-

Posts

1,126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Stuntflyer

-

So nice, Chuck. Everything seems to be fitting together as planned. However, I know that there where several iterations in design to get there.

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Chuck and I like to use a number 2B pencil on one edge of the joined surfaces. It leaves a strong glue joint and a clean line once sanded out.

- 25 replies

-

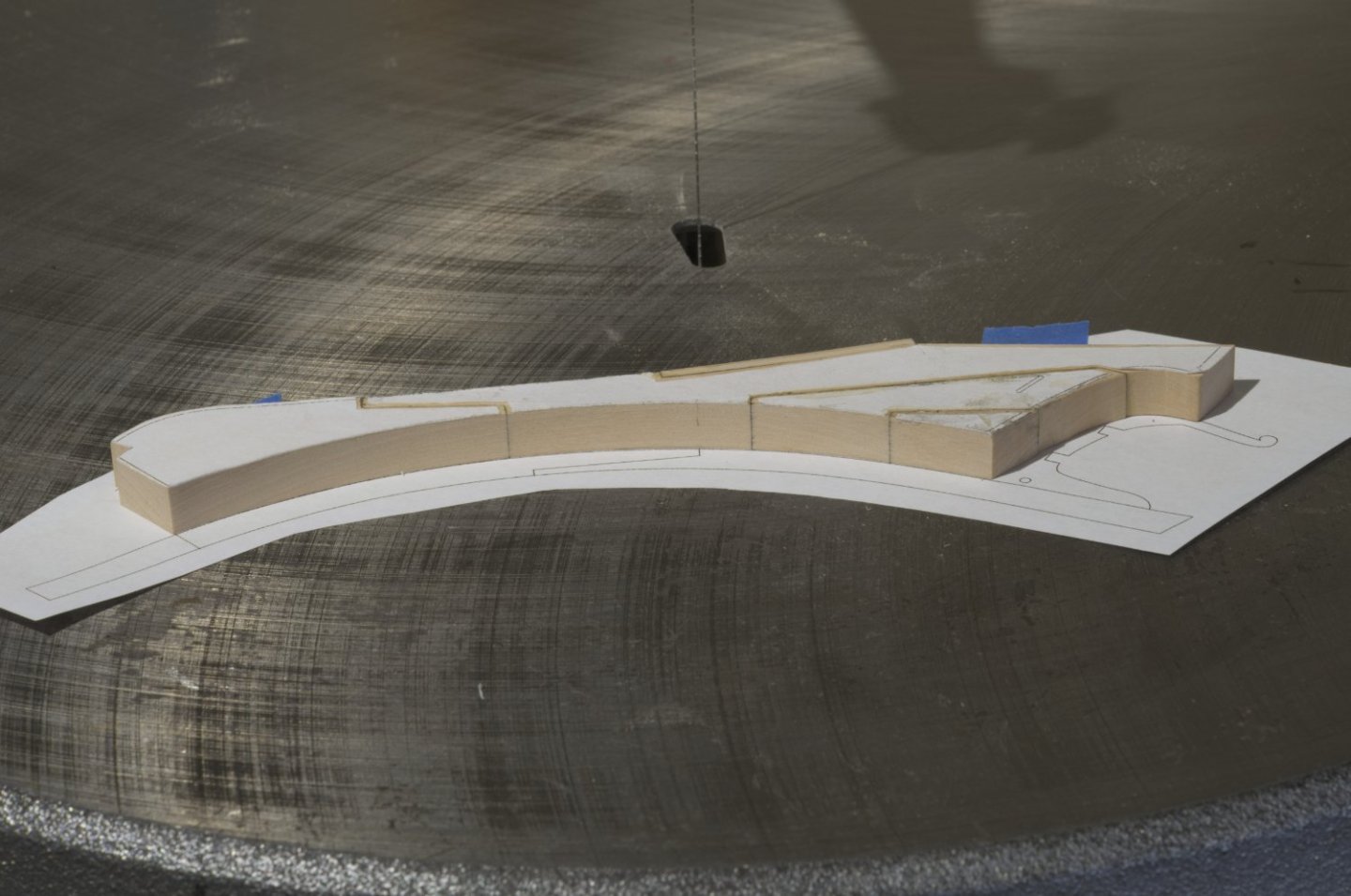

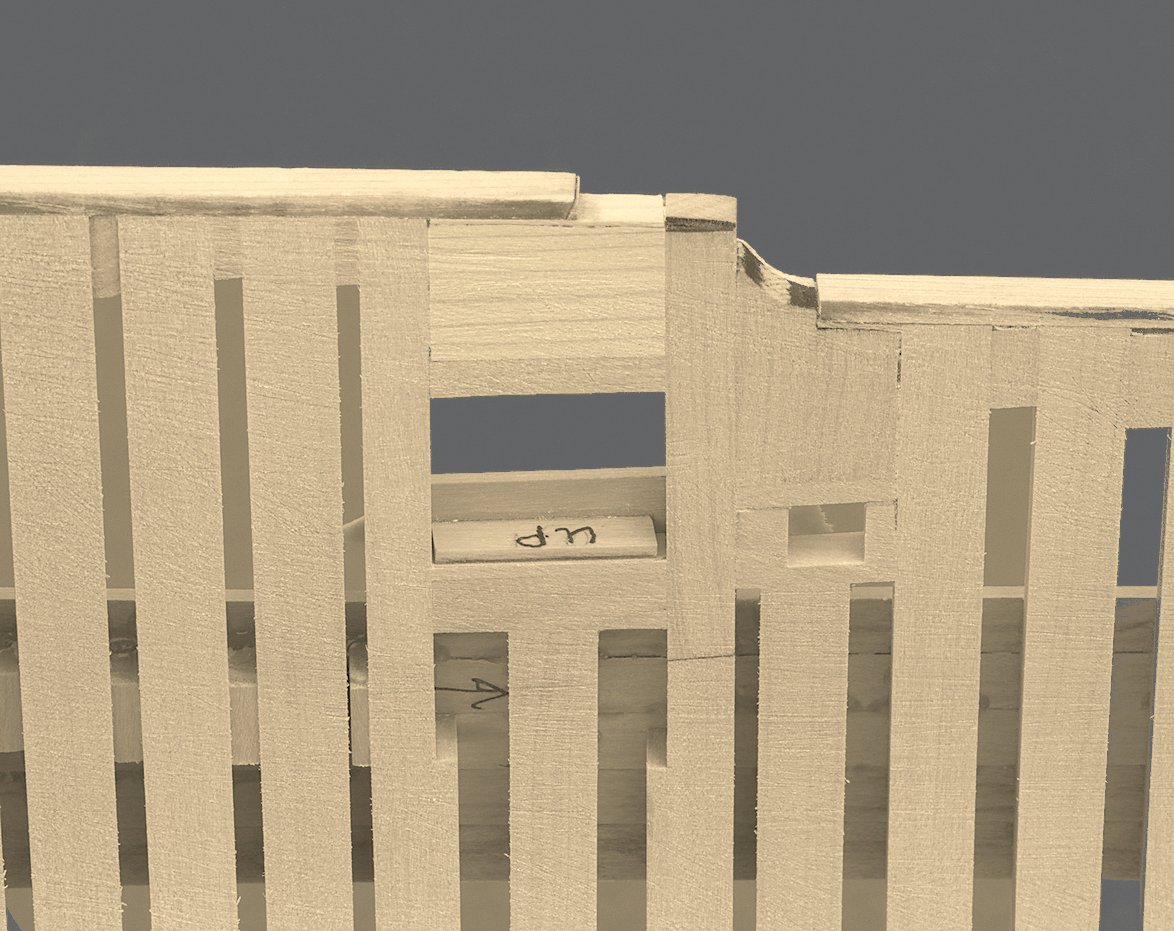

I like to use paper templates held down with acid free rubber cement or even Elmer's School glue. I have always found that it's better to leave a little wiggle room when cutting the outline. In certain cases, rather than shaping each section individually, I just cut the joints accurately and then join the various sections together. After doing that it's easier to get a more accurate outline of the joined parts while the templates are still attached. I'm not suggesting that you would do that with the stem and keel pieces. Just something that you might consider doing in the future. Here is an example of this from my Speedwell build. Mike

