-

Posts

113 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HSM

-

Brig USS Enterprise 1799 info gathering

HSM replied to CharlieZardoz's topic in Nautical/Naval History

-

- 2 replies

-

- photo

- photo etch

- (and 7 more)

-

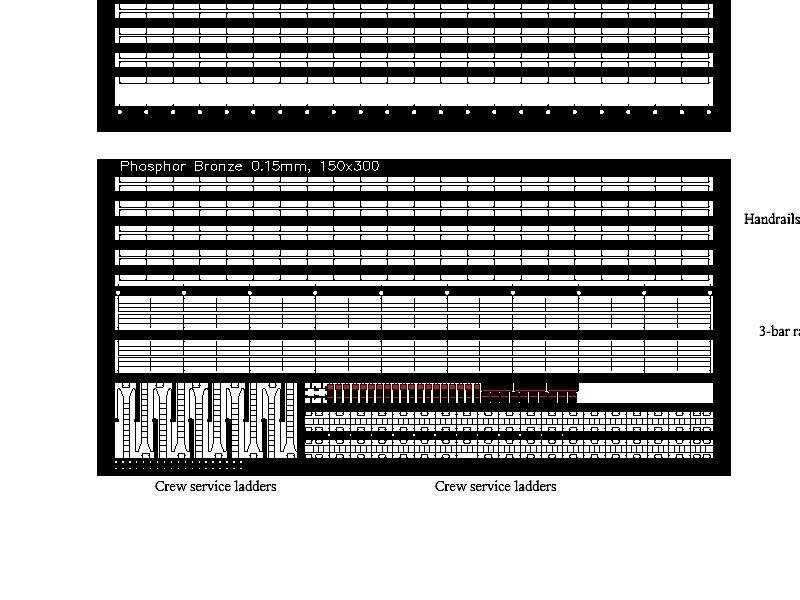

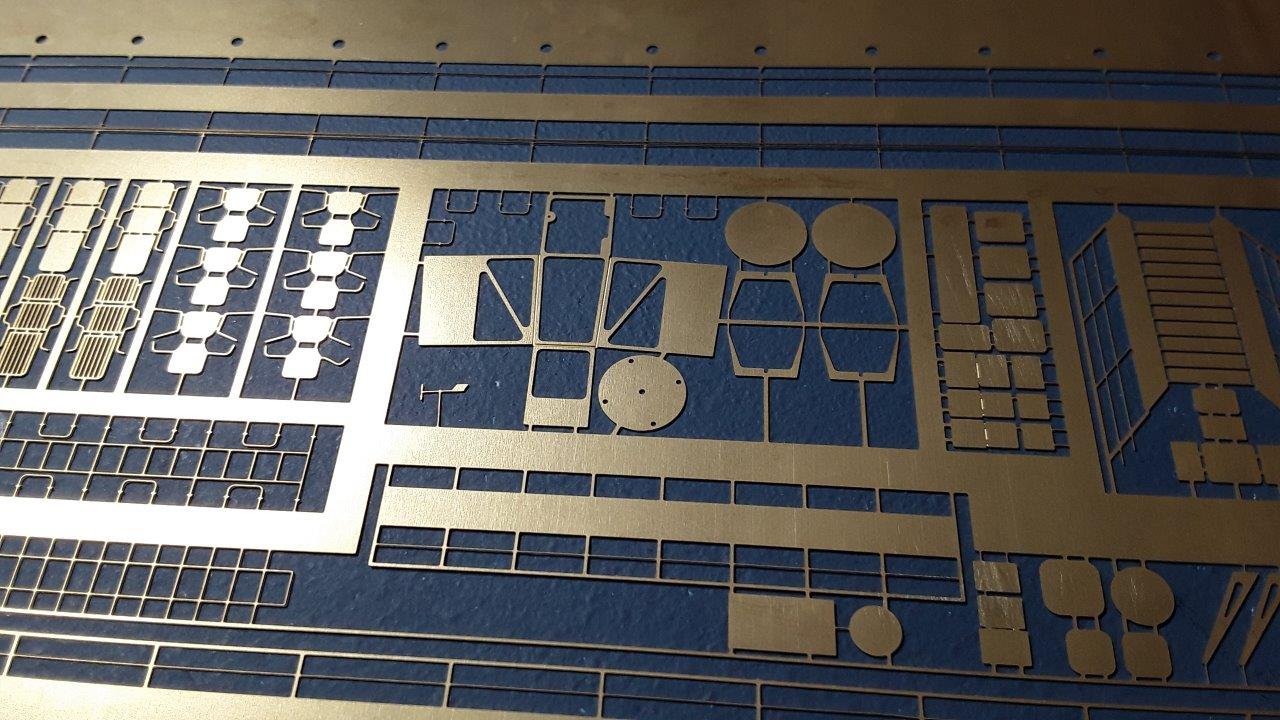

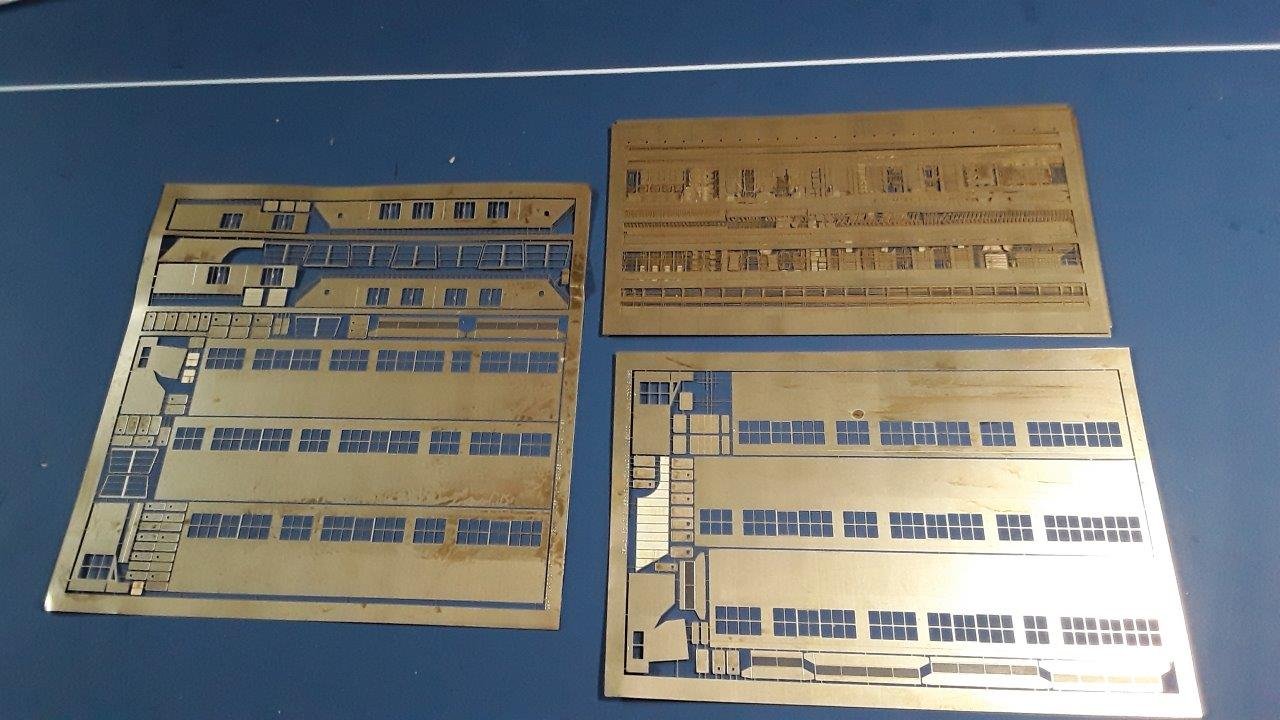

Hey all, I just published video 5 on making custom photo-etched parts and soldering. Hope it helps someone, or at least is mildly entertaining! https://historicshipmodel.com/how-they-are-made Next-up I will be making some custom photo-etched brass sheets! Any small, thin details you see on the model such as ladders, railings, window frames, antennas, radars, etc... etc... are photo-etched brass. I will show you how I did it from planning and drawing the parts in CAD to sending the files for fabrication to folding the parts to soldering them together and painting. Lots to cover here, but it makes such a difference in the model!!!

- 2 replies

-

- photo

- photo etch

- (and 7 more)

-

Yes Allan you would be right! I am in Winnipeg, Manitoba just North of where North Dakota and Minnesota meet. Your accent identification is impressive! As far as the fibreglass, I'm happy you enjoyed that segment but I'm sure there are much better videos on the subject out there. What I did worked but the radio controlled model airplane guys do that all the time and likely have better explanations.

