-

Posts

249 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GTM

-

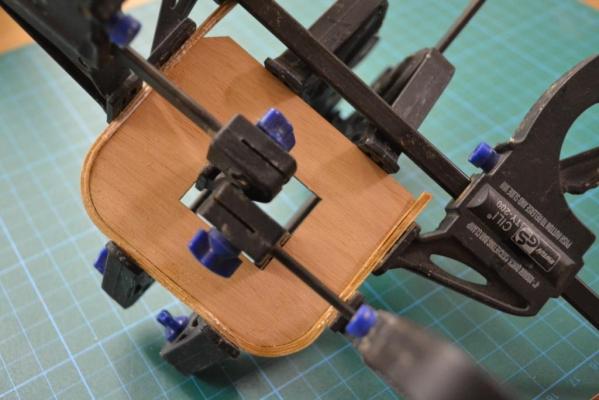

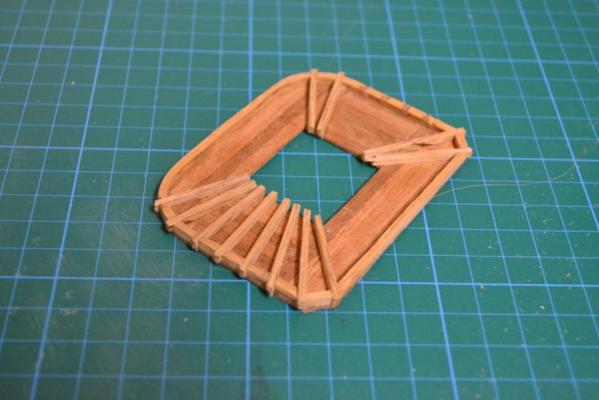

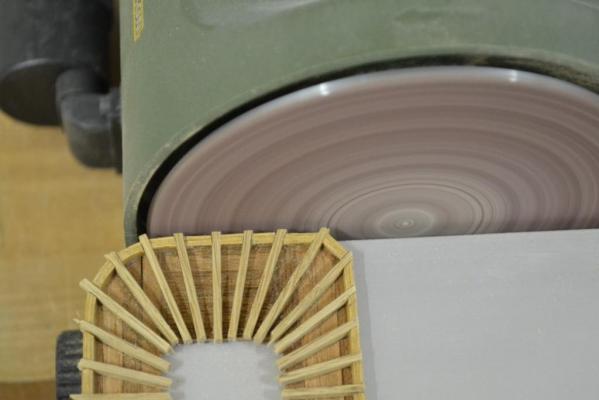

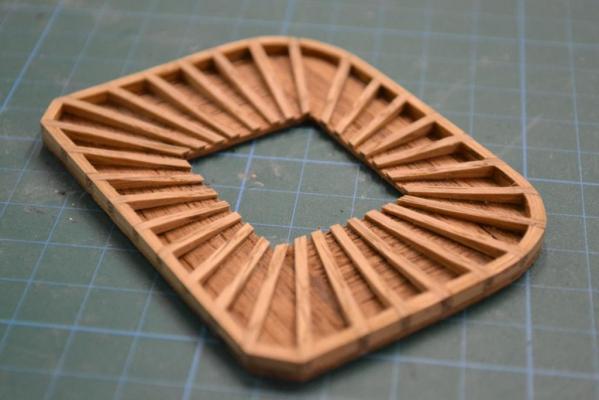

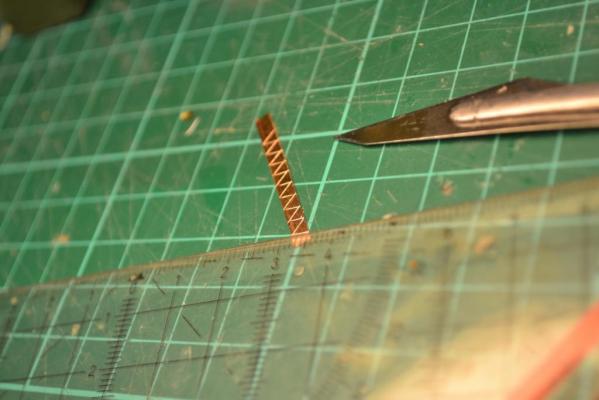

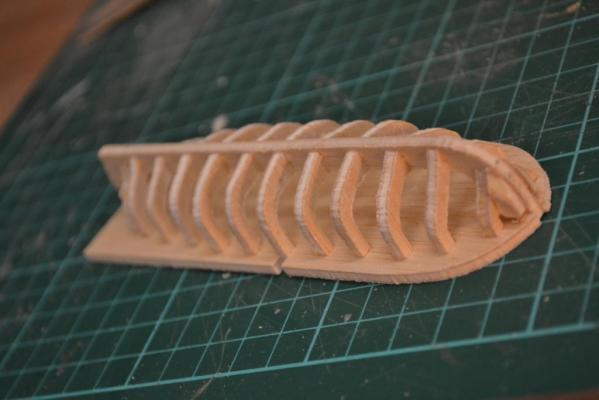

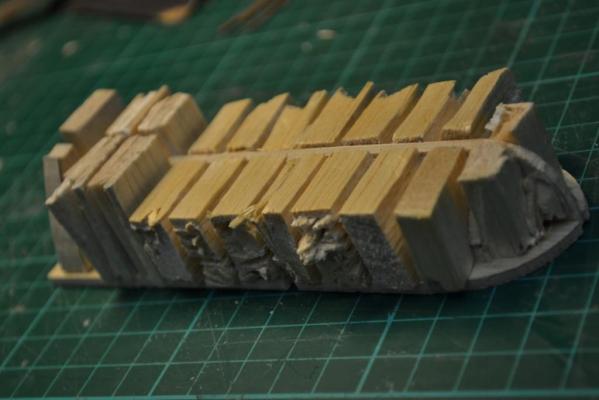

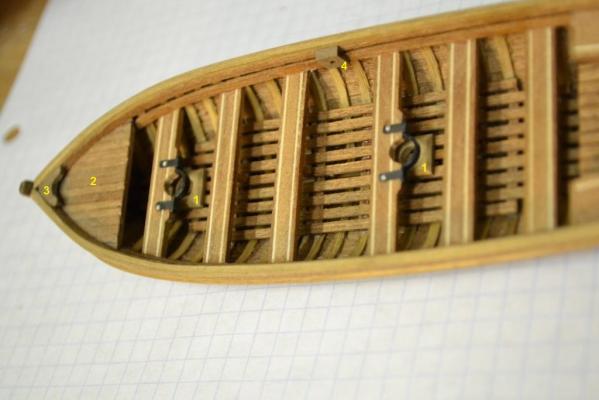

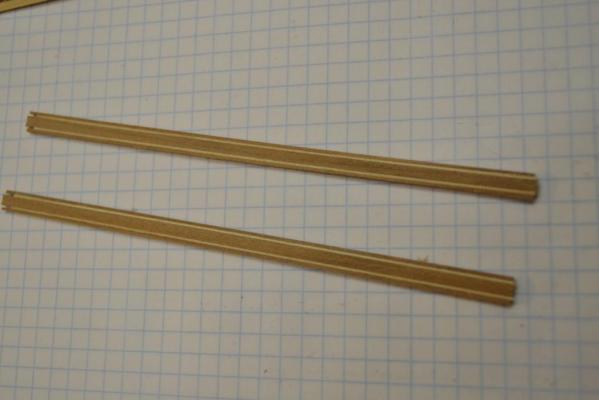

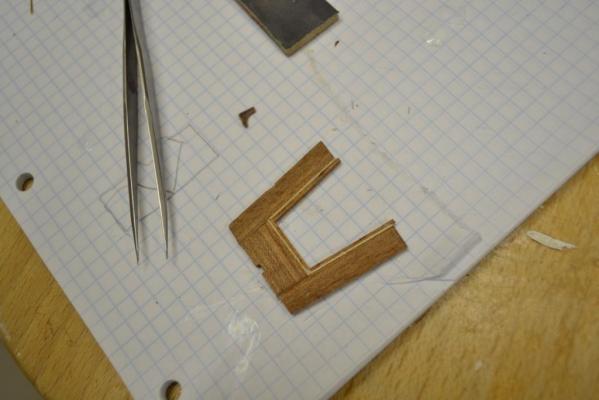

Thank you all, for the motivating responses .. And guess what ! (almost after a year), an real update !! I have cleared an corner in the basement and started concentrating on the tops of the ST. Again the kit version of the tops are made of plywood and are pretty basic, so naturally I will build them from scratch. So I started with preparing the planks for the platform itself. And to glue/shape the platform. The kits version doesn’t have a “ring” around it, so I decided to add one. For this I used the “size modified” plywood version as a template, and glued 4 pcs. Of 0.6mm oak strips together. Positioned the ribs.. .. and after some rough shaping, I started to shape all the ribs with a scalpel blade I can see now on the pictures that 'm still a bit rusty, so a few "minor" details/adjustments are needed..

-

