DmitriyMarkov

Members-

Posts

61 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Moscow, Russian Federation

Recent Profile Visitors

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

DmitriyMarkov reacted to a post in a topic:

Borodino by Captain Slog - Dom Bumagi - 1:200 - CARD

-

DmitriyMarkov reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

DmitriyMarkov reacted to a post in a topic:

HIJMS MIKASA 1902 by Jeff59 - HobbyBoss - 1/200 - PLASTIC

-

Landlubber Mike reacted to a post in a topic:

Borodino by RGL - FINISHED - Zvezda - 1/350 - PLASTIC

Landlubber Mike reacted to a post in a topic:

Borodino by RGL - FINISHED - Zvezda - 1/350 - PLASTIC

-

DmitriyMarkov reacted to a post in a topic:

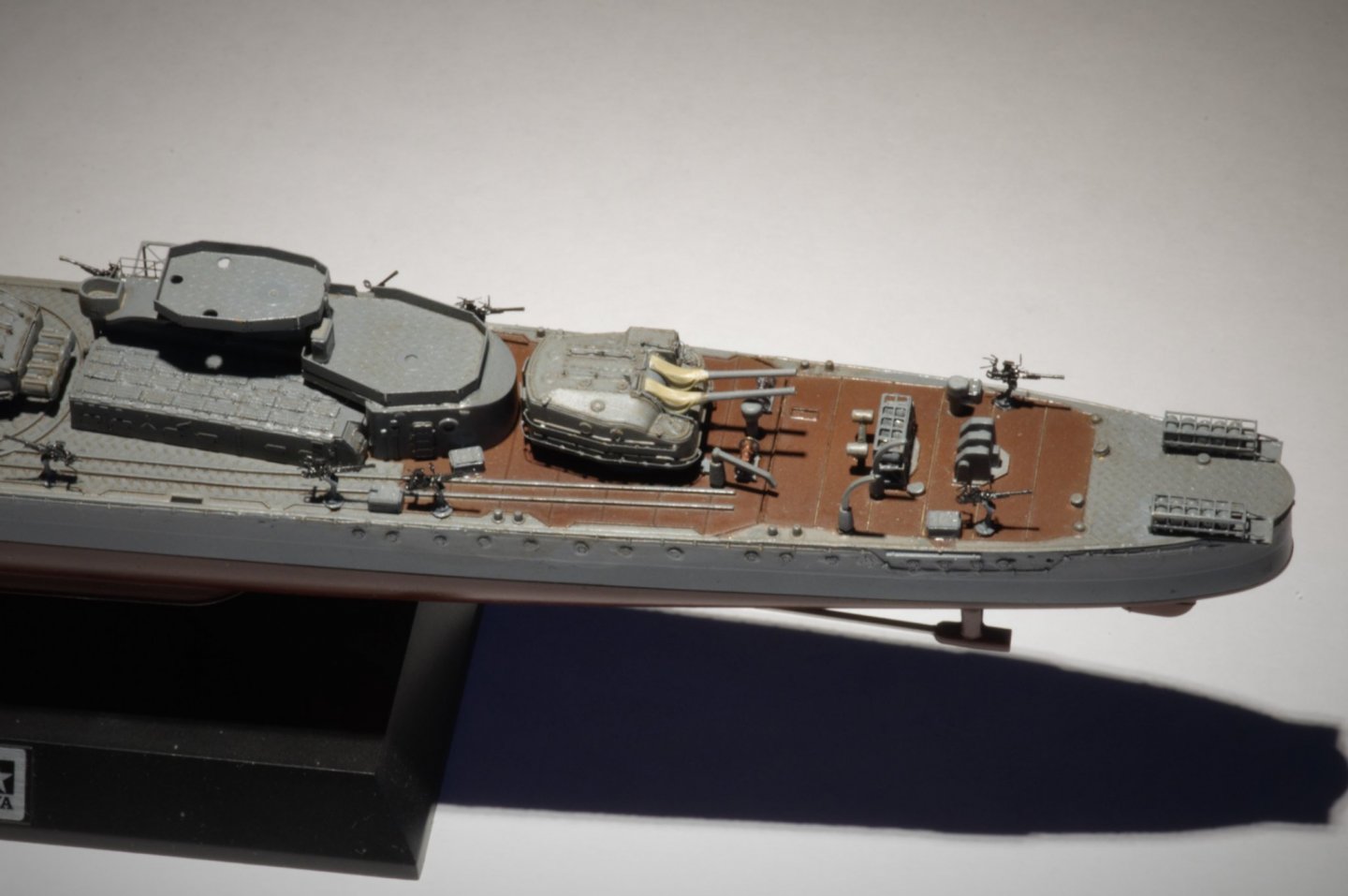

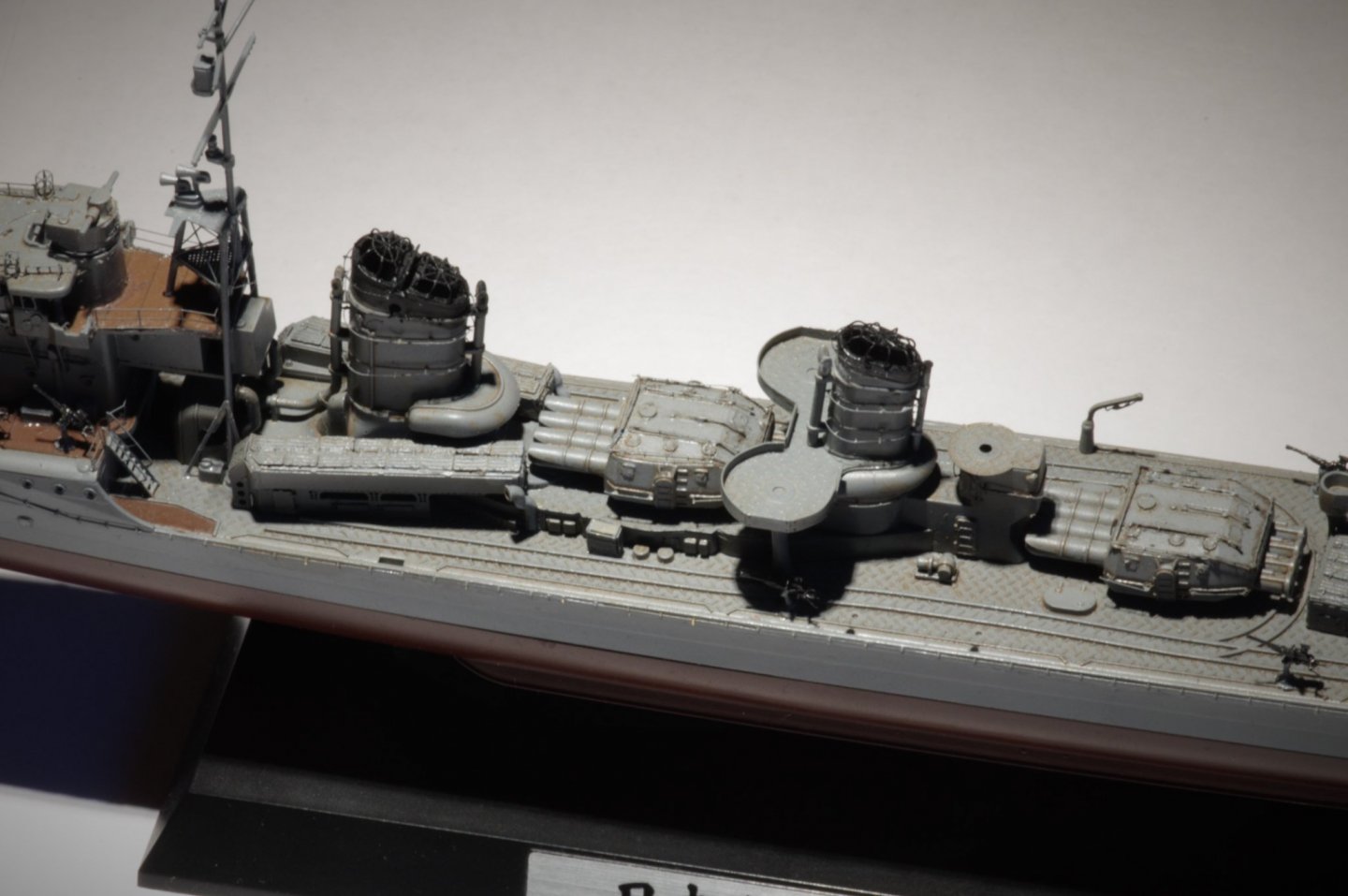

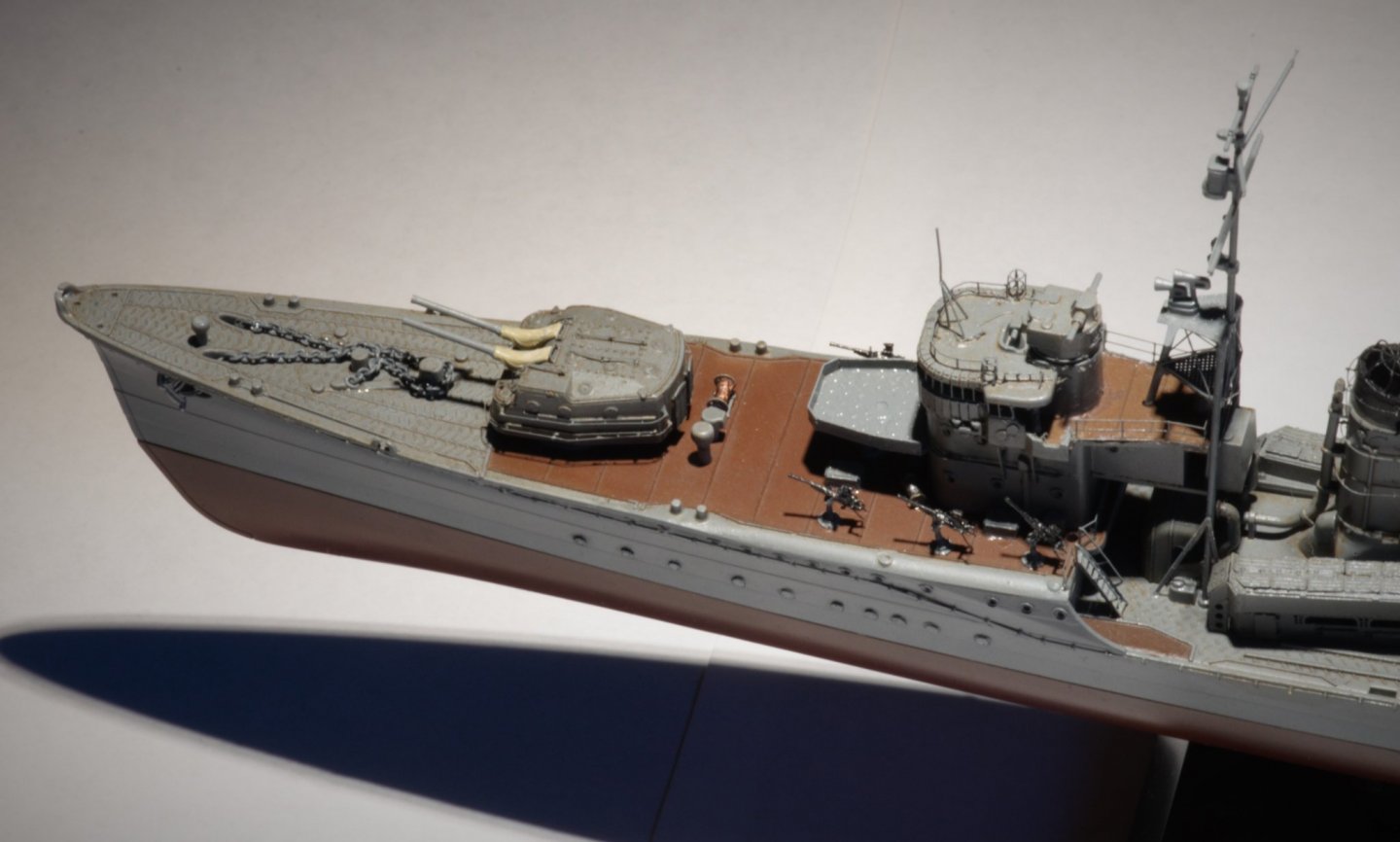

Shimakaze by Landlubber Mike - FINISHED - Hasegawa - 1:350 - PLASTIC - Japanese WWII Destroyer

