-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rameyke

-

Ha! Sal was partially correct about the first row of planks above the wale. I could not tell by the pictures, but as I was pulling the planking off, I noticed that the first piece of planking above the wale at the bow was in fact 5/32 x 1/16 on both sides. The rest of the row was the correct size. I must have grabbed the wrong width wood when I was bending those pieces. Well, my first attempt at planking has been pulled. After cleaning up the old glue and doing a little work on the rabbet, I am happy to say that i reinstalled the upper wale. I have a nice clean run. No lateral bends and it meets up at the keel in the bow very nicely. Augie, your advice on redoing the planks and pre-trimming the piece that meets the bow was used and appreciated. Sal, thank you for the diagram. Sanding the back of the corner where the plank hits the rabbet worked out nicely. Tonight I will start planking above the wale again. I realized that the upper wale would be covered by another layer, so I went ahead and used the kit basswood for this piece. Just in case I needed to tear it off again Much nicer run of the plank. No lateral bend like last time.

-

Hi Sal, I did use the batten and i think after I made my markings, I still created the bad bend in my board. I think I tried too hard to make it match my mark, but missed one. It was a little low, then I corrected at the next bulkhead. Looking at the diagram you attached, I did not sand off the inside edge where it meets the rabbet. Augie pointed this out as well. My first plank is 5/32 and the second row is 1/8. i think the shadow in the image along with the bad placement makes it look like they are the same size. Thanks you all for the advice. I am sure I will be asking for more.

-

I like that idea for making the waterways. I will have to remember that.

- 659 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi John. I am pretty new at this hobby too. This is my second build. I have to say that Chuck's instructions are top notch with this kit. When I near completion, I plan to purchase the USF Confederacy which is another of Chuck's kits availble from Model Expo. There are a number of Syren Builds on here; Augie, Dubz and DrWatson are a few of my favorites. There are others, and I dont want to offend those builders. I keep going back to their buids to get inspiration and check to check my work As you can see from my build, I started a couple years ago, then life got in the way. I am back at it and hope to be able to stick to it this time. I just keep feeling like I am making mistakes. Especially now that I am starting to plank.. It is such a gorgeous ship, I want to be able to do the kit justice. That is one reason I am posting my log. It will hopefully keep me honest and not take shortcuts. Ken

-

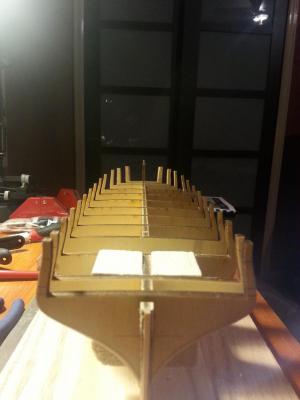

So i got a little too excited to lay my first planks, and I am having a bit of trouble at the bow. I guess I need to carve out the rabbet a little more. I can not seem to get a nice joint where the planks meet the keel. Also the port side seems to have a severe bend in my upper wale. I did not notice it until after I started my 3rd row of planks on that side and I could not seem to get a clean curve. I am not sure how i ended up bending it there. Seems like my starboard side is a little better, but I am not completely happy with it. So before I go any further, I am going to remove those planks and clean it up. Anyone have any hints on getting the planks to butt against the rabbet a little better? I am pre-bending the strips. May be I just need to cut the rabbet a little deeper. Bow is so ugly right now. I guess I need to make my angle on the plank a little better and cut the rabbet deeper so the ends will stop popping out. A little better on the starboard side, but still not happy with it. Also you can see the difference between the wale that I prebent using the frames and the first row that I used a jar. I think the first row bend is a little better as it was bent a bit more than I had to, and seemed to hold in the rabbet a little more. It also had a nicer curve in it. The run on the wale on my starboard side seems ok. Still going to redo it since I dont like the bow. Port side, showing the strange bend at about bulkhead 8. You can clearly see how it affected the first row of planks. I do have to compliment Crown Timberyard again on the quality of the boxwood he shipped. It is very easy to work with, and looks great. The only issue with it is me.... A newby trying to work with it. Any hints or suggestions would be appreciated. I have been looking at other build logs, but you all seemed to be able to get past this part so cleanly.

-

It has taken me a little while to get through all the pages of this build. But once again Augie, you inspire me to build more. I am really enjoying watching this build now that I am caught up.