Thanks Mike for pulling up my build from the MSW archives, you must have digged very deep .. Hej Guys, I know it has been a long time without any updates the main reason is space.., i had to pack most of the stuff away as the shipyard had to be cleared when i (after a dramatic change in my employment) started my own business. The shipyard now looks more like a stockroom and is completely filled up with boxes and equipment. I hope to be able to clear a corner soon, so i can start working on her again So don't be surprised to see some "real" updates of the ST soon

-

Not a lot of time I have spend on the ST, but I’m still alive and kicking So here’s an update about the progress I did so far. Instead of using the bright colored blocks provided by the kit, I made my own 4mm blocks out of teak wood. .. Not the best wood to use for manufacturing blocks.., too grainy as you will see and a lot of them ended in the trash .. But I like the color.. After having prepared the bowsprit, I placed it in position.., but I might regret it placing it in this early rigging stage of the build.

-

Thanks David, An dramatic change of employment has taken all my attention at the moment I’m afraid future updates on the ST will be quite irregular for an unknown period of time. An minor update. I (finally) managed to make my own hearts from teak wood and mounted/rigged the first ones on the bowsprit.. Underneath an visual sequense ..

-

Wow, Really nice job on the planking !!

- 270 replies

-

- red dragon

- artesania latina

-

(and 1 more)

Tagged with:

-

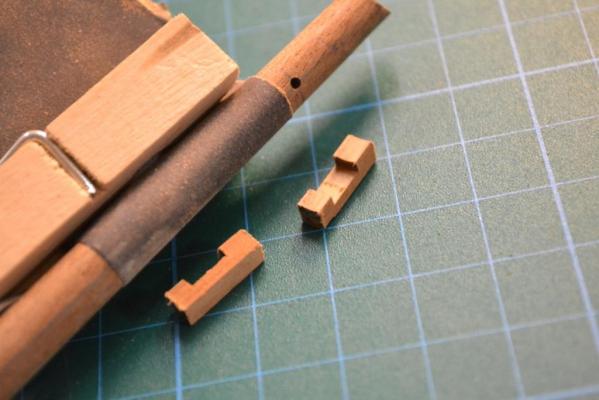

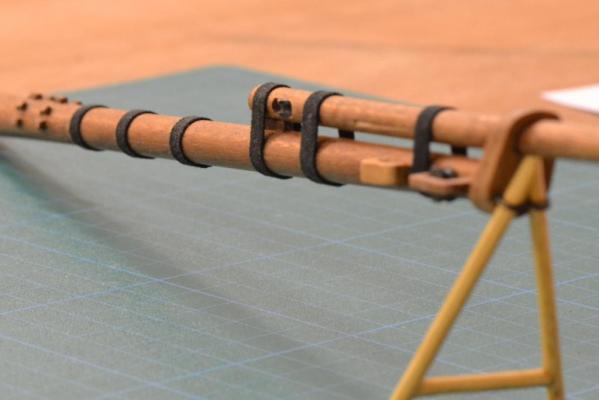

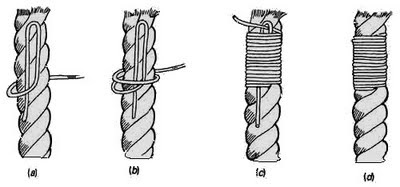

Thanks Sjors !! I know, I know.., I didn’t planned all this from the beginning at all.. Mainly thanks to my decision not to use any paint on this model ship makes the “plywood” parts and some of the supplied fittings not so attractive looking.. Today I had some quality time and continued working on the bowsprit.. I started with making and shaping the “Bee Blocks” (the back of them with help of sandpaper and the mast) so they should be a perfect fit. ..Milled a groove in the Jib boom for a sheave, and assembled the dolphin striker .. a close-up of the assembled Bowsprit Head and the bowsprit with jib boom. The drawing shows cut-outs in the bowsprit for the gammoning rigging, but instead I glued 2x5 small pieces of wood on the bowsprit and shaped them into so-called “gammoning cleats” by using a scalpel, a few different files and sandpaper for the final finish and not to forget I also added (black) wooldings. I used the following technique for securing the wooldings. What remains are the blocks and hearts (but after having looked at them) I will most likely "somehow" make my own.

