-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

the Netherlands

Recent Profile Visitors

-

Hi there Volker, I'm going to follow this log as well. I wish you all the best with your second build and it's nice to see you took it up a nodge with a more complicated ship. Very nice! My Albatros is not even half way through it's build, but I enjoy every step of it. Natan

- 9 replies

-

- San Martin

- Occre

-

(and 3 more)

Tagged with:

-

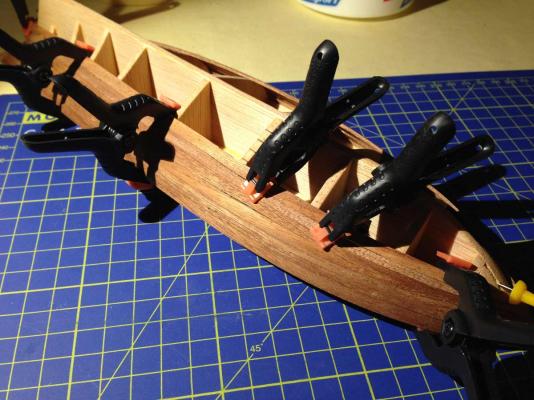

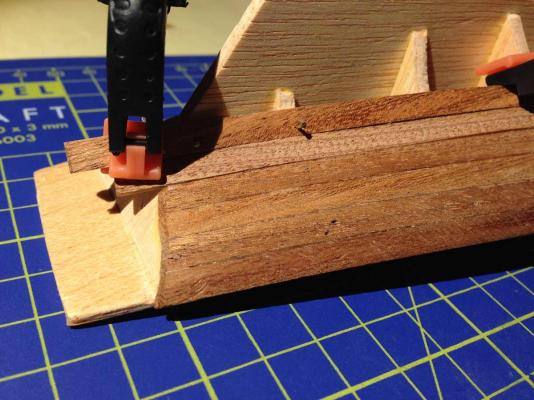

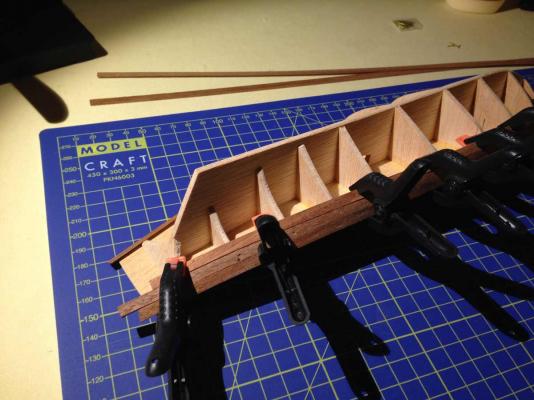

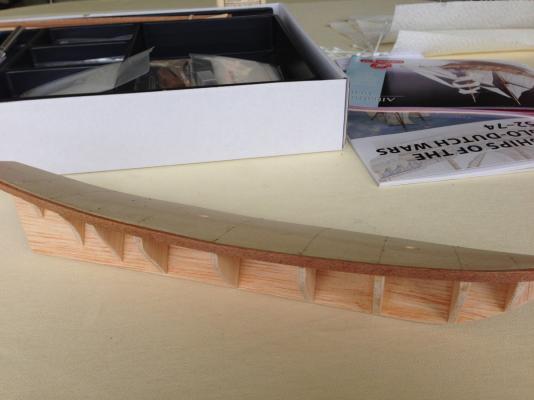

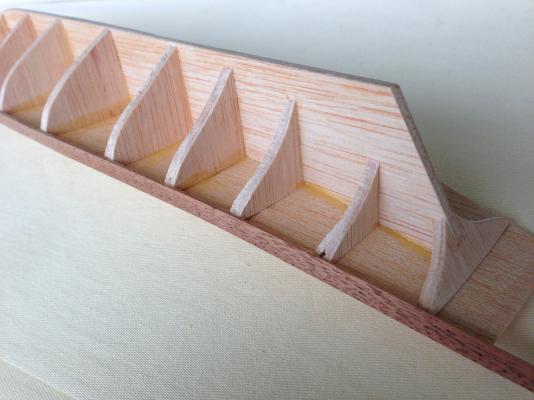

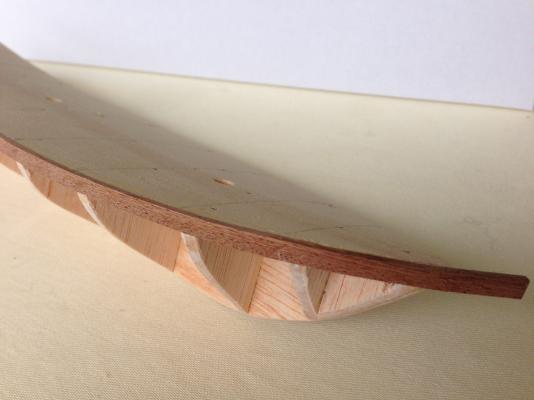

Here’s another update on the hull of my Albatros. As before I soaked the planks and clamped them on while wet and left them like that to dry for at least eight to ten hours. Although this makes it relatively easy to bend/shape the planks, it’s still hard to get a smooth end result. The planks are thick and there is only one layer to work with so it has to be right the first time. If I soak them too long (an hour or more) they become too soft and it looks like they cave in between the bulkheads because of the pressure from the clamps. The clamps even leave pressure indentations on the edges of the planks… If I don’t soak them long enough (less than 30 min) it’s hard to bend them and the lower side tends to push away from the bulkheads leaving and uneven surface. I will go on though. Mr. Sandpaper and Volkers wood filler will be my big friends when I am finished planking the hull ;-)

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

That's quite a bit for an Albatros kit. Was that a Constructo or any of the other kits? Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

Thanks for the tip Volker. Right now I am still struggling with the planks on the hull, but I will apply that technique when I start sanding and smoothing it. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

natant reacted to a post in a topic:

HMS Mars by j21896 - Caldercraft - 1:64 - modified kit

natant reacted to a post in a topic:

HMS Mars by j21896 - Caldercraft - 1:64 - modified kit

-

VolkerBo reacted to a post in a topic:

Albatros 1840 by natant – Constructo – Scale 1:55 - Baltimore schooner - first wooden ship build

VolkerBo reacted to a post in a topic:

Albatros 1840 by natant – Constructo – Scale 1:55 - Baltimore schooner - first wooden ship build

