barkeater

NRG Member-

Posts

320 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by barkeater

-

Proxxon mini lathe verdict

barkeater replied to Srenner's topic in Modeling tools and Workshop Equipment

Just to be clear, I have the Proxxon db250 which online goes for $230-270 with one add for $97, although with that price I would be quite skeptical. I forgot how much I paid but it was well worth it in time spent and the decreased wear on my wrists given the dozen or so yards I did as well as the ornamental balustrades on my current model. Rich -

Proxxon mini lathe verdict

barkeater replied to Srenner's topic in Modeling tools and Workshop Equipment

I have the Proxxon and use the add on 3 jaw chuck like Rob. The pass-through ability is key as it allows for longer stock and helps avoid whipping. The two shown by Gregory don't seem to have this pass-through feature. Overall, I'm well satisfied with it and the money I spent. I've done larger oversize pieces down to 3-4 mm thickness. Rich -

The problem with using CA for planking is that it stains any exposed surface and is just about impossible to sand out because it penetrates. This persists when you overcoat with varnish or shellac. A stain can even be seen when you paint over the area because you lose the grain of the surface as it is replaced by plastic. A good rule of thumb is to use PVA on wood or any wood product such as paper and leave the CA for bonding metal or plastic to wood. You can use it where you need a quick bond but if you've shaped your wood beforehand this is rarely necessary. PVA clamped by hand if you can't get a mechanical clamp on it and counting count to 100 usually is enough to hold your bond. Rich

-

I do not pin or glue my yards and don't have a problem in getting them how I want them. Since I've never done it, I can't say from experience but the thought of drilling holes in my masts after they have been stepped makes me nervous. Another example of different modelers taking different approaches. Rich

-

I can't really add much to what Steve said. Hopefully you can figure out most of it by comparing the instruction list to the dimensions of the wood supplied along with the quantity supplied for each. I would add that walnut, can also be used for the second planking. Rich

- 21 replies

-

For identification try The Wood Database which lists many different types with pictures. To identify I really need to see the grain. I do wonder if the dark grey/black wood is dyed. The dowels are probably birch. The brown wood is probably walnut and or mahogany. The light colored could be bass or not. Hopefully someone here has built this kit. Good luck, and welcome to ship building. Rich

- 21 replies

-

The picture shows my modification of Mondfeld's ships boat making jig in "Historic Ship Models". I had used this type of jig previously but as I got ready to do some ships boats for my current build, I decided to modify the jig. The result was a more stable to work with jig where the work piece being temporarily fused together gave greater stability and allowed for easy construction and sanding. Where the original jig had the mold or plug placed in a cut-out of plywood, I used a solid piece temporarily joined by two screws to the mold. The outline is then drawn around the mold on the plywood, and the position of ribs marked. The screws are then removed and holes for the ribs are made using adjacent drill holes cleaned out with a scalpel. Two blocks are then glued to the undersurface to give elevation so the screw heads will not keep the jig from sitting flat and to allow for the ribs to project beyond the plywood and so be well seated. Screws are then reinserted, and the ribs are then steam bent and placed in their respective holes. The temporary fusion of the mold to plywood makes the bending and placing of ribs much easier and steam bending can be finished with the ribs in place on the form giving better results. The keel, post and transom which were previously made to fit the mold are then placed over the ribs and glued in place. Mondfeld shows notching along the keel for the ribs, but I just glued them without making notches. This eliminated the chance of having an inaccuracy between the notches on the keel and the holes for the ribs in the plywood. I was worried that this would give instability to the boat when removed but after planking and adding an external wale, the little boat is tight. The ribs projecting beyond the planking can be snipped with a pair of scissors. Finally, when carving your mold remember that there was no uniform design for ships boats which were built locally so you don't have to go crazy in exactly coping plans. Just try to keep it bilaterally symetric. Rich

