Cannon Fodder

Members-

Posts

147 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Cannon Fodder

-

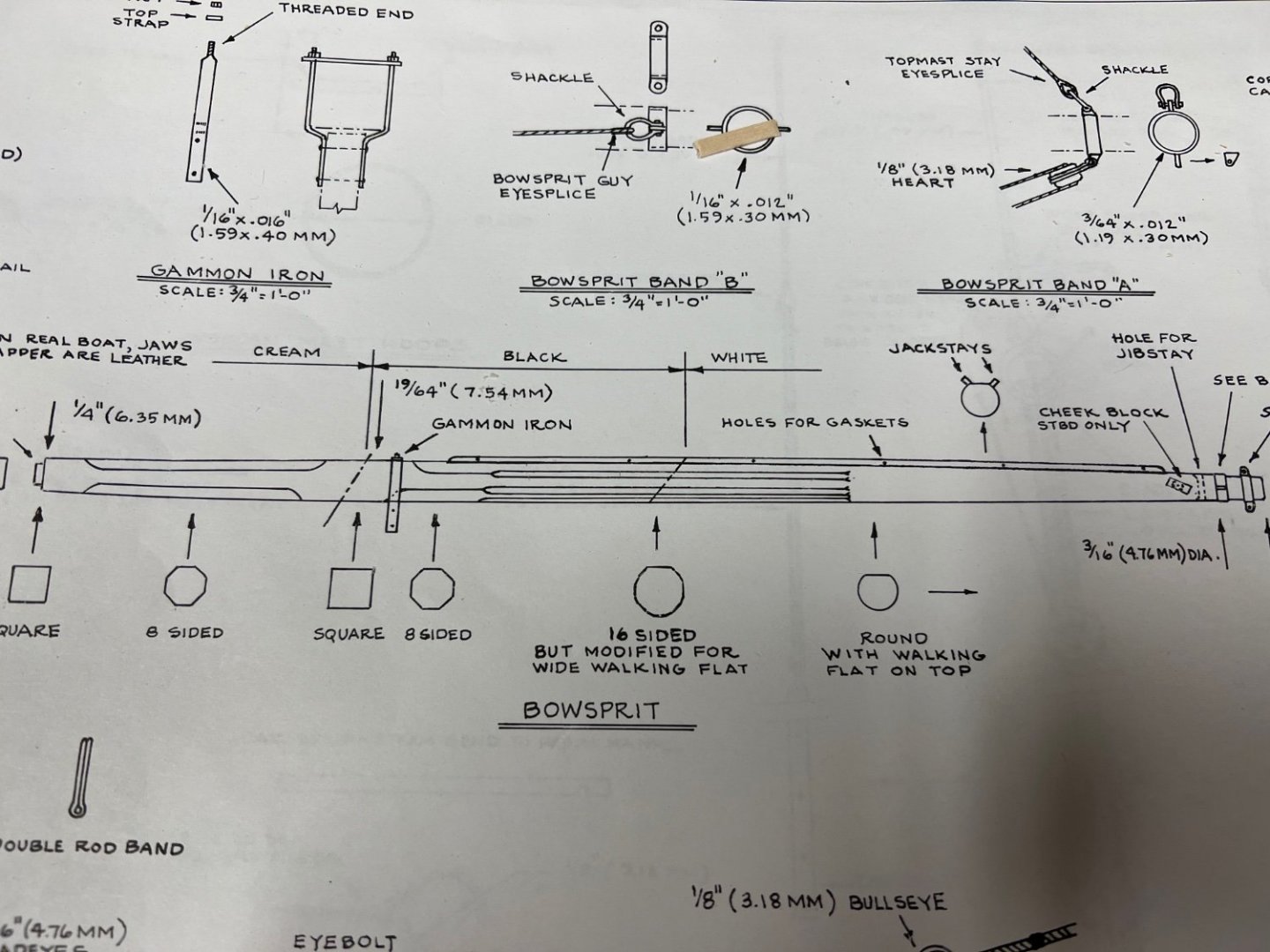

The bowsprit is proving complicated and slow going. Also just disappointed in the ability of the wood the hold any sort of crisp carving. 16 sided section just looks round. Needs more tapering to the tip, had started at the tenon and was carving outwards. Maybe with all the garnish it won’t look so bad.

