-

Posts

1,207 -

Joined

-

Last visited

-

paul ron reacted to a post in a topic:

Miniature Russian carving tools

paul ron reacted to a post in a topic:

Miniature Russian carving tools

-

Mr Whippy reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

Mr Whippy reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

-

Alan Cabrera reacted to a post in a topic:

MEDDO first carving attempts with #11

Alan Cabrera reacted to a post in a topic:

MEDDO first carving attempts with #11

-

scrubbyj427 reacted to a post in a topic:

Micro Drill Press

scrubbyj427 reacted to a post in a topic:

Micro Drill Press

-

flying_dutchman2 reacted to a post in a topic:

Gutermann Polyester thread for making rope.

flying_dutchman2 reacted to a post in a topic:

Gutermann Polyester thread for making rope.

-

Alan Cabrera reacted to a post in a topic:

MONTAÑES by Amalio

Alan Cabrera reacted to a post in a topic:

MONTAÑES by Amalio

-

michael.brandt91 reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

michael.brandt91 reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

Bob Cleek started following vossiewulf

-

Vossiewulf,

I am always in awe of your tools and being a tool Junkie myself I like to check things out before buying. I notice your previous thread on Micromotors and I am currently about ready to pull the trigger on an NSK Evolution.

This thing has gotten pretty pricey but I would rather buy once than experience future problems. I have a Ram now that I have had for about 20 years but it is time to upgrade and this NSK will do about 40,000 RPM's. I just wanted to check with you before I commit. Do you have any thoughts or opinions on these. From what I understand they are indeed the Rolls

Royce of micromotors.Thanks,

Bill

-

DanielD started following vossiewulf

-

adapt this idea for a small spray both?

vossiewulf replied to Bob Blarney's topic in Modeling tools and Workshop Equipment

At the custom furniture shop I worked at, we used solvent lacquer, did have TEFC motors on the spray room fans, but the spray room guy typically turned off the fans before spraying the final coat, more than half the time without wearing a mask. It would literally be a cloud of lacquer in there through which the spray room guy could only dimly be seen. He thought he got a better finish doing it that way. I and all the other people told him he was completely whackadoodle to do that, he never listened. No idea what happened to the guy but I assume he didn't live to a very old age. On the up side the spray room never exploded, but we were waiting for that too as he was a smoker. -

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

-

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

-

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

-

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

vossiewulf reacted to a post in a topic:

HMS Cruiser by Thunder - FINISHED - Caldercraft - 1:64 Scale

-

vossiewulf reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

vossiewulf reacted to a post in a topic:

La Créole 1827 by archjofo - Scale 1/48 - French corvette

-

vossiewulf reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

vossiewulf reacted to a post in a topic:

French 74-gun ship by matiz - scale 1:56 - Tiziano Mainardi

-

Otto Frei is where I've bought many, many things. The Venn diagrams of professional jeweler's tools and ship modeler's tool needs overlap quite a bit. Contenti is another very good supplier, I just tend to use Otto Frei as they're just on the other side of the bay from me so I get next day delivery with standard UPS. If you know anything about the Bay Area you'd know why driving over myself is a seriously less than entertaining option, getting anywhere around here now means fighting 8 and 10 lane wide 20mph traffic everywhere, even on weekends. About 3AM Sunday night is the only chance you ever might be able to use cruise control for more than a few seconds. I've had a 535 for over a year and I haven't even figured out how the cruise control works, much less used it. I'd go completely crazy from the traffic if I didn't take the car up into the hills near me on the weekends for some back road, no traffic, windy road driving at irresponsible speeds. In fact when I went up to see the new Dockyard Supervisor, it required crossing the hills north of Santa Rosa, very windy with lots of switchbacks, and some serious fun was had. On the way back, some 20-something in a Hyundai Veloster thought he was going fast until the old dude in the BMW twice as heavy as his car made it clear that said old dude could pass him if he wanted It's not threadjacking if it's your own thread! I forgot to answer this also Davy, sorry. You maybe have better luck than I did with epoxy, I tried two different kinds on brass that was brightened just before bonding and the damned things still popped off with the slightest stress. The key with brass is the first thing you said, you mechanically pinned it. If you pre-drill holes in the straps and use mini brass nails to mechanically attach them, all is good. I considered that too but I didn't think the nails at 1/64 would be strong enough to get them into pressure-fit holes, I might have been wrong about that. I have more 1/64 kits sitting in the closet so we may revisit this, but at least I'm sure now that if I get annoyed with brass I can make something strong enough with good detail in styrene.

- 624 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

-

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

-

vossiewulf reacted to a post in a topic:

Santa Lucia by usedtosail - FINISHED - Panart - 1/30 scale - Sicilian Cargo Boat

vossiewulf reacted to a post in a topic:

Santa Lucia by usedtosail - FINISHED - Panart - 1/30 scale - Sicilian Cargo Boat

-

That's amusing, I thought Dalmatians had their spots from day one. I love dogs just as much as cats, but I never replaced my last dog who lived to be voting age. Also people in the Bay Area love animals, but there are houses and cars packed together in every spot possible, so you have to either work at getting them proper room to run or take them to doggie daycare which dogs love but it's expensive. With my job I just don't have the predictable time required, we have emergencies at all hours and I can be directing the application side of the response for many many hours and that's a weekly thing at least. I hope I'll be settled down again one day someplace dog-friendly.

- 624 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Keep in mind that although it's fairly strong, rice glue will still fail before the wood, and western joinery generally assumes the glue is stronger than the wood. If you look at traditional Japanese joinery, in general it is much more complex than western, and usually includes one or more mechanical interlocking features so the joint will have the full failure strength of the wood. However, that's only applicable to building furniture or anything else that will take significant stresses. I see no reason why it wouldn't be an excellent ship modeling glue for those who generally use PVA, at least for anything besides the hull planking.