- 25 replies

-

Shawn, You're good to go. I'm looking forward to seeing your build log. Mike

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Mast steps Over the weekend I completed the two mast steps. The location of these is very important and the plans really helped me out here. Mizzen step: The first thing I did was to tack glue the three sections together with a spot or two of school glue. Then I milled the notch which goes over the keelson. After breaking the pieces apart, I milled the notch into the top of the middle piece and glued the aft and middle sections together permanently. Next, I angled the bottom edge about 5° to account for the upward sweep of the keelson. I worked the two sections until everything was sitting flush with the limber strakes and keelson. The fore section was then positioned over the keelson, against the first two pieces, and shaped accordingly. You might be asking, why didn't I just glue all three pieces together from the start? It wasn't long before I realized that the shape of the fore and aft pieces were not Identical. The aft piece had a slightly different angle at the foot than the fore piece. This is due to the twist in the limber strake, I think. Doing this in stages allowed me to get each piece angled correctly without the hassle of trying to work the whole piece at once. According to the plan, the center of the mizzen step sits .151" (approx 5/32") in front of the aft edge of frame 11F. I glued the step into position using a cross piece and shim to account for that distance. This also helped to get the step perpendicular to the keel. Main step: This was made basically the same way as the mizzen step. It sits over frame Ba. Unlike the mizzen step, I didn't need to taper the foot. The distance between the centers of the two steps is approx 9-5/32". For the pins I turned down a 1/16" dowel using the Dremel tool. They are press fitted without the need for glue. I've had so much fun making these that I almost forgot that I need to finish up the outer hull planking.😏 Mike

