-

Posts

1,164 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Stuntflyer

-

-

Ben, I agree with you. 1:48 is the way to go.

Mike

- FrankWouts, Matt D, Vladimir_Wairoa and 5 others

-

8

8

-

I'm in on the POF build as soon as the Winnie is completed. I would probably go with boxwood. Don't want to burn up the laser which means I would have to scratch the framing. I'm looking forward to that. Exciting stuff ahead!

Mike

- VTHokiEE and FrankWouts

-

2

2

-

Just my older Nikon D5100 with a 60mm f/2.8 macro lens. A tripod of course.

Mike

- Moonbug, FrankWouts, glbarlow and 1 other

-

4

4

-

11 minutes ago, glbarlow said:

did you use the fruitwood gel on your figurehead? It looks great, for me it seemed to cake on so I’m sure I’m doing something wrong with the thick gel stain.

Glenn, I used the Fruitwood gel stain. If you brush it on and then rub it off with your thumb, it won't "cake". Just leave enough on to get a change of color. You would be putting it on very thin so maybe two applications would be enough. Btw; using your finger to rub it off is a good way to leave the majority of the color in the recesses of the figure. It will give the figure a more three dimensional look.

Mike

- Ryland Craze, glbarlow, FrankWouts and 1 other

-

4

4

-

Yup! Your the first one to spot that. Those areas will be where the fenders are going.

Mike

- KenW, FrankWouts and scrubbyj427

-

3

3

-

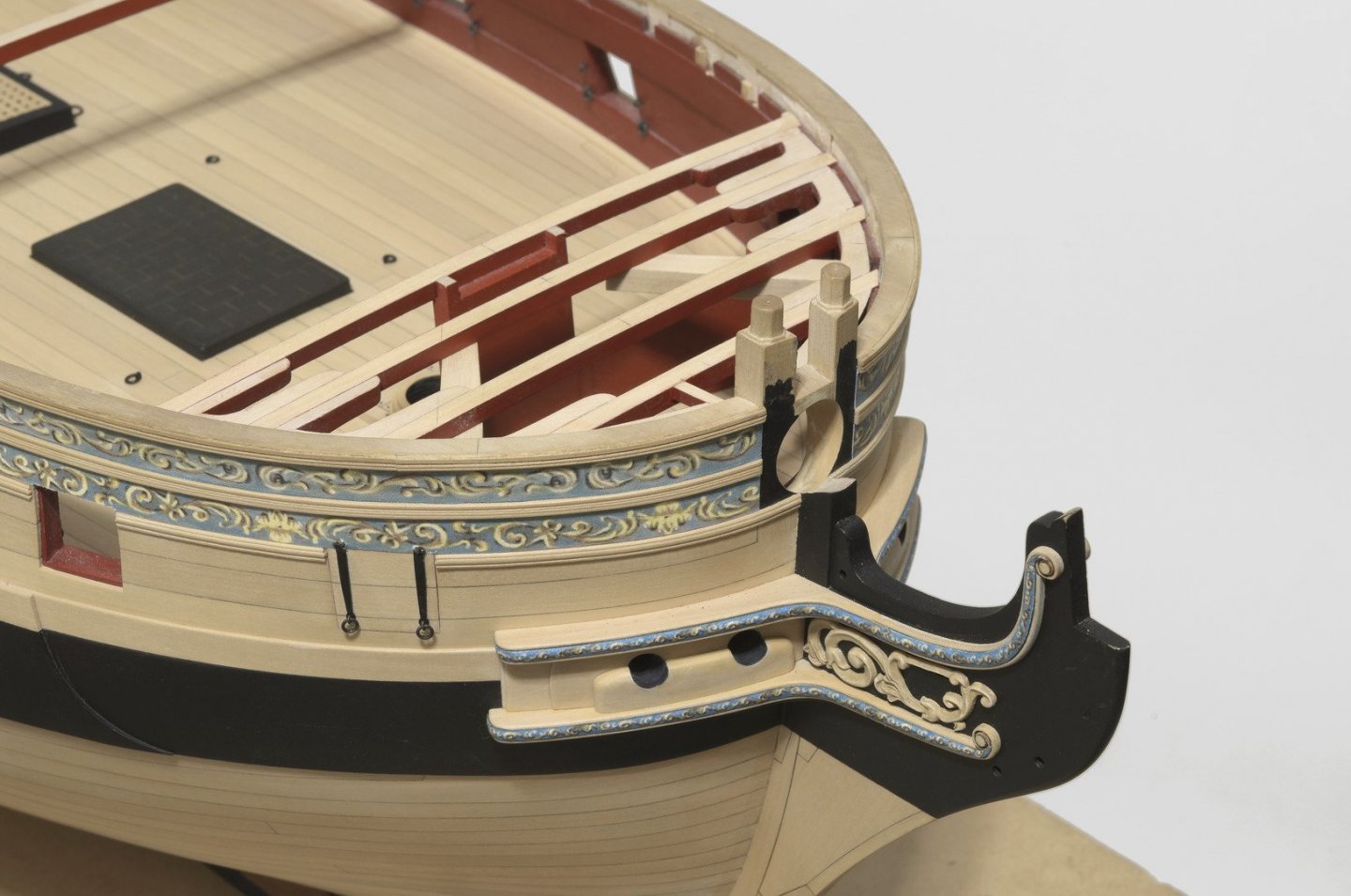

Moving onto chapter 9, I decided to start with the caprail along the waist. I've completed one side. What's interesting is what I had to do in order to get the caprail close to the scroll molding which it sits against at both ends. It was tricky and took some time to do. I'm happy with the result.

