-

Posts

1,190 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bedford

-

It's been a while, no reasons, no excuses, I just haven't felt like doing anything with her..... I am in the process of making chain plates but had to get more brass to do it so while waiting I fitted the shroud tables and realised that she looked a bit unfinished in the hull. Then I realised she needed a stripe.

-

Batavia by *Hans* - FINISHED

Bedford replied to *Hans*'s topic in - Build logs for subjects built 1501 - 1750

And he slips in a semi nautical reference, "You ain't Robinson Crusoe" -

Batavia by *Hans* - FINISHED

Bedford replied to *Hans*'s topic in - Build logs for subjects built 1501 - 1750

That's not much really when you consider the James Craig cost $20 million to restore. It is all relative though. Steve -

I agree with the new compass placement, it just looks right!

- 2,196 replies

-

Lovely work Michael. No radio eh? Brave man, that! I would never have the intestinal fortitude to do that. Steve

- 2,196 replies

-

G'day Bruce! Have you seen Bruce? No Bruce.

- 420 replies

-

- lettie g. howard

- schooner

-

(and 1 more)

Tagged with:

-

More hold ups, I got my dear old mums' old sewing machine out to try my hand at sail making and it didn't work, I could not get the bobbin working. I reasoned that dear old mum had no mechanical aptitude at all and she could do it so I must be over thinking it. I asked a lady friend to come and see what she could do with it but she had no luck either. Tonight I started pulling it apart and bits of the bevel gear that drives the bobbin fell out onto the table. That's terminal in a 40 year old machine so I will borrow the afore mentioned friends' machine. Michael, you were talking about all the things you saved over the years and while I try to limit the amount of bits I keep, the macine is full of cams, gears, shafts, specialised screws and a good healthy motor and speed control unit. I will be stripping the machine out before I toss it.

-

I'm with the "I have to remind myself it isn't full size" brigade. I aspire to this level of build but fear I just don't have the patience. Steve

- 2,196 replies

-

Batavia by *Hans* - FINISHED

Bedford replied to *Hans*'s topic in - Build logs for subjects built 1501 - 1750

I have seen the stern section in the Freemantle museum and been aboard the replica when she was in Sydney at the Australian Maritime Museum. There is a book called Islands of Angry Ghosts that tells the gruesome story of the Batavia as well as the story of discovering and recovering the artifacts. It is a chilling read. This build is quite interesting and I love the stern you have made. Steve -

One thing I got from the video is a much better realisation of the size of the model, she will be magnificent under sail

- 2,196 replies

-

I have been otherwise occupied for the last few days, yesterday I was just about to start work on the schooner when my son knocked on the door and said "wanna come 4wd'ing" uuuuuuuuuuummmmmmmmmmmmm, yeah! Only 10 mins from home is a nice place with plenty of variety but I didn't get home til 7:30 and was a bit tired so didn't touch it. Today, on my way home from work and my son rings, "Dad, can you do me a favour"? mmmmm, what? "Come and get me unstuck" He was about 20K's out of town up a track he should not have attempted on his own and I had to winch my car around his so I could winch him out, 3.5 hours after I left work I got home! No work on the schooner tonight either ! Wish me luck for tomorrow.

-

Yes, it's a sad day when we can't learn from our fellow modellers. Steve

- 420 replies

-

- lettie g. howard

- schooner

-

(and 1 more)

Tagged with:

-

Never mind Bob, I wish I lived around the corner from you so I could learn more. That works beautifully. Steve

- 2,196 replies

-

Bob, yes all the hardware will be accessable via deck houses and hatches but the running rigging will be in brass tube which will be fixed in the hull and never be seen again, this way I don't have rigging running through a bunch of blocks below deck which could be a maintenance nightmare. I have to make sure it is all aligned where it needs to be and everything fits and works freely before I fit the deck. I think that if I build another such model I will approach the hull / deck / control and rigging from a VERY different angle, the idea is rattling around in my head now but it is way too late to do it with the schooner.