-

"Was thinking...can you pre drill so nail slides in with glue? " Yes, use cyanoacrylate to glue metal to wood. The problem then becomes that you can't remove them. Much easier and nicer looking to not use them and rather pre-bend and glue. Rich

-

This topic comes up on a fairly frequent basis. Those little nails tend to split the wood or bend as you've probably already found out. You can predrill to prevent the splitting but then you are left with holes or nail heads. I don't use them at all planking either first or second layer. You are better off pre-bending the plank by wetting it and using heat or a jig. Remember to let the wood dry (at least the second planking) as there can be some shrinkage. I just apply pva (wood) glue and hold or clamp in place. If I'm manually holding the plank in place, I usually only have to hold for 1-3 minutes to get a bond. I try to stay away from cyanoacrylate as it stains and is very tough to sand out. The nails are however very handy in pinning furniture such as the ships wheel or stanchions in place. Rich

-

I'm not really sure what your question/situation is. If you are talking about installing planking, I usually drill my trenail holes after the planks have been glued in place with a #72 drill bit and a twist drill or pin vise. Need more info as to your situation. Merry Christmas and Happy Holidays. Rich

-

Who uses nails?

barkeater replied to bigcreekdad's topic in Building, Framing, Planking and plating a ships hull and deck

I never use metal nails for planking. I trenail everything. That being said I use the nails to attach furniture, to strengthen joints as well as using them to simulate bolts. A lot of times I hide the nails, so they won't be seen from the outside when I need a joint strengthened. I have to admit that although a lot of us complain about the nails and the hundreds that seem to be included with kits, I have had to actually order more as I've run out since switching from kit construction to scratch building. I need to do gun port lids coming up and I'm going to need 4 for each lid with 28 lids. Although I can't see them for planking, they sure are handy for ship modeling. Rich -

San Cristobal especially Revelation series but you could probably get as many as you want from a cigar store as they get thrown away. Rich

- 269 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Okay, back to the drawing board. My wheel is 3.5 mm thick. In your scale it would be 2.525 mm. This is the best I can come up with If you want to give it a try. In cigar boxes they use a divider for top and bottom layers which is 1mm sheet of what I presume is cedar. I have used it to simulate complex mast construction (see picture). If you used this, it would give you a thickness of 3mm which you could sand down to 2 1/2 mm. Spokes would be tiny. Perhaps you could use bamboo thinned like a you make trenails with a draw plate. Rich Rich

