-

Posts

41 -

Joined

-

Last visited

About Tankerman

Profile Information

-

Gender

Male

-

Location

South Somerset

-

Interests

Model ships, static and working radio control.

Gauge 1 and 0 gauge model railways.

Model Classic Sports Cars. Classic commercial vehicles.

Recent Profile Visitors

-

DocRob reacted to a post in a topic:

What plastic ship kits have you done?

DocRob reacted to a post in a topic:

What plastic ship kits have you done?

-

Harvey Golden reacted to a post in a topic:

What plastic ship kits have you done?

Harvey Golden reacted to a post in a topic:

What plastic ship kits have you done?

-

Old Collingwood reacted to a post in a topic:

What plastic ship kits have you done?

Old Collingwood reacted to a post in a topic:

What plastic ship kits have you done?

-

Tankerman reacted to a post in a topic:

LPG Tanker Chaconia by Javelin - Radio - 1/100

Tankerman reacted to a post in a topic:

LPG Tanker Chaconia by Javelin - Radio - 1/100

-

vossy reacted to a post in a topic:

What plastic ship kits have you done?

vossy reacted to a post in a topic:

What plastic ship kits have you done?

-

Tankerman reacted to a post in a topic:

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64

Tankerman reacted to a post in a topic:

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64

-

Tankerman reacted to a post in a topic:

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64

Tankerman reacted to a post in a topic:

HMS Indefatigable 1794 (prototype) by James H - Vanguard Models - 1:64

-

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

-

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

-

Tankerman reacted to a post in a topic:

HMS Sphinx 1775 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Tankerman reacted to a post in a topic:

HMS Sphinx 1775 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

Tankerman reacted to a post in a topic:

HMS Wolf 1754 by catopower - Shipyard - 1/72 - CARD - 10-gun Brig

Tankerman reacted to a post in a topic:

HMS Wolf 1754 by catopower - Shipyard - 1/72 - CARD - 10-gun Brig

-

Tankerman reacted to a post in a topic:

HMS Wolf 1754 by catopower - Shipyard - 1/72 - CARD - 10-gun Brig

Tankerman reacted to a post in a topic:

HMS Wolf 1754 by catopower - Shipyard - 1/72 - CARD - 10-gun Brig

-

popeye the sailor reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

popeye the sailor reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

-

mtaylor reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

mtaylor reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

-

Old Collingwood reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

Old Collingwood reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

-

Canute reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

Canute reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

-

Kevin reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

Kevin reacted to a post in a topic:

HMHS Britannic by Kevin - Trumpeter - 1/200 - PLASTIC - from Titanic kit - Started September 2022

-

Deluxe Materials "Glue 'n' Glaze" is the product I have found that is better than PVA glue for glazing windows and portlights. It is similar in consistency but seems to give a better appearance.

-

Tankerman reacted to a post in a topic:

HMS Sphinx 1775 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

Tankerman reacted to a post in a topic:

HMS Sphinx 1775 by Blue Ensign - FINISHED - Vanguard Models - 1:64 scale

-

thibaultron reacted to a post in a topic:

SS Great Britain kit

thibaultron reacted to a post in a topic:

SS Great Britain kit

-

48th Scale imperial rulers. Where?

Tankerman replied to John Murray's topic in Modeling tools and Workshop Equipment

This may be of help: https://www.blundellharling.com/product/imperial-academy-architects-triangular-scale-rule-12-300mm/ Good luck -

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

Tankerman reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates

-

Air Compresser

Tankerman replied to Guyuti's topic in Painting, finishing and weathering products and techniques

I can thoroughly recommend this compressor from a totally reliable specialist supplier. It is very well constructed, quiet and very reliable. I have had a Sparmax compressor for many years and would not consider anything else. https://www.everythingairbrush.com/product/sparmax-professional-mini-piston-airbrush-compressor-2-5-litre-air-tank/ Chris -

Waterslide Decal Paper

Tankerman replied to hof00's topic in Painting, finishing and weathering products and techniques