-

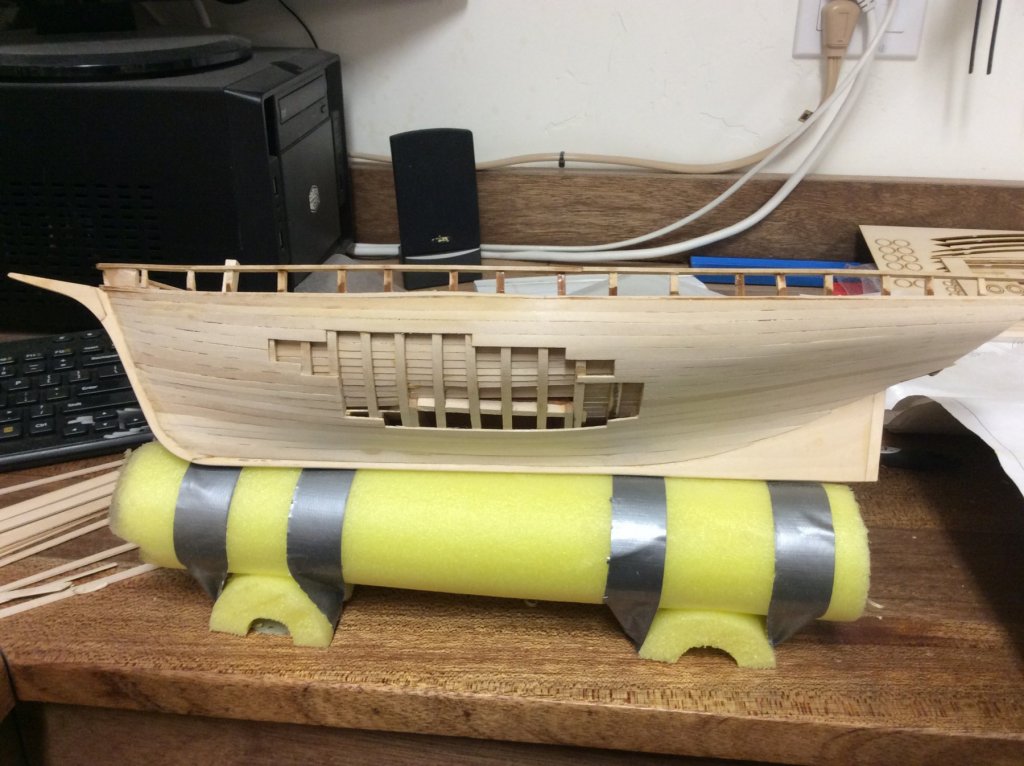

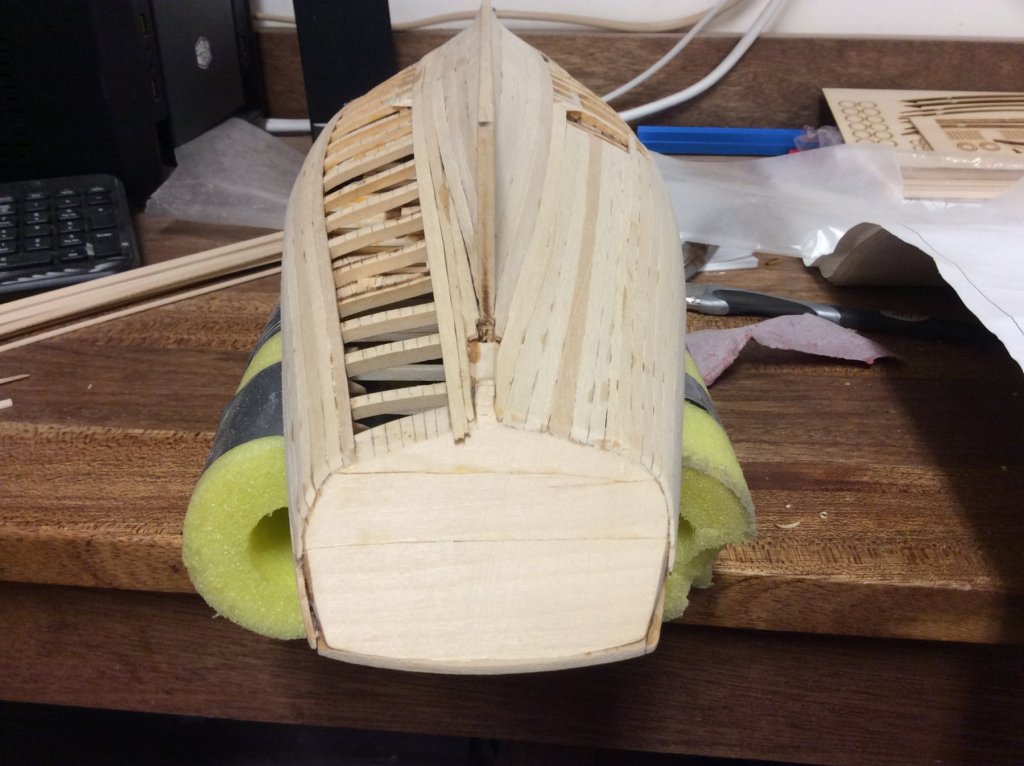

Planking a hole in the side of a boat... challenging. Sticking to my planking plan was a real challenge. Much more use of CA glue this time around for me. Still learning how not to glue my fingers to the boat. I am learning to work through my short comings on it and enjoy it. Was frustrated there for was while. Better now and going with the flow. This side much more even and with the “plan.” The bow junction where the plank meets the keel, still a challenge for me. Fingers get stuck here alot(CA). Garage cabinets that are still partially doorless are to blame for some of the hiatus, a maternity leave I covered as well at work. At least now my 7 and 8.5 yo daughters are respecting the shipyard. fixed transom still evident. Here’s the hole. Lots of pics, just cause. I am glad to be working on it some.

-

I powered through to the end. The rigging being pretty simple with pretty good instructions as well. Officially finished nearly 4 years in the making.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