-

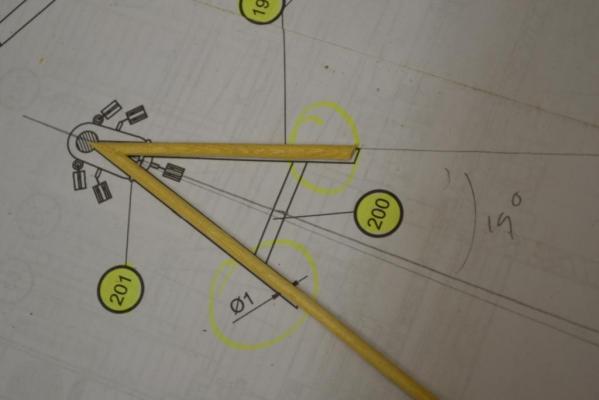

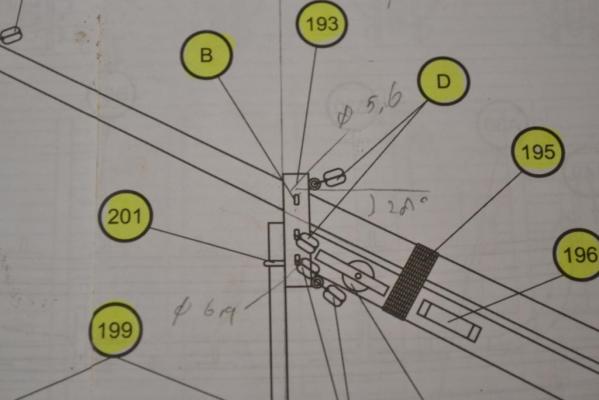

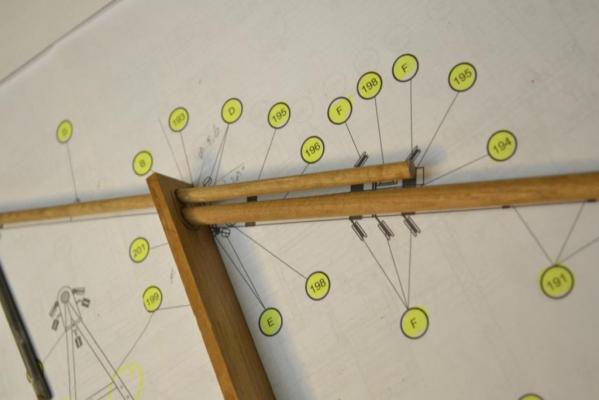

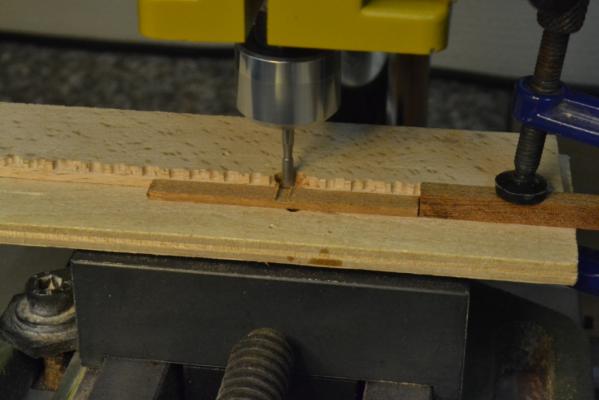

A slow start… , I worked a bit on the bowsprit. The first thing I noticed was the “bowsprit cap” (no. 193) The kit includes a version which was laser pre-cut, but “made of plywood”. So (with a little help of Santisima Trinidad drawings found on a Spanish website) I started working on another version which was based on the angles and diameters of the Occre Kit. So for the first time I could “try-out” the proxxon drill stand in an angled position and drilled 2 holes in a 28 degree angle with a Ø5mm router-bit. And (after some small file-adjustments) with the right angles. Additionally I also could try-out my newest tool in the workshop (a proxxon disk sander) with strange angles So here’s my version of the bowsprit cap..

-

I agree Sjors, this “dark side” is getting pretty close... I’ll see if “the force is with me” when I’m finished with this build. I completed the assembling of all 4 anchors and have “pre-“rigged them. Nothing spectacular to mention about how I did it, but installing them now would not be so clever I think. I’ll wait with that until I have installed the masts & rigging. From now on the instruction-book stops telling in detail what to do next. However, there are several (close-up) pictures of a complete rigged ship and 1:1 drawings of the masts & detailed rigging drawings. So after 2 years and 3 months of building, I’m finally ready for the next step: masts & rigging..