Each end had to be shaped like this. .

Mike

-

Glenn, Tom, Thomas, Thank you very much!

Mike

- FrankWouts and glbarlow

-

2

2

-

-

-

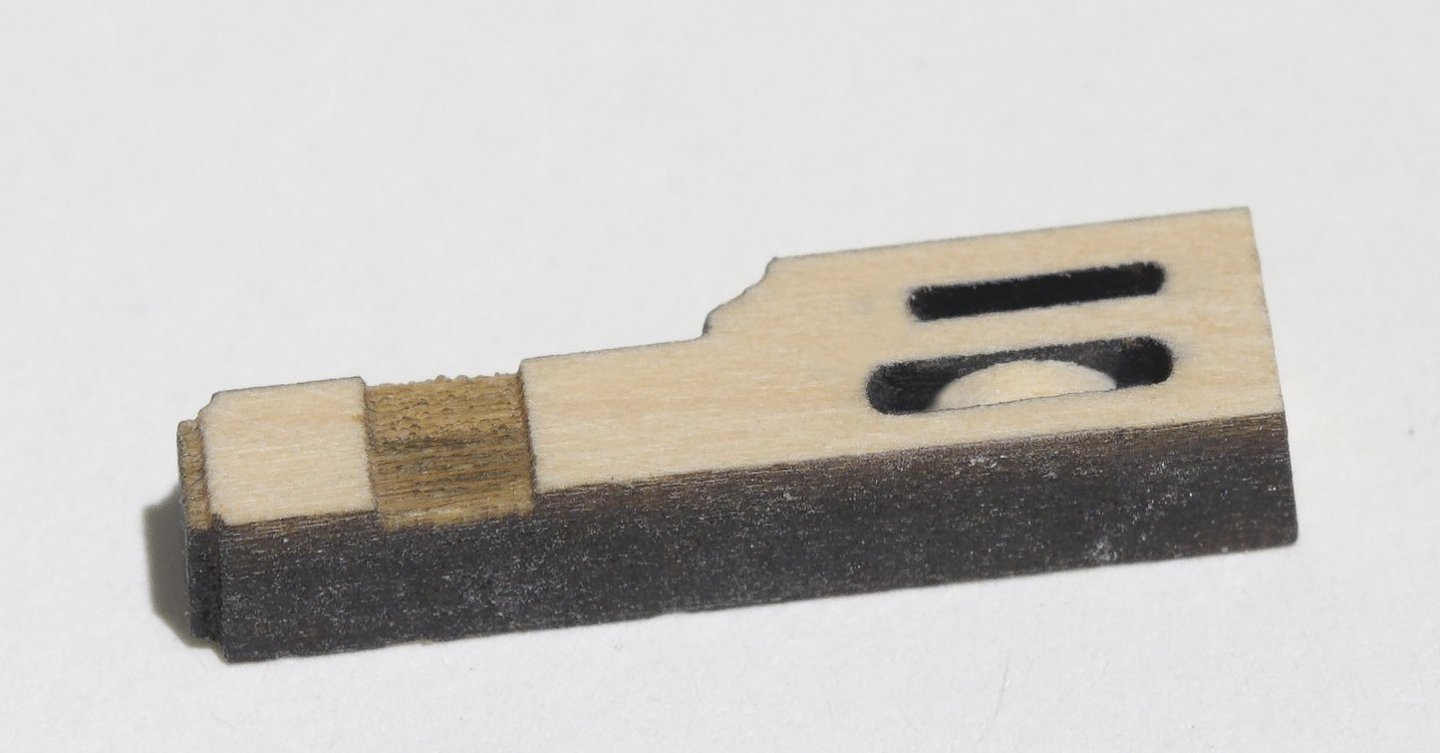

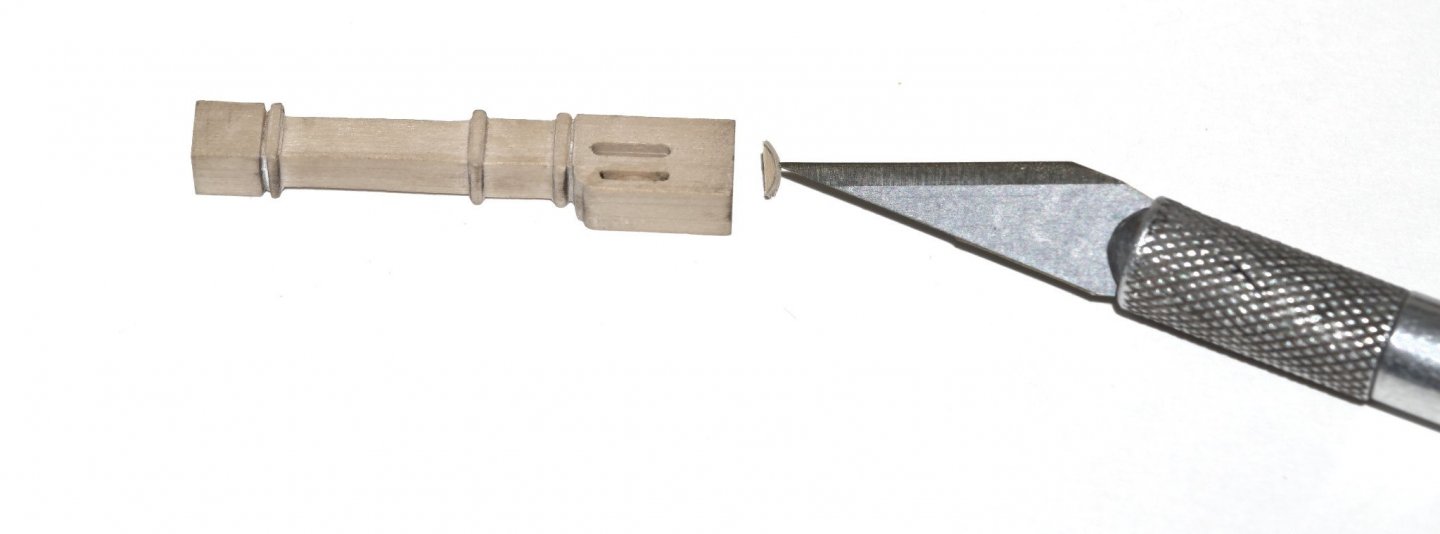

Fore bitt sheaves: Rather than trying to round off the existing laser cut sheave slots, I prefer to simulate the sheaves with wooded disks.

