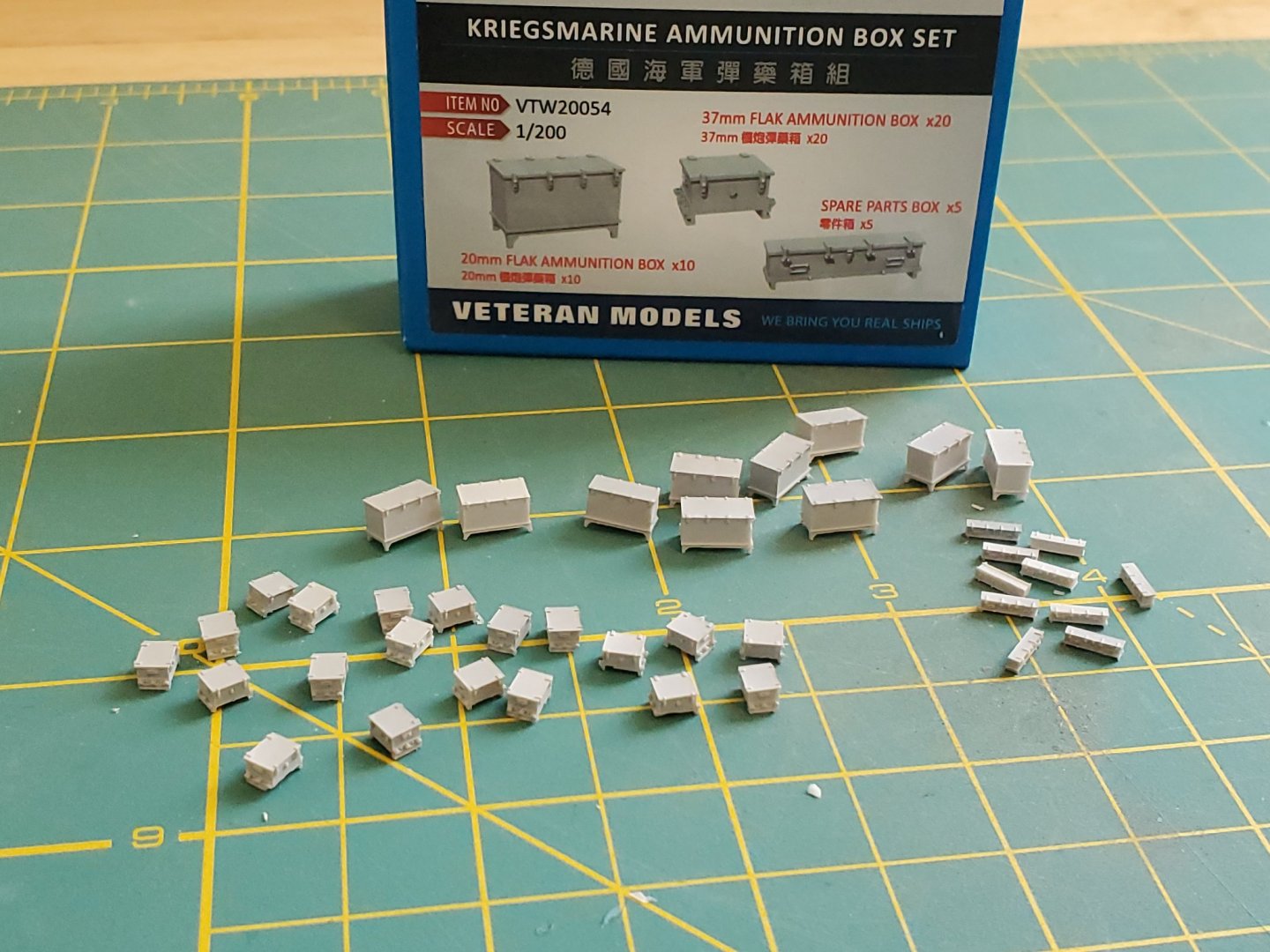

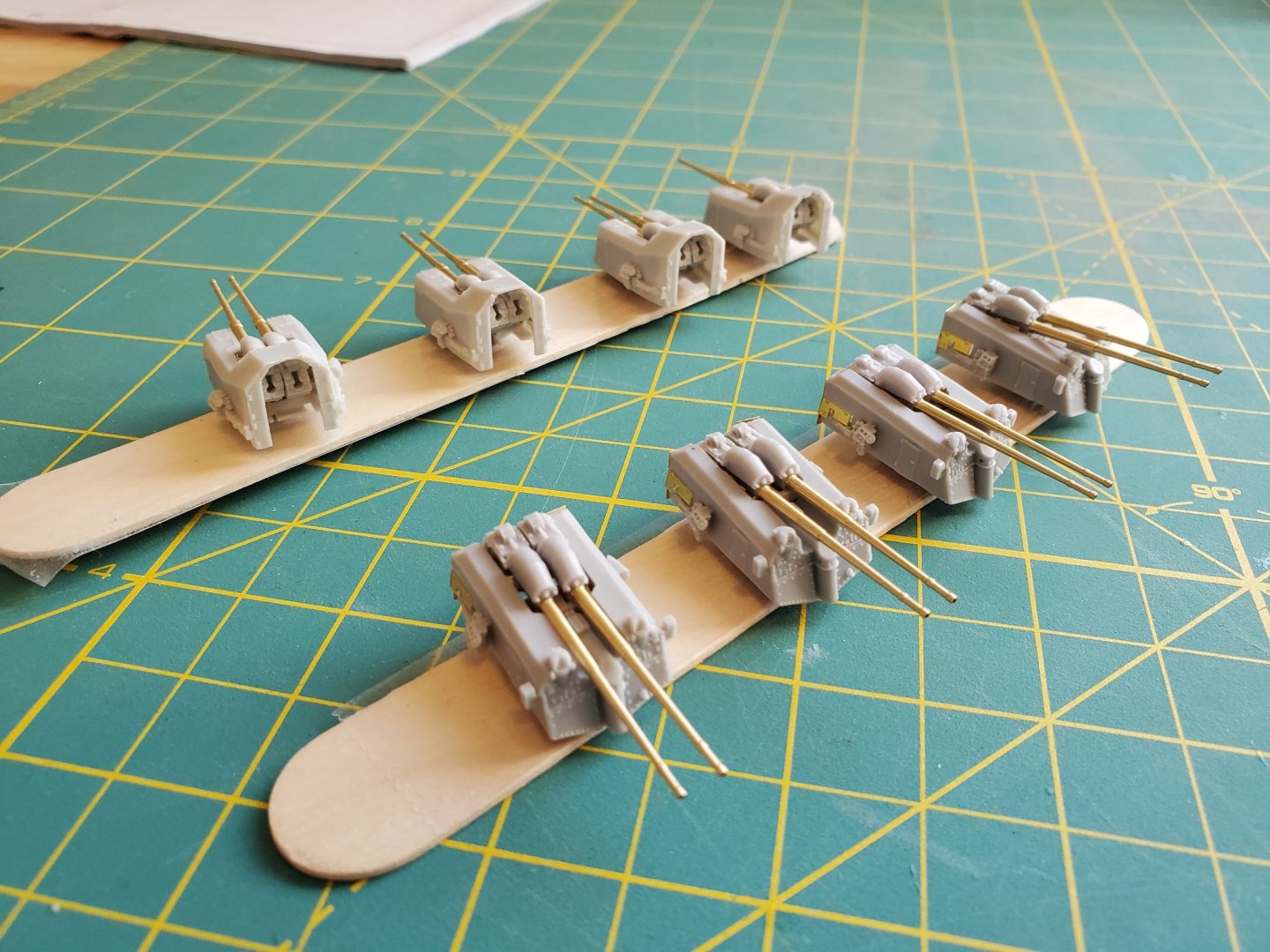

Thanks all! been on a rampage these past few days on Bismarck... got the flak guns installed, railings up on level 2 of the superstructure and marathoned 6 more tiny Veteran Models AA guns. Damn those things are a nightmare. Also got some Veteran Models ammo boxes cleaned up, painted and ready to go.

-

Hey everyone... long time, no see. I got burned out again and took a couple years break, I figure since this thread had dragged on so long I might as well. Anyway, my other hobby is getting boring now so I'm back to working on Bissy; thought y'all might be interested in seeing what's going on. [img]https://i.imgur.com/hz8BPdy.jpg[/img] Picking up pretty much where I left off last time but in a new hobby room; this weekend I mostly worked on guns: [img]https://i.imgur.com/Dz22dtD.jpg[/img] finished up the small deck area (minus some firehose rolls) [img]https://i.imgur.com/lNxuRCy.jpg[/img] Replacing the kit Flak guns with these awesome Veteran models versions, each one is it's own little kit as usual. [img]https://i.imgur.com/u6Gcv3o.jpg[/img] After assembly and ready for paint [img]https://i.imgur.com/QST7AKc.jpg[/img] [img]https://i.imgur.com/MHuZmRN.jpg[/img] A preview things to come... [img]https://i.imgur.com/LIs1Rhx.jpg[/img] ...and back in the box for safekeeping before they finally get installed. Thanks for looking!