-

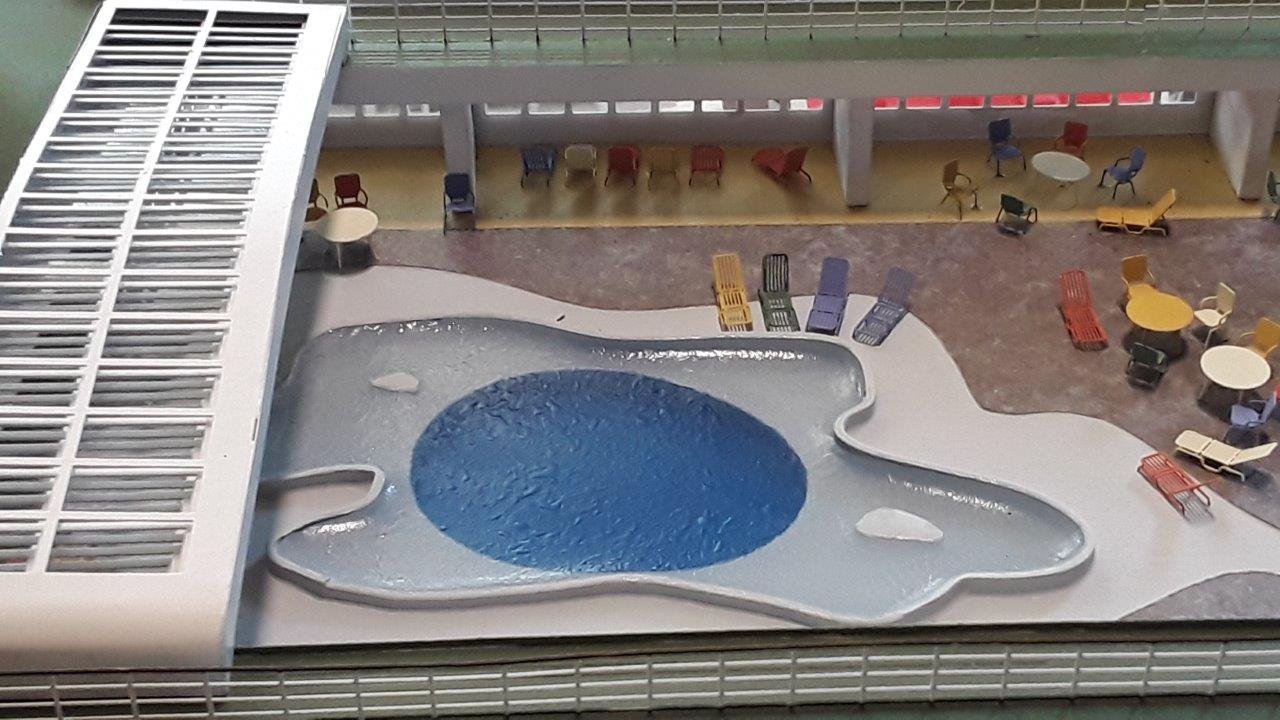

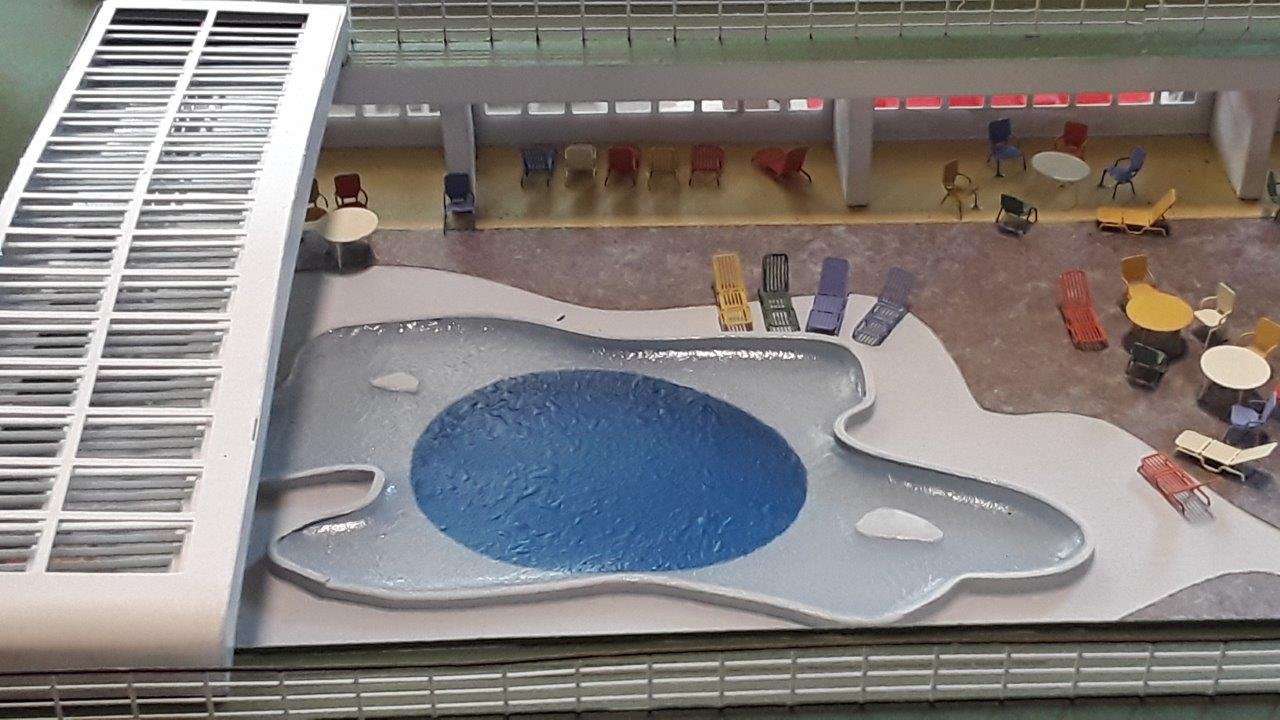

This isn't really a build log in the classic sense, it is more of a video build log of my recently completed scratchbuilt 1:144 scale cruise ship Oceanic (1963). I documented the build and have edited it into several videos on the design and construction and figured some here may be interested in seeing how it was done. Hope you like the pictures and videos! https://historicshipmodel.com/how-they-are-made

-

I recently bought the same printer you have and have used it to make davits and lifeboats for a cruise liner I am making. It produces amazing results doesn't it? Being a newcomer to 3-D modeling I am impressed with your figures. Can you briefly tell how you made the computer models?

-

I have a 3D printer (Anycubic Photon) and use it for making multiple complex parts (propellers, anchors, davits, lifeboats, etc... for a scratchbuilt ocean liner I am working on). but for masts and spars you are better off with wood. The 3D parts are amazingly detailed and look awesome when properly processed, but they are still plastic. Making correct tapers, etc... is certainly possible, but you have to have a good 3D modeling package and know how to use it.

-

Workshop Essentials - Favorite Features

HSM replied to Justin P.'s topic in Modeling tools and Workshop Equipment

About a year ago I bought this motorized adjustable height table legs. Have wanted something like this since my first model (am working on number 46 now) and its changed the way I work. No more bending at awkward angles and trying to work carefully while uncomfortable! Consider adding it underneath a portion of your workbench. -

I bought this one a few months ago with the intention of pushing it under my work table and pulling it out when I work on an awkward area like high rigging or whatever. For the $200CAD that it costs (tabletop is extra) it is very well engineered and high-quality. I have since moved my chair out of the workshop because everything I do I can now do standing up. I can set the table height to wherever I want it to be comfortable and go to work. I have not gotten rid of the chair yet but I could see doing so in the future. If you spend lots of time in the shop these things are great!