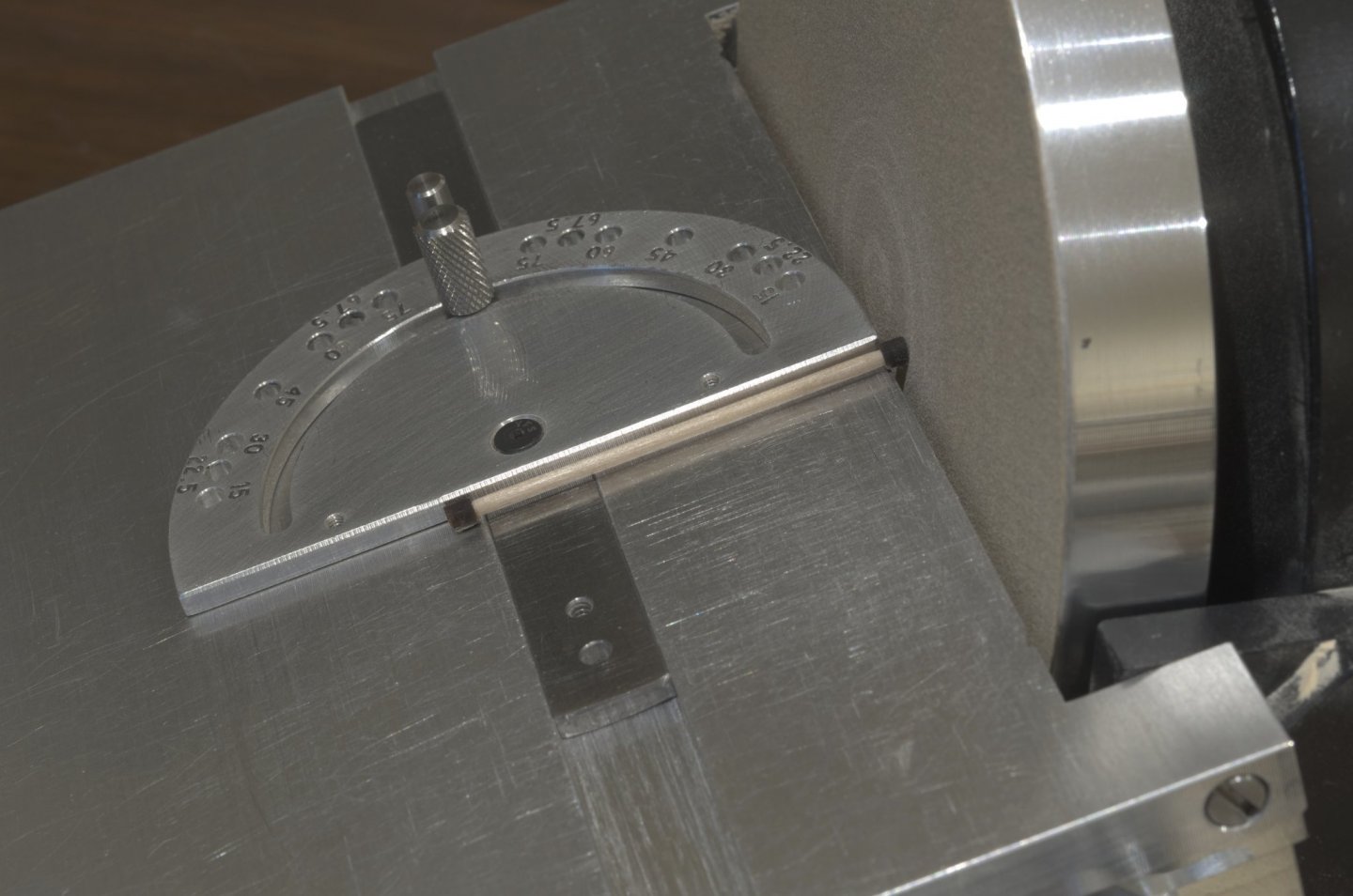

There are 2 sheave slots on these bitts. One is 1/32" wide and the other is 3/64" wide. I used "plastic cutting" end mills to deepen the slots an additional 3/32". This allows for the disk to be recessed slightly after being inserted into the slot. Though not essential, I find that a milling machine makes things a lot easier when doing this kind of work.

The diameter of the disks are equal to the length of the slot between the sheave holes. The thickness of the disks are the same as the width of the milled slot. This allows for a press fit into the slot without any gluing being necessary. If for some