-

Posts

110 -

Joined

-

Last visited

-

Dave B reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

Dave B reacted to a post in a topic:

HMS EURYALUS by Matiz - FINISHED - scale 1:56

-

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Dave B reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

Dave B reacted to a post in a topic:

Sloop Speedwell by Chuck - Ketch Rigged Sloop, 1752 - POF

-

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

-

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

-

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

Scottish Guy reacted to a post in a topic:

Professional Building Slip - Hobbyzone

-

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

-

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

-

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

Mr Whippy reacted to a post in a topic:

HMS Speedy by Dave B - Vanguard Models - 1:64

-

Dave B reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

Dave B reacted to a post in a topic:

Medway Longboat 1742 by bartley - 1:24 scale

-

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

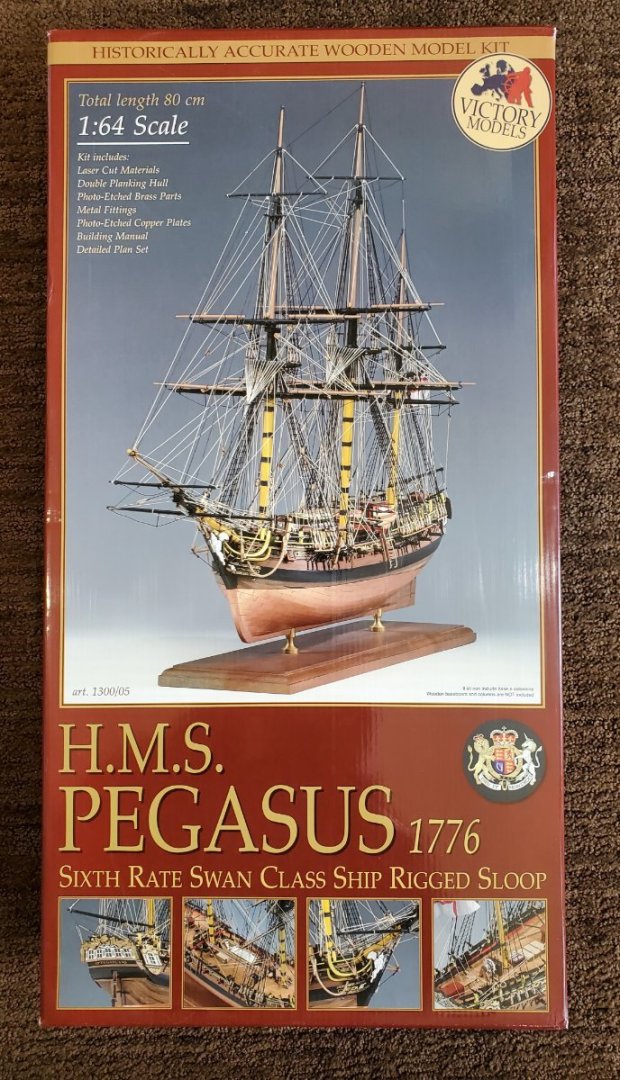

Keith Black reacted to a post in a topic:

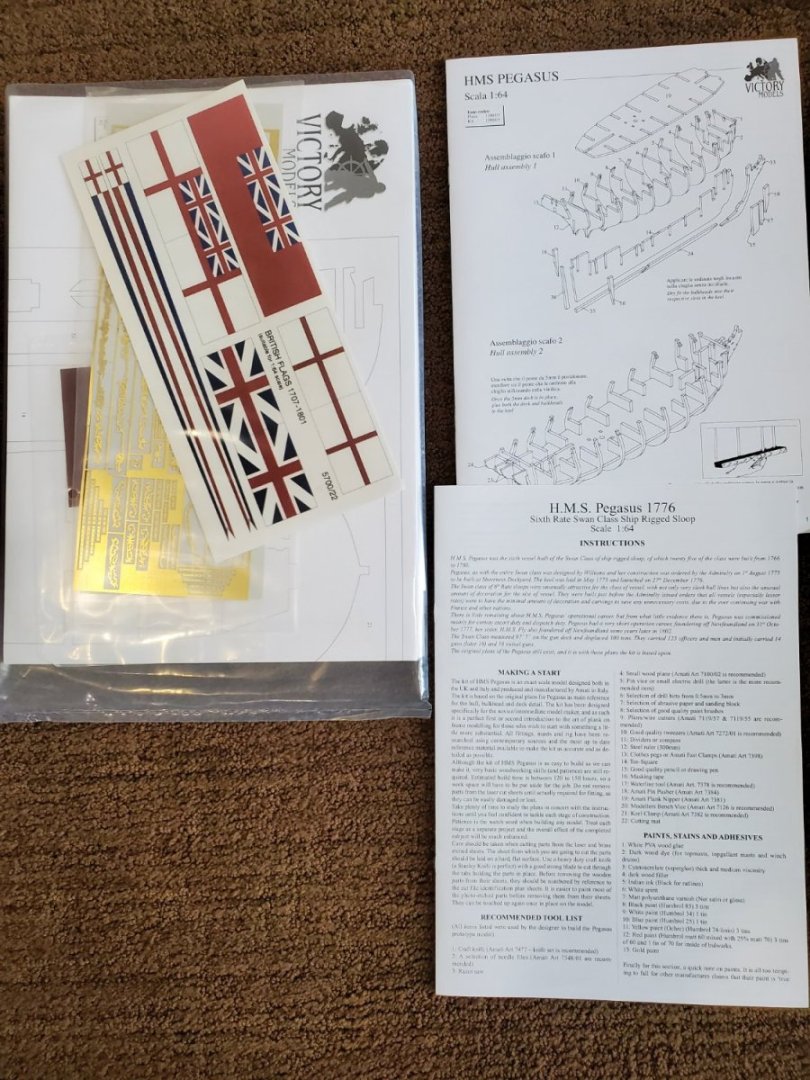

HMS Pegasus from Amati Victory Models for sale $300

Keith Black reacted to a post in a topic:

HMS Pegasus from Amati Victory Models for sale $300

-

mtaylor reacted to a post in a topic:

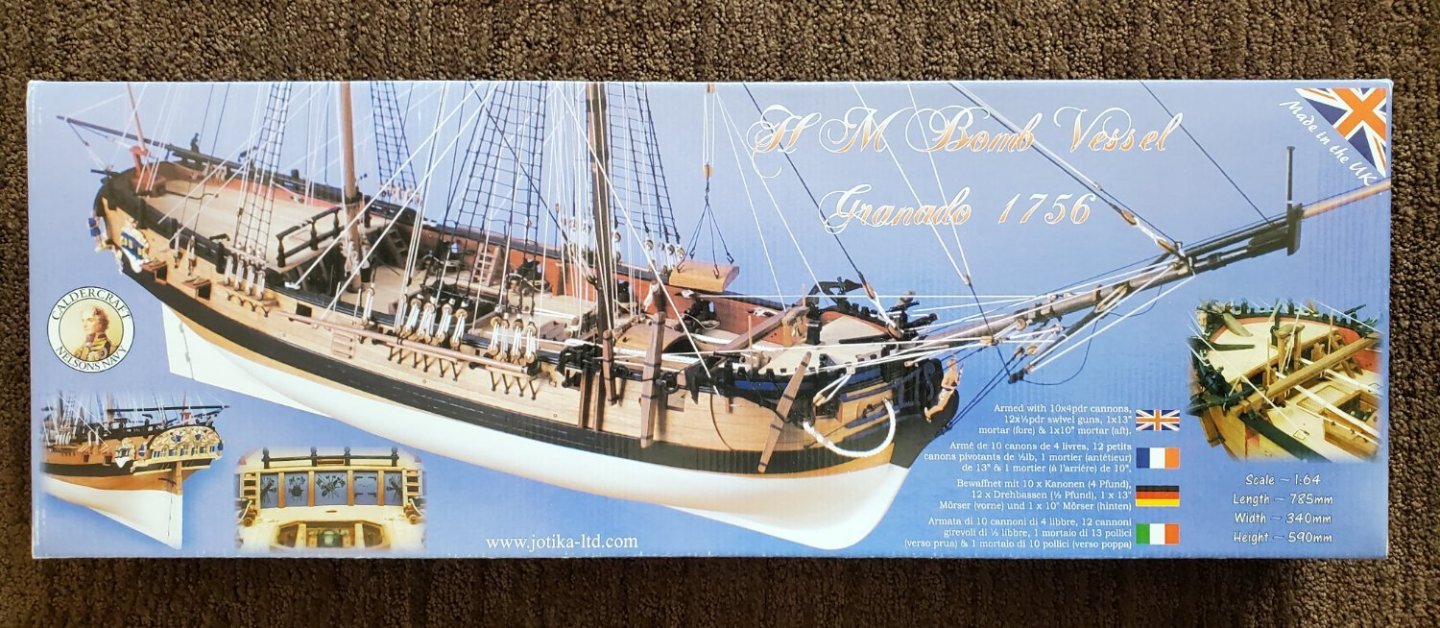

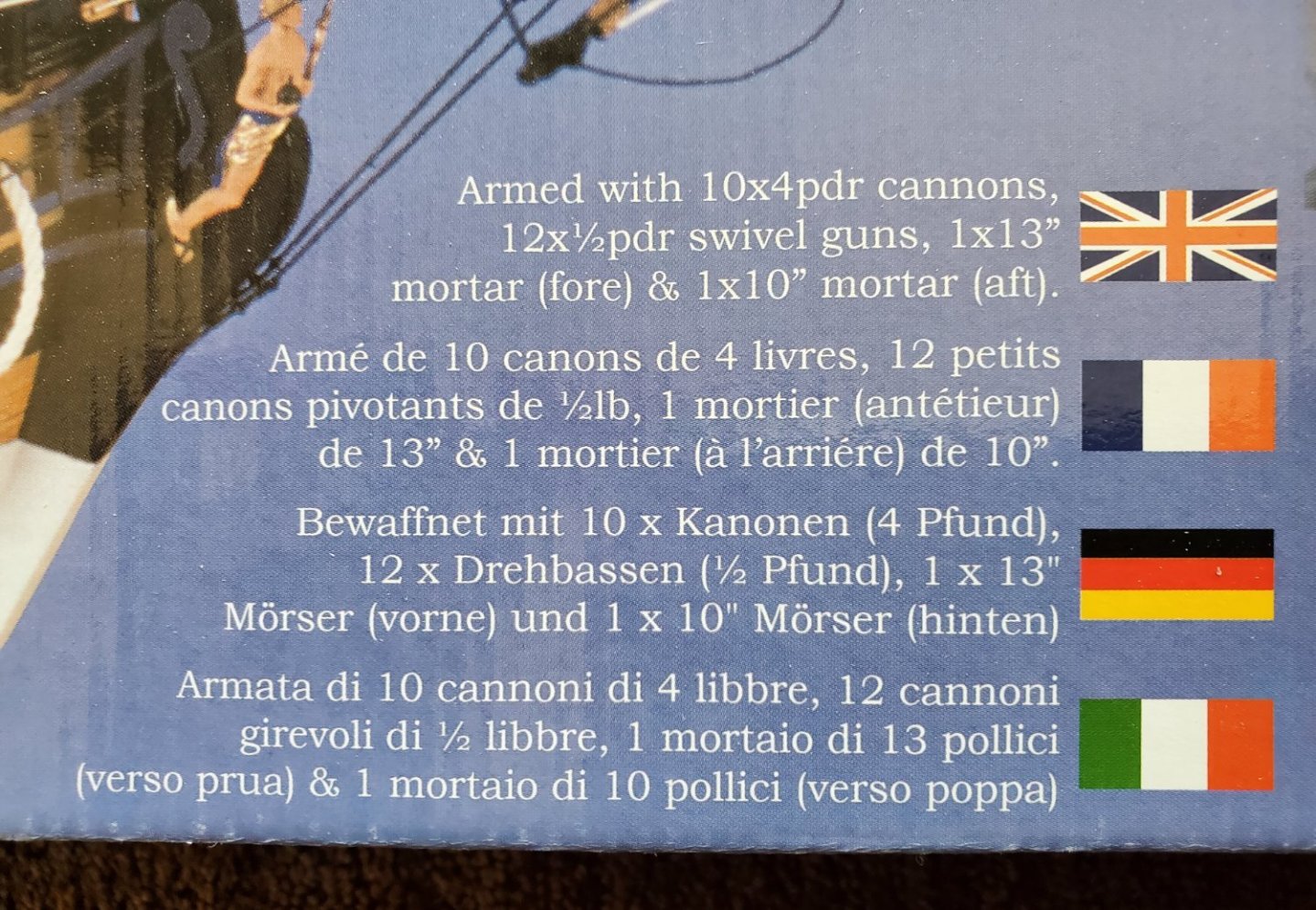

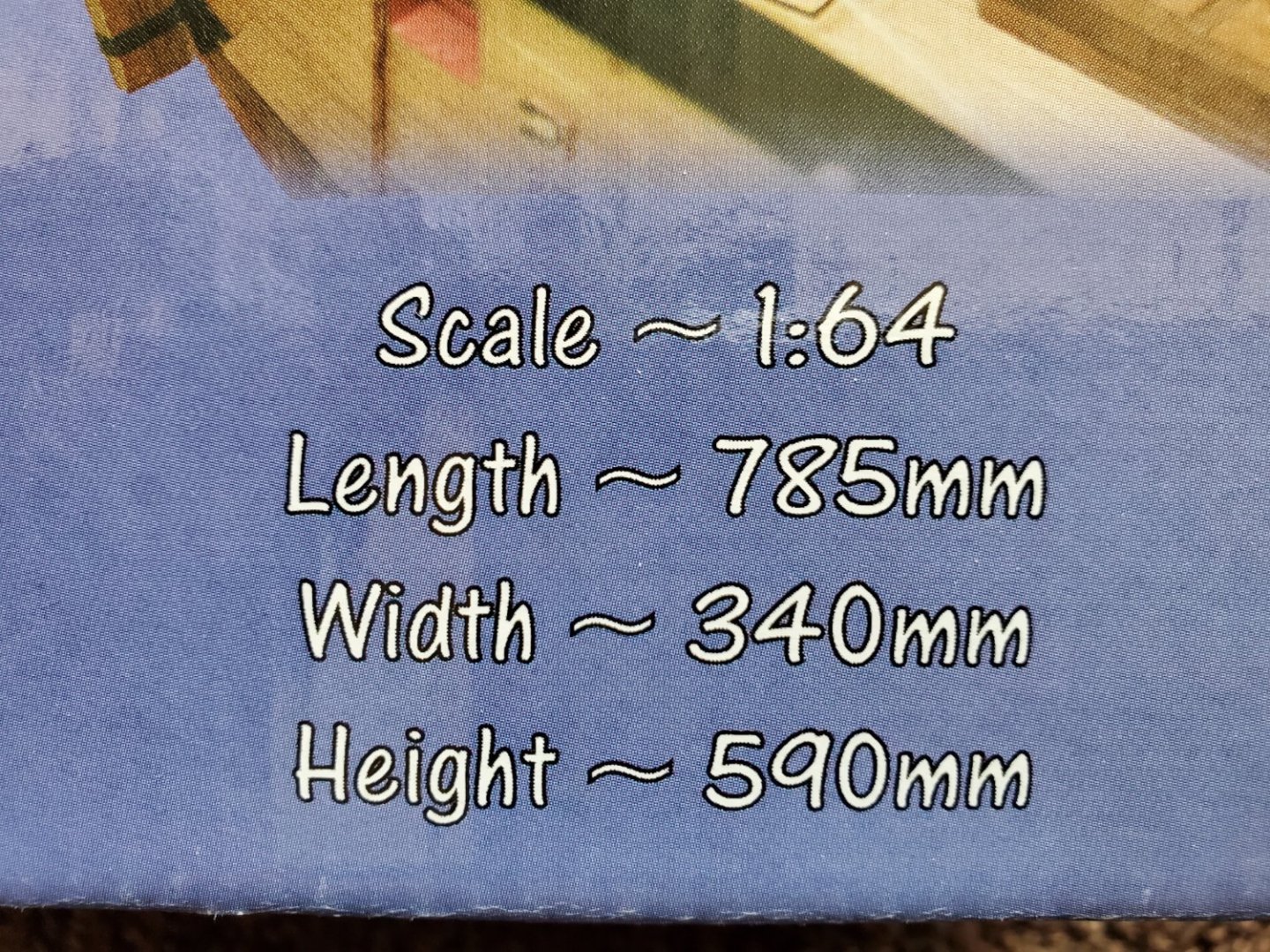

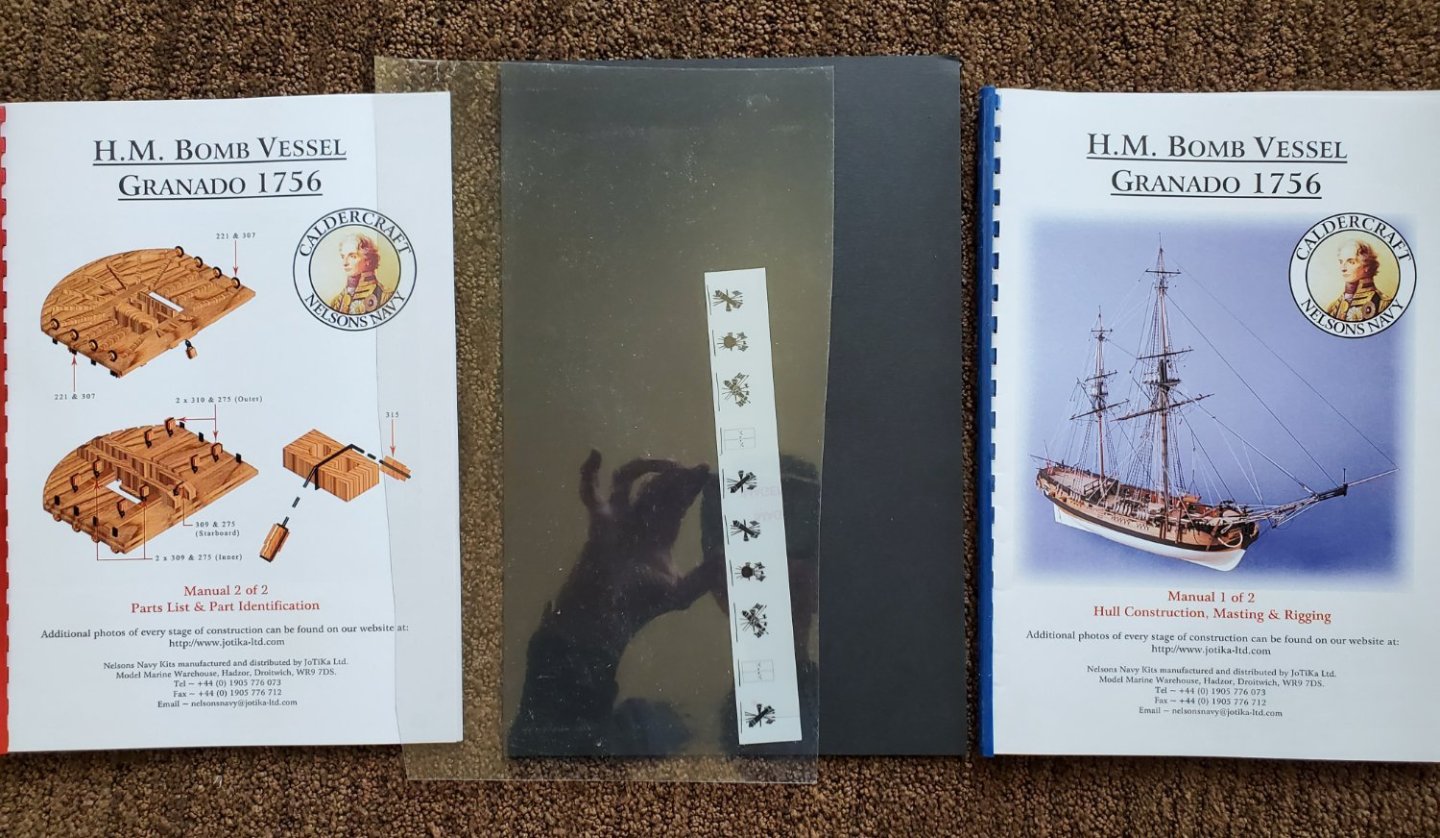

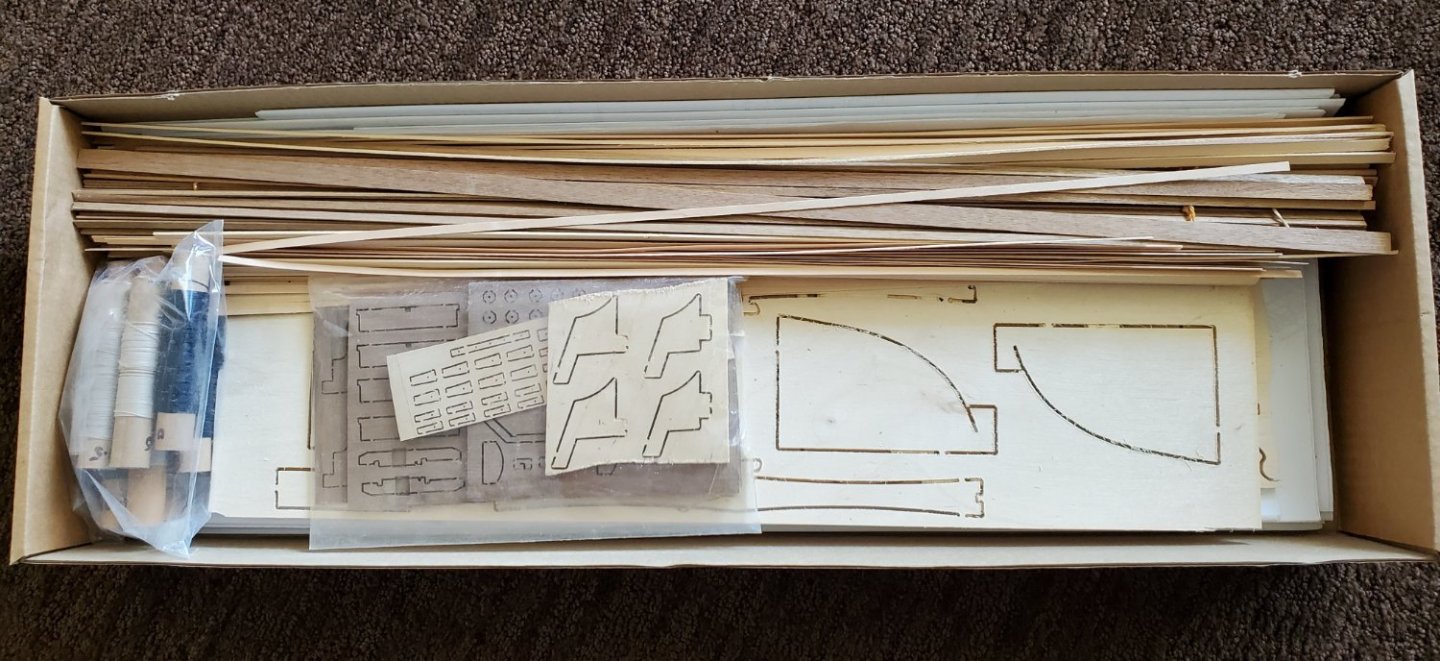

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

mtaylor reacted to a post in a topic:

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

-

GrandpaPhil reacted to a post in a topic:

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

GrandpaPhil reacted to a post in a topic:

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

-

GrandpaPhil reacted to a post in a topic:

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

GrandpaPhil reacted to a post in a topic:

Kit for sale - Caldercraft Bomb Vessel Granado 1:64 now $199

-

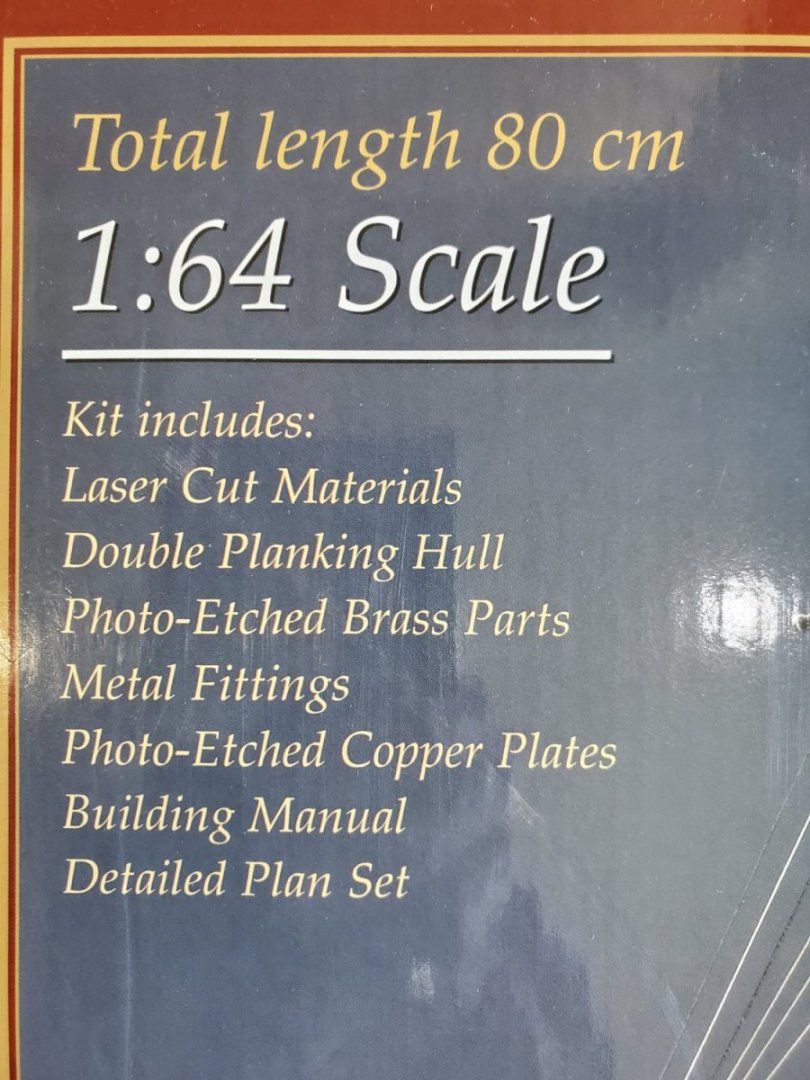

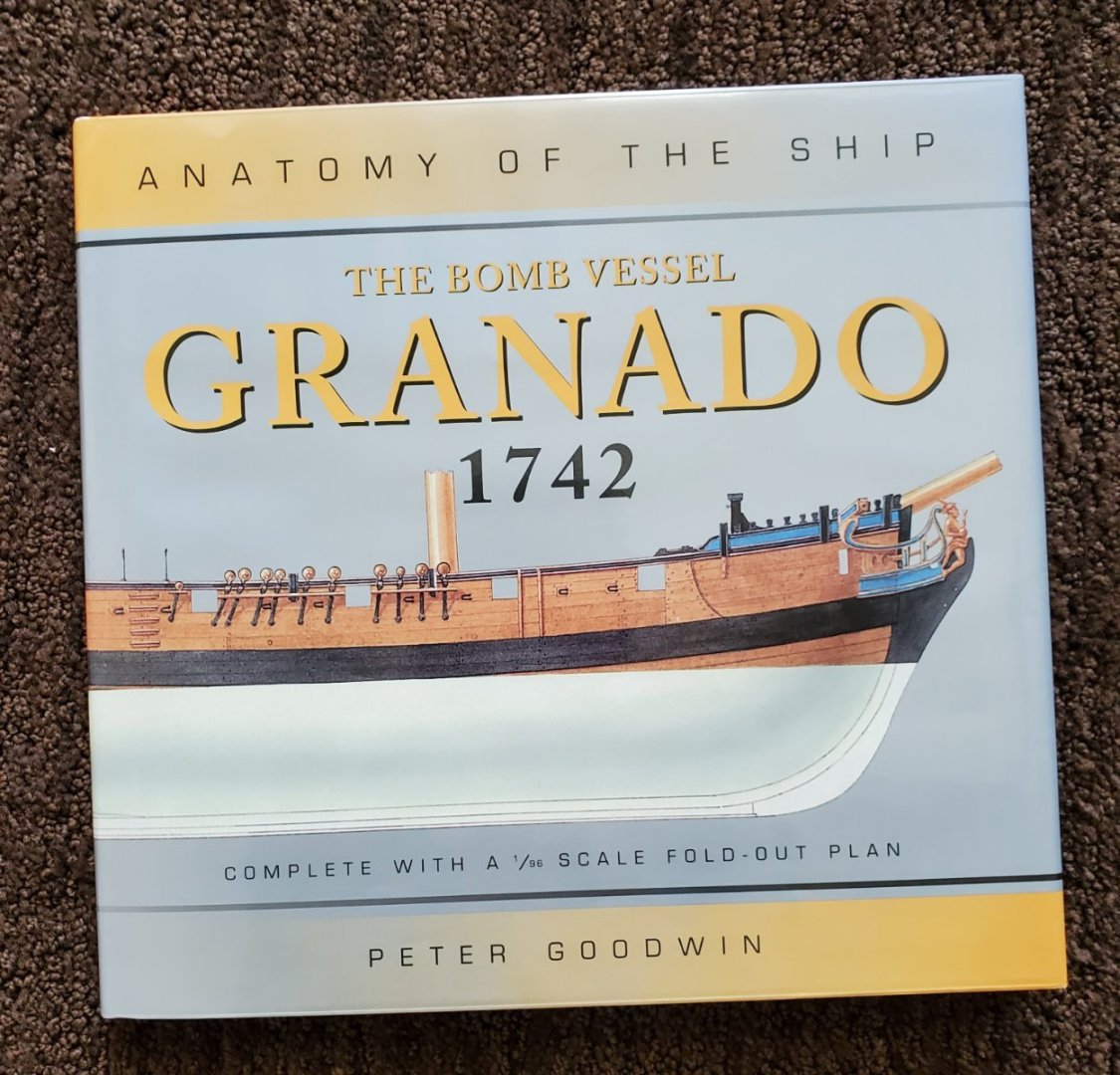

Hi all, This kit is in unstarted condition, contents in great condition as shown in the photos. It is an older kit that I purchased in 2006 but it's been stored in my closet the whole time. Price is $275 plus shipping. The book from the "Anatomy of the Ship" series is not included but I will sell it to the purchaser of the kit for an additional $25 plus shipping if desired. It won't fit in the same box as the kit, so would have to send it separately. I will also be listing a Caldercraft Pegasus kit soon.... Thanks for looking, Dave

-

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Dave B reacted to a post in a topic:

SOLD: Kit For Sale - Vanguard HMS Sphinx

Dave B reacted to a post in a topic:

SOLD: Kit For Sale - Vanguard HMS Sphinx

-

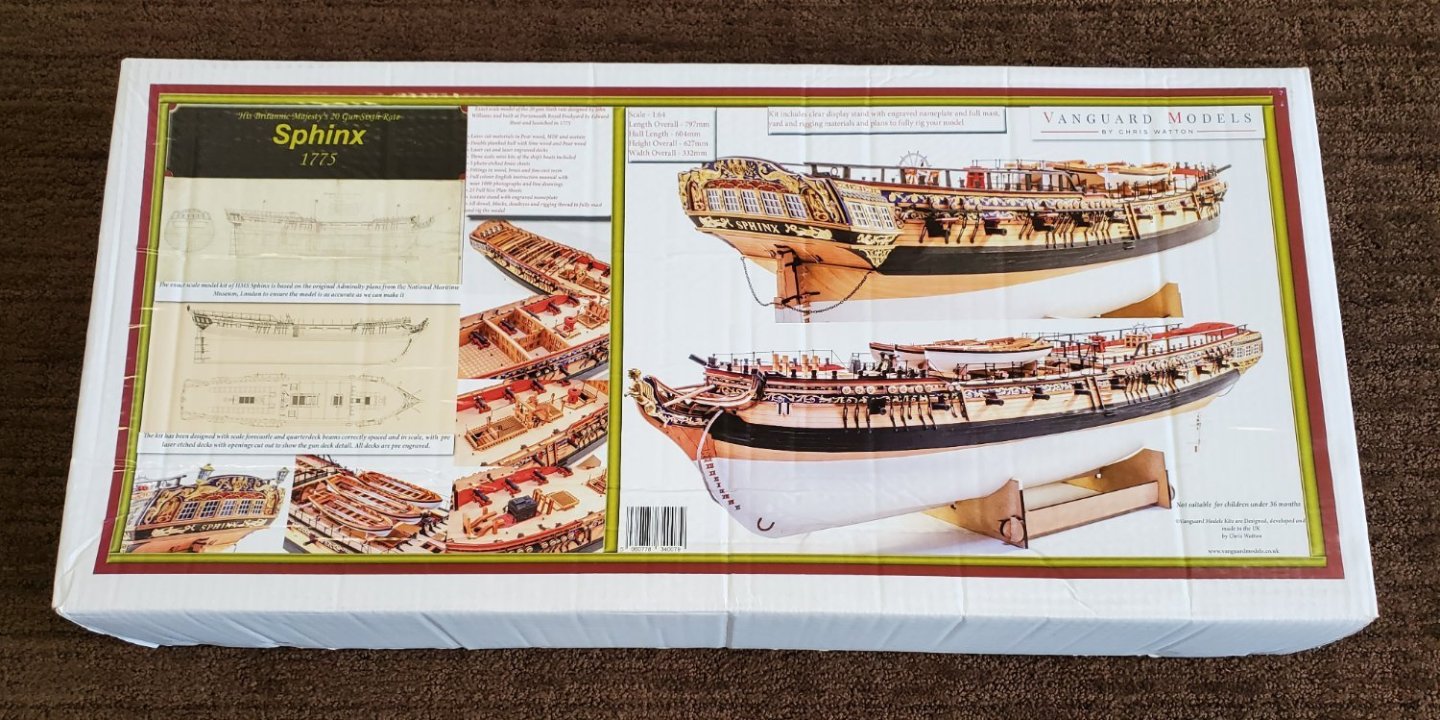

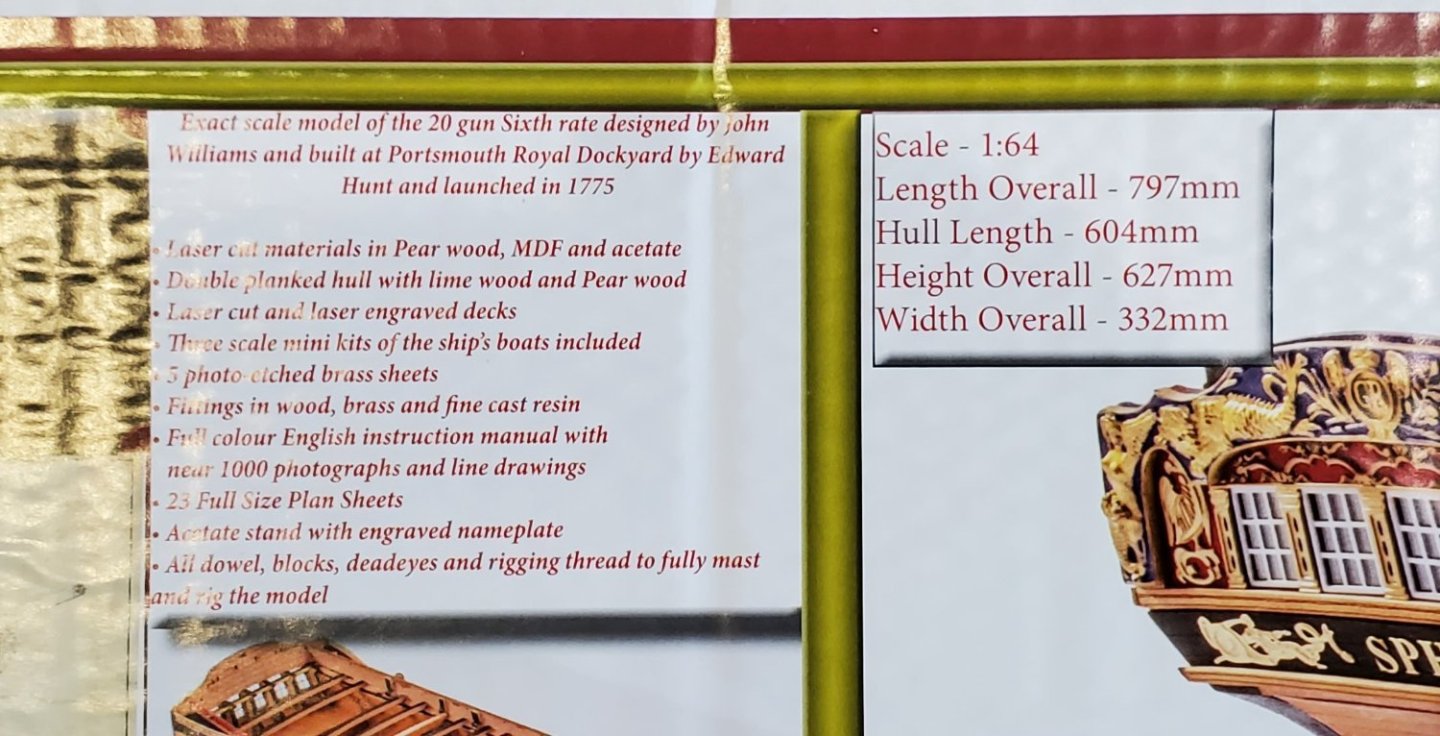

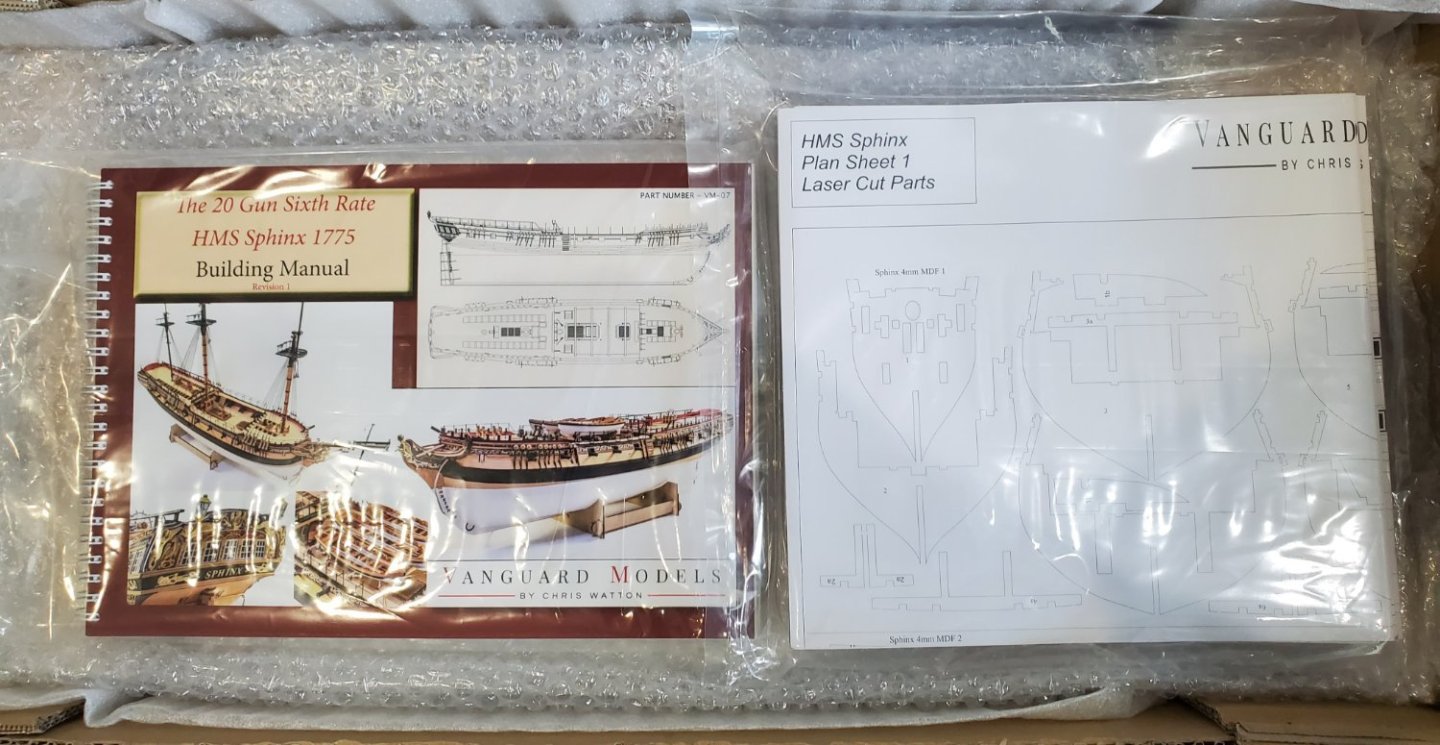

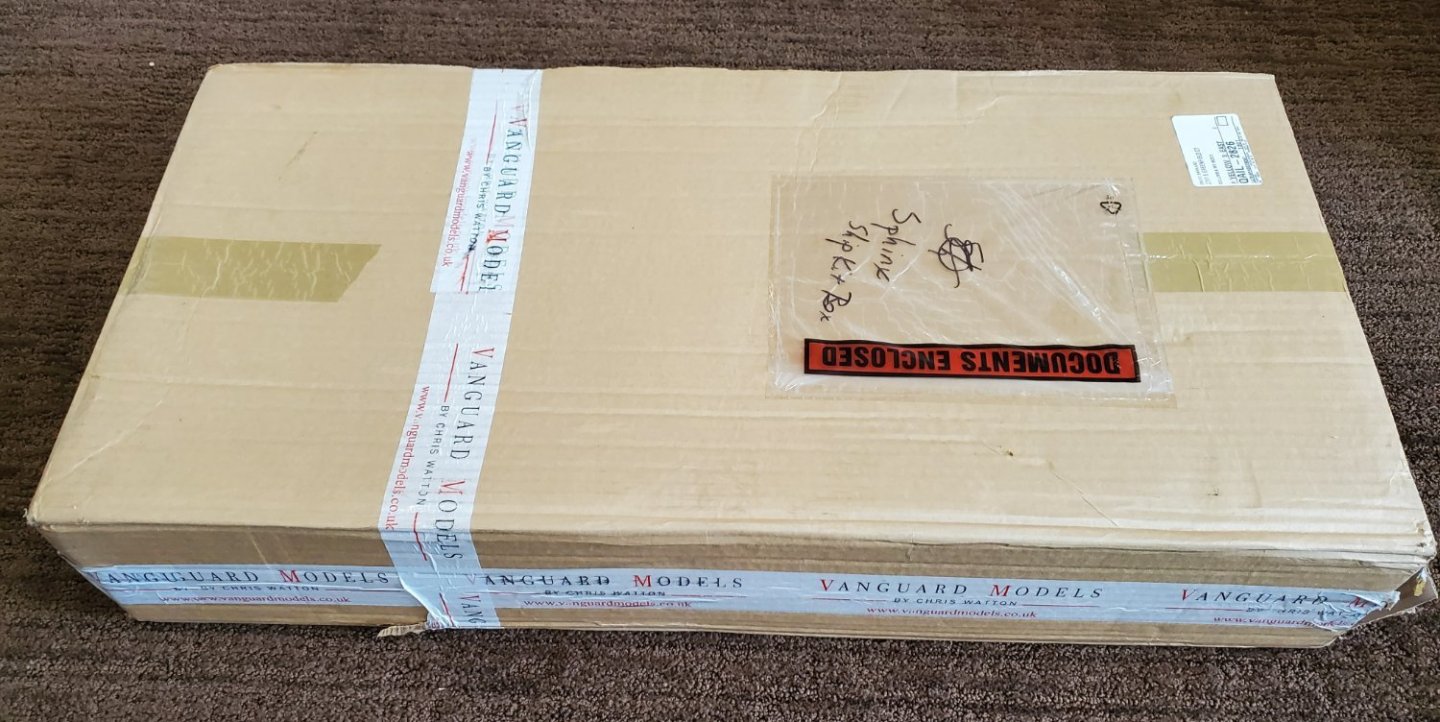

Hello all, I am selling this Vanguard Models kit of the HMS Sphinx which is in completely like new condition. 1:64 scale, overall length 797 mm (31"), advanced skill level. I have not opened up any of the sealed packages inside. Everything is exactly as originally received. It includes the optional pear fittings package. I am pricing it at a 25% discount from the current price on the Vanguard website for the kit and pear fittings set. That would be $750 at the current exchange rate, plus shipping to USA addresses. Thanks for looking! Dave

-

Dave B reacted to a post in a topic:

HMS Speedy by Theodosius - Vanguard Models - 1:64

Dave B reacted to a post in a topic:

HMS Speedy by Theodosius - Vanguard Models - 1:64

-

Dave B reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 - Vanguard Models - 1:64 Wooden Ship Model Kit

Dave B reacted to a post in a topic:

HM Armed Cutter Sherbourne 1763 - Vanguard Models - 1:64 Wooden Ship Model Kit

-

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Dave B reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