-

Photo Etching - do it yourself

HSM replied to Dziadeczek's topic in Metal Work, Soldering and Metal Fittings

It is always fun to experiment, but I have been there and done that and I don't do it anymore. I had the Micromark PE kit and used it for several projects. It works, but is very time-consuming and finicky. About 75% of my attempts were unusable for one reason or another but with lots of work and practice I did use it to make decent parts for maybe 4-6 projects before I gave up. Now I send .DXF files to https://ppdltd.com/ and a week later receive perfectly formed parts. Cheers and good luck, however you decide to make your parts! -

Straightening thin brass wire

HSM replied to vossy's topic in Metal Work, Soldering and Metal Fittings

You have lots of responses, but I am wondering why stretching does not work... As suggested by xken, put it between 2 pliers, or a vice and pliers and pull on it until you feel it stretch a bit. This is called the yield-point. If you release it carefully it will be perfectly straight. I much prefer this method to any of the others, but do whatever works for you. -

I bought an 8050 (thanks again for the recommendation John!) and love it. I haven't used my old flex-shaft dremel in months. The battery seems to have sufficient run time, at least for me. I have never had it go flat or slow down during a job and I use it daily. The fact that it doesn't remember your last set speed is the most significant drawback to this tool. It can be quite annoying when you are doing lots of slow speed work and have to continually be pushing buttons. I put a jacobs chuck on it and it blocks the lights in such a way that there is light everywhere EXCEPT where the blade meets the work! On the possibility of the battery getting weak over time, I have had mine for 6 months and if it were to die right now I would spend the money to buy another one. I like it that much. It is not perfect, but is well worth the money for the cordless convenience. I don't think you would regret buying an 8050.