-

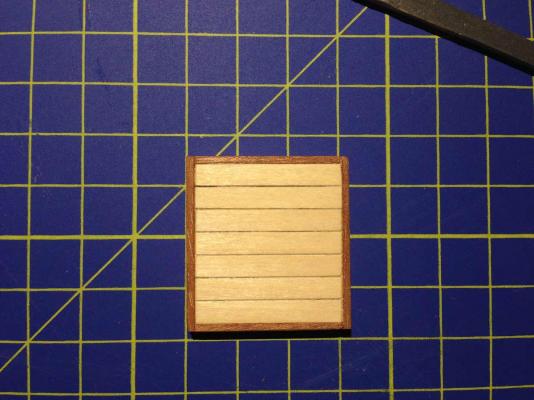

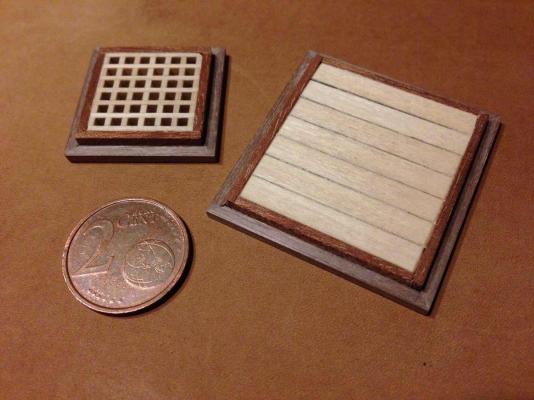

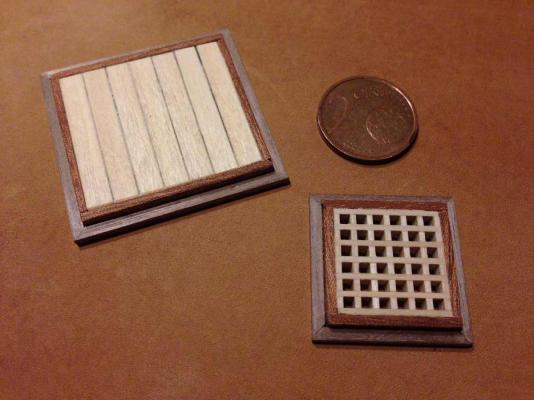

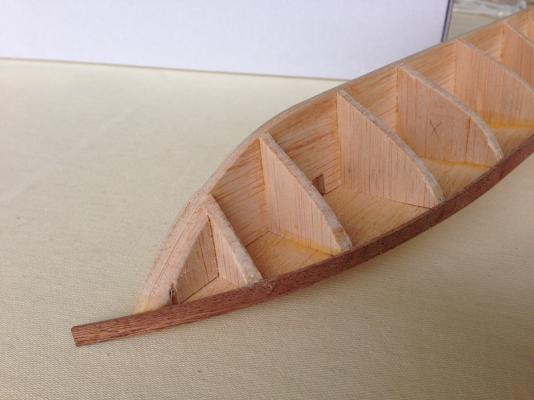

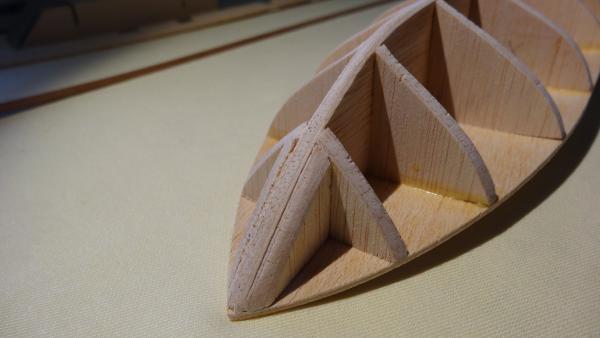

Since the deck is finished and I am about half way on the hull, I thought is was a good idea to start work on some items that will go on the deck. Taking good measurements here is important, because following the instructions can lead to some irregularities. The quality of the wood is fair here, in contrast to the wood that is provided for the deck... Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

After gluing one plank to each side (as shown in my last post) I added another two and will work my way down adding two planks per side per time. It's tempting to start working on other parts of the ship, but I decided to stick to the instructions and take my time to let the planks dry after both soaking and gluing. I bought a digital caliper and Amati's Master Cut to make work a little easier and I have to say that really helps. I don't have a dedicated workspace yet, but I just keep looking out for the right equipment to make this hobby more and more enjoyable. My posts for the near future are going to be a little less frequent, since all I will be doing is adding planks to the hull. I promise to keep taking pictures after every step, but I will add those pictures to a later post because it makes no sense putting every plank I add in a separate post ;-) So, until then... Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

Well done Volker, that ship is a great example of how it should be done. I will try to achieve the same results with my build. Natan

- 20 replies

-

- albatros

- constructo

-

(and 1 more)

Tagged with:

-

Another small step. I glued the first plank to the other side of the hull and made a start with the deck. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