-

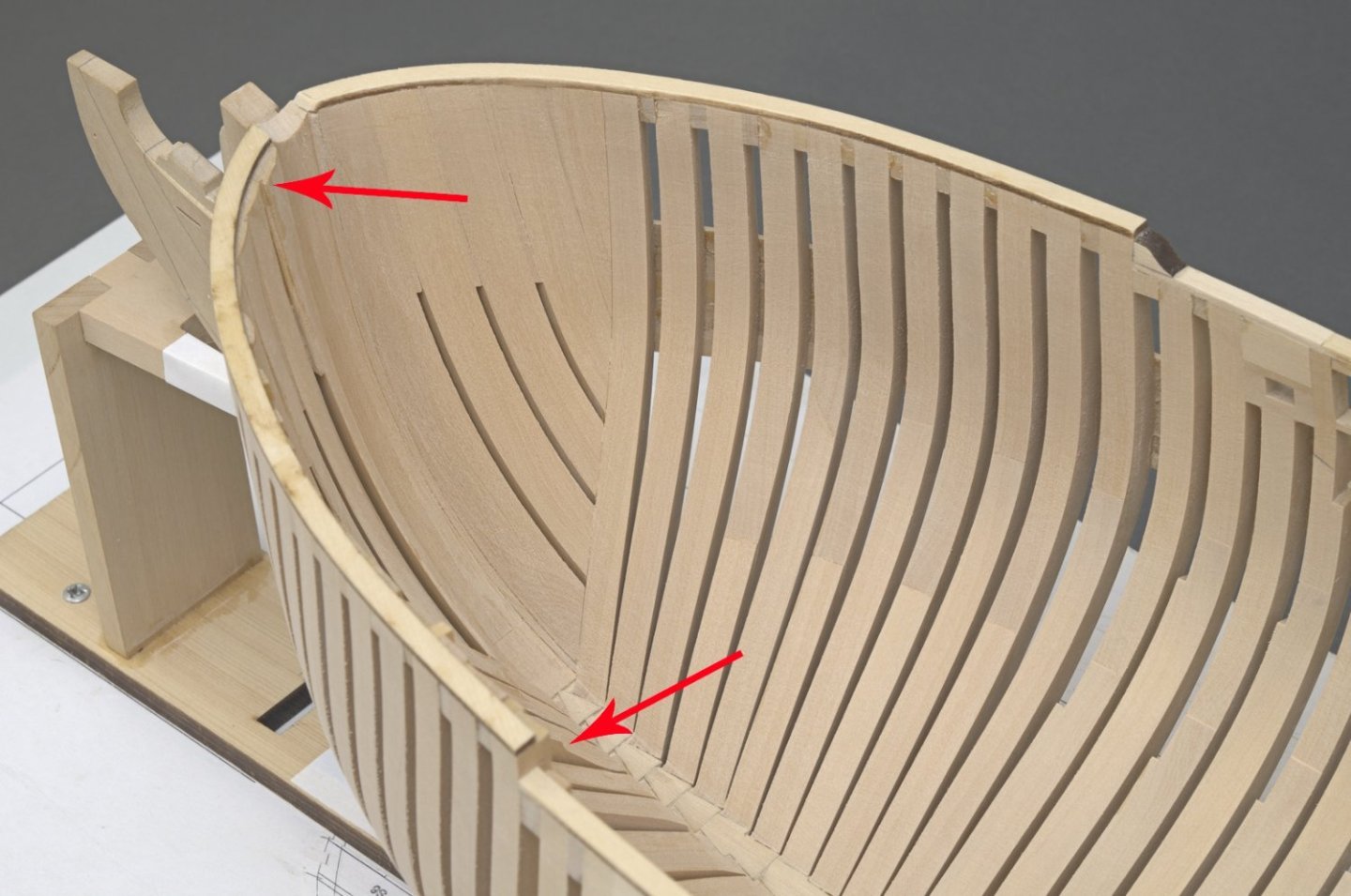

Limber strakes I guess these strakes are for the most part hidden. Still, having never made them before I decided to give these a try. I used the plan drawings as usual for the templates. Rather than shape them exactly to the template, I left some wiggle room in case adjustments where needed. The rabbet on the inside edge was cut with a simple scraper made from a hacksaw blade. After adding the center section, I proceeded to add the fore and aft sections while trying to maintain as smooth a run along the outer edge of the strakes as possible. Both the aft and fore sections have a twist which needs to be taken into account one way or another. I was able to twist the aft section with wet heat and hold it in position while the slow drying CA set. I couldn't get enough twist in the fore section. If these were made from AYC rather than boxwood, it wouldn't have been a problem. Rather than torture myself, I went with some very expensive and exotic tools in order to give me a helping hand. Mike

-

Drawing center lines

Stuntflyer replied to Stuntflyer's topic in Modeling tools and Workshop Equipment

Thanks everyone, Issue solved! I can make a miniature version of the Pioneer marking gauge. -