- 269 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

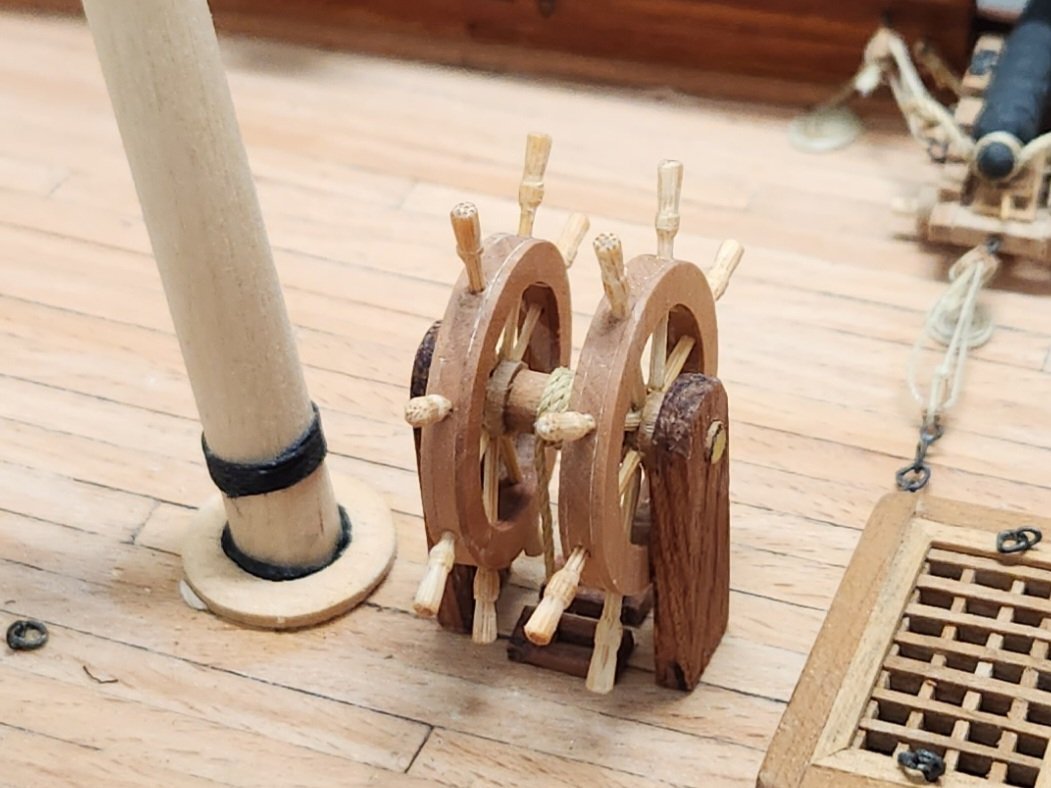

You may want to try this. I work in 1/48 scale. I take thin sheets of wood (2mm or 1/16 in my scale) and cut out 3 circles of the desired diameter. I have used cherry and pear. Glue these together at 45 and 90 degrees oriented to the grain. You now have a plywood type piece with strength in all directions. Next trace the inside diameter of your wheel. Using a thin hand drill you drill all along this line cutting out the center. Microfile to smooth. If your tri-ply piece is too thick you can sand to thin. Next figure out where your spokes go and drill the center thickness of your wheel to insert the spokes. The spokes are actually two pieces, inside and outside the circular wheel so your drill holes do not have to be as large as the spokes as you can taper the ends to fit into the holes. Now repeat the drilling on a piece of dowel for your center pin or axle. You then cut tapered spokes to fit in between your central pin and the wheel. Once this is assembled and glued add your spoke ends exterior to the wheel. Rich

- 269 replies

-

- Sophie

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I'm with you on the unpainted wood. I have used both walnut, and cherry for planking as well as red heart, mahogany, yellow heart and ebony where appropriate. I like birch for decking, but I know others don't like it. For accent and decorative areas, I have used bubinga, purple heart, leopard wood, rosewood, tulip and even maple. Carving and complex curves I go with pear which is easily workable but lacks any grain detail and frankly looks boring to my eye. I like it when you can see variations in color and grain when going from piece to piece and pear is monochromatic and dull. I'm sure there are some others I use which I can't recollect now but as you can see, I like to use a variety. Rich

-

Welcome to the forum. Sounds like you've got a good start. Rich

-

Trouble with scuppers

barkeater replied to wmherbert's topic in Building, Framing, Planking and plating a ships hull and deck

I never realized they were painted. Since they were made out of lead, I always assumed they were. grey and make them out of brass coloring them using brass black. Since I like the look of natural wood with trenails visible, I don't have to worry about matching paint colors as I only paint decorative carvings. Rich -

Construction of Masts for 18th Century 'Ships of the Line'

barkeater replied to tmj's topic in Nautical/Naval History

To give the complex construction appearance to the mast I used the wood (? cedar) from a box of cigars where they use it to divide the top and bottom layers of cigars. It is really thin and flexible., I did not need to cut into the mast to fit it. I just cut it to the shape I wanted using the illustration Gregory shows above, wrapped it around and glued it in place using pva. Richard /\ -

Estimating the size of a mast top

barkeater replied to Dan DSilva's topic in Masting, rigging and sails

If you want to do a round top, from Lees "Masting and Rigging" Appendix I "When round tops were carried the following were the proportionate widths of the bottom of the tops based on the length of their respective topmasts: Main 0.28, Fore 0.29, Mizen 0.27 and Sprit 0.4." Hope this helps. Rich -