-

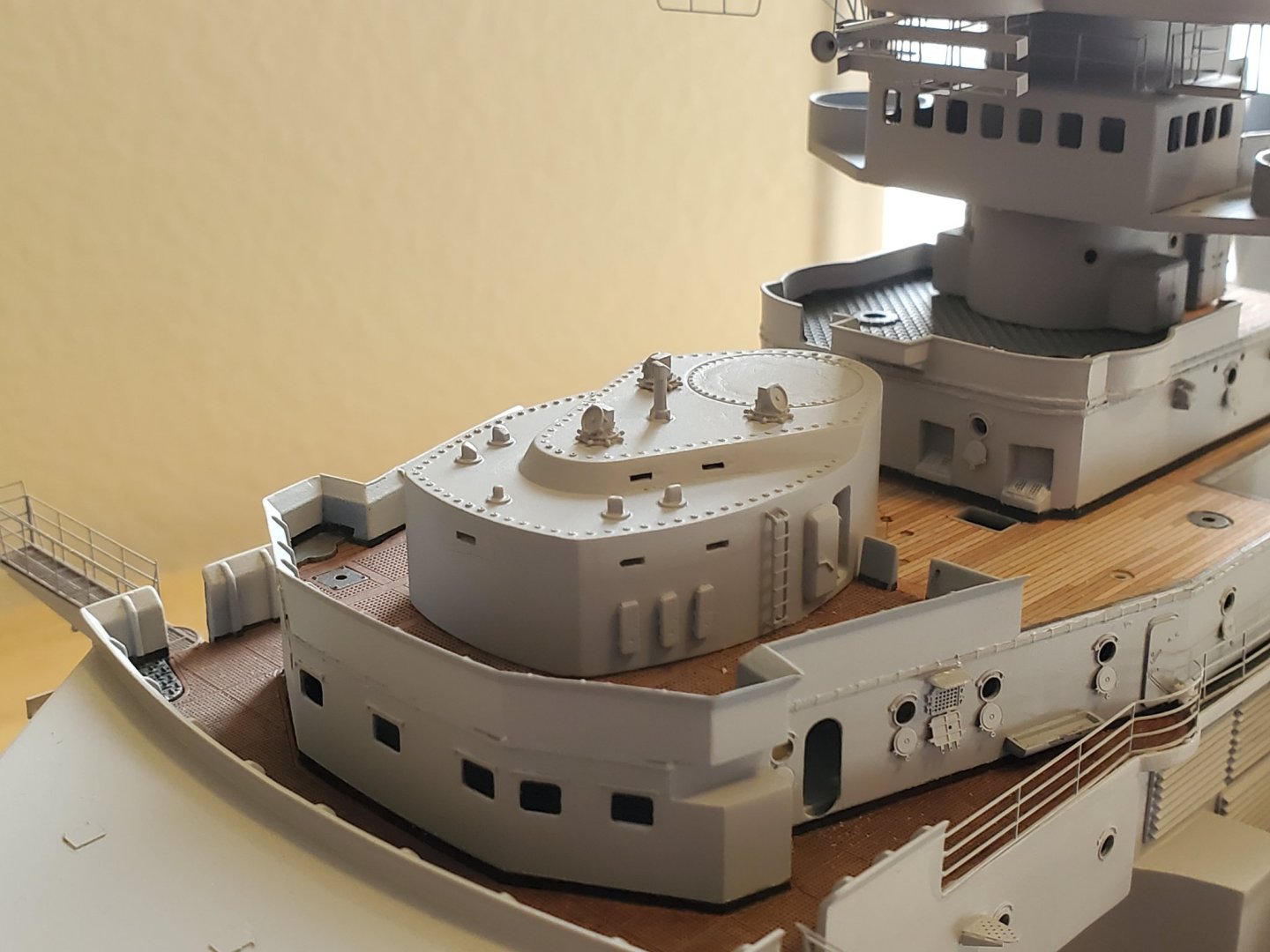

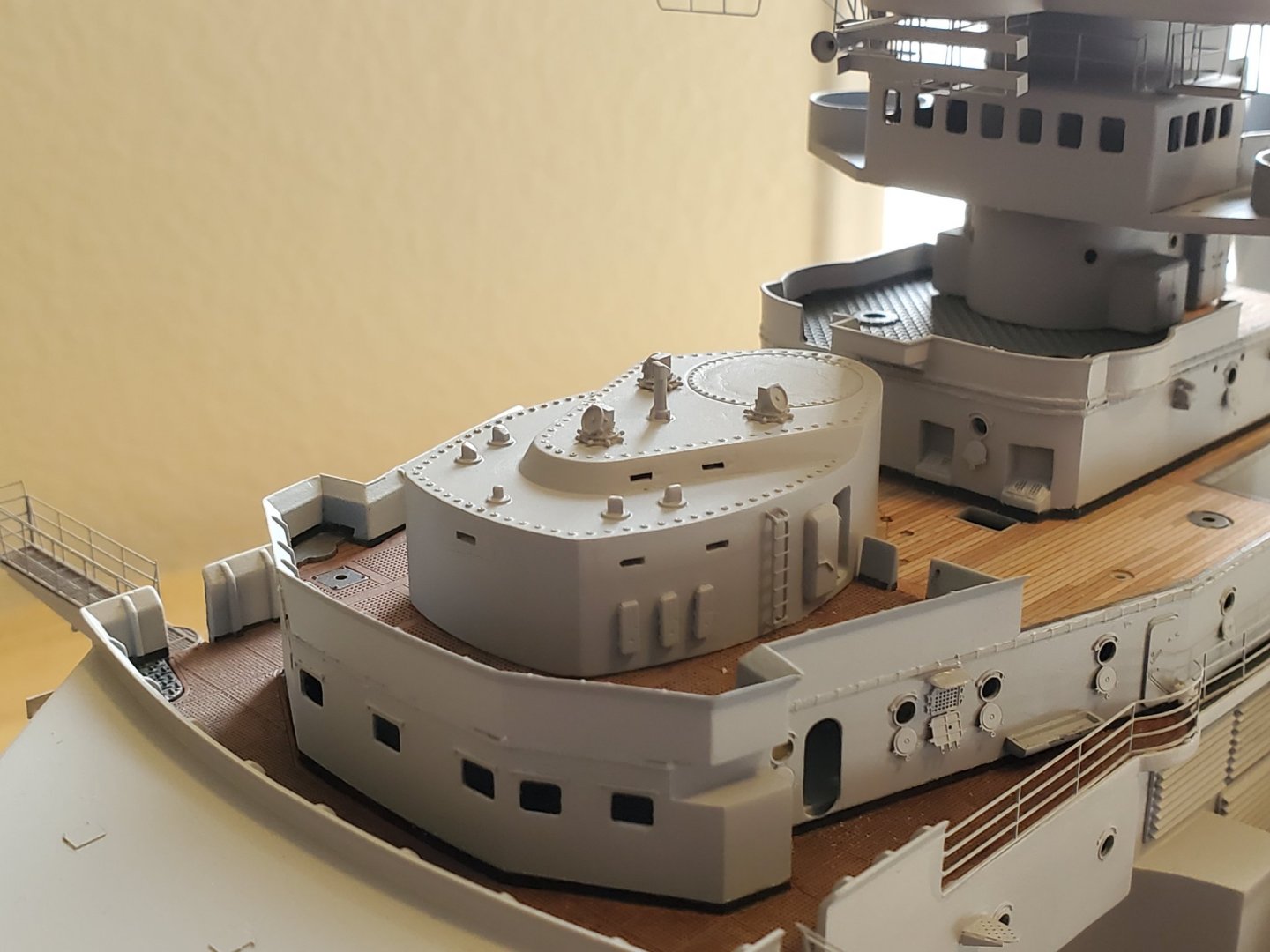

Made some more progress this weekend, got the rear superstructure PE all done and painted: Something I did that I don't see many other Bismarck builders do is paint the roof of the main hangar in dark grey (the same color as most all steel deck areas of the ship). I decided to do it because you can see it was painted likewise on the actual wreck... makes sense as this area would be walked around on to access the smaller boats that will eventually take residence here. I also put a huge amount of tedious work in on the many PE vents here; they were a bear to complete but look good. Here's the scariest one before installation: Anyway, there will be some touch-up to do still on this section but the next project is going to be the funnel and forward hangars. After that I'll return to do the smaller details such as the guns, railings/stairs and storage boxes that litter the superstructure.

-

Thanks! I appreciate all the interest and feedback on this build... It's a huge project and I can use all the positive reinforcement I can get!

-

I thought those little access hatches looked strange sticking out too but with paint on 'em they disappear nicely into the surrounding structure. Nice work!

-

Another quick update... I'm focusing attention on the aft upper superstructure lately. Some might question the practice of scraping off perfectly good molded detail only to replace it with tiny brass bits but I assure you, I am not insane. OK, OK... maybe just a little bit. Anyway, all the decks are installed and masked, tiny holes are drilled for bar steps and the photetch is going on. Tedious work as like the main superstructure level, there is A LOT of it. There's some debate on whether the aft section of the upper deck here was metal or planking; I decided to join the metal camp. Two flak guns would later be placed here but near as I can tell they weren't installed yet for my build's timeframe so I'm leaving them out.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.