DmitriyMarkov reacted to a post in a topic:

Shimakaze by Landlubber Mike - FINISHED - Hasegawa - 1:350 - PLASTIC - Japanese WWII Destroyer

-

yvesvidal reacted to a post in a topic:

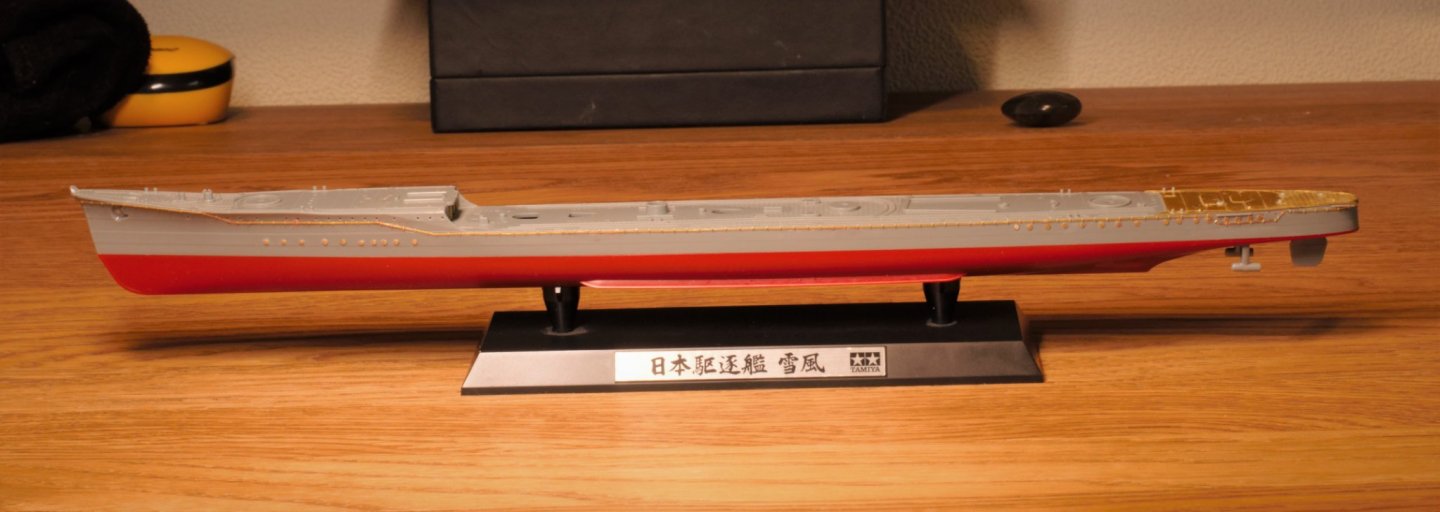

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

yvesvidal reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

CDW reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

CDW reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

Old Collingwood reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

Old Collingwood reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

mtaylor reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

mtaylor reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

Canute reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

Canute reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

Thanks, Mike ! As far as initial plastic is concerned - well, it's Tamiya: you can drop some glue into the box, shake it - et voila - You've got a model 🙂 Best regards, Dmitry

-

oneslim reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

oneslim reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

RGL reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

RGL reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

EricWilliamMarshall reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

EricWilliamMarshall reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

EricWilliamMarshall reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

EricWilliamMarshall reacted to a post in a topic:

IJN Yukikaze by DmitriyMarkov - Tamiya - 1/350 - PLASTIC

-

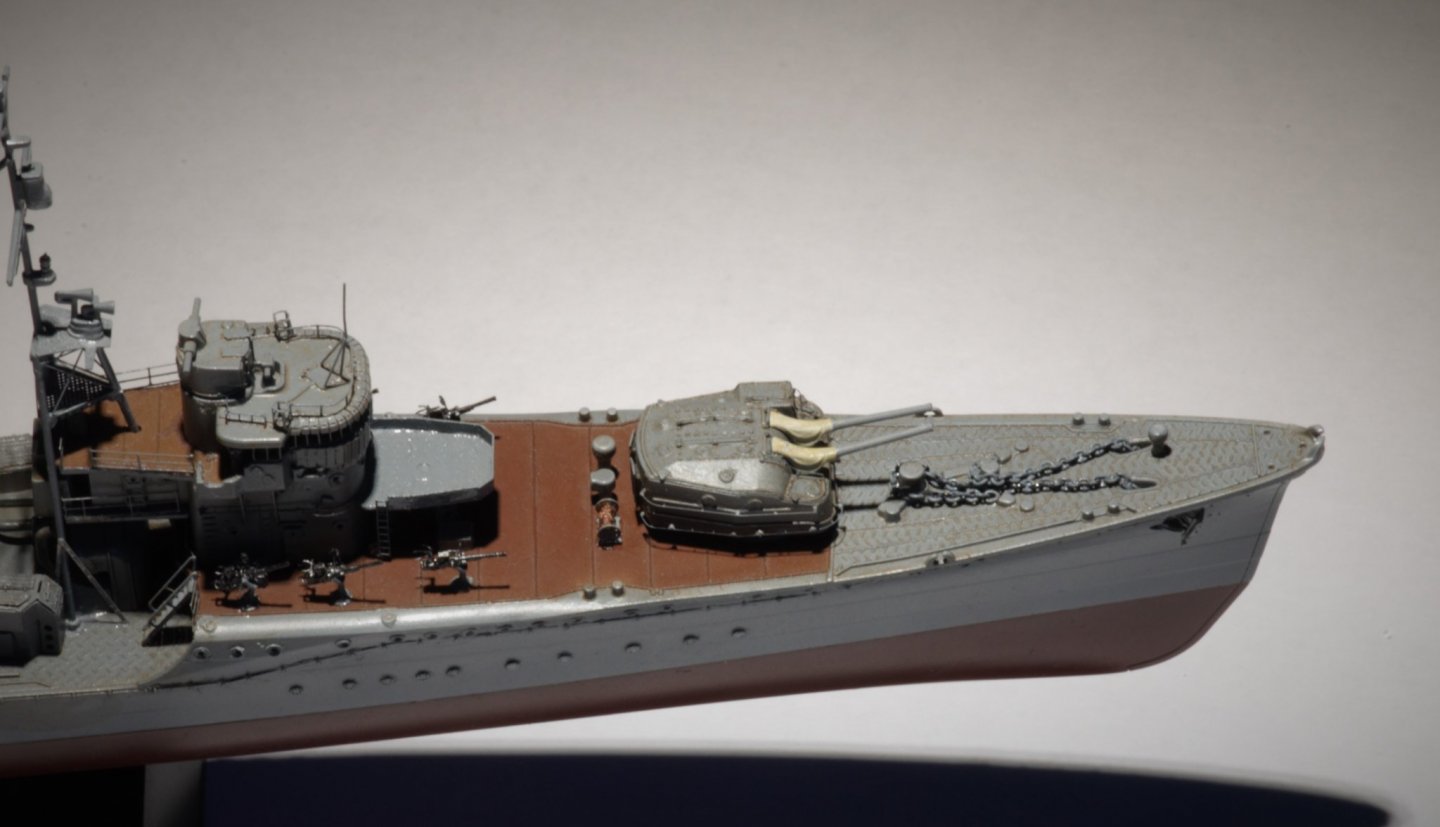

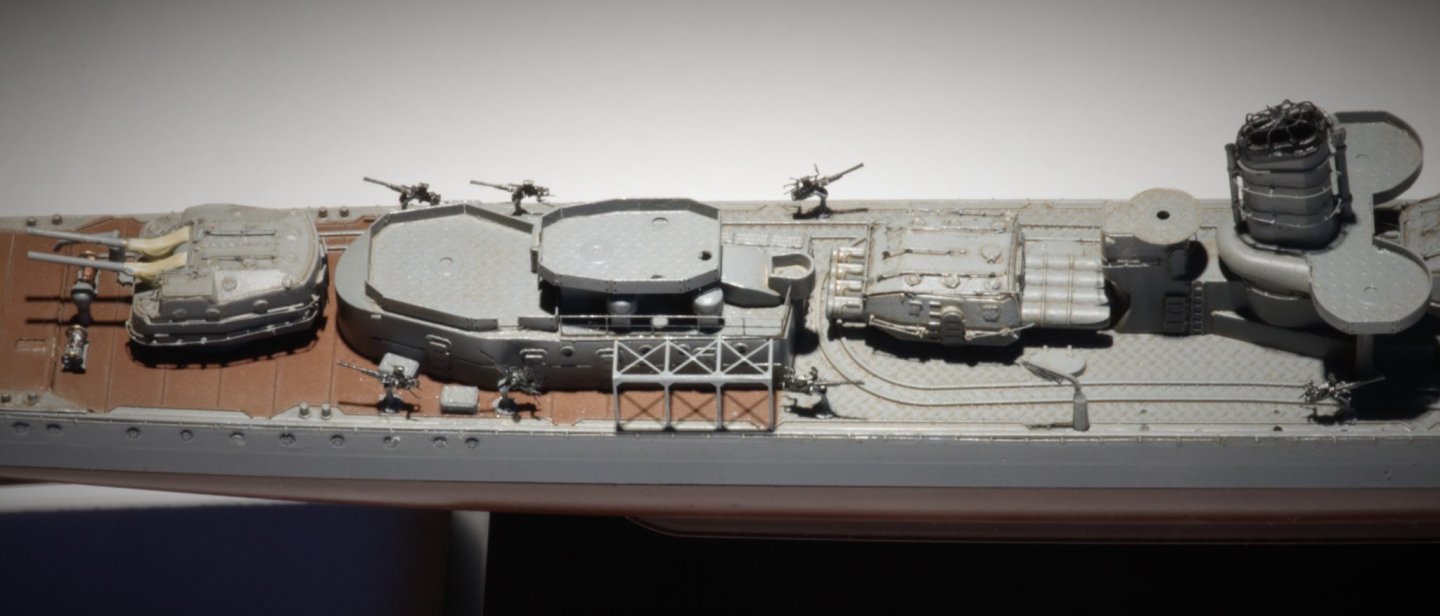

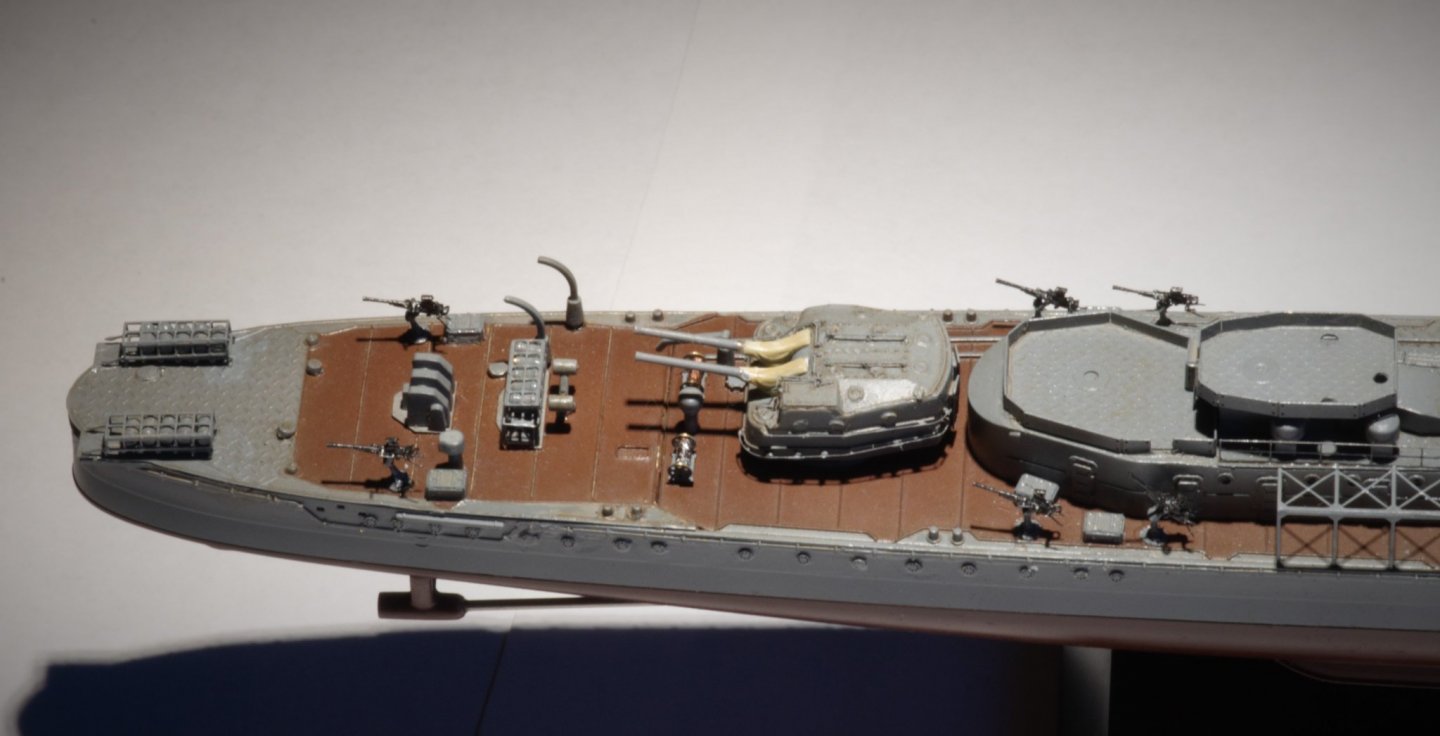

Hello everyone ! I'm glad to be back - have some time to post pics of present status of the project - here we go:

-

My congratulations! Great craftsmanship and a beautiful model as a result! Best Regards, Dmitry

- 973 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

Dimitris. started following DmitriyMarkov

-

Thank you! That's mainly due to Tokina macro - lens which allows to get very close to the object part without much post-editing and also due to shooting in an aperture priority regime with an aperture closed as possible ( I use a tripod and always a timer). P.S. I've noticed that there were some mistakes in this post so it can be misunderstood - I've made corrections and stressed them with red colour 🙂 I'm so sorry for my English...