-

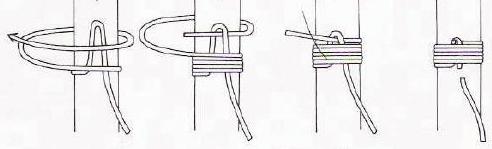

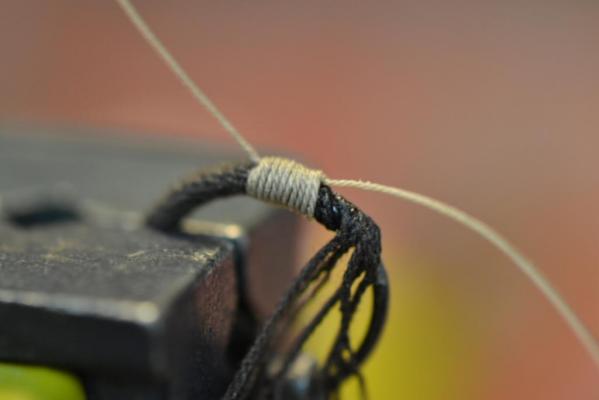

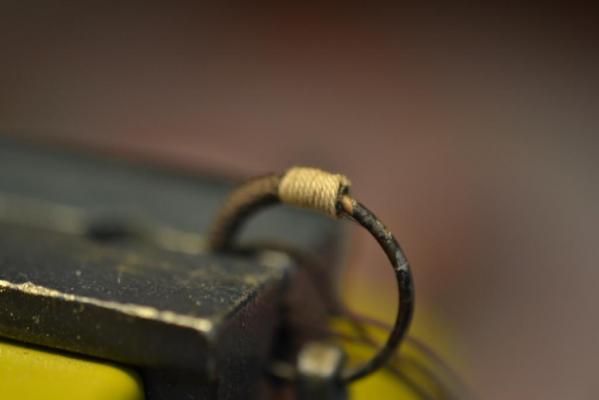

Thank you Sjors & CaptainSteve & all the likes !!! After spending "months” on building the ships boats, it is nice to start on something else Today I started looking at the anchors and after some research I found out that the included (cast metal) "stock" is not in the correct scale. At least in the 18 century the stock has the same length as the shank, so I made a new stock for all 4 anchors. Thanks to this research I also found out that the anchor-ring has to be covered with “tarred cloth, rope and yarn” .. So I gave it a try but failed miserably the first few times .. and I’m not going to show my first results.. “learning by doing” (and thank god for the invention of thin CA glue) I “developed” the following technique.. After positioning “5 pcs.” of Ø0,35mm ropes with my hands, I used thin CA glue to “fix” these ropes temporary in position, I wrapped the ropes several times around the ring and placed the ring in a vice so I could “permanently” fix the ropes with "common whipping". Common whipping: I cut the ropes just before the whipping by using a sharp scalpel blade and use thin CA glue to prevent any unraveling. After having wrapped the ropes all the way, I use the same technique again: fixing the ropes with CA glue, whipping, cut the ropes and “securing” with thin CA glue. I’m satisfied with the end-result, but naturally “Macro pictures” shows every mistake ..