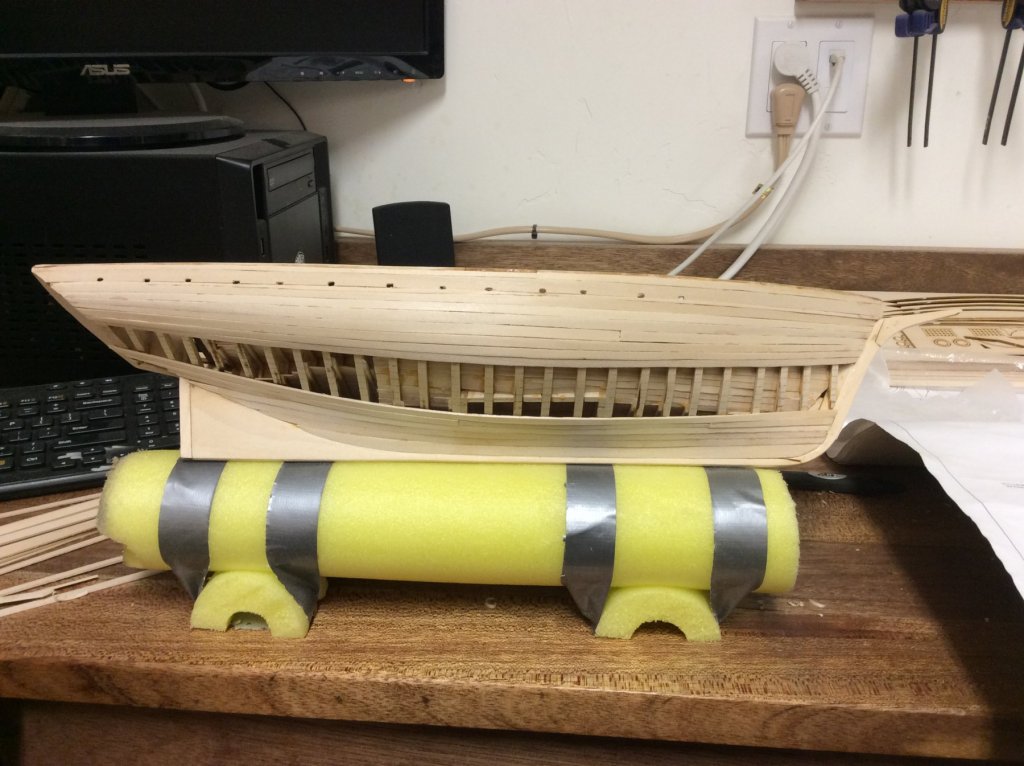

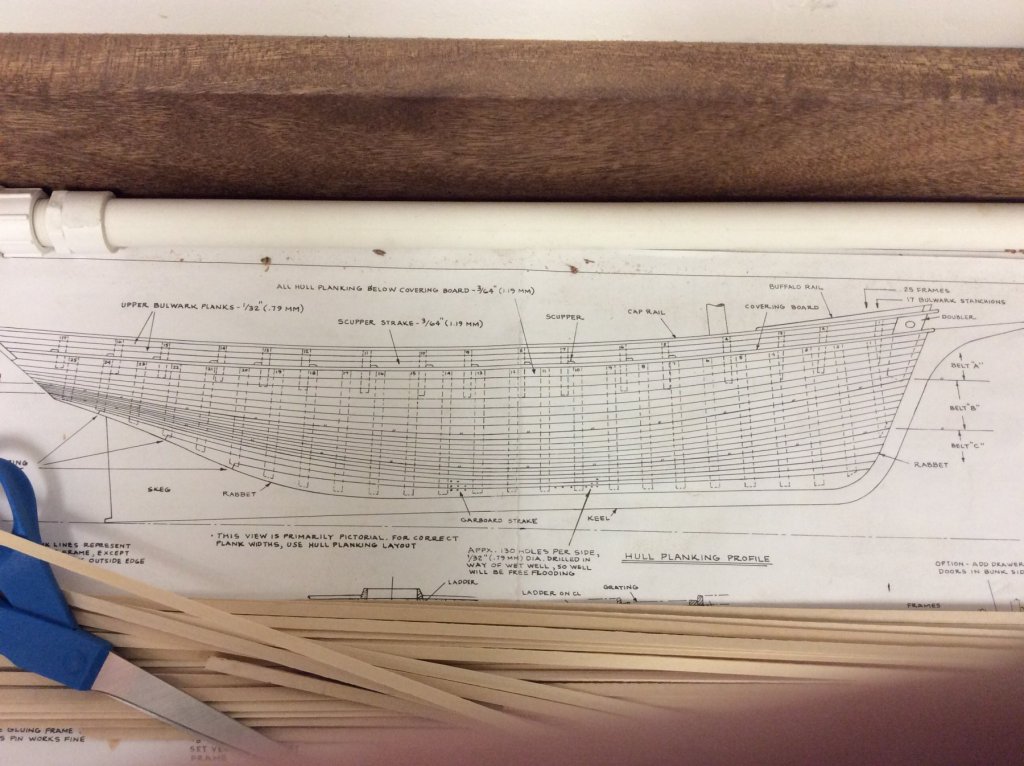

The hull lined out completely. Garboard strakes in place. Plus one...the imperfections of the hull now stand out. Also I repaired the transom. and of course the lining on the transom looks terrible, now that I take a picture. Hmmm...I like the look of the starboard better. I'm going to plow ahead with my plan to plank symmetrically, one strake on each side.

-

I have dry fitted the foremast. Finished the aft cabin mostly. Door handles were too much for me. They are actually functional! Lots of CA all over my fingers.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