Very much by trial and error wefalck, I was lucky that the red on the truck was a good match. Chris -

Waterslide Decal Paper

Tankerman replied to hof00's topic in Painting, finishing and weathering products and techniques

I have used this method on several of my models and show two examples below: The T2 tanker is the very old Revell kit at around 1/450th. scale and I wanted to show it as one of the many T2s owned by the company I sailed with. The company logo was downloaded form the web. The "Caltex Glasgow" and port of registry in the correct font and size ( less than 2mm in this case } were added to the file over a black background. The file was then printed on to a white decal waterslide transfer paper by 'Experts Choice' using a domestic inkjet printer. Once the ink was dry the sheet was sprayed with a clear acrylic varnish to seal it, after which the images were carefully cut from the sheet and applied to the model. The tractor unit is a conversion of the standard AMT 1/25th. kit of the White Freightliner to represent the ones operated by Carolina Freight. The logo on the door is a commercially available decal but the fleet name on the roof deflector and front bumper, the fleet number and legal lettering are generated in a 'pages' file on a Mac to the correct size and font, given a red background and printed off on white decal paper. The red print colour matched the red paint I used on the cab. I hope this helps you HOF. -

Having bought a jar of this to try I wouldn't be without it now, such a versatile glue. Not only the windows but all the PE and resin decoration on the stern of my Sphinx are securely attached with it.

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Here you are: https://www.abebooks.co.uk/servlet/BookDetailsPL?bi=30549031522&searchurl=an%3Dwilliam%2Bmowll%26fe%3Don%26sortby%3D17%26tn%3Dss%2Bgreat%2Bbritain%2Bthe%2Bmodel%2Bship&cm_sp=snippet-_-srp1-_-title1

-

Just before I read your post I had been fitting my interpretation of the frieze decoration to my model of H.M.S Sphinx. Reading from various sources about ship decoration during the Georgian period I was not convinced that a small 20 gun frigate would have had that much gold gilt work and the frieze was more likely to have been painted in yellow or ochre paint if indeed it was decorated at all. As I wanted to include all the exquisite etched brass pattern that Chris W. has provided I decided to use a white primer followed by a coat of light yellow acrylic colour by Vallejo. When dry this was then coated in Humbrol Clear gloss varnish. The detail on the etch is then highlighted with a wash of Seraphim Sepia from the Citadel range of washes called "Shades". The photo shows the fitting of the first row of decoration on my model and I am very happy with the result. Over the next couple of days I will apply the the rest of the decoration. I hope this gives you some idea of the possible alternatives. Chris