-

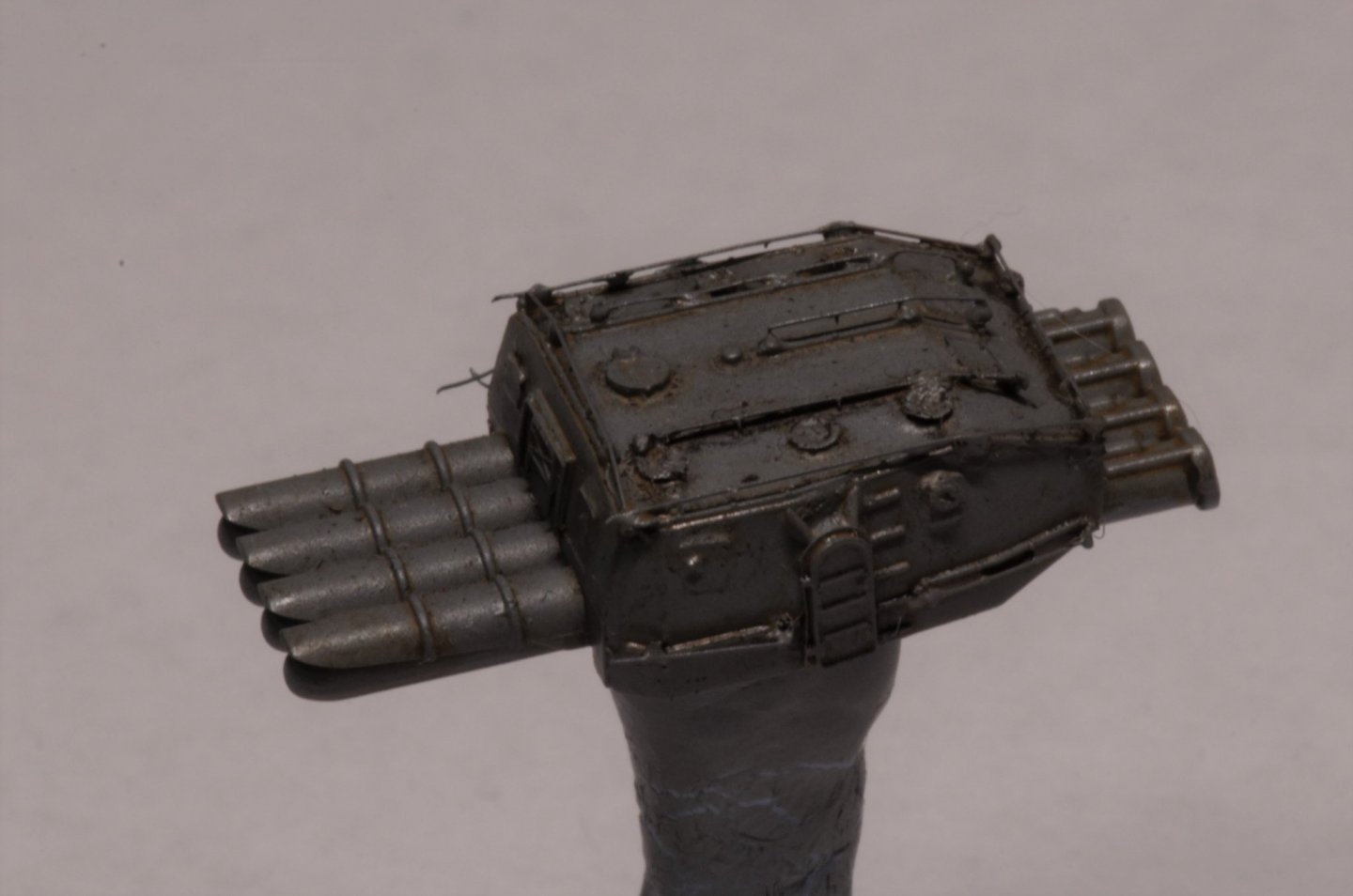

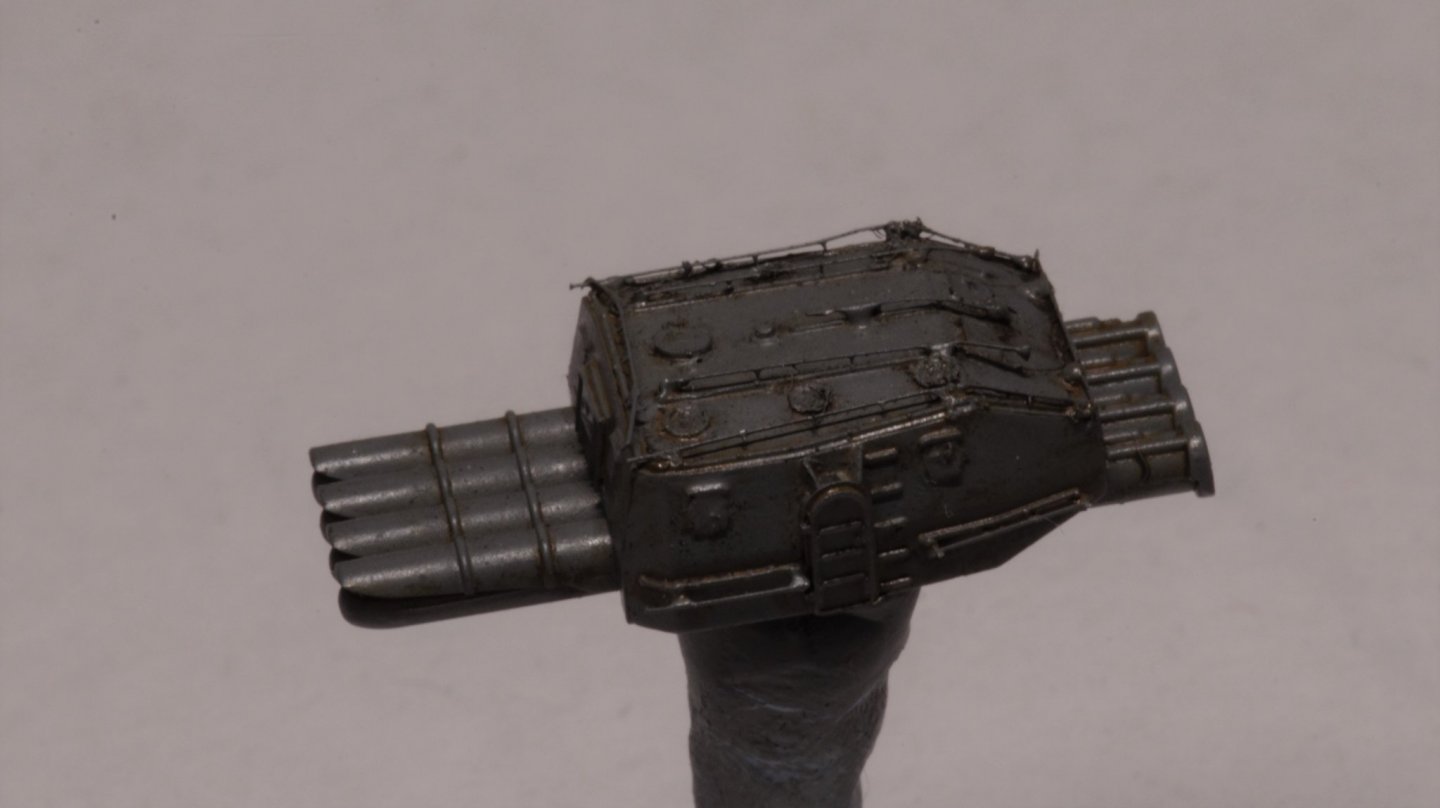

Thank you very much! Handling of those turrets and torpedo launchers became fiddly due to handrails everywhere (they've drunk a lot of my blood those handrails). Weathering is just a simple wash - I tried to remove as much as I could and at one moment when surface was still wet from solvent it seemed ok, but when surface has dried this wash fragmented into "brown" fraction which conducts like a filter and "black" fraction which condensed into shadowy places of structures and for my taste there's still too much of them both but I wouldn't dare to remove more 'cause solvent now can damage paint and laquer - their integrity is "balancing on a ledge" after wash and solvent.