-

LETTERING

HSM replied to timjina's topic in Painting, finishing and weathering products and techniques

The Bluenose is a perfect subject to use white decal paper on because the hull is black. I have made 2 MS Bluenoses and drew the name and scrollwork in Turbocad, with the yellow and black printed, leaving the letters white. It worked great and the decal was all but invisible. -

My top 4 most useful tools

HSM replied to Tim Moore's topic in Modeling tools and Workshop Equipment

#11 Exacto blade and handle A Dremel 8050 as suggested by John Allen in a previous post A small disk/belt sander Digital caliper -

If you were asking about the Nonsuch built in 1650 and sailed into Hudson's Bay then yes there are very good plans available. I have a set from the Manitoba Museum where the reproduction is housed in my hometown of Winnipeg, Canada. The plans are 1:24 scale and there are probably 15 or more large, detailed sheets. They must be builders' plans because there are some minor differences between the drawings and the physical ship, so they are not "as-built" plans. I started building a scratchbuilt Nonsuch several years ago in between commissions but then got too busy with other projects and have never been able to get back to it. It is an absolutely beautiful ship! Jarod Matwiy www.historicshipmodel.com

-

Thanks for the suggestion John! I have had 15 great years out of my corded Dremel, and wasn't even thinking of replacing it until I read your review, and then other reviews online. I have been leery of battery operated tools in the past, but for smaller jobs (probably 80% of them) this will be great! I will keep my old, powerful corded Dremel and I'm sure the two will complement each other well. Will stop at Home Depot on my way home and pick one up :-)

-

Copper plating tape.

HSM replied to Burroak's topic in Building, Framing, Planking and plating a ships hull and deck

The plates stick like white on rice, but they do adhere better to a glossy surface than they do to a flat one. They are also very thin so they don't hide imperfections in the hull surface. -

Military modellers have literally THOUSANDS of figures available at a scale of 1:35 and I am sure you will be able to find figures posed and dressed exactly as you like. I just ordered figure sets from HobbyInc for figures I required for a diorama to copy a famous photograph of a meeting between King Aziz of Egypt, FDR, Admiral Nimits and an interpreter that took place on the cruiser Quincy. In my case I had to find clothing and poses that matched the photograph and was able to match each figure pretty accurately. The military figure kits come with the body parts all separated so you can mix and match if you don't like the arm position of this figure you can take one from another figure.

-

Small desktop mill for modelling

HSM replied to Roks82's topic in Modeling tools and Workshop Equipment

I use this Micro-Mark X-Y table that I can attach to my drill-press when I need it. Works great for small jobs. https://www.micromark.com/MicroLux-X-Y-Table-Attachment -

How much rope do you leave after tying things off?

HSM replied to RPaul's topic in Masting, rigging and sails

I generally put the line through the pin-hole, then around and through again, then I put the pin in the hole to hold it in place. Once I have adjusted all (or most) of the rigging I glue down all of the pins and clip off the excess line. I then add rope coils of appropriate sized line that I make off of the model. You are right... If they yard is down then you would have less of a coil than you would if the yard is hoisted and there would be lots of line to coil. -

I am working on the Euromodel Friedrich WIlhelm zu Pferde (strange... spellchecker doesn't like that name!) and am wondering about the shroud run on the mizzen mast. The deadeyes for the fore and main mast have wood spacers (channels) that hold them away from the hull and there is room for the rigged shrouds to clear the bulwarks. The deadeyes on the mizzen mast are attached without the spacer to hold them away from the hull, and there appears to be no way to get the shrouds to clear the bulwarks. The shrouds are forced to bend around the hull and I am certain that would never happen in real life. The shrouds would chafe badly and the railing on the poopdeck would be excessively stressed. My model will be built admiralty style without masts or rigging so I will likely install the deadeyes as shown on the plans, but what am I missing here? Attached are some photos that show the area:

-

Belaying pins

HSM replied to bluenose2's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I think all belaying pins are removable. If the lines need to be freed quickly a sailor can just pull the pin out and let out the line. If it were me I would end up with a tangled mess and swinging from my ankle from the yardarm but I'm sure a sailor would be able to keep it under control quite well. -

Someone mentioned moving the lift blocks from the main mast to the topmast so they are more forward. I have done similar even if the plans show the blocks on the aft section of the masthead. Plans are a good starting point, but if there is a more practical and functional way to do it I'm sure the sailors of the day would have made a similar modification in real-life.

-

Copper tape

HSM replied to Dan_L's topic in Building, Framing, Planking and plating a ships hull and deck

I use copper tape at work for electronics and at home for ship building. Stained glass suppliers are your best bet. If you have a local shop I would bet they have 1/8", but be aware they come with different colors of adhesive on the back. I think it comes in black, silver and clear. You want clear for hull plating. -

Looks great! Now get in there and make it messy!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.