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

For anyone that is using acrylics, Vallejo makes a really good primer available in white, black and grey. It goes on smooth and provides a nice texture for the paint to stick to. I utilize it on all my miniatures and plastic models. I use Vallejo and Badger Minitair paints exclusively. The nice thing is they are great in airbrushes and when I break out my brushes. The Valejo liquid metals that JPett mentions above work fine on this primer too. From my mini painting hobby, those liquid metals are the bee's knees. Great coverage, and the metal flakes are very fine and produce a superior finish. Note: You MUST thin with rubbing alcohol. Adding any water based thinner to these will create a big mess. But the finish of these makes the extra work worth it. Also you can use them on acrylic surfaces without damaging the underlying paint.

- 39 replies

-

- Airbrushing

- Tips

-

(and 1 more)

Tagged with:

-

I just received my first order of boxwood from Jason at Crown Timberyards. Let me thank Jason for the fast turnaround on my order. It arrived just in time. I am almost done sanding and shaping the stern and am hoping to start laying down some planking on the upper bulwarks. At the time, i bought all that Jason had in the sizes I need. Jason, if you are reading this. Thanks, and I will be ordering more wood very soon. I gotta say, this stuff is nice! The strips are super smooth and not a bit of fuz on them. I am glad I read others experience and recommendations of boxwood for my Syren.

-

Well, the Admiral was visiting family in Michigan this past weekend, so I got to spend some quality time with my Syren. I made a nice pile of dust from sanding... Oh the sanding... And more sanding... Did I mention I did alot of sanding? Finally got all the gun ports installed and the bullwarks sanded. Here are some pictures. As usual, please let me know if I am on the right track, or if I need to sand some more, or you see anything I have done incorrectly. Thanks Ken Not sure if I need to sand more on the bow. Yes.. I like to watch movies while I build.

-

Spent the evening sanding the starboard side of my gun ports. I now have a really nice pile of sawdust building up. I am not quite done sanding the outboard side of them yet. Here are a couple close up shots of the outboard side of my gun ports after a little sanding. The aft end has not been sanded yet. I am realizing that I probably should have framed in the rest before I started sanding. Section still unsanded. On another note, I just ordered a bunch of 1/16x5/32 and 1/16x1/8 boxwood strips from Crown Timberyard. I will make sure to let you all know how it looks when it comes in. As always, any feedback (good or bad) is welcome Ken

-

Well, I finally got a little progress made. I was able to spend some time this weekend making dust and got the gunport sills installed. Note to self. Must read a little more carefully. I first installed all the sills on one side and then went back to read the next step. That is when I noticed that in the well written manual, Chuck said that the 3/16th by 1/4 sills should be installed so that the 1/4 side makes up the top of the sill. I installed it the opposite way. Luckily I had used wood glue and was able to disolve the bonds using a little rubbing alcohol as I had read in this forum. 1st sill installed. You will notice that it is installed wrong side up. I figured this out later and had to remove one entire row of these. All Sills and tops installed. I havent yet finished the framing of the gunports. Next step. Another view of the sills. I created a little block on a handle that was the size of the gunports according to the plan. I used this to make sure I put the tops of the gun ports at the right height. While framing in the sides of the gun ports, I used a caliper to measure from the inside edge of one gunport to the inside edge of the adjacent port to make sure the spacing is correct. Hopefully I did this correctly. I will post a picture of the gun port framing later today. Any comments and / or critique is welcome. If you spot something screwy, please say so. I dont want to get too far in. Thanks for looking. Ken

-

So back in May 2013, I was working on this build pretty regularly. Then the riding season started up and I spent most of my time training. Then raft / kayak season was in full swing and by build took a back seat... Then an entire year went by (not sure where it went). I spent some time on other hobbies that I enjoy such as model airplanes and painting wargame miniatures. But a couple weeks ago, I pulled out the syren and started sanding again. She's still in the same state. My bulkheads are installed and the filler blocks are there. I have created a ton of dust sanding and trying to get the bulkheads faired up so I can start framing. Anyways, it is good to be back and building my Syren. I do have a question though. I want to do some upgrades, and I noticed that hobbymillworks is no longer accepting orders. I want to upgrade the following Plank wood, Wood for the deck, Hooks, blocks, deadeyes, carondales and the 24 pounders. I see that Chuck has Syren Ship Model Company, which looks like he is supplying some awesome upgrades. Is there a good place to get the upgraded wood? From what I have read in Dubz and Augie's and other build logs, it seems that Pear or Boxwood would be best. Any other recommendations? Thanks to all of you.