-

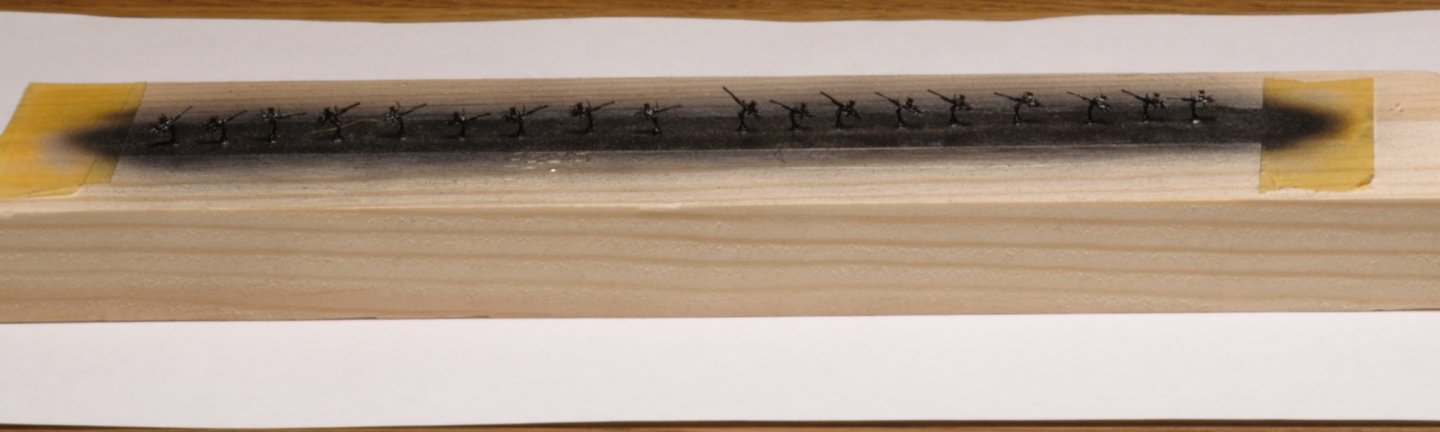

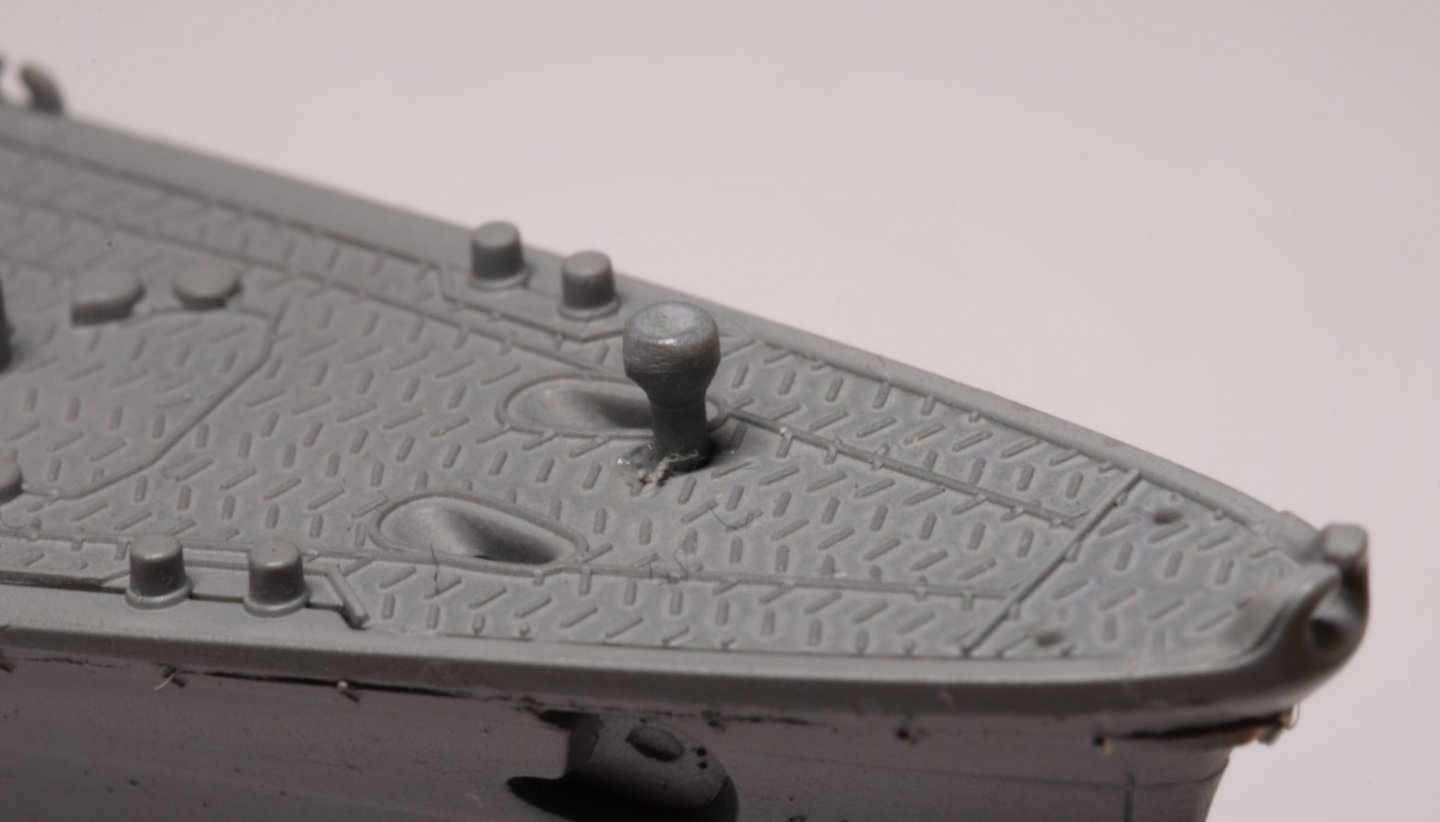

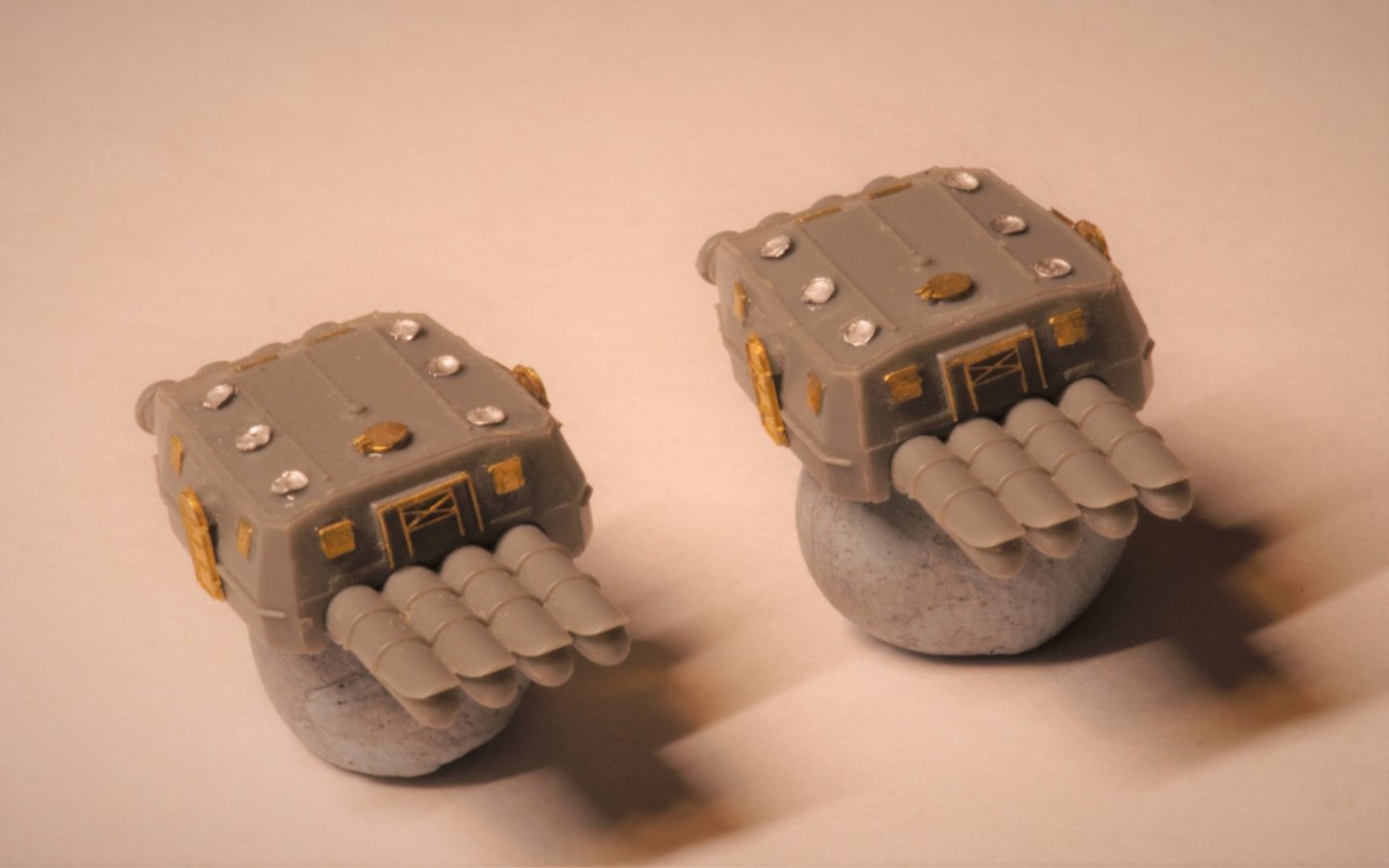

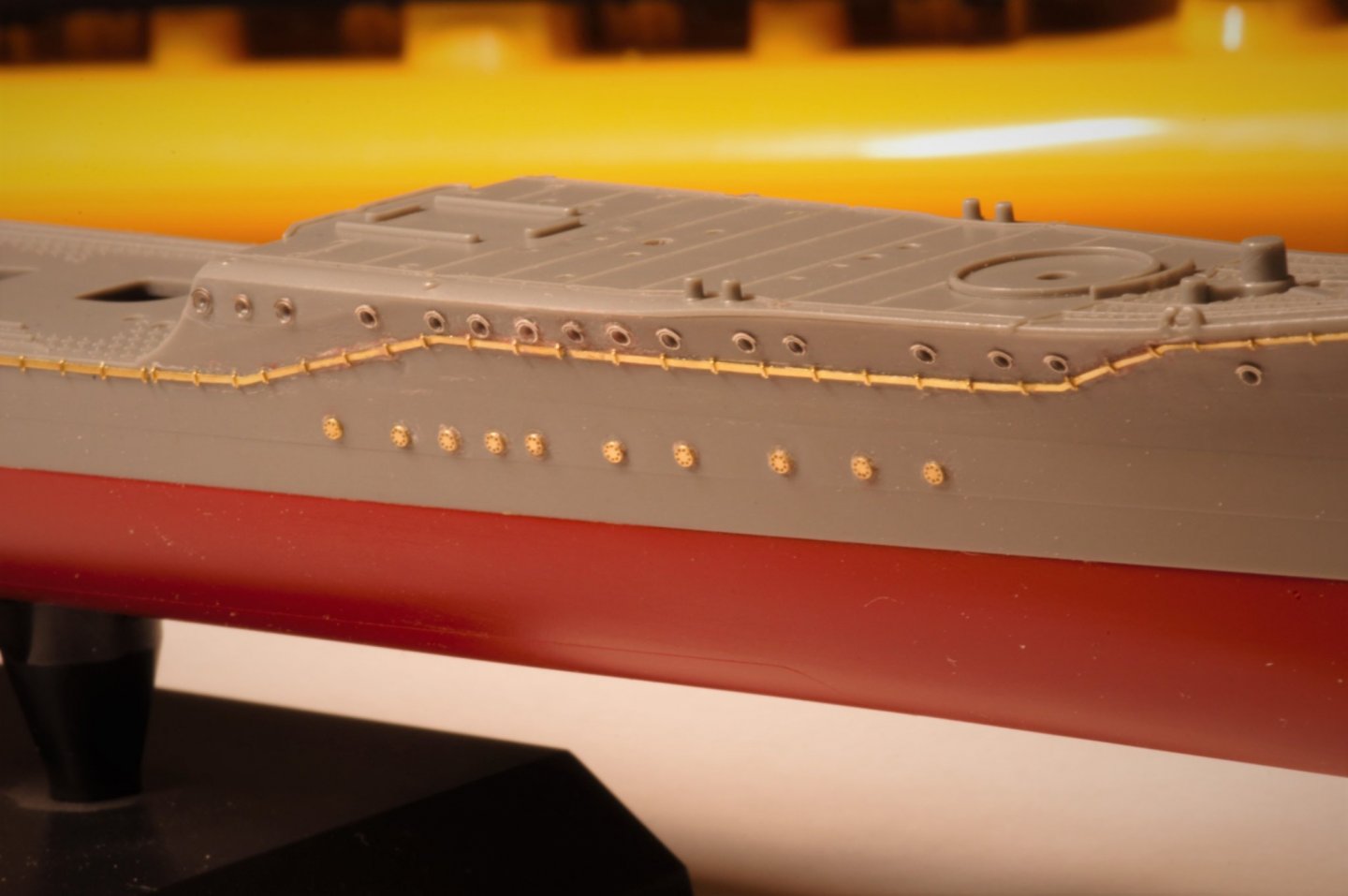

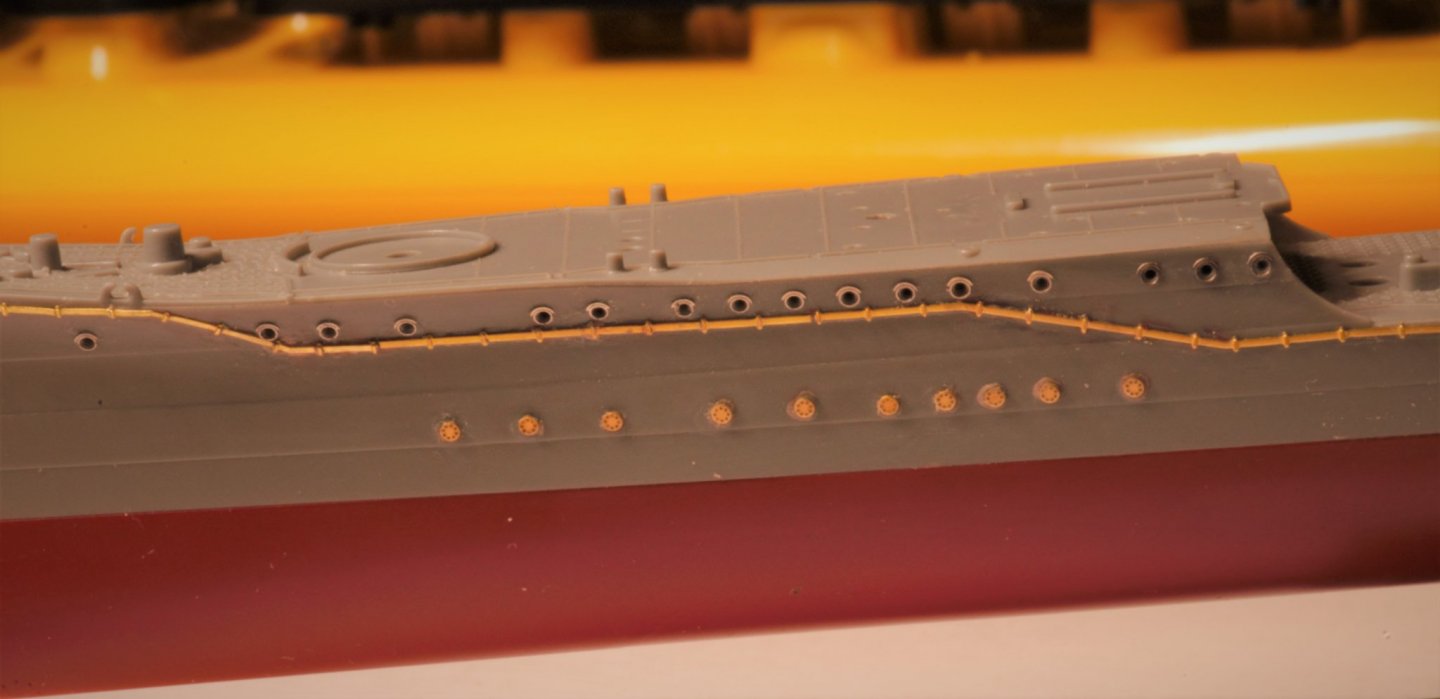

Hello everyone! Well, here's aforementioned progress: First, I've assembled and painted 25mm autocannons - there's circa 16 of them on the ship. Each Veteran's 25mm consists of 2 resin and 2 PE parts. Next, I've equipped guns and torpedo launchers with handrails (tricky little devils they are ), then paint, clear layer and wash. Hull was painted and given a layer of clear gloss. I try to be honest - I show things I'm proud of and also things I'm not quite proud of 🙂

-

Thanks, Javlin! I've got some progress since my last post here - just don't have enough time to take pictures. Hope I'll be able to share this weekend.

-

That's all just jaw-dropping stuff!! Beautiful work.

- 202 replies

-

- battleship

- scharnhorst

-

(and 2 more)

Tagged with:

-

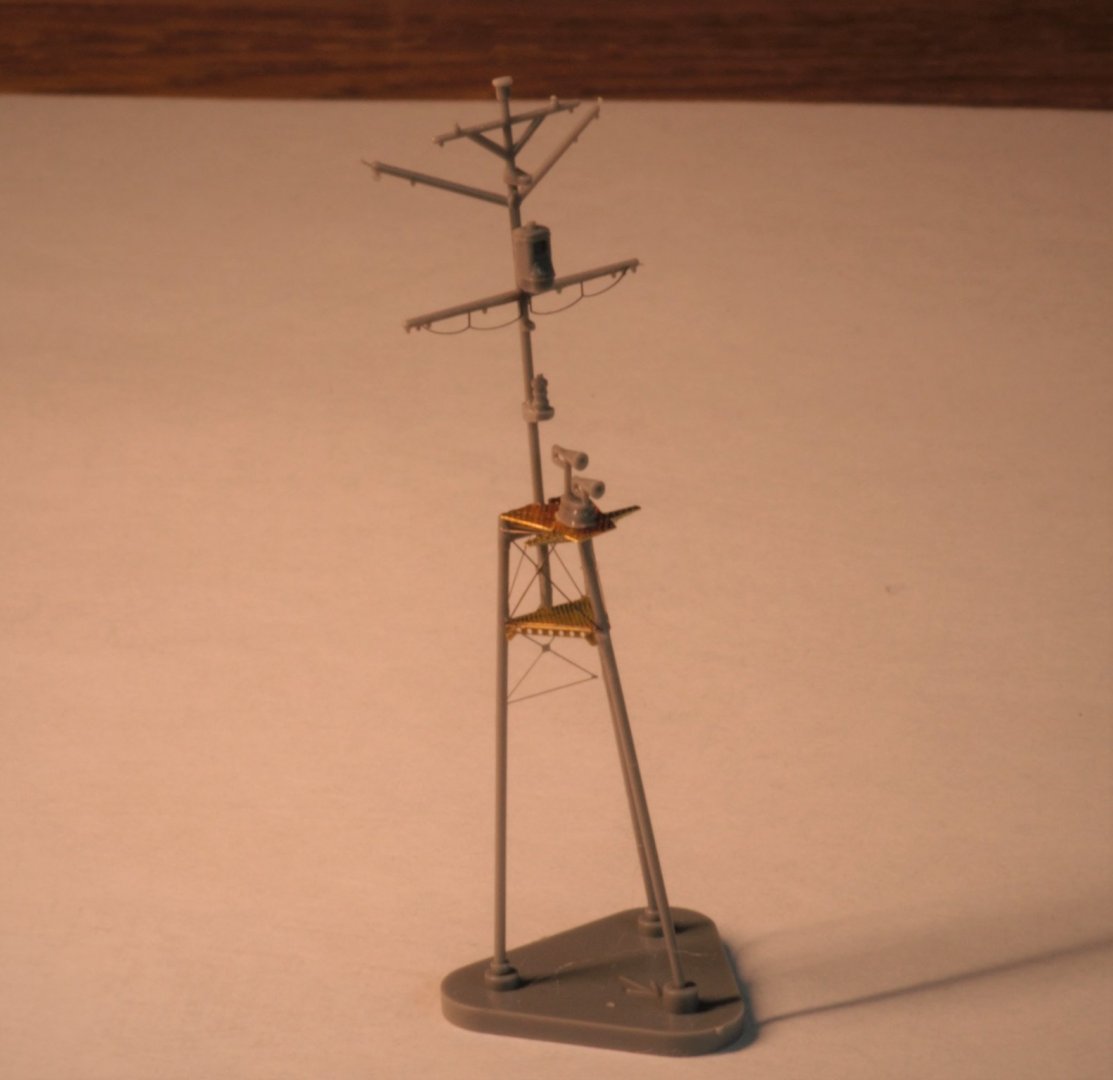

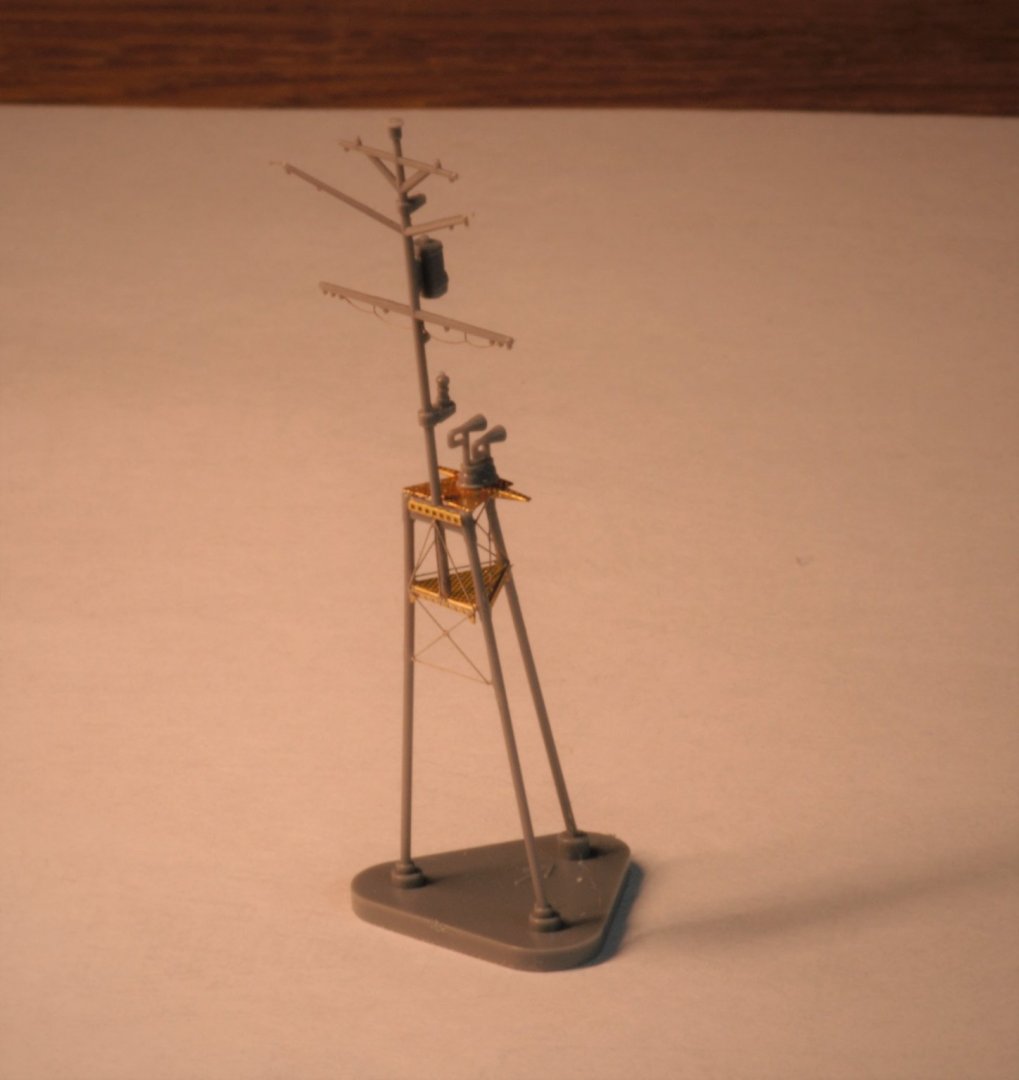

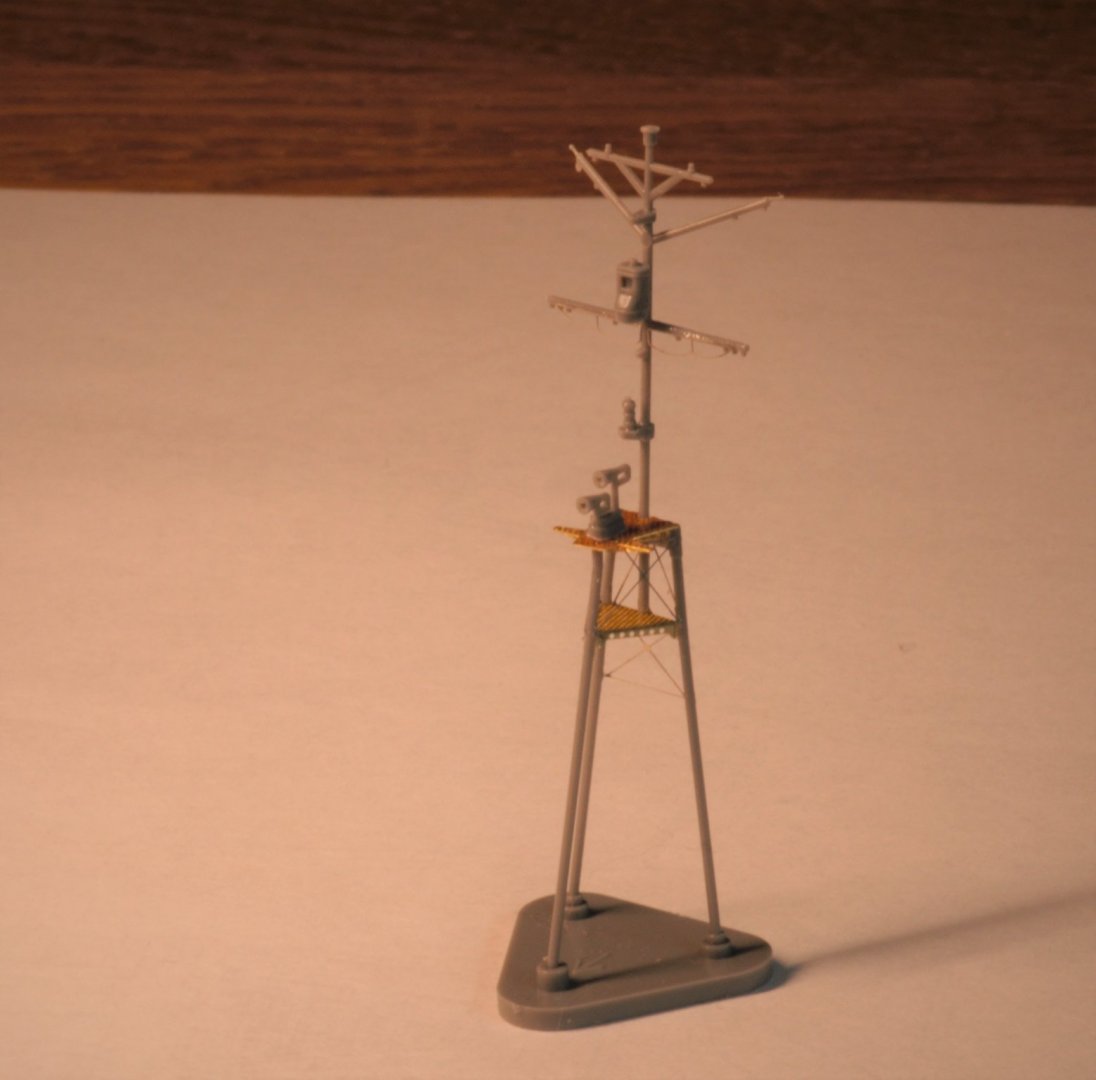

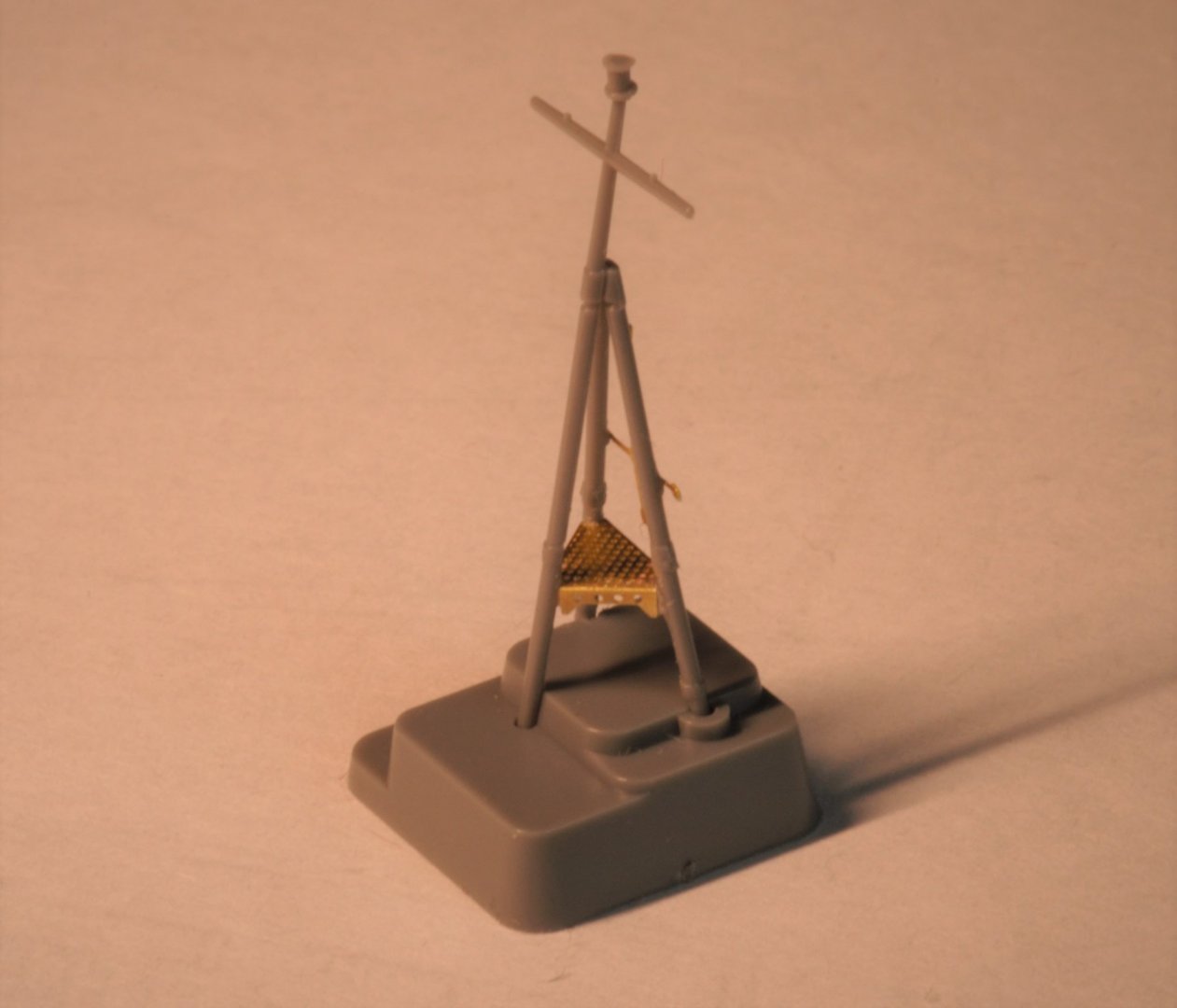

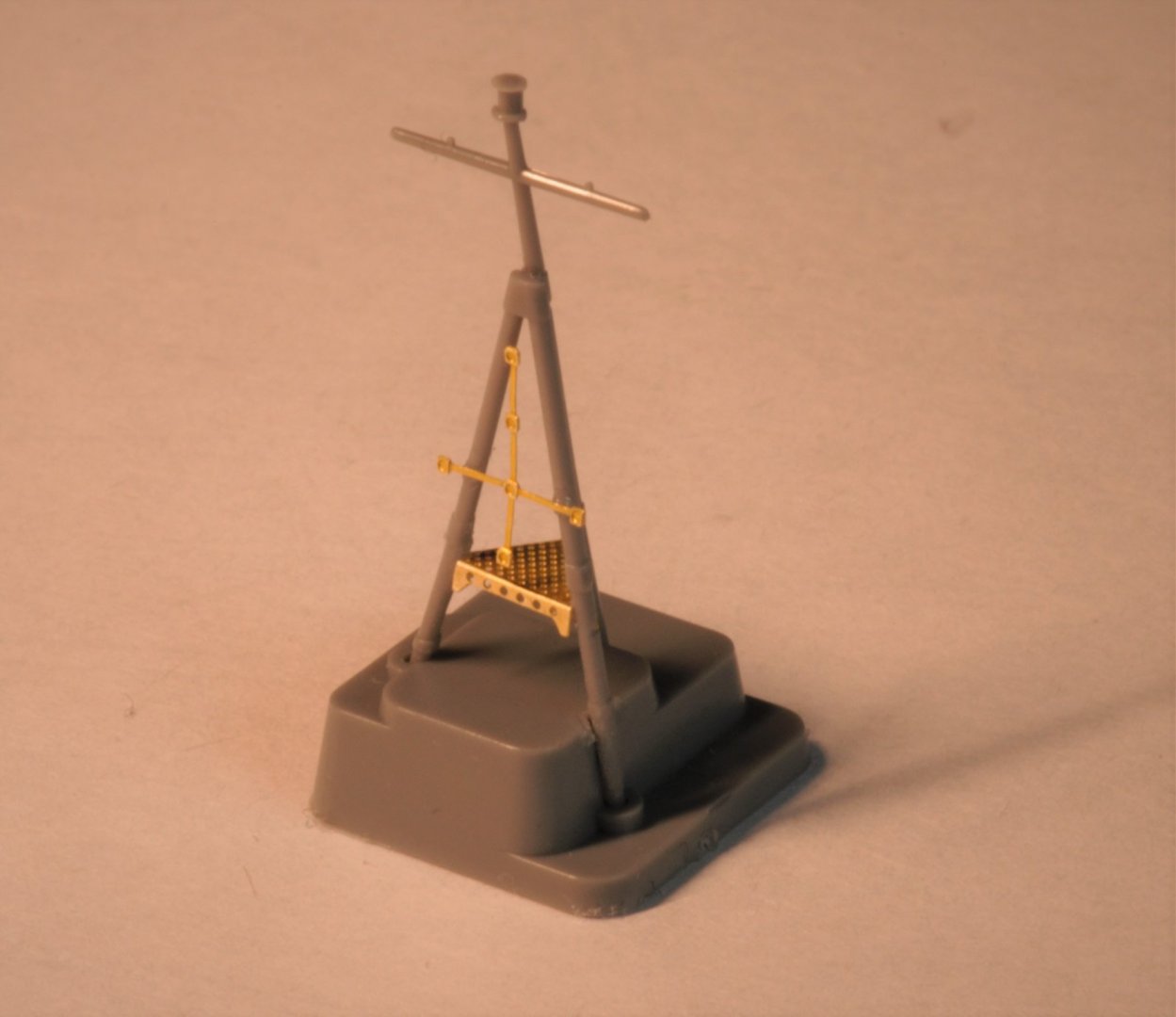

Hello everyone! I've made masts )) Fore mast has more details but went much easier, mizzen mast is triky - I've tried my best, even re-made it couple times but still haven't managed to get it right. Well, here we go:

-

Thanks! I just try to somehow reach what other colleagues do on these forums 🙂 Actually it's not quite a punch set - these are my wife's tools for rolling-in of gems in decorations 🙂 We share each other's hobby tools from time to time. I can hardly tell a manufacturer's name - in our country they usually can be aquired via jewellery-tools stores. I think the same is right for most of other countries as well. Best regards and happy modelling!