-

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

vossiewulf reacted to a post in a topic:

Lady Nelson by vossiewulf - Amati/Victory Models - 1:64

-

I think it looks great, much more accurate than almost all sterns you see on cutters built here, including mine.

- 241 replies

-

- mermaid

- modellers shipyard

-

(and 1 more)

Tagged with:

-

I do also, but Chris needs to be cautious while building a small business. Chris, your initial plan sounds good, my suggestion is to keep adding figures to those available at a slow pace that won't distract you from your main kit development goals, and continue to do so as long as they sell reasonably well. Go captains > say three crew figures > lieutenant > bosun > more crew figures. And even if French ships aren't on the docket, if the rest of the figures sell well I would think about doing the same for the French navy. The argument for is that even though I'm not much interested in figures, I've seen thread after thread of people looking for quality figures and not finding much. I think we rarely see figures on ship models partially because there isn't a viable option to put figures on deck of a similar quality to that of the ship build. The other argument is if no one is really serving this market, it's possible without too much cost and difficulty to become the premiere supplier. And that drives traffic to your site from people looking for figures, and a portion of them end up buying ships too.

-

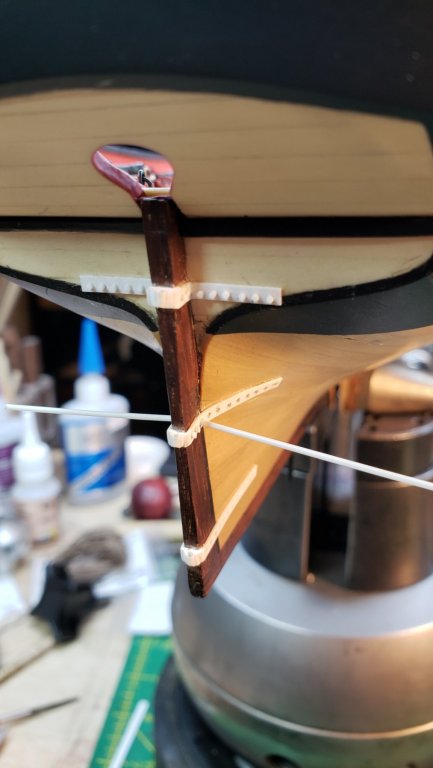

Unfortunately in my place I made the workshop impossible to cut off, seeing as it's the house's alleged dining room I've had no problems with cats knowing that there are places they aren't allowed on, but of course the young ones will jump up just to prove they can the second you leave the house. So extra safety measures will be required at least until she gets out of bratty cat teenager phase. I didn't have cats until I was 21, when I moved into a house with a girlfriend after college, and pretty soon there were four cats and three dogs. For whatever reason I picked up cat language pretty quickly and have had them since. My wives have always laughed at me having regular conversations with them as they follow me around the house and monitor my activities. Progress remains slow, just haven't had much time to work on it, but steady in that I try to move forward a little bit every day regardless. Unless I talk myself into rudder pendants, the rudder is done. I just don't see pendants on the contemporary models, but I still find it hard to believe they'd go into the North Sea and the channel with nothing holding the rudder on but gravity. At least I'd feel like a colossal moron for drowning in a capsizing ship because the rudder just fell off and I had no backup to catch it. This was also one of those cases where cup burs come into play. I don't use them super regularly, but when I do, boy howdy do they speed along the process. Here as you see below, after I tore off the brass and started using styrene, I drilled holes for .030" styrene rod, and after letting the CA set for 30 seconds on those rod pieces, I just clipped each one off close with a good nail clipper. Then I went over them all with the right size cup bur in the rotary tool, and we have reasonably even nice rounded bolt heads very quickly. By the way, I drilled the holes in situ instead of on the mill or something to give it a more handmade look, but I ended up wobbling more than intended in a couple places. Rarely does a good idea go fully unpunished. Next up is deadeyes, which I've started but am at the moment wondering how to chuck them somehow to properly round them off. I've tried a few things so far with no luck, I'm considering just drilling a hole through the danged things and then filling them later with side grain wood.

- 624 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Sorry Sam, somehow missed your reply here. Yes, this is going to be a challenge Right as I cross into doing rigging, I'm going to have a 12 week old fuzz-covered energy bundle that some people call Tonkinese kittens. With Takita when she was little, I had to keep an array of pens on the edge of my workbench so she could entertain herself while sitting in my lap by throwing the pens on the floor. I have no idea why cats think that is the funniest thing ever, but they do. I had to keep continuously replacing the pen supply or the next thing on the floor was an important part. I can only hope the new one doesn't decide that ship parts are prey items like yours did. Speaking of the rudder, it's finally more or less done, will post some pics tomorrow.

- 624 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

S.E.5a by CDW - Squadron Encore - 1:32 Scale

vossiewulf replied to CDW's topic in Non-ship/categorised builds

This actually reminded me that I built that as a kid in the early '70s. It was the first time I tried to do camouflage painting by hand, as I recall it came out awfully, but I learned a lot. I may go buy one just to see it again after all these years. -

The whole "article" was a paid advertisement for Artec Eva, something you see more and more. The Team Chooses to Use the Artec Eva Scanner to Study the Viking Shipwreck And so, upon Auer’s strong recommendation, the team moved ahead with using Eva for working with the Big Ship. Experts using the faster 3D scanner Artec Eva to scan and document the discovery before damage set in to the Viking shipwreck. (Thomas Van Damme)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.