-

Last night I got around to planking the partial deck that will be under the companionway. When I built my Swift, I did not know about simulating caulking. I used the pencil method on this piece, and I am so happy with the appearance. At first, I could not figure out how it would actually show up, since the pencil is just on the edge of each plank. But once I sanded it and stained it, I think it came out awesome. Such a simple thing and it adds so much.

-

One trick I use for painting edges and thin lines: Use the side of your brush not the tip. Start with something like 00 size brush and dip it into your paint. You want the paint to be slightly thinned. If you are using something like a Valejo Model Color paint, you can paint straight from the container. Any of the oils you are going to want to thin. Dip your brush into the paint and then touch it to a paper towel. This will remove much of the liquid from the brush, while leaving the pigment, thus eliminating the bleeding effect. It will take more coats, but its worth it. Next run the side of the brush bristles along the raised edge. This ensures that you dont have to rely on a steady hand or the brush tip to paint the edge. I will try to find a picture to explain it better. Hope it helps

-

Airbrush Compressors

rameyke replied to jre8655's topic in Painting, finishing and weathering products and techniques

I currently use an Iwata Eclipse dual action airbrush for miniature painting (yes, I paint minis for wargaming). For my purposes I have a very small 2 piston compressor that I got at hobby lobby. I think its called the hurricane or something like that. It will go up to about 40psi and I usually spray at around 15 - 20 psi. For minis we usually use very short bursts, but when I am undercoating, I spray in longer bursts and this compressor keeps up just fine. The ones at the hardware store with a 1 or 2 gallon tank will in fact suit your needs. Your airbrush will not empty a 2 gallon tank so fast that the compressor cant keep up. Most of the pro modelers that i know use them. However, they are LOUD. If you are only painting out in the garage or workshop, that will probably be ok, just wear ear plugs. Most of the hobby level compressors with tanks have a 1 or 2 gallon compressor and they do just fine. But the difference is they are super quiet. I use mine and my wife and I can watch tv in the same room. Please keep in mind the the type of paint you are using. If you are going to spray indoors, please stick with Acrylic paints. At lower pressures, air brushes produce very little overspray. With your face right there painting, you might consider wearing a paper face mask. But little to no over spray will get much further. Above there is a link to a compressor on Amazon that sells some TCP global compressors. They are quite nice and affordable while being quiet and producing enough volume to keep up with our purposes. If you were detail painting a full size car, you might consider something else, but for our uses, these small ones are plenty. Let me know if you want some airbrush info. Dont be intimidated, just get it out and try it on some scrap. Ken -

Looking great Augie. If mine turns out half as nice...I will be happy. Ken

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I started installing the filler blocks last night. I am using a caliper to make sure my bulkheads are parallel from port to starboard. They seem pretty square, but a couple of them were about 1 mm off. On those, I am using the clamps that are running stem to stern to correct it a little. I think once these have had a chance to dry, the rest can just be clamped in. I did make sure that, after correction, the adjacent bulkhead spacing was correct as well. As I install more filler blocks, I will have to check and double check for square. I think I read in someone else's log that this was something to keep an eye on... Though it might have also been in Chuck's manual. Anyways, here is a picture of her current state.

-

I finally got a chance to upload the latest pics of my Syren. You will notice, she is now on a building board. I built that out of a scrap piece of oak from home depot and a couple strips of poplar. I laid the poplar next to a straight edge to make sure they did not have a curve or warp in them before screwing them down. The strips are just tight enough to hold the keel and still let me pull the whole thing out and replace as needed. I dry fitted all the bulkheads and finally glued them in. I am now working on the filler blocks made from some scrap that I had laying around. overhead of the whole thing I think everything looks pretty straight. from this angle too. Thanks for watching

-

Pulling up a chair and watching. The block idea that Kieth posted should work if the overbend does not. Just make sure you put the blocks on both sides of the bulkhead former and i would put them between all of the bulkheads. Chech out some of the Syren builds for pics. The blocks staightened the bend in my former. Also be sure the blocks fit tight but do not push the bulkheads out of square

-

Everytime i visit the site, you have managed to make some more progres. Those yards look really good, but i have come to expect nothing less.. I guess i should spend less time on MSW and more time in the shop. Anyways, nice work Augie!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

The shelter told us that Eva might be boxer/husky.But the vet thinks boxer / cattle dog. She barks to much to be a besenji. Whatever she is, she is 100% sweet. I work at home most of the time, and she lays on my feet allday. For an 11 month old pup, she is very mellow.I did not get my grill last weekend, but maybe tomorrow.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.