-

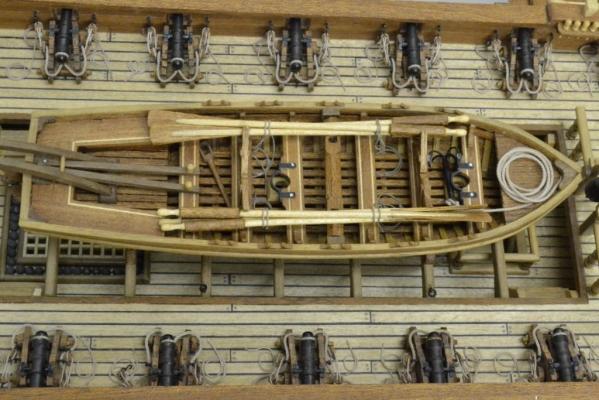

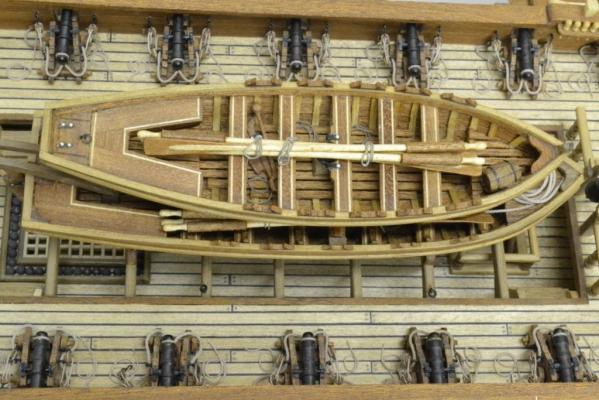

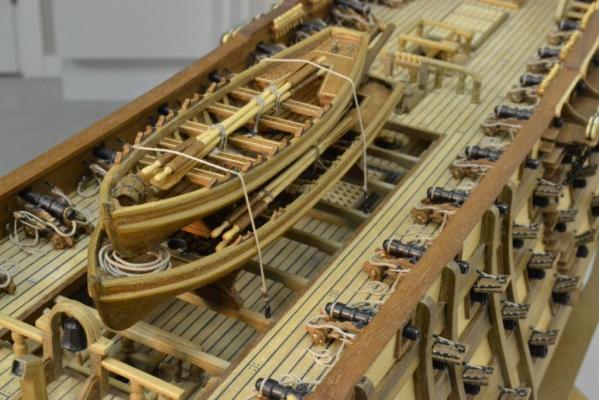

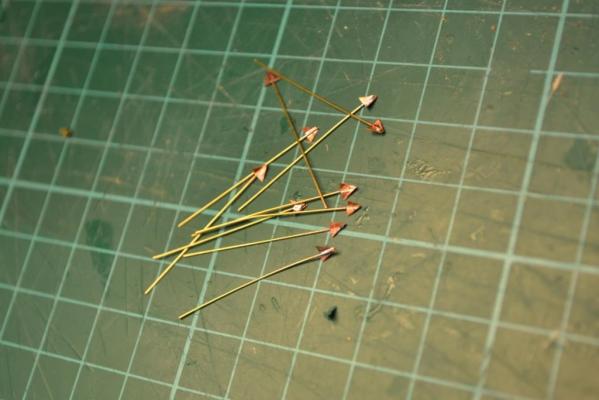

An ”minor” update.. I placed the ships boats into their final position, however also this took much longer time as I had in mind. First I wasn’t satisfied with the supplied “plywood” crutches, so I decided to make my own. But I couldn’t find much inspiration for them (so mine are based on the supplied ones) however i think i added a bit more “vintage" to them. Here’s a “dry fit” picture. The next thing I decided to make was some mini-hooks for the rigging (This post “LINK” explains in more detail how I made them). Because I wasn’t happy with the color of the supplied rigging blocks I tried to make a few myself with some darker wood types. I ended up in using teak (probably not the best choice) as teak is quite grainy, but this was what was available to me. With this macro shot I can see that the rigging (and the blocks) looks much better from a distance … Also all the oars needed to be lashed in their final position, and I spend quite some time in “coiling” randomly all the ropes with my previously mentioned (rigging of the cannons) technique. Too bad that most of all this will be invisible after positioning the second ships boat … And, “at last”.. I could rigg the boats in position, and (off course) I had to make some extra rope-coils.. Taa-Daaa !!!

-