Thank you very much Nigel, That's what I did the first time, although it might look as if I was rushing it when looking at my first few posts. Those pictures were taken during a three day time period, but I uploaded them in just one night. I am soaking another plank right now for the other side and I will leave it pinned down for tonight and tomorrow during the day. The planks are indeed thick and therefore hard to shape but I will try my best. My biggest concern is filling out the hull without too many 'stealers' so I can make it look as authentic as possible. This boat is mostly to sharpen my skills again, and after finishing it I will move to an Albatros with double planking (Mantua). I know that's a lot more work, but it will also be easier to handle because the planks are thinner and closer to the way big ships are built. My end goal is building the Friesland or the Sovereign of the Seas. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

Danke schön Volker ;-) I will follow your build log. Let's stay in contact since we are on the same project. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

Planking has started. It's only the first plank on one side so I have lots more work to do. I put the wood in boiling hot water in the sink (with a bottle on it to keep it under water) and let it stay for about 30 minutes. This was enough to be able to bend it into shape so I pinned it down and let it dry. Then I glued it and pinned it down again for the night. I'm happy with the results so far, on to the other side. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

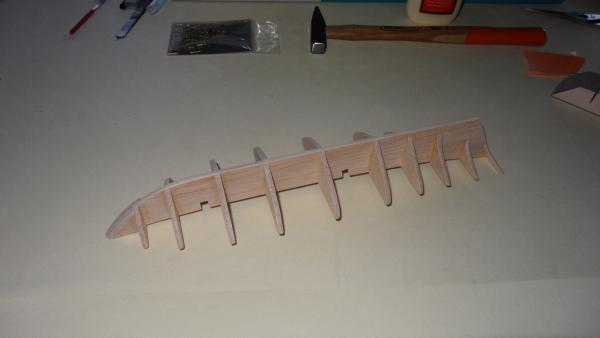

First update on the Albatros. I just couldn’t wait to start building, so after digging up my tools from the basement, buying a fresh bottle of Tidebond together with a pile of sanding paper (ranging from 400 to 1200) I started to work. The false keel turned out to be al little bent, but I took a gamble and started attaching the bulkheads hoping to straighten out everything when attaching the deck further down the process. I came out lucky there, because everything is in line now but it took quite some work. Lots of sanding to get the frame ready for the deck, and lots of frustration while adding the deck, because the nails are so extremely thin and soft they bend even when looking at them. After finally securing the deck I sanded away for another 90 minutes and I guess I am ready for measuring and calculating in preparation of the actual planking of the hull. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

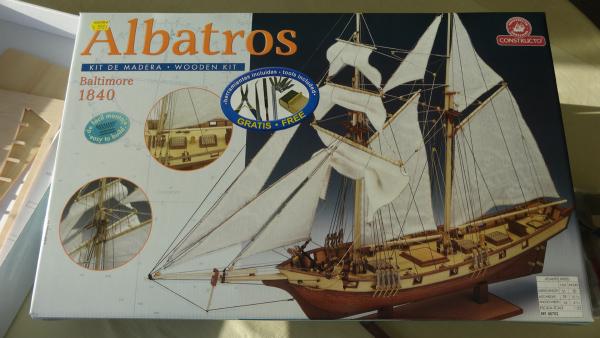

As a kid I tried my best to finish a partially built Billings kit from H.M.S. Bounty that was given to me by an acquaintance who gave up in frustration. Being too young/inexperienced/impatient/much interested in 1:24 plastic car models, I never finished it either and got rid of the kit after many years. Somehow, this hobby got under my skin so I chose to pick it up again. Since I was overwhelmed by the technical skills that are required when working on the Bounty, I decided to make an easy start so I got myself the Albatros from Constructo. I am well aware this is not a very detailed model and after opening the box I also found out that the materials are acceptable at best. All the better for me though, because I want to gain experience with planking and rigging. I will post pictures and my thoughts as I go along, but being very busy with my work please don’t expect me to do so on a very regular basis. Feel free to comment on my work and do share your thoughts and expertise, as I haven’t done any wood modelling for more than twenty years. Natan

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.