reason they are a tad loose going in, just brush in some W-O-P in order to hold the disk in place.

After inserting the disk, the inside area should be painted black. Any paint that gets onto the face of the bitt can be sanded or scraped off easily with a #11 blade. For added protection you could give the outer area a coat of W-O-P to prevent the paint from seeping into the wood.

The slot has been deepened an additional 3/32" which allows the disk to recess below the face of the bitt

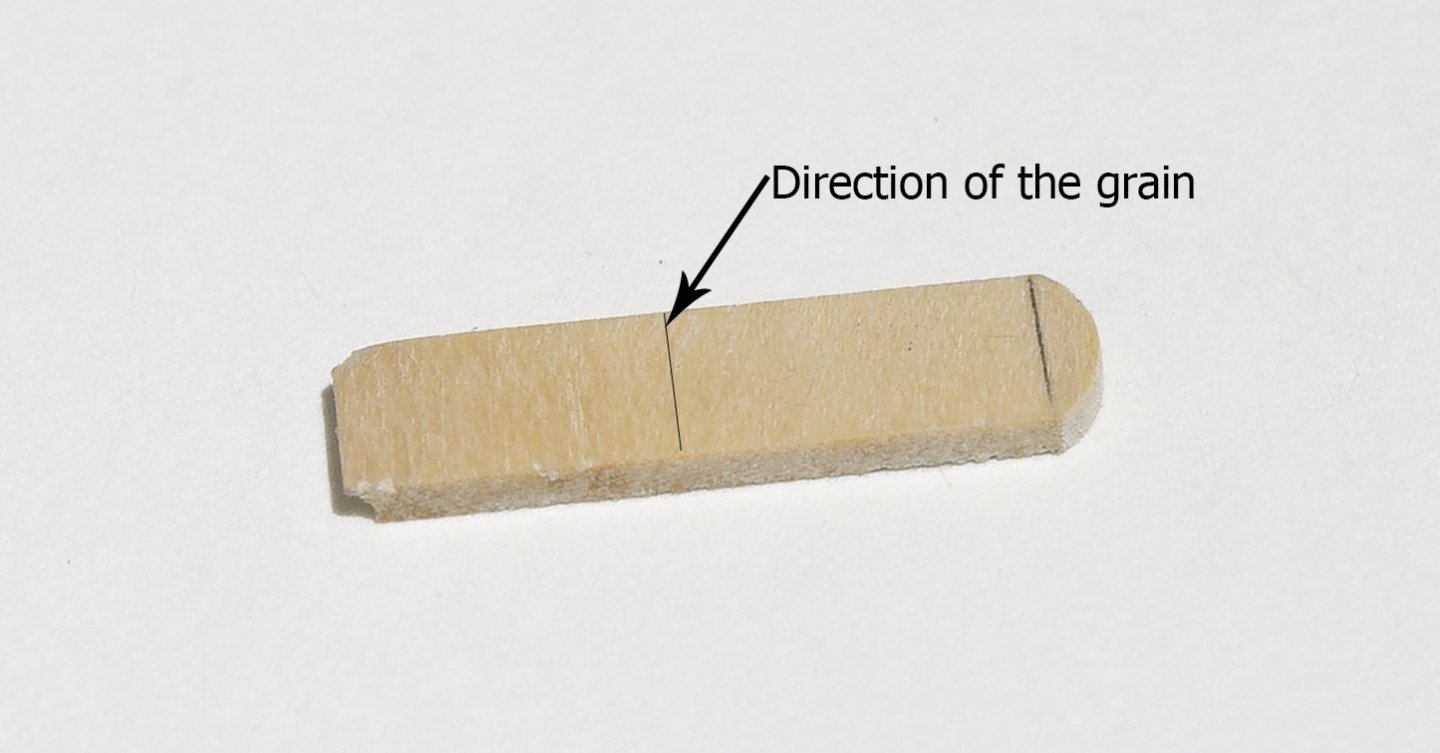

Note the orientation of the grain. This makes it easy to slice off the tiny section of the disk with a #11 blade.

