-

Posts

202 -

Joined

-

Last visited

-

mtaylor reacted to a post in a topic:

Another OcCre "Save The Date" Release - April 28, 2024

mtaylor reacted to a post in a topic:

Another OcCre "Save The Date" Release - April 28, 2024

-

DavidG reacted to a post in a topic:

HMS Snake by drtrap - Caldercraft

DavidG reacted to a post in a topic:

HMS Snake by drtrap - Caldercraft

-

DavidG reacted to a post in a topic:

HMS Victory by CraigVT - Panart - 1:78

DavidG reacted to a post in a topic:

HMS Victory by CraigVT - Panart - 1:78

-

DavidG reacted to a post in a topic:

HMS Sphinx 1775 by rvchima - Vanguard Models - 1:64 - 20 Gun Sixth Rate Frigate

DavidG reacted to a post in a topic:

HMS Sphinx 1775 by rvchima - Vanguard Models - 1:64 - 20 Gun Sixth Rate Frigate

-

DavidG reacted to a post in a topic:

Mayflower 1620 by rlwhitt - Model Shipways - 1:76

DavidG reacted to a post in a topic:

Mayflower 1620 by rlwhitt - Model Shipways - 1:76

-

DavidG reacted to a post in a topic:

Sovereign Of The Seas by firdajan - 1:96 - CARD

DavidG reacted to a post in a topic:

Sovereign Of The Seas by firdajan - 1:96 - CARD

-

DavidG reacted to a post in a topic:

OcCre HMS Victory Limited edition

DavidG reacted to a post in a topic:

OcCre HMS Victory Limited edition

-

KeithAug reacted to a post in a topic:

Blades for Artesania Latina Cutter

KeithAug reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

clearway reacted to a post in a topic:

Le Pourquoi-Pas? 1907 by Greg Davis - Constructo - i.e., Why Not?

clearway reacted to a post in a topic:

Le Pourquoi-Pas? 1907 by Greg Davis - Constructo - i.e., Why Not?

-

Keith Black reacted to a post in a topic:

Le Pourquoi-Pas? 1907 by Greg Davis - Constructo - i.e., Why Not?

Keith Black reacted to a post in a topic:

Le Pourquoi-Pas? 1907 by Greg Davis - Constructo - i.e., Why Not?

-

Hello Peter, good luck for your search for the manual. It may sound silly at first... but if you have the plans and still feel the need to a pictorical manual, look thorugh a manual of a different ship from the website of Artesania Latina or Occre. These type of kits have very similar design, and you may get answers to building sequence, planking tips etc, even it's a different ship. Hope you find what you are looking for, though.

-

DavidG reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

DavidG reacted to a post in a topic:

HMS Bellona by Nearshore - Corel - 1:100

-

mtaylor reacted to a post in a topic:

Blades for Artesania Latina Cutter

mtaylor reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

Belco reacted to a post in a topic:

Blades for Artesania Latina Cutter

Belco reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

Roger Pellett reacted to a post in a topic:

Blades for Artesania Latina Cutter

Roger Pellett reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

brunnels reacted to a post in a topic:

Blades for Artesania Latina Cutter

brunnels reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

davyboy reacted to a post in a topic:

Blades for Artesania Latina Cutter

davyboy reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

Toolmaker reacted to a post in a topic:

Blades for Artesania Latina Cutter

Toolmaker reacted to a post in a topic:

Blades for Artesania Latina Cutter

-

Blades for Artesania Latina Cutter

DavidG replied to brunnels's topic in Modeling tools and Workshop Equipment

Amati sells such blades like this one, but have a look around as there are different types of them. But this plastic tool is not designed to cut such thick strip as the 4x4. For that one you will need a saw. The use of this is to make repeated cuts by the same length or same angle, like cutting deck planks from thin strip (after adding a stop to the tray). If you can't cut the strip by a handheld knife, neither this tool will do. -

DavidG reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

DavidG reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

-

DavidG reacted to a post in a topic:

Artesania Latina 1/72 HMS Victory Cross section Trafalgar 1805.

DavidG reacted to a post in a topic:

Artesania Latina 1/72 HMS Victory Cross section Trafalgar 1805.

-

if you look for kits, the new Artesania Latina Victory section is probably the best one on the market now.

-

you may have a look on the Artesania Latina Hermione kit for a second build here https://artesanialatina.net/en/ships-advanced/484-wooden-model-ship-kit-hermione-la-fayette-frigate-8421426325171.html?mot_tcid=e87a7115-6a0e-4f2d-91d3-dbc3fbc2526a. It's a newer design than the Occre one, and definitely fulfils the need for detailed instructions. Still uses plywood parts a lot, but for the price it seems to be a decent offering.

-

in addition to the good tips above, you may consider scratch building it from various strips, I would even consider styrene. There are no difficult shapes here, and the decorative trim can be made from brass wire or modified eyebolts. The panes can be built up from segments, glued to a transparent background, or maybe take some overscale kit gratings, and sand it thin.

-

Then probably you could consider the minicraft 1/350 with the Tom modelworks photoetch detail. A great example shown at titanicmodel.net

-

probably the cheapest option to make it yourself with premade profiles and plexiglas: https://store.amatimodel.com/en/eberle-saws-for-modeling/product-profiles-for-show-cases-b256002.html https://occre.com/en/collections/peanas-modelismo-naval

- 14 replies

-

Hi Evan, good luck for your bottom plating. I did it on mine, it took me a month, but enjoyed the process, despite most of it will be hidden. There seems to be three sources for the layout; the mentioned planking expansion, a scaled underbody view and the Woody kit. Note, all 3 are different patterns. The styrene kit is probably the less hassle, and fits well to the kit hull, however quite expensive. I investigated the planking expansion drawing as well, but it requires to re-draw it from scratch to the hull, which I didn't feel ready to do. So ended up using the bottom template from facebook, which neither fits very well to the existing plating of the kit, but by omitting some plates, can be tweaked to an acceptable result. There are around 500 plates to cut individually. Here is how it looks: The kit has some partial plate detail in the bow area, where I had to adjust what to include and what not. But after a coat of primer (which I sprayed yesterday) it looks acceptable. I look forward to see your approach. best, David

-

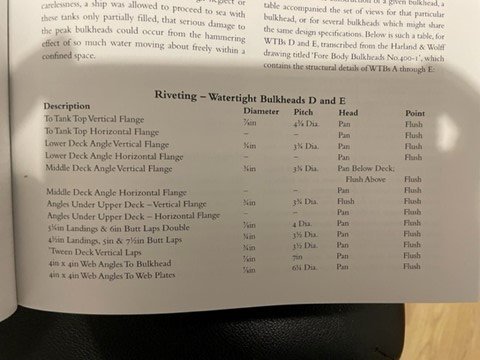

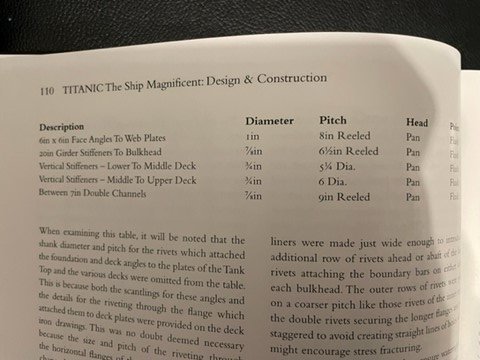

you are good to go with scale 1 inch rivets. they will be very small if done in scale. here are the reference sizes. good luck for the build.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.ffac2f8a24d212961a83eab4efb06a6c.jpeg)