MikeConnectrix

Members-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MikeConnectrix

-

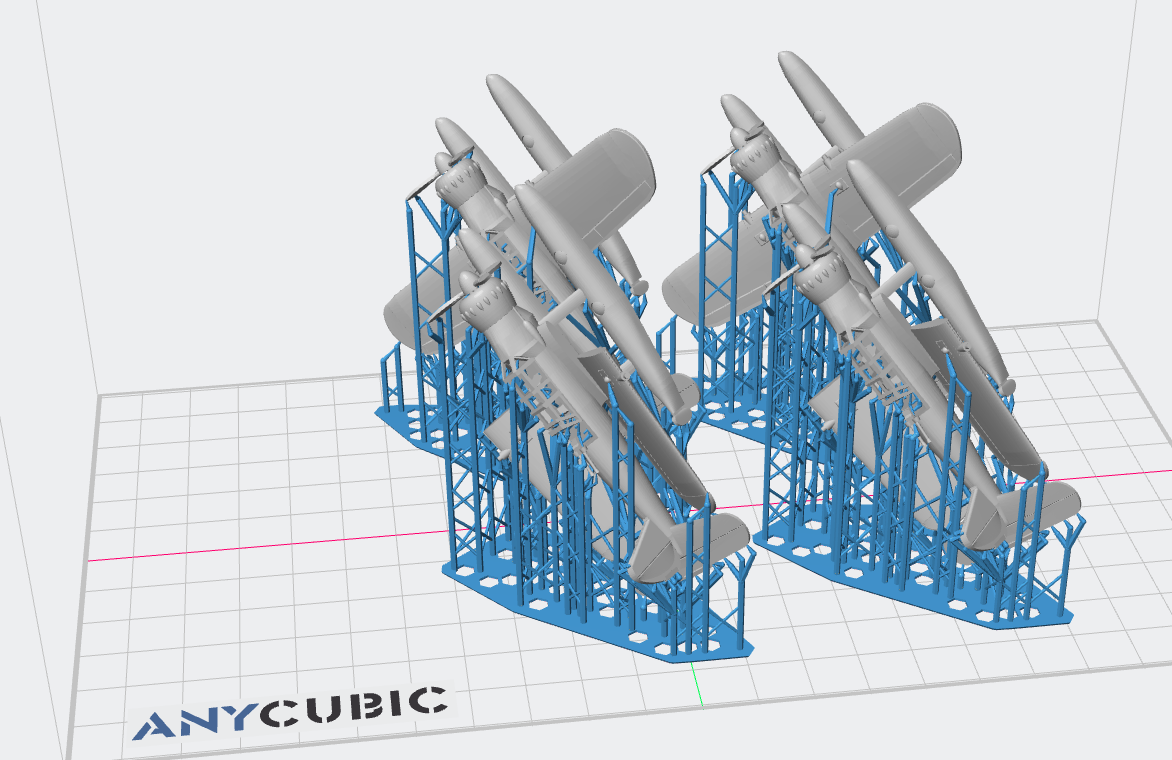

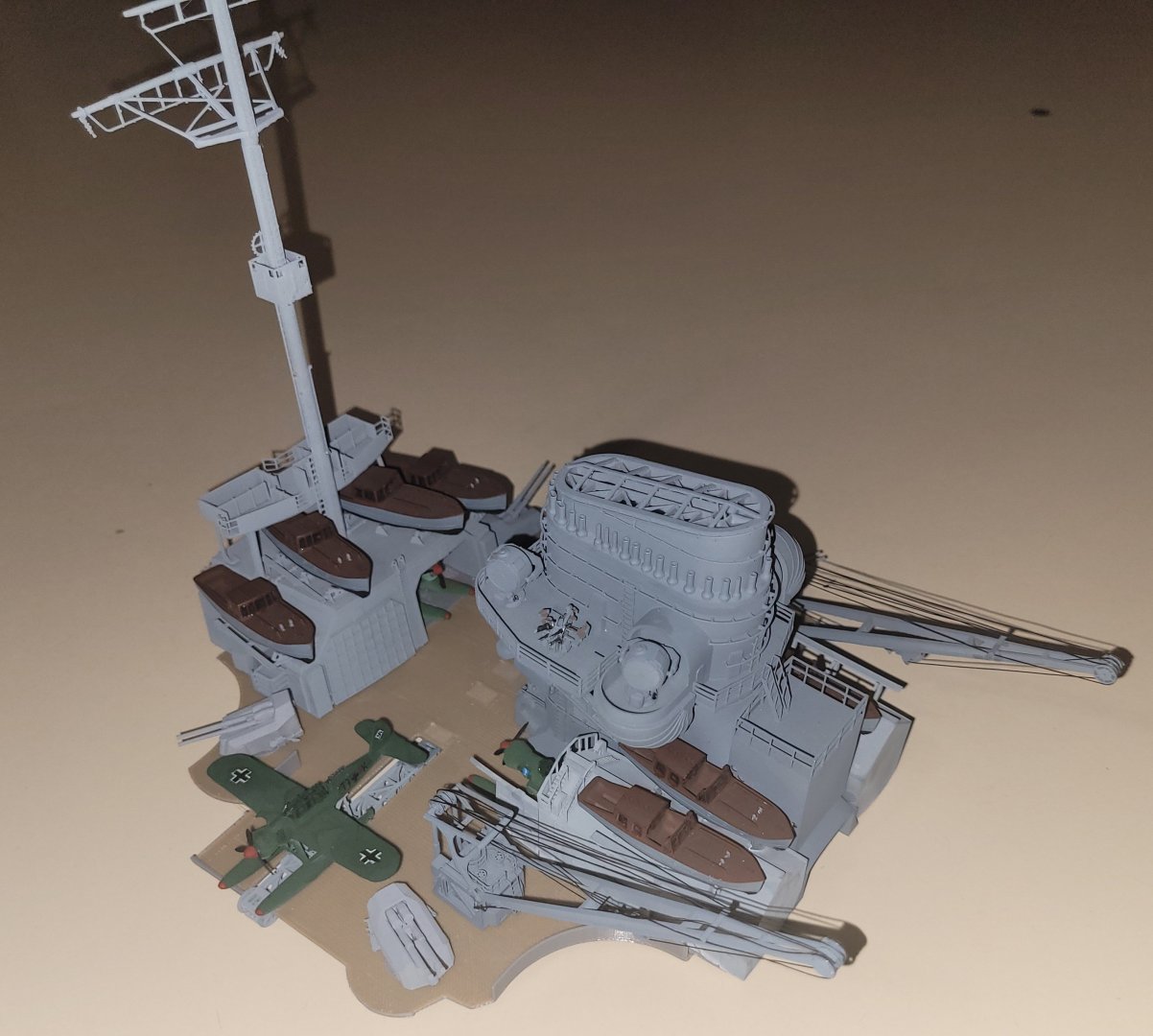

One of the many resin prints to come. I used an Anycubic M5S with a 0.05mm layer height and printed all 4 in one hit. These just need to be painted up, decals applied and glass mimicked with Microscale Krystal Kleer. A 1:200 completed one included for reference. My print layout resulted in some warped wing tips (Not bad, passable), next time I would probably try it like this:

-

I don't quite know why, but had a section of 15mm T-slot at 395mm lying around, so made the stand based on that. 400mm will work OK as well. The supports are just friction fitted to the T-Slot. You could glue it etc but it's a pretty snug fit and quite sturdy as is. Just make sure the hull profile matches when the sliding the pieces on. None of them are interchangeable. The forward ones are one profile, the rear ones have a different hull profile. I am yet to make a name plate holder.

-

As I said, unique and impressive. Did I hear someone saying you needed a guy with a drum down the back.. Agreed!

-