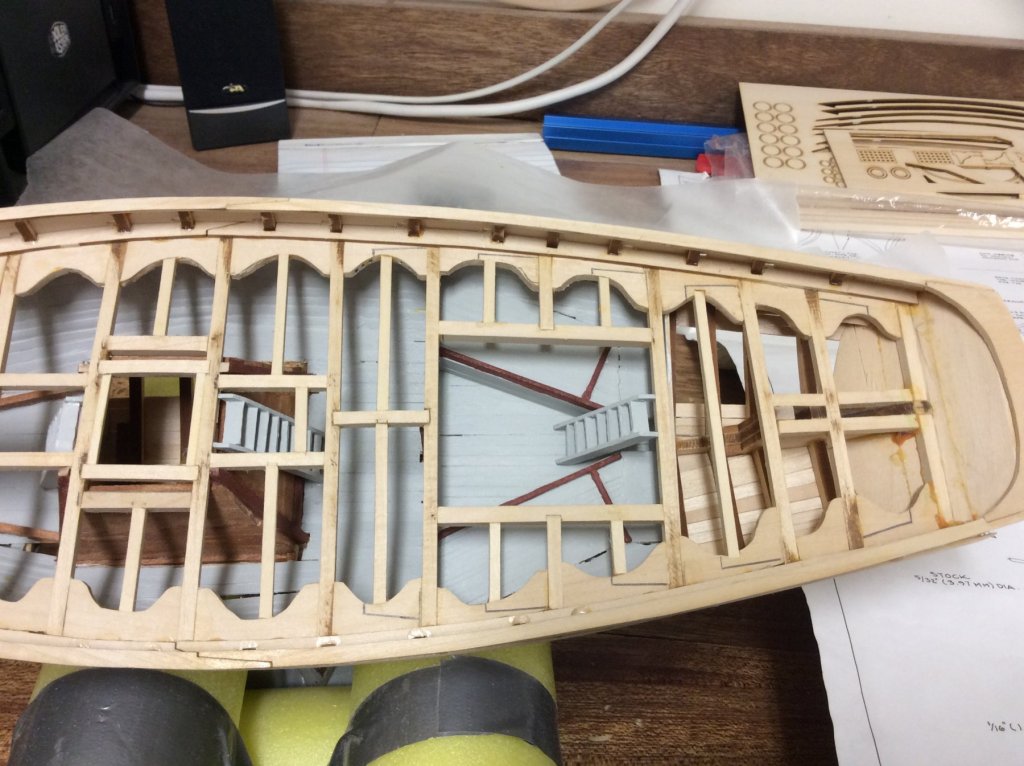

I have a new and improved jig to hold the model as I plank I was worried about the bow breaking. I am continuing to line out my hull. I had placed three planks but ripped them off when I got possessed by Chuck. I am fearful of the transition from lined out hull to actual planking. It seems that every strake will need thinning along the entire length, Ihave twenty strokes at midship at frame number 12. The plans do give detailed planking drawings.

-

Ugh, spend about 30 seconds bending the tiniest hinge ever then spend 5 minutes looking for it on the floor.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

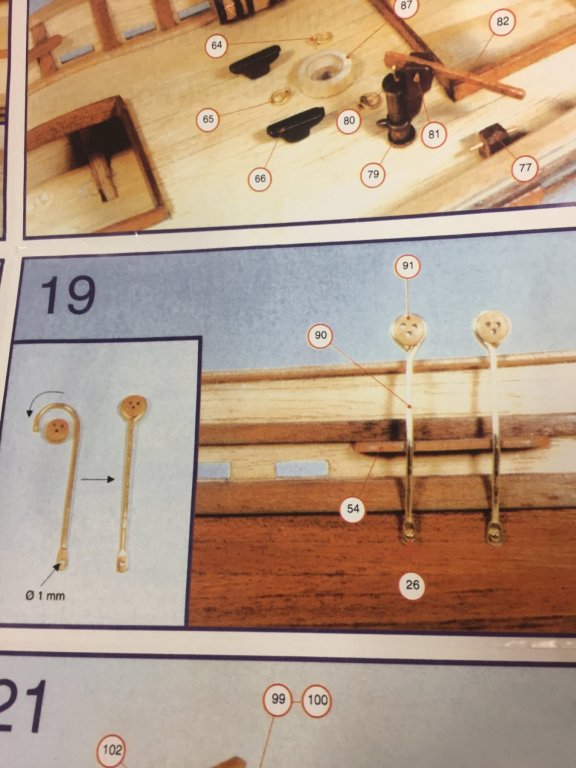

A little hammer and anvil turned out best result. I found those chainplates? To be the hardest part of this build so far. Here's a photo update. Those cabins were way more involved than I anticipated. I have one done and am working on the other.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

I've been working on the cabins between getting frustrated with working with brass. I've never done anything like this. I am super impressed with myself. I did not think that veneer would wrap around the edge like it did.

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

Searching on the site I found that if you heat brass up, even if it cools down it will be softer, looks like I need a torch of some sort. Also found I might be making an order with micro mark for some appropriate metal working tools. Gotta love new tools!

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

I might need large vice grips, was able to flatten in but then it snapped off, and like you said kinda chewed up...

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

-

Question for you swift builders out there watching, any ideas on how to flatten the end if the piece of copper wire used for the chain plates of the main and foremast? I am then to drill a 1mm hole in it. Swashing in my vice only gets me so far....

- 84 replies

-

- swift

- artesania latina

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.