Thank you very much Michael, and thanks to all who hit the “like button”. Yes !!, I'm finished with the second ships boat.. The techniques and look i used is similar to the first boat. Underneath a very brief photo sequence. Here a few shots of both, with the fittings in place.. .. I wish everyone in MSW a happy 2015 !! ..

-

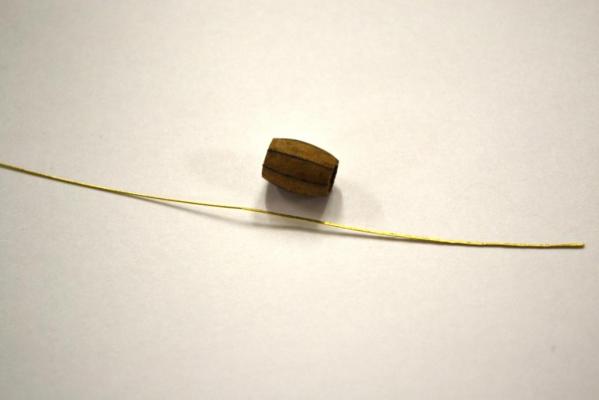

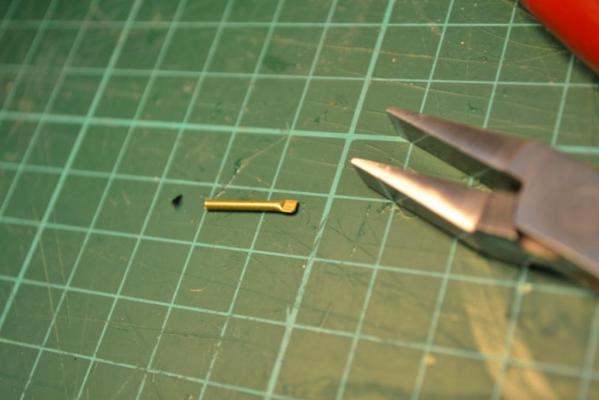

I’m still working on the second ships boat.. pictures of the (slow) progress will follow soon. In the mean time I spend some time on other details for the ships boats.. I had an idea in my head about how to make “barrels”, and started working on a prototype. I cut a “square lath" into “8” triangles with my FET saw and glued these in a "square lath" again with pieces of (black) paper in between. The picture underneath shows much better what I’m trying to write .. Using a lathe I turned it into a round stick and drilled a hole in one end. I shaped it with a file, sandpaper and a scalpel into a barrel shape and glued a top & bottom in position. "Flattening" 0,3mm brass wire, soldered it into a circles and blackened them. Maybe not the best, but here it is: my first prototype of an barrel.. I also spend some time on the oars (the kit’s supplied oars where made out of cast metal.) No more “new” ship boats details, I will leave it with this and continue with the second ships boat ..

-

An great idea !!! A shame it’s too late to implement on the Santisima Trinidad.. I will remember this one for sure

-

Hej Kevin, Keep in focus !!! and i'm sure, the force will be with you !! I’m looking forward to any "victory" update !!