-

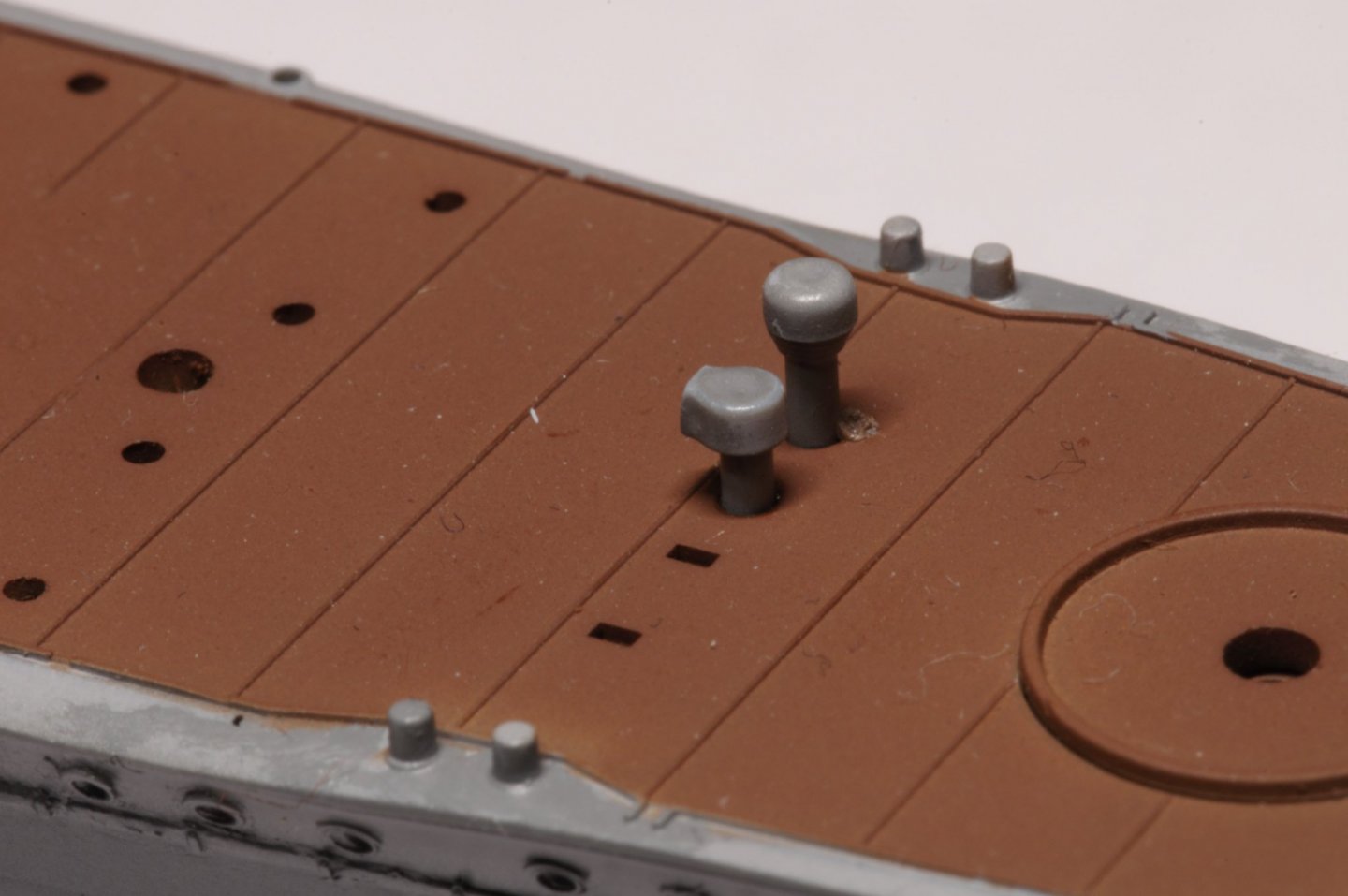

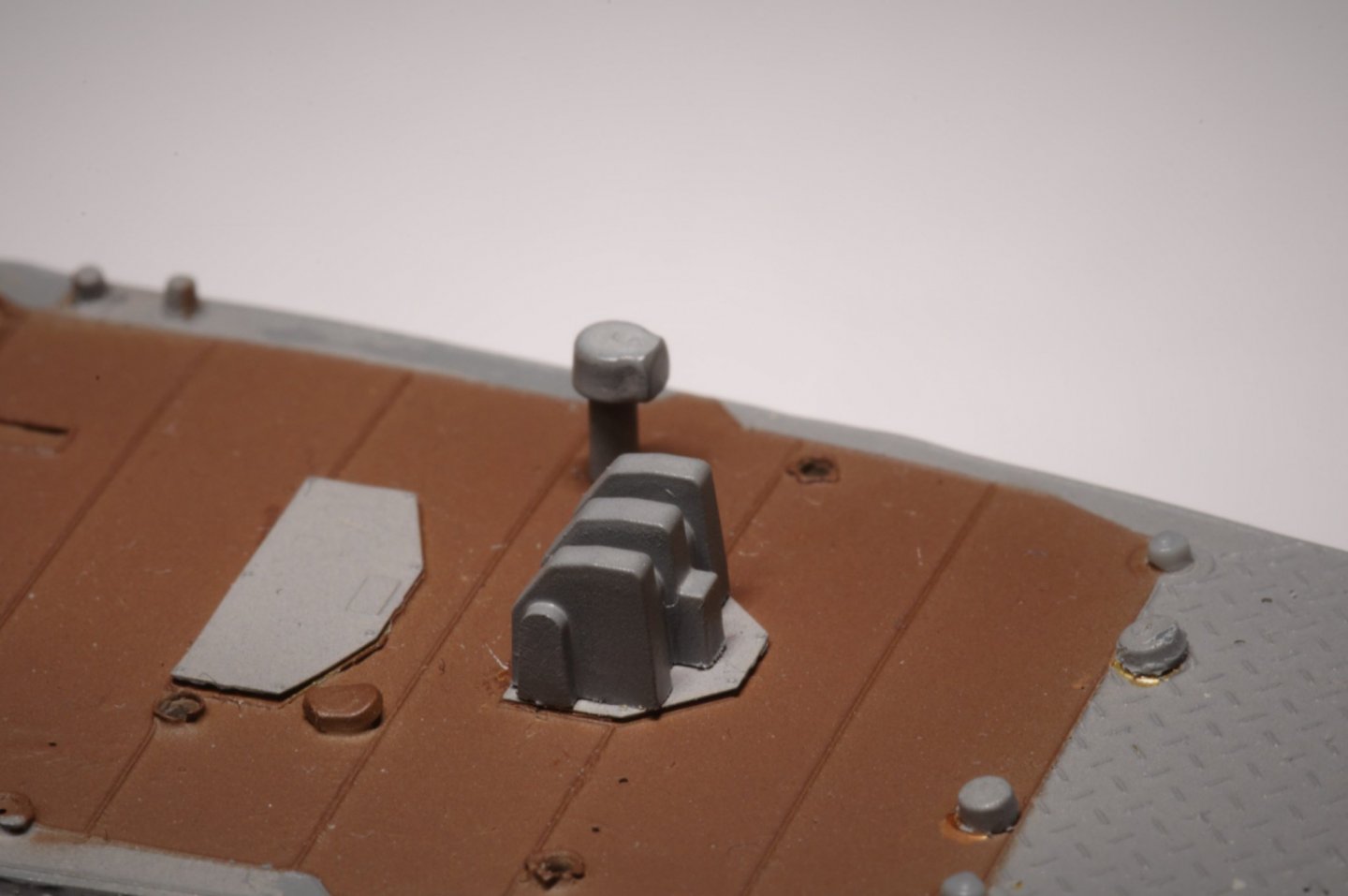

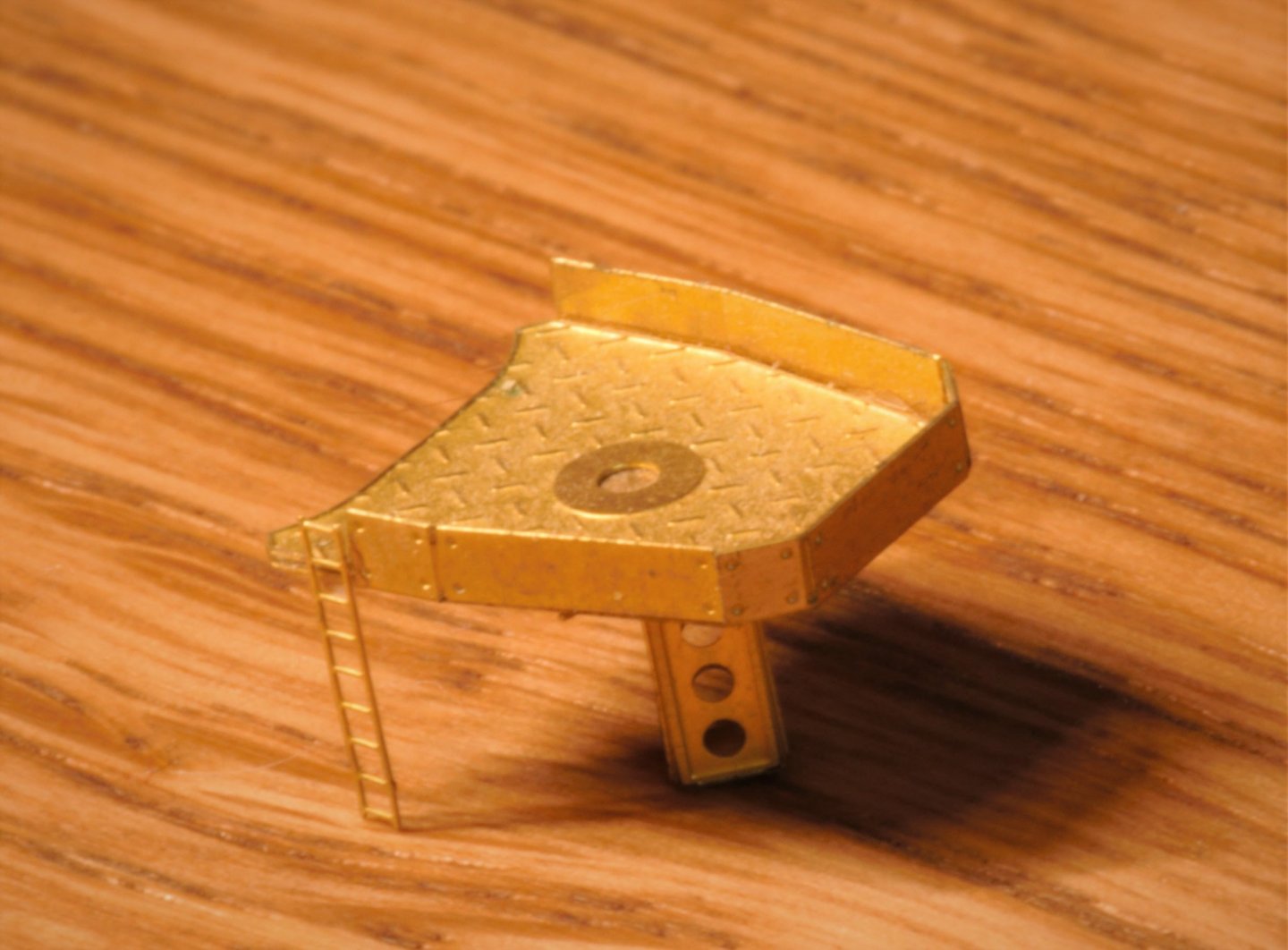

As I've said earlier I came across shortage of some details in Lion Roar kit - so I had to improvise and punch some round-shaped elements on roofs of torpedo launchers from self-adhesive aluminium foil. It turned out to be slightly bigger than needed - but that was the smallest available diameter in our punch set:

-

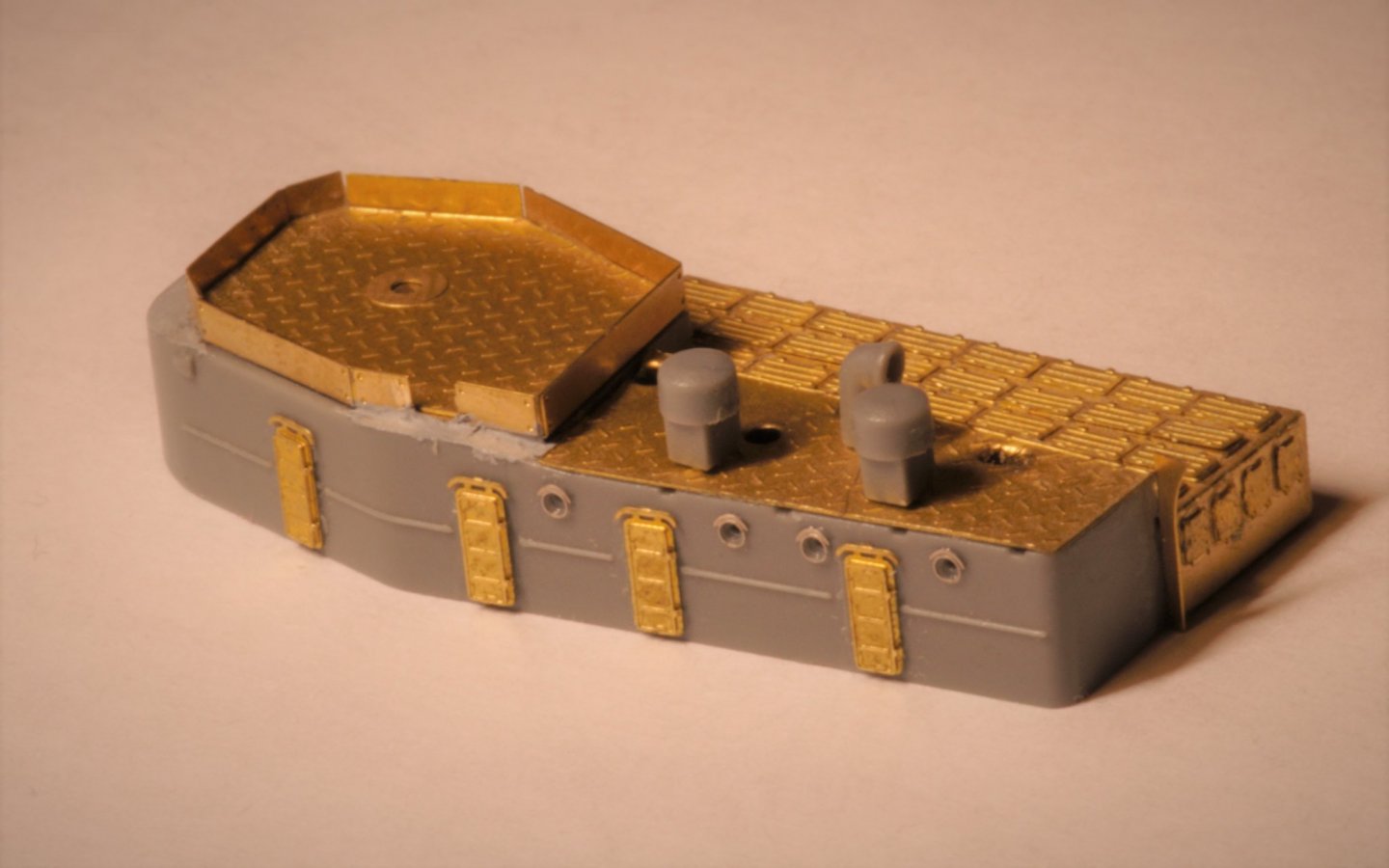

Thank you very much, gentlemen! Meanwhile some portholes are finished ( actually those were all portholes that were left untouched until present moment):

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.