-

You might just have given me some ideas there Bob, excellent! Steve

- 420 replies

-

- lettie g. howard

- schooner

-

(and 1 more)

Tagged with:

-

It always intrigues me how you see these shapes inside the stock material. I guess that comes witha lot of machining experience. Steve

- 2,196 replies

-

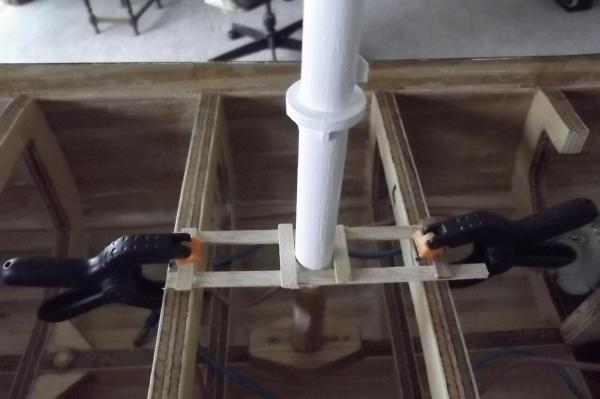

I was going to move the motors forward when mounting them permanently, this would have meant no cutting ribs and it would have helped move the centre of gravity forward but this involved making drive shaft extensions, I made one that would fit over the 3mm prop shaft and reduced down to fit into the 3mm coupling on the double cardon joint. I was concerned though because a double cardon will allow the shaft to move sideways so it could bend out of true under power which would be catastrophic so I ditched that idea and cut out some ribbing and mounted them with the couplings direct onto the prop shafts. After fitting the motors I floated her in the bath and powered her up to make sure the motors and props were operating properly and freely. Holding the stern down to the correct water level I powered her up to a reasonably high speed and the motors sang in harmony like a twin engine plane does (for anyone who knows what I mean) this told me they are well ballanced and should not cause the handling issues the mis-matched smaller motors did. I also made frames to locate the masts in the correct position so I can move onto the next phase of construction. Before I can fit the deck I need to rig her and get all the operating systems fitted and working properly. Then I can close the hull. This means partially fitting the standing rigging and fitting the running rigging then unshipping the lot so I can fit the deck and deck houses etc.

-

Again, beautifully made Michael, lessons being learned left, right and centre here.

- 2,196 replies

-

Beautiful work Michael, You keep comming up with great ways of doing things and the details are brilliant. Steve

- 2,196 replies

-

Mark, you are of course right. The whole idea of sea trials is to find weak links and induce the failures that are impending and to that end it was an extremely successful trial. Especially given that no harm was done to ship or systems. I would hate to see that smoke rising slowly through closed deck houses etc with a deck on and the hull closed and no idea just how bad it is. I took her out again yesterday evening for a trial with the smaller motors fitted without the reduction gearboxes and while they are more than capable of driving her to scale speed and then some, they seemed to make her harder to control. On return to shore I noticed that the starboard motor starts before the port motor, they should be the same. When ramping up the speed very slowly there are probably 200 revs in the starboard before the port starts and this matches the handling issues. Obviously the starboard is pushing harder than the port motor so I will ditch them and re-fit the larger 540 can motors knowing that they will effortlessly handle her under any conditions.

-

You are doing some great things Michael, pity about the timbers but it's all about trial and error, especially with a scratch build. I am sure you will get it perfect. Steve

- 2,196 replies

-

Yes Michael, new model, heaps of hours and thought, not to mention $ put into it and SMOKE rising! I was lucky she was back into shallow enough water that I oculd get to her fairly easily and thankfully no more smoke rose so I wasn't in too much of a panic. I was going to gently motor in past the rock and end the trial but she had to get pushed in past it. John, yes the low speed looks right and will be most commonly used but having all that power in reserve means the auxilliary power will have a good chance of overcoming the wind should the need arrise. After the test I moved the throttle servo to a variable auxilliary channel on the radio because then I can just set the speed where I want it and forget it. With it on the same stick as the rudder you tend to be powering up and down and even into reverse accidentally while steering. Most importantly while she is under sail I won't accidentally engage the motors. At this point I envisage motoring out until she is free to navigate and then raising the sails and vice-versa when bringing her in. Yes, the splash near the tree was the platypus. I know they are out there and I have gone out many times and sat quietly in the late afternoon hoping to see them but they are ellusive little buggers and to date I have never actually seen one properly.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.