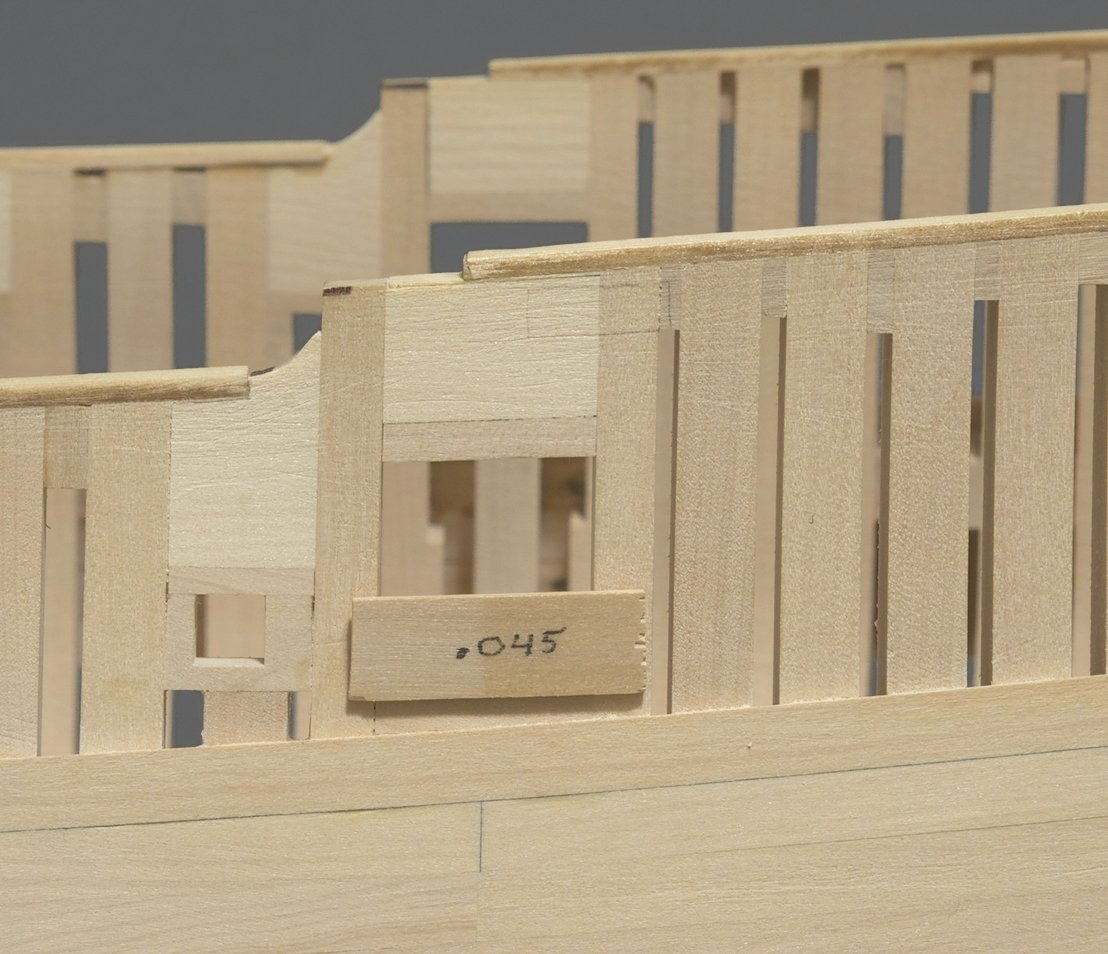

Fixed blocks This weekend seemed to be a good time to get started on the fixed blocks. Six are on the ship with the two really small ones near the transom completed, but off the ship. I'm not sure if I will add them before or after planking that area. I decided to scratch them, using the mill to make the slot between the two holes. When I originally drew in the upper wale location with the hull template, I also marked the location of the blocks. I could have gone with that and it would have been fine. However, since I started the build I've tried to measure off the plan sheet whenever possible. So, here again, that's what I did. I only needed to measure and drill the position of one of the two hole locations for each block. Then it was just a matter of establishing the distance for the second hole while aligning the top of the block parallel to the shear. Here is how I made the tiny rounded shape representing the sheave. It's only .020" deep. Mike

-

Very nice! That's pretty much how I imagined it would be done. You mentioned that you didnt want to go with shiny metallic copper paint. I wonder how metallic paint would look with Dullcote on top.

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Chuck, you've got some really nice detail going on here.

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Rusty, Chuck, Thank you! Keelson I've been working on the keelson for a while. A little bit here a little bit there while fairing the frames. I went with boxwood as usual and milled scarph joints. I used 30lb (.023) black mono for the bolts. I noticed that the keelson would slip and slide a bit on the frames so I pinned it in two locations. This enabled me to center it port and starboard while saving a lot of eyeballing when gluing it down. Mike