-

kit review 1/72 Brockley Combe, 1938 Cargo Ship - Navarino Models

Tankerman replied to James H's topic in REVIEWS: Model kits

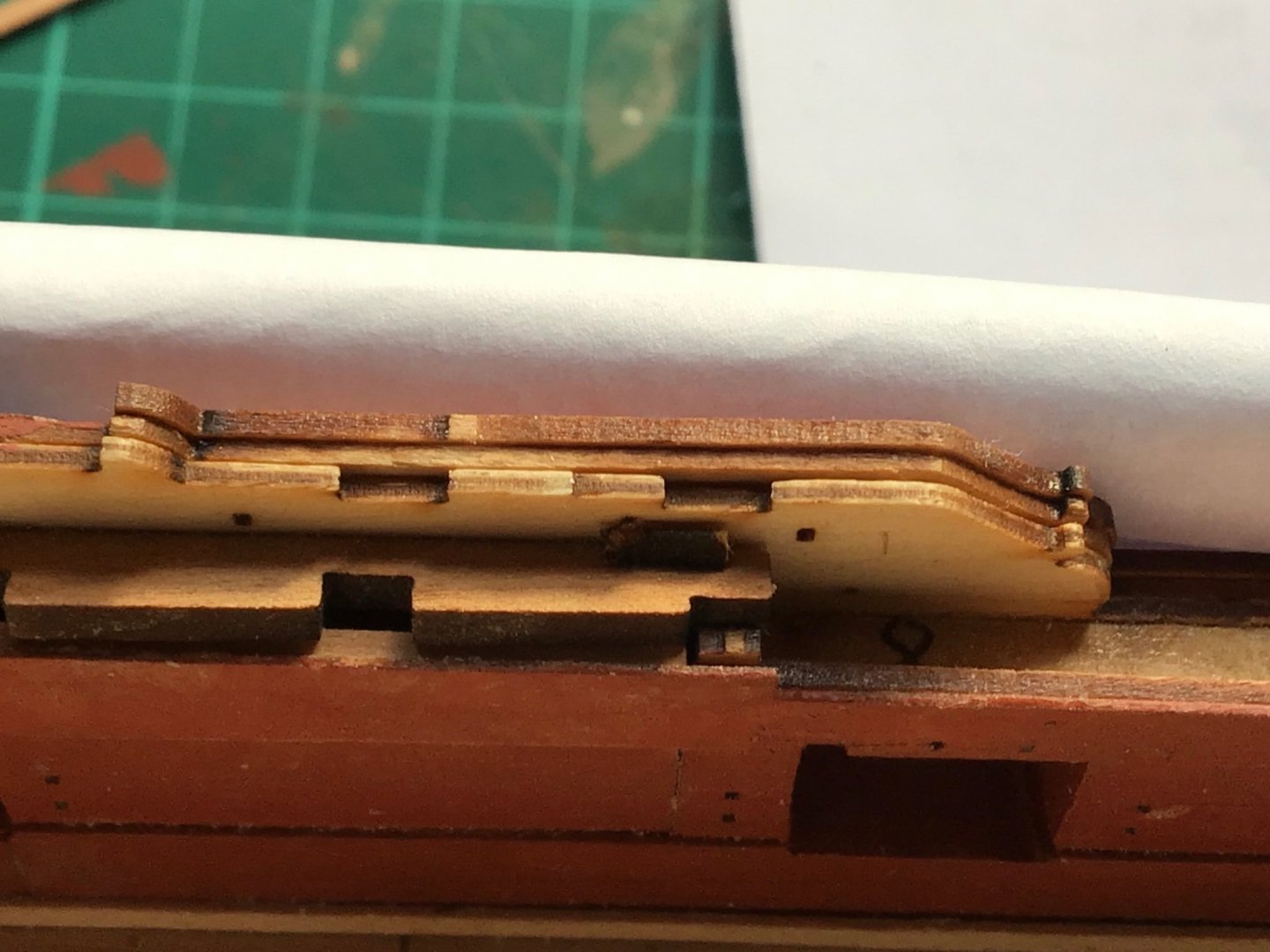

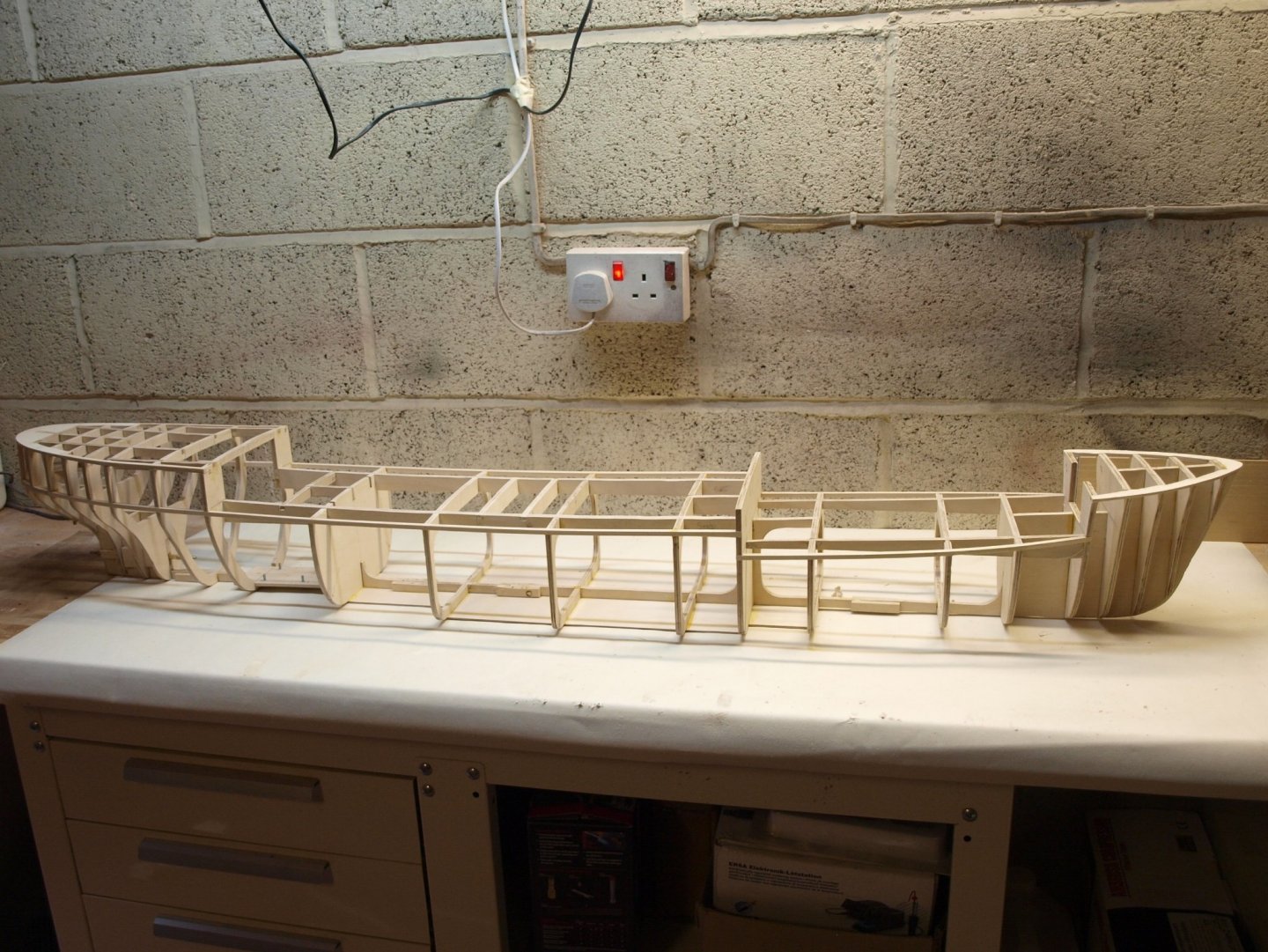

The hull bulkheads of the kit would require a lot of modification in order to fit a motor and stern shaft, as well as space for batteries and associated radio gear, keeping in mind that some access is required for maintenance. The photos show my scratch built hull frame for the motor collier, the M.V. Ballyloran. This is a 1/48th. scale model but the principles are the same and you will see that the motor bedplate and stern tube are fitted at this early stage to ensure an accurate alignment. Should you decide to build the M.V. Brockley Coombe I would recommend a book "British Motor Coasters" by Charles V. Waine which is a very complete history of this type of vessel and where you will find a General Arrangement drawing of M.V. Brockley Coombe and photographs.- 6 replies

-

- brockley combe

- navarino models

-

(and 2 more)

Tagged with:

-

I agree, my reading and research on the subject means I have reached the same conclusion as you. Chris

- 858 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

B.E. this book would add more interest in your search for the colour "blue": http://modellbau-muellerschoen.de/Shop-en.htm?fbclid=IwAR1Z1MSLyl5JG6KSoLfZbK_vKumG63wh8itcYxOTGQZ_YBbbTgHVB6Z6zyw but at a price! Chris

- 858 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I second that Malcolm, it is a great testament to the hard work that Chris and James have put in to the development of this kit and I'm looking forward to the arrival on my doorstep of a big box from The Forest of Dean in the next week or so. Long live Vanguard Models. Chris

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.