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

One of the details I wanted to add was a grapnel anchor.. The main problem was how to manufacture these.. An idea came up in my head using a 1,5 mm brass tube and 5 pcs. of 0,4mm wire and I started working on it. Underneath again a visual sequence of the idea. Even though the result is not bad, especially after blackening, I wasn't satisfied with the “hooks” and the wire i used, .."peanuts" maybe.., but anyway, I started on version 2. This time i used a 2mm brass tube and a slightly thicker (0,5 mm) brass wire and also a different hook type. And by using 2 mm brass tube, I could shape the shaft a bit more, but.., unfortunately it could only contain 4 wires.. It’s still not perfect, but I leave it for now… This is the final result after some fine-tuning, blackening and a cable attached.

-

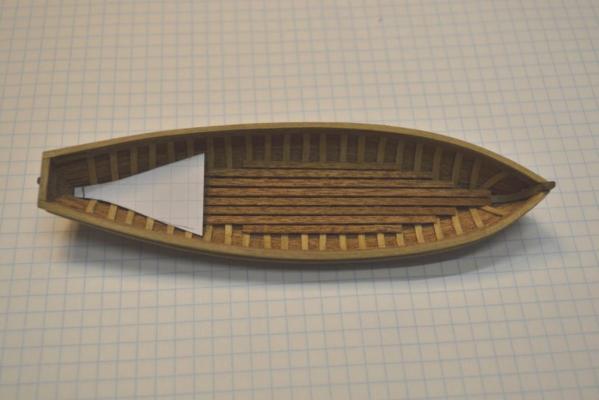

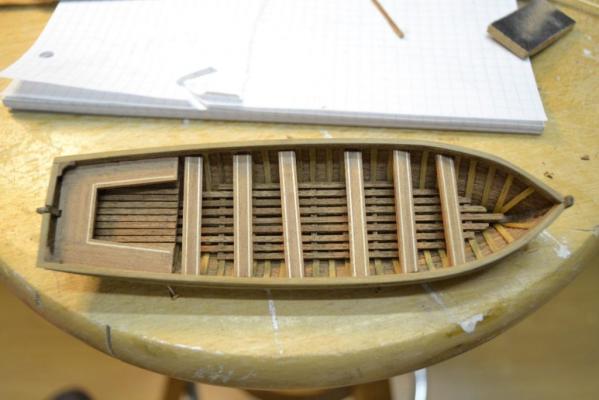

..As I had expected.., at last, I'm finally able to present an update. The ST kit includes 2 ship boats, so I continued with building the second one. The build method I used for the second one is pretty much the same as i used for the first one. Mainly because of the experiences/practice I had with building the first ships boat, this one was pretty straight forward and without too many problems. I decided to post a photo sequence of the progress so far, the pictures should speak for themselves.. So this is "status quo" after removing the template. this time I could remove the body without destroying the template. You also might notice that this boat is a bit different in shape, therefore I’m planning to add some other details to it.

-

Hej Sjors, She just looks fantastic !!.. Are you considering a display case for her ?

- 1,873 replies

-

- occre

- san ildefonso

-

(and 1 more)

Tagged with:

-

I found a few hours of spare time and managed to complete most of the details.. The windlass and knees are now installed.. I also installed an (removable) davit with davit supports, which is used in combination with the windlass, and installed the rudder with a removable tiller. ..and still a few more details left to add..

-

Thank you Brian, and others for visiting and all the likes.. Unfortunately mainly because of other duties at home & work the build is/will be pretty slow for some time to come.. Here's what i did so far.. The stern bench is now fixed in place. I made brass mast clamps and fixed them on the thwarts. Added mast steps (1) and added decking (2) and a breasthook (3) and started working on the windlass mount (4). ...

-

Thanks Laurence for your visit and your kind words, very appreciated and motivating.. Next fase.. With the cannon carriages and hatches in my head I re-developed the “sandwich veneer” technique I used. But instead of using thin cardboard I used thin stripes (0,6 + 1,0mm) veneer and sandwiched/glued these into a lath. Also embedded/added a stripe of veneer into the stern sheet. I dry-fitted the components in the next picture, to verify positions and scale. ..but i think it looks promising.. ..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.