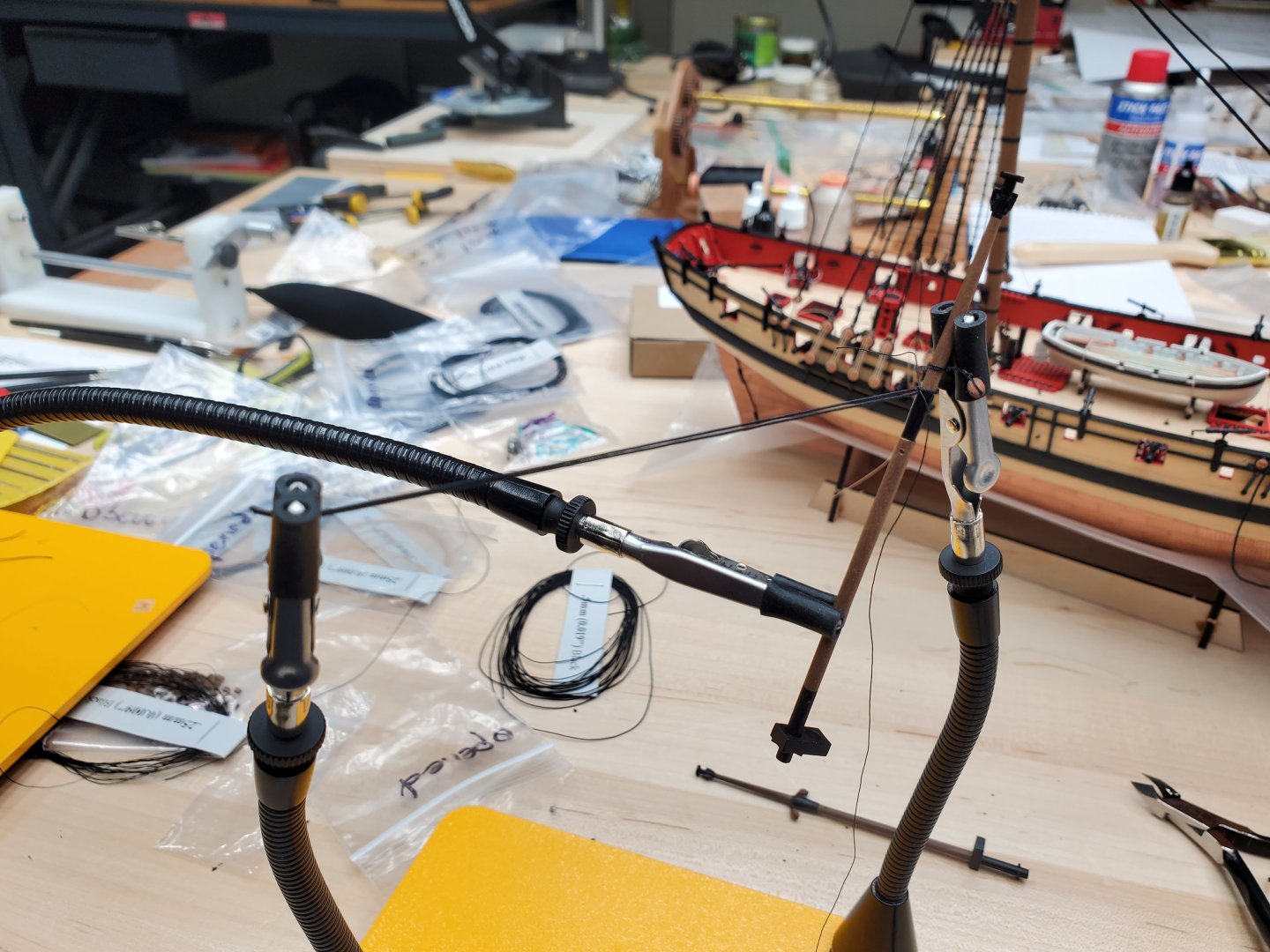

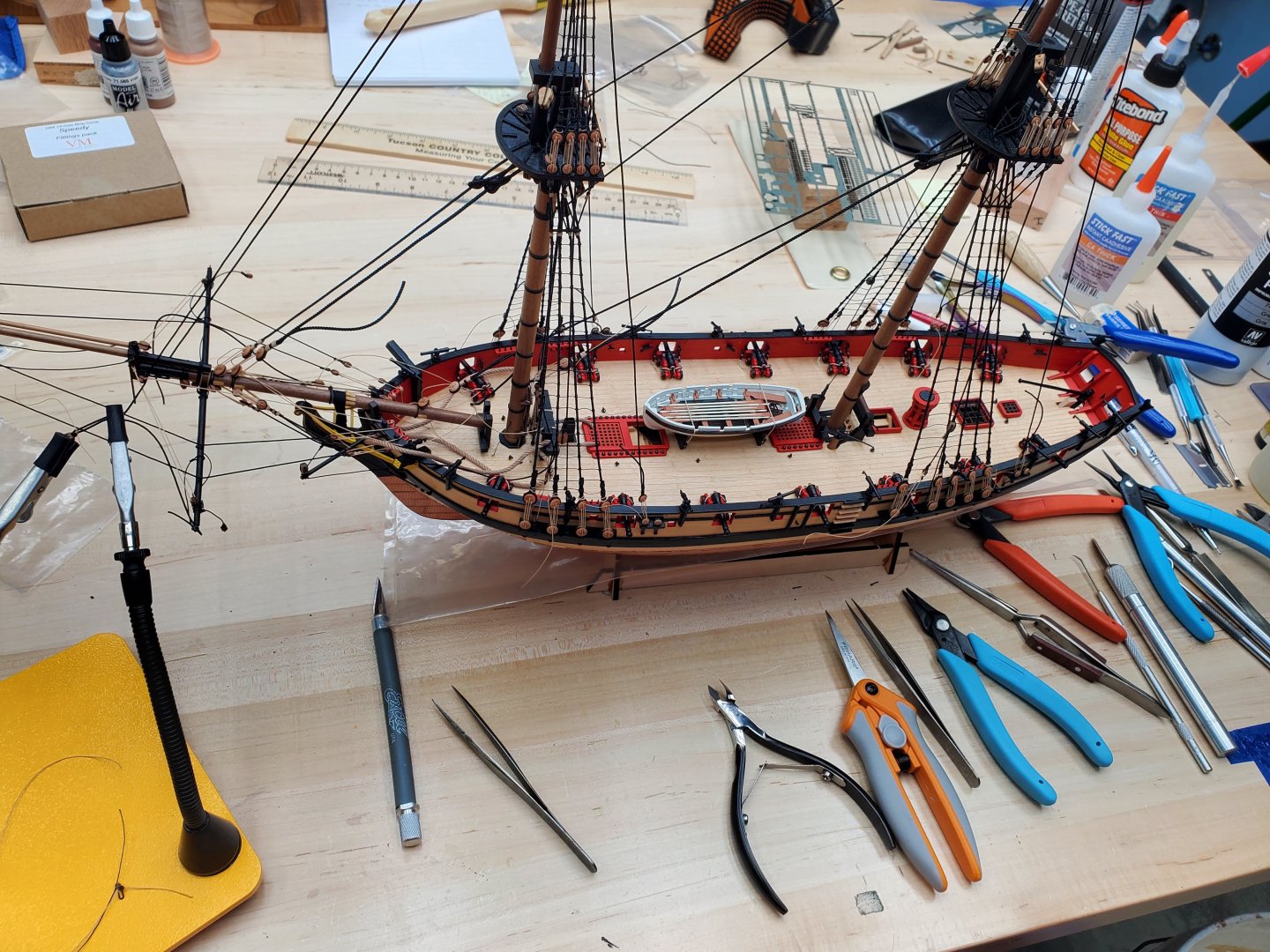

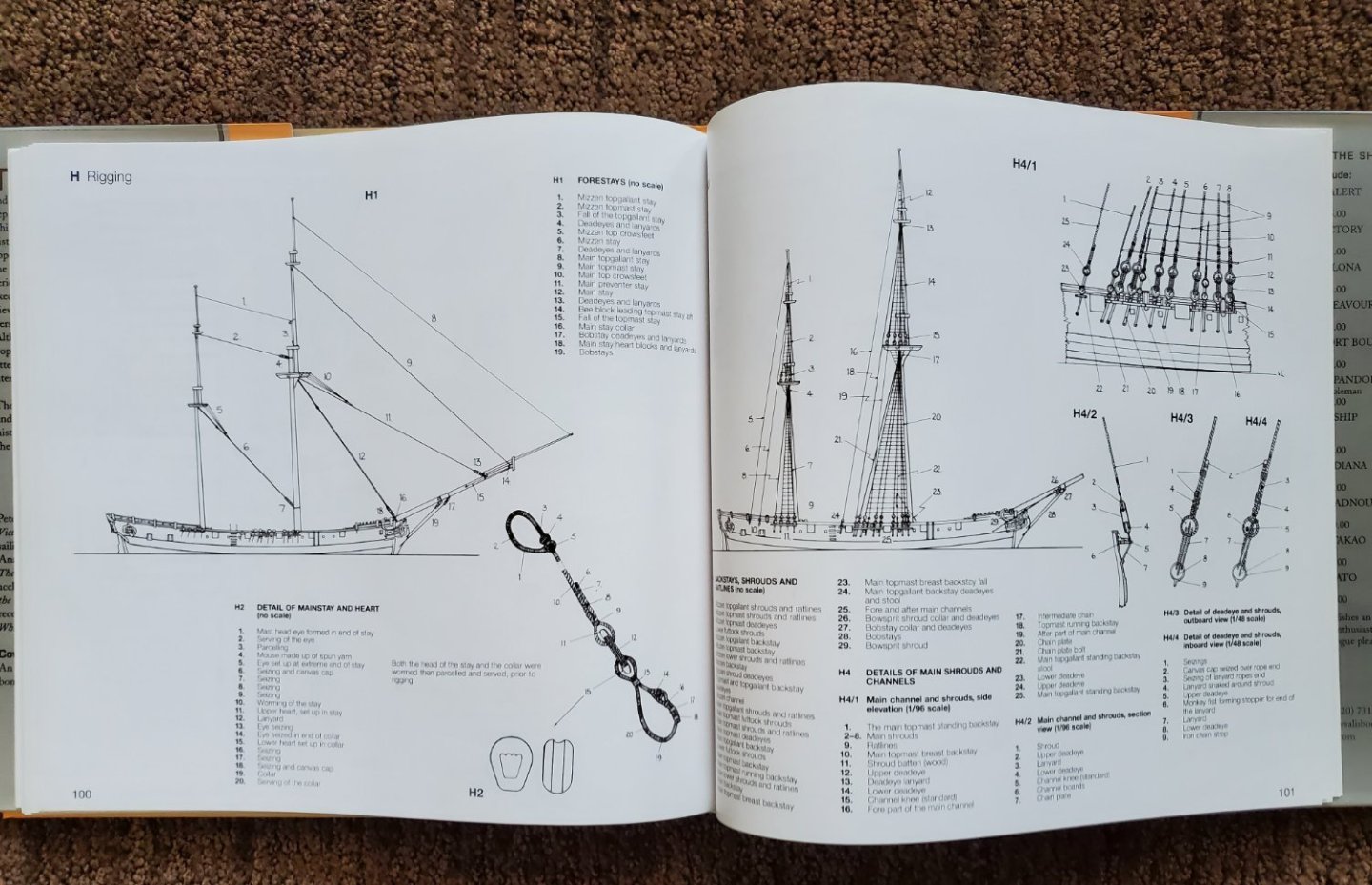

Hi everyone, Looks like it's been over 4 months since my last update....crazy how time goes by I've been making progress though, sometimes very slowly, with the rigging. The ratlines were definitely a trial and error experience for me. I'm still following along the kit instructions/plans supplemented mainly by Delf (Derek)'s excellent build log to guide me. Here are a few photos of where things are now with my Speedy. Please excuse all the lines left hanging but I want to make sure I haven't done something wrong before I make the final trimming of them and as long as I can still get to them easily I figure just leave them for now. Thanks for following along!

-

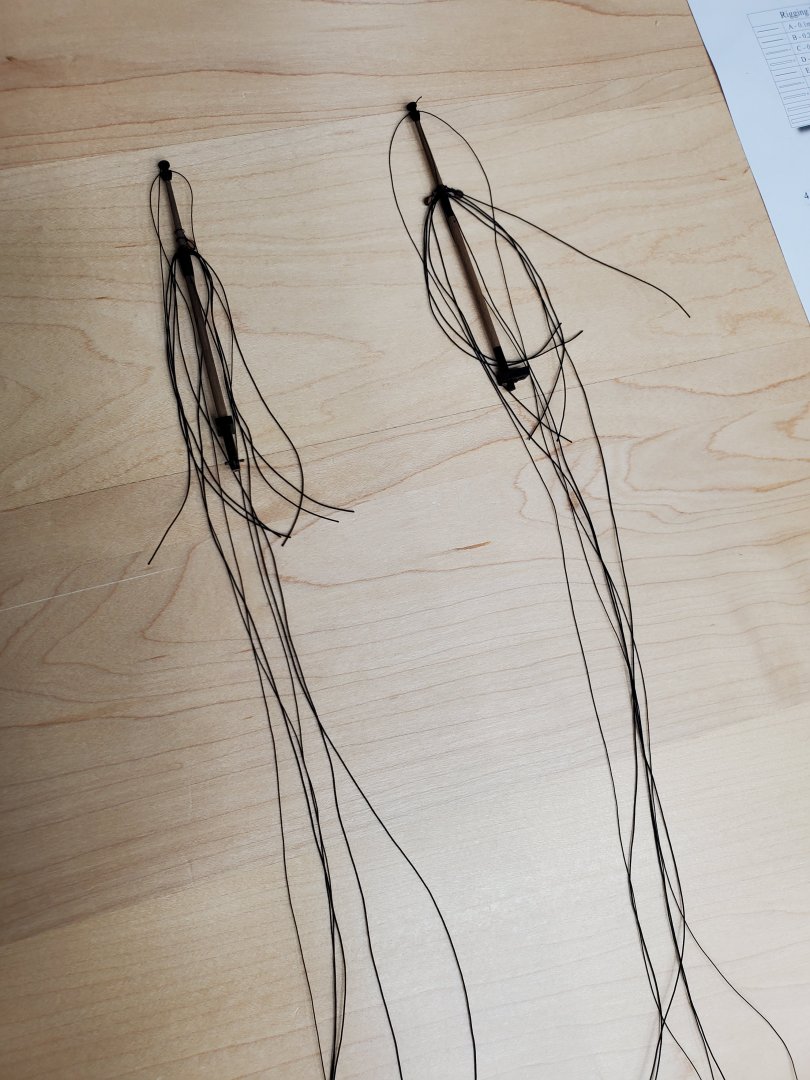

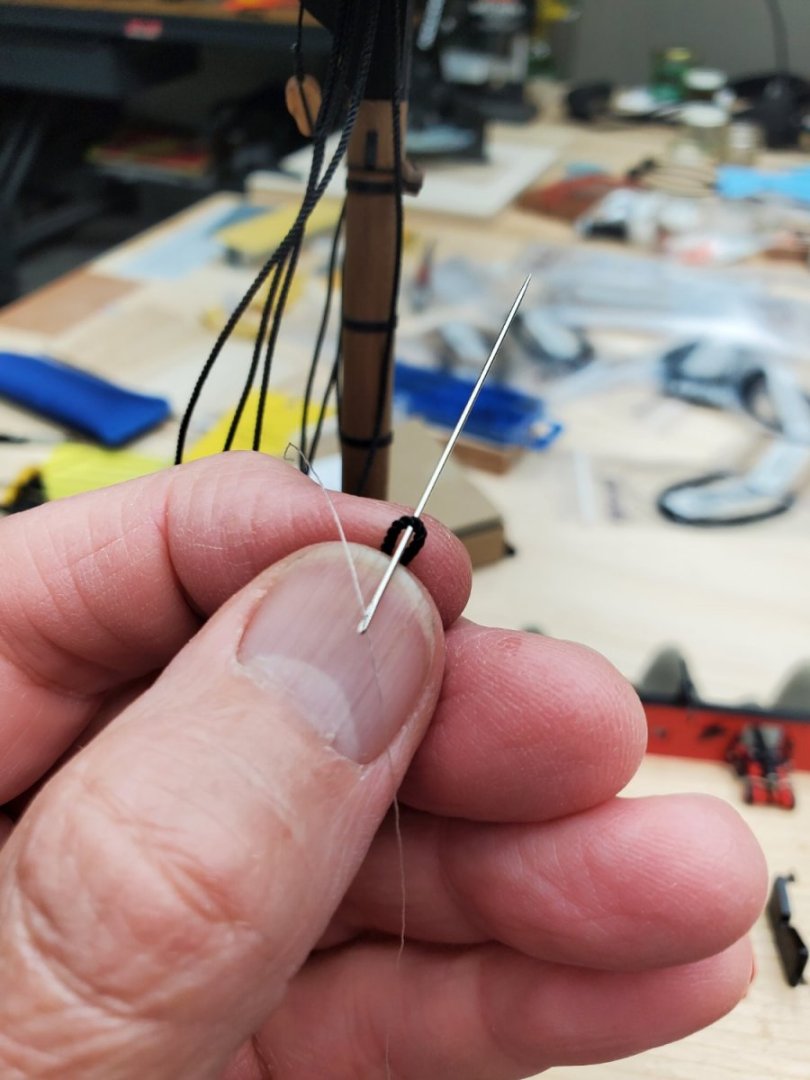

Here's how I used it to determine the length and where the seizing above the deadeye should go. I used another trick (I think from Delf) and threaded a little white thread through the bottom of this so that I could work on these off the ship after doing all of them. Mast is tight in the deck so I know the position is accurate but I'm able to remove it.

-

Hi and here's an update. Been moving along in spurts this past few months. Seems like I spend as much time looking at other build logs as I do actual building. They are so helpful. The plans are great but seeing photos and detailed explanations is helping me with the rigging which I haven't done in this amount of detail for many years. I've got the bowsprit on and a lot of that associated rigging attached, and now getting to work on the shrouds. For the first time ever I did serving of ropes. My Syren serving machine was a little rough going at first but got things smoothed out, I had some parts too tight apparently. Thanks again for all the great help from the build logs! Dave

-

Thank you Glenn for the postive comments and answer to my question! I've made more progress, almost finished with the bowsprit. It was tricky getting the 3 wooden parts lined up and attached correctly, and again the photos from other build logs helped me out with that along with the excellent plan diagrams. Dave

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.2af961de34b2f8da35eb779deb4c7068.jpg)