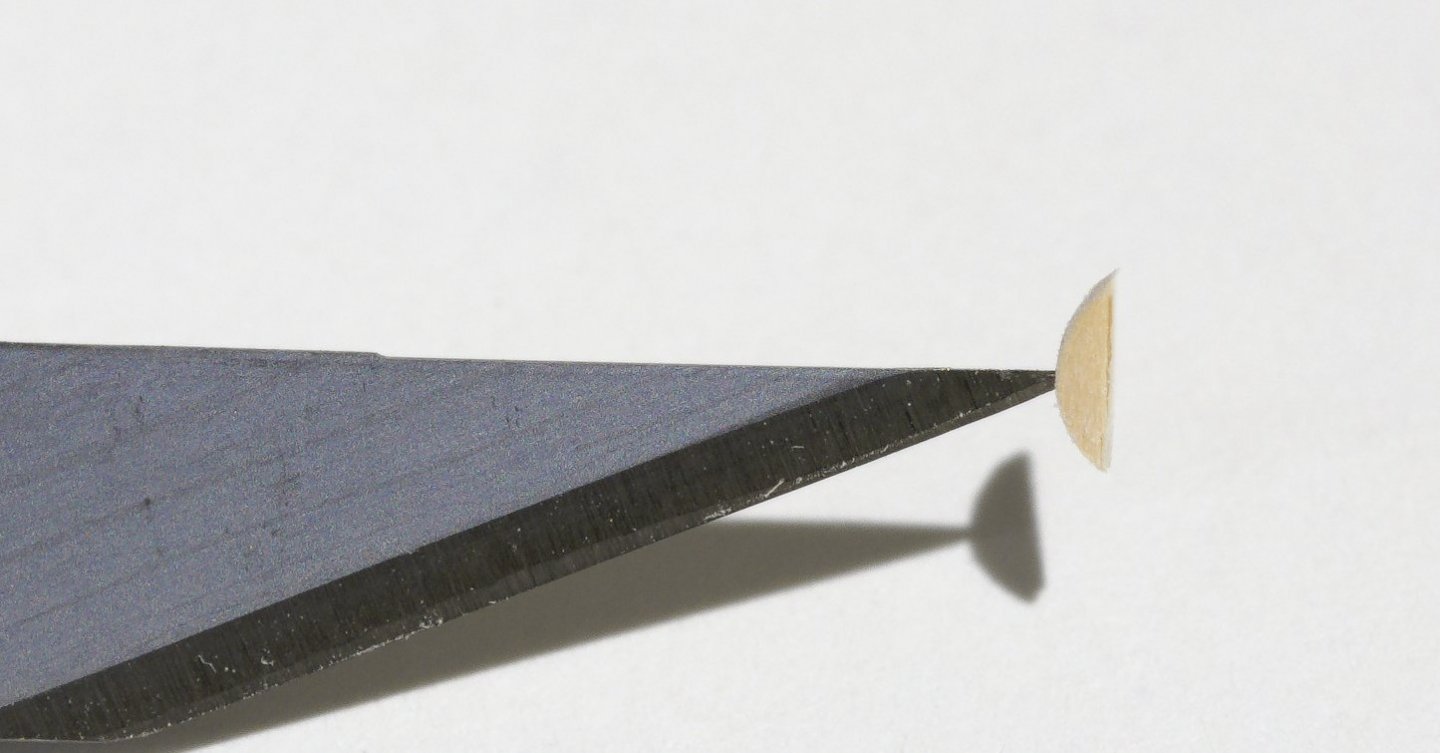

A helping hand to insert the disk into the slot

Mike

-

Hi Steve,

That’s interesting what you did with those stiffeners.

Mike

-

Using Windsor and Newton, I mixed some yellow ochre, Raw sienna and burnt umber into white until the desired boxwood color was achieved.

- glbarlow, FrankWouts, Jorge Diaz O and 2 others

-

5

5

-

9 hours ago, Chuck said:

So I needed some feedback if I should change up my approach for the next parts which will require a bit more care to build actually.

I would be very disappointed if you decided to ease up on the level of detail that you have put into the parts for this build.

Mike

- scrubbyj427, Chuck, WalrusGuy and 5 others

-

8

8

-

On 10/23/2021 at 12:13 PM, Mldixon said:

Were all the deck guns on the Winnie 12 pounders?

The QD guns are smaller.