-

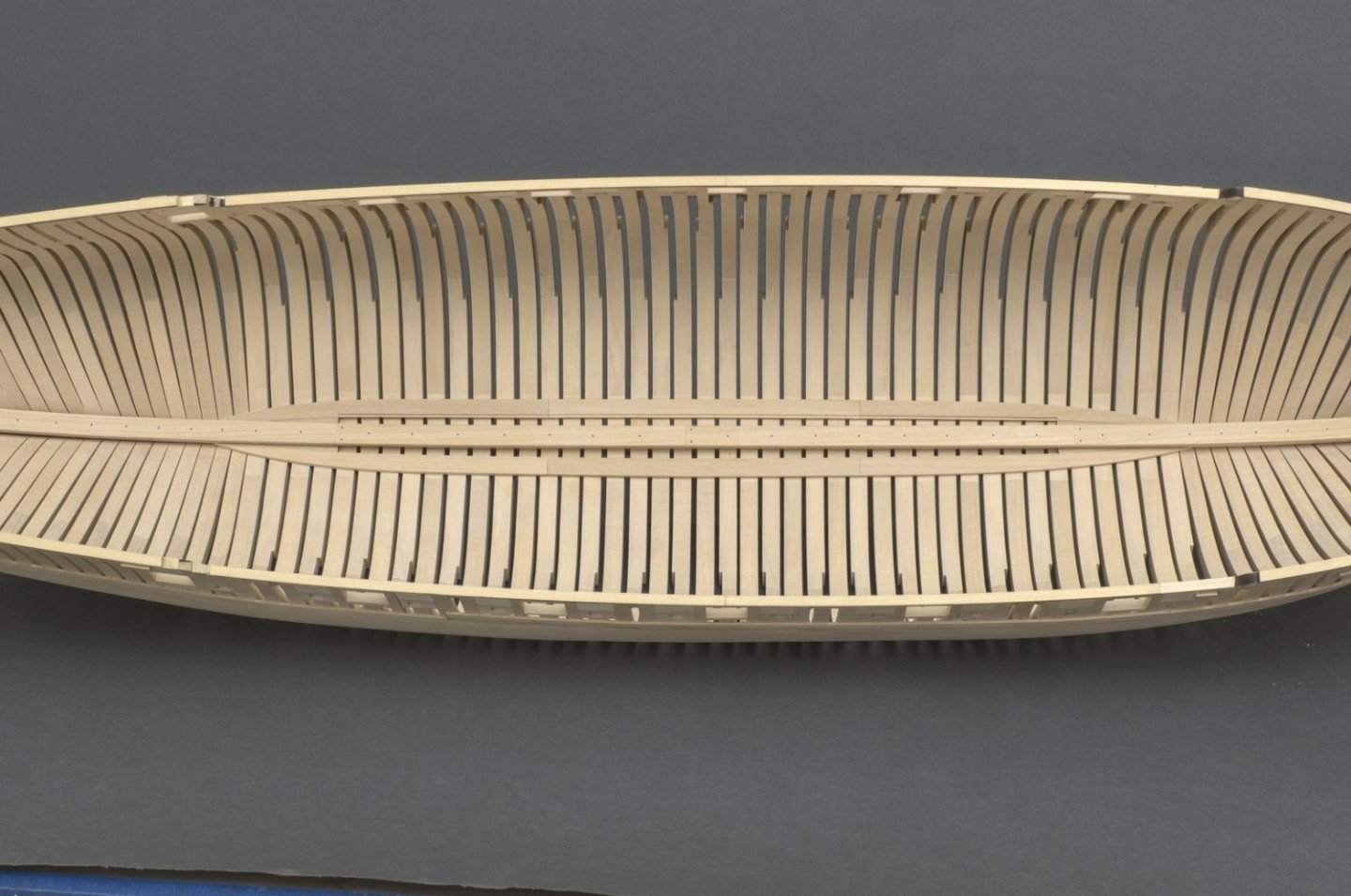

Hull planking, pt. 1 Fairing the outer hull was fairly straight forward. There is plenty of extra meat on the frames which gave me lots of wiggle room. The fairing cap edge should remain untouched, if at all possible. Easier said than done! Final sanding was done with 400 grit. Btw; I totally forgot to take some photos of the outer hull after the fairing was completed. Sorry! Once everything looked good I added the first strake (the upper wale). This was done with three planks. I did my best to eyeball the run as I added each plank and not to strictly rely on the drawn line which I made from Chuck's hull template. From there on it was just a matter of adding the two remaining wale strakes and a few more strakes above the upper wale. I also added the small filler piece which goes between the lower wale and the square tuck. With the added support given by these strakes, I decided to fair the inner hull. This ended up being more time consuming than I thought it would be. It took me several days to complete the work. Working the bow timbers, even with a Dremel or 80 grit, was slow. Once I was close I switched to a miniature curved scraper to smooth out the work. You can see just how thick the wood was in places. When fairing the area around the lower gun port sills, I found that a simple depth gauge came in handy. Including the 3/64" outer hull planking, the width of the sill should be 3/16” or maybe a hair less. I made this simple “T” shaped jig that I could place against the frames and then mark the width of the sill from inside the hull. Ready for the keelson Mike

-

Chuck, very nice! Quick question. Is that bulkhead removable so that it will go in after the deck is laid?

- 786 replies

-

- speedwell

- syren speedwell

-

(and 1 more)

Tagged with:

-

Drawing center lines

Stuntflyer replied to Stuntflyer's topic in Modeling tools and Workshop Equipment

My apologies for not at first seeing Bob Cleek's post above and only those below his. My objective was to find the tool that would pencil mark the center at any width and be able to draw a center line over the length of wood. It appears that the Lee valley one, although not auto centering, would be the type I was looking for. It has the ability to mark and draw a center line even if the wood has a curve to it. -

Drawing center lines

Stuntflyer replied to Stuntflyer's topic in Modeling tools and Workshop Equipment

Gregory, I like the tool. I'm also wondering if the smallest one would work. I'll wait a bit to see if there is a smaller version out there. -

Drawing center lines

Stuntflyer replied to Stuntflyer's topic in Modeling tools and Workshop Equipment

Thanks, Kauz. I've seen that before. I was just wondering if there was a manufactured center line marker available online.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.