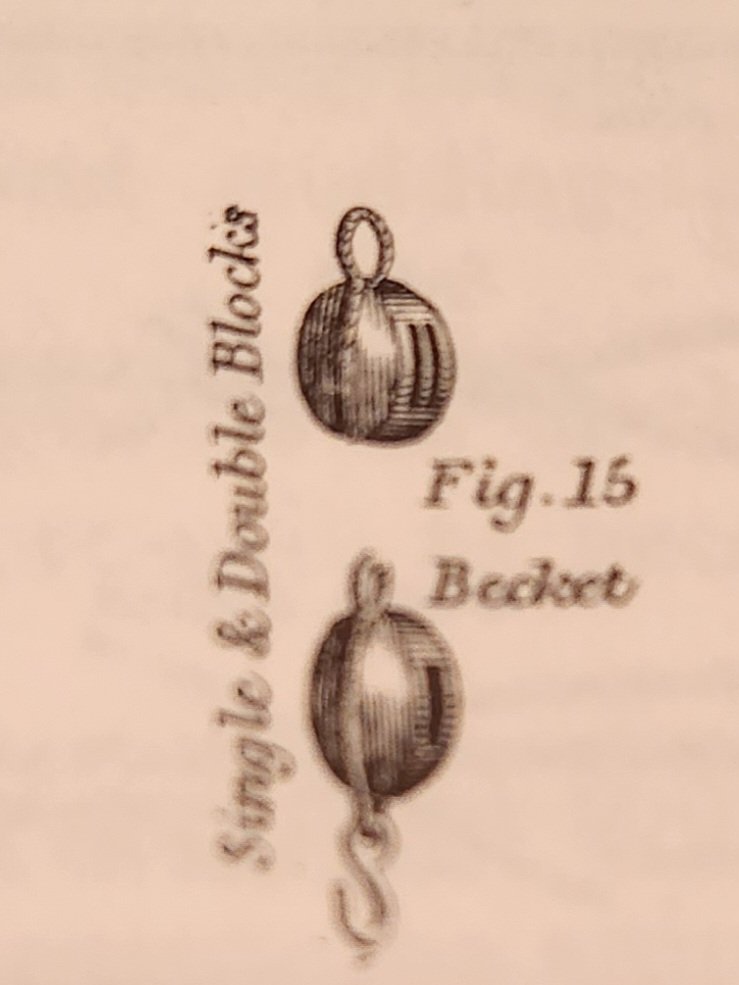

Bill I was not quite sure what you were referring to at first. The picture is from Biddlecombe's The Art of Rigging. I don't do beckets to connect the block to a line. I will form a loop when attaching to an eye or hook doubling up the line after it has run through the eye and seize both the going and coming portions together. I work in 1/48 scale with my single blocks measuring 2x2x3.5mm. In forming a loop to attach to a line, I'd have to form the loop around something the diameter of spaghetti for scale and you really would not be able notice it unless you used magnification. I try to put as much detail into my work as possible but for me, putting in a becket for a block to line attachment just doesn't seem to be worth the added time, effort and aggravation. I attach the line (example: yard lift) to the block continuing the end of the line around the block as the stropping and then seize it to the line as I described earlier. Rich

-

Bill I use thread for stropping my blocks. I make my blocks with a groove to fit the thread Then I serve or secure the two ends using smaller thread (fly tying thread works well) with multiple overhand knots (5-7) and then hit the knot and the stropping block thread lying in the groove with thinned pva (wood glue). I the snip one of the two ends. The other end is your rigging line, or you can attach to an eye bolt, hook or whatever. When a block is part of the chains, I use silver wire which I mold around the block to the correct shape then remove the wood block, silver solder and blacken with brass black. Rich

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.