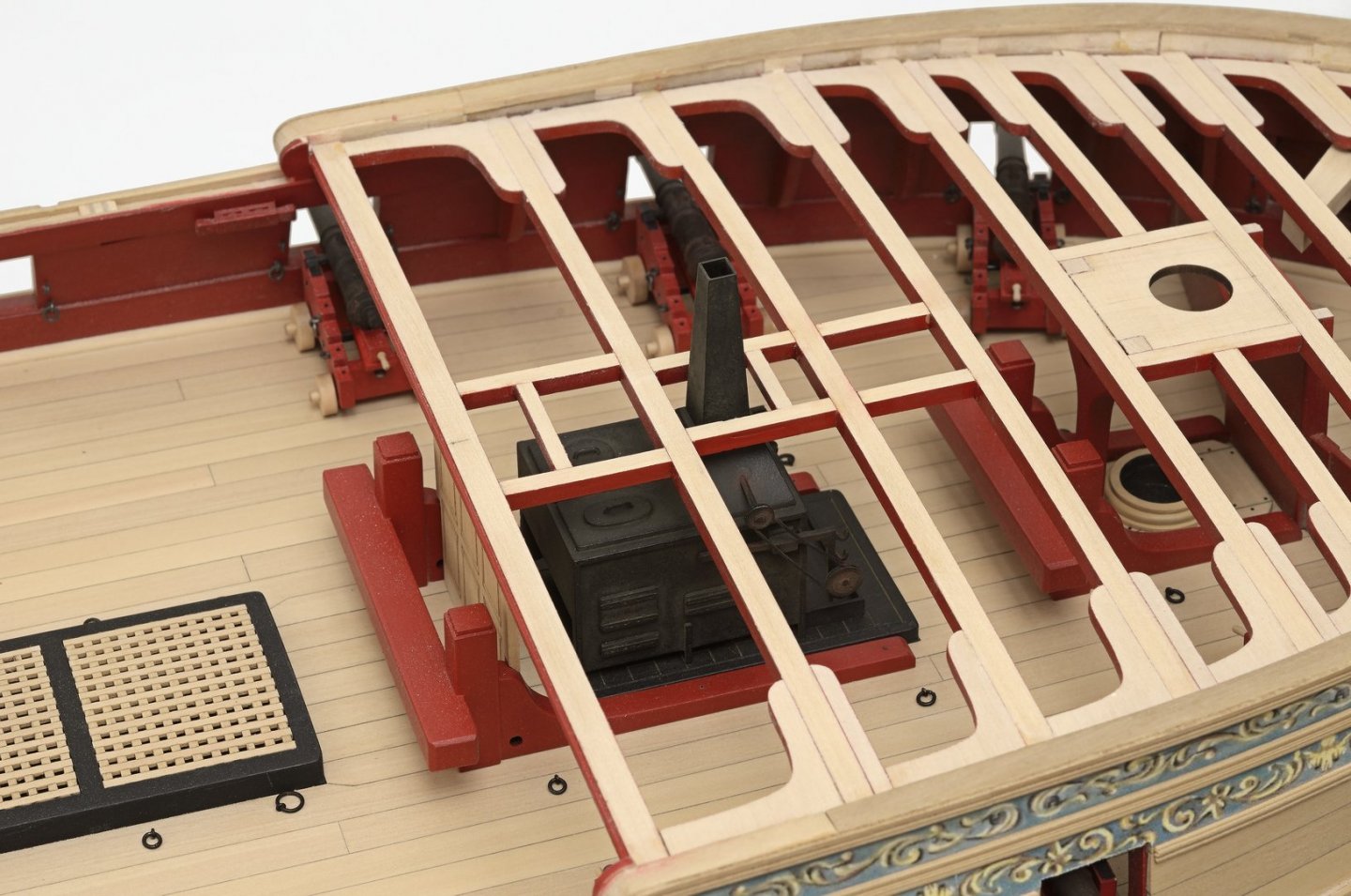

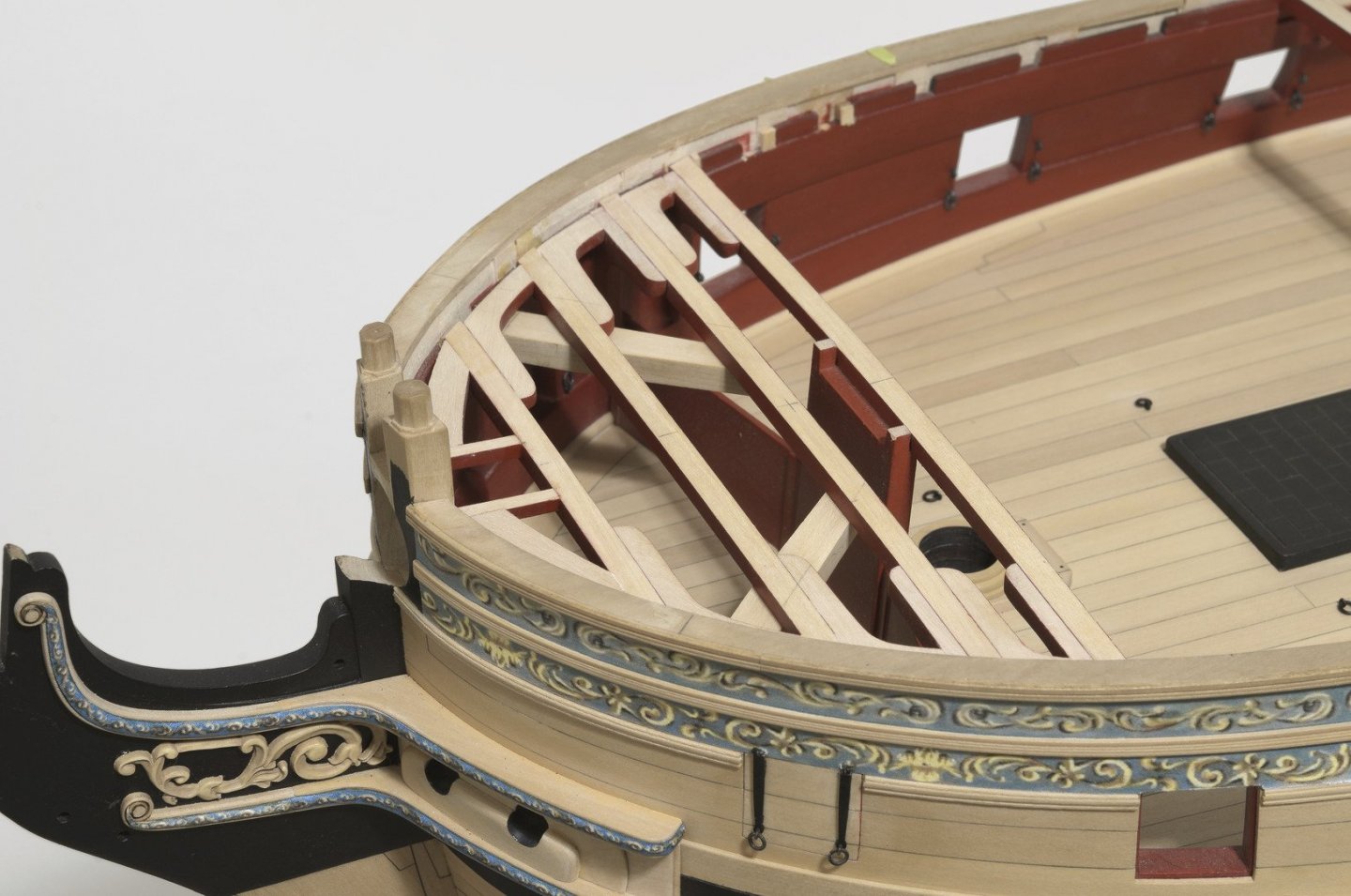

I started working on the forecastle area of the ship. The first four beams are in along with lodging knees, hanging knees, carlings, cat tails and the manger. To my count there were 32 individual pieces needed for the work so far.

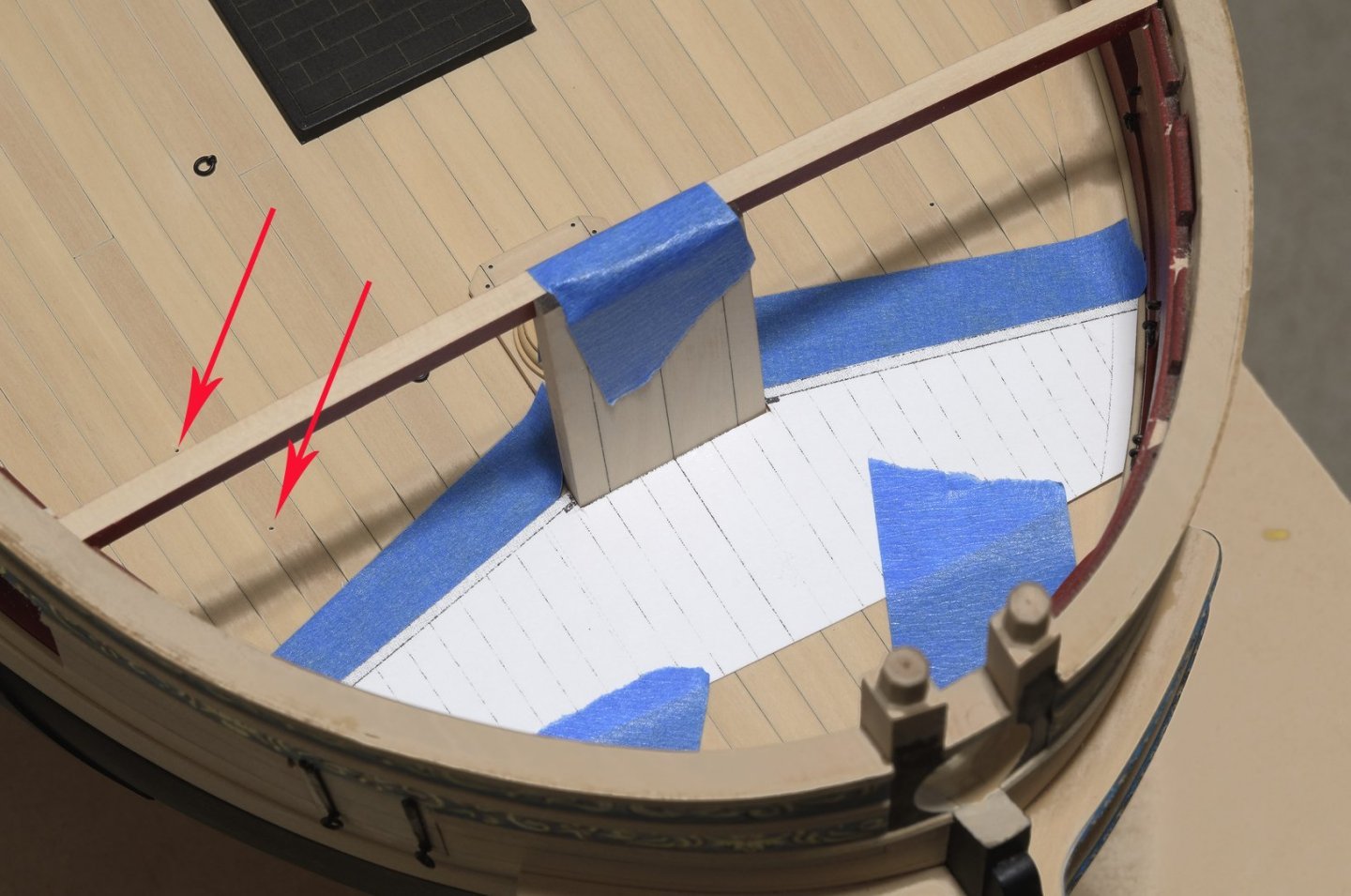

The manger which consists of 12 pieces was assembled as one. A card stock template along with layered blue masking tape was used to establish the location for the boards which will sit on the deck. Btw, those char lines on the bowsprit step are no longer visible. They were blocked out with some boxwood color mix that was applied before painting the manger red. Also, those arrows show where I drilled for the next gun carriage.

Mike

-

-

- Gahm, Chuck and FrankWouts

-

3

3

-

Been working on the stove kit. Just want to say that Chuck has done a masterful job of precision cutting these parts. Everything fits with little or no sanding required. The stack has been thinned down at the top to about 1/64".

I forgot to photograph the drain pan. Anyway, here it is ready for paint.

Mike

- Chuck, WalrusGuy, scrubbyj427 and 11 others

-

14

14

-

Chain pumps. . . I decided to make the 4 Rhodings from 1/16" x 1/64" brass strip. The square portion of the crank handle is only 3mm in length. Any longer and I think they would look out of scale. After blackening the brass rod I used some weathering powder to age the look of the metal.

After that I added the the decorative moulding to the forward edge of the breast beam. Then came the elm pumps and QD bulwark planking. For the carlings I made simple wood templates that fit between the beams in order to position the carlings equidistant from the center of the deck.

Mike

-

Really nice work there! Love the colors too. So, what's next?

Mike

-

1 hour ago, bdgiantman2 said:

Would these be accurate?

Well, I really don't know, Brian. Perhaps Chuck or someone else will be able to give you the answer.

Thanks for stopping by!

Mike

-

-

I'm still working in the area of the chain pumps. Getting the pumps to sit properly is a bit fiddly. Your basically there when the chocks are sitting flush on the mast partner and the deck and there is no rocking of the pump. In order to achieve this I had to shorten the tubes on the bottom of each pump.

In making the jeer butts and gallows I deepened the sheave slots on the mill. I used 1/32" and .045" end mills as needed. Then I inserted tiny discs to simulate the sheave. With a press fit, no gluing was necessary. I just applied some W-O-P over the sheave to better hold the disc in place. Okay, it's not PVA, but it does have holding properties and keeps things a whole lot neater.

I used some layered masking tape to help in aligning the pump while gluing it in place.

Mike

- egkb, FrankWouts, JpR62 and 18 others

-

21

21

-

Those black caps really enhance the look of the ship. Nice!

Mike

- FrankWouts, Chuck, Ryland Craze and 1 other

-

4

4

-

I just edited post #395 as I felt it needed a clearer explanation.

My apologies,

Mike

- Jorge Diaz O, FrankWouts and WalrusGuy

-

3

3

HMS Winchelsea 1764 by Stuntflyer (Mike) - FINISHED - 1/4" scale

in Member Build logs for the HMS Winchelsea

Posted · Edited by Stuntflyer

Work continues on chapter nine with some of the forecastle planking completed. W-O-P has not been applied which makes it harder to see the butt joints. Hopefully you will see enough to get the idea. That center piece behind the bollards was made that way which makes it easier to hold. The grain runs port and starboard. This makes it easier to slice off that long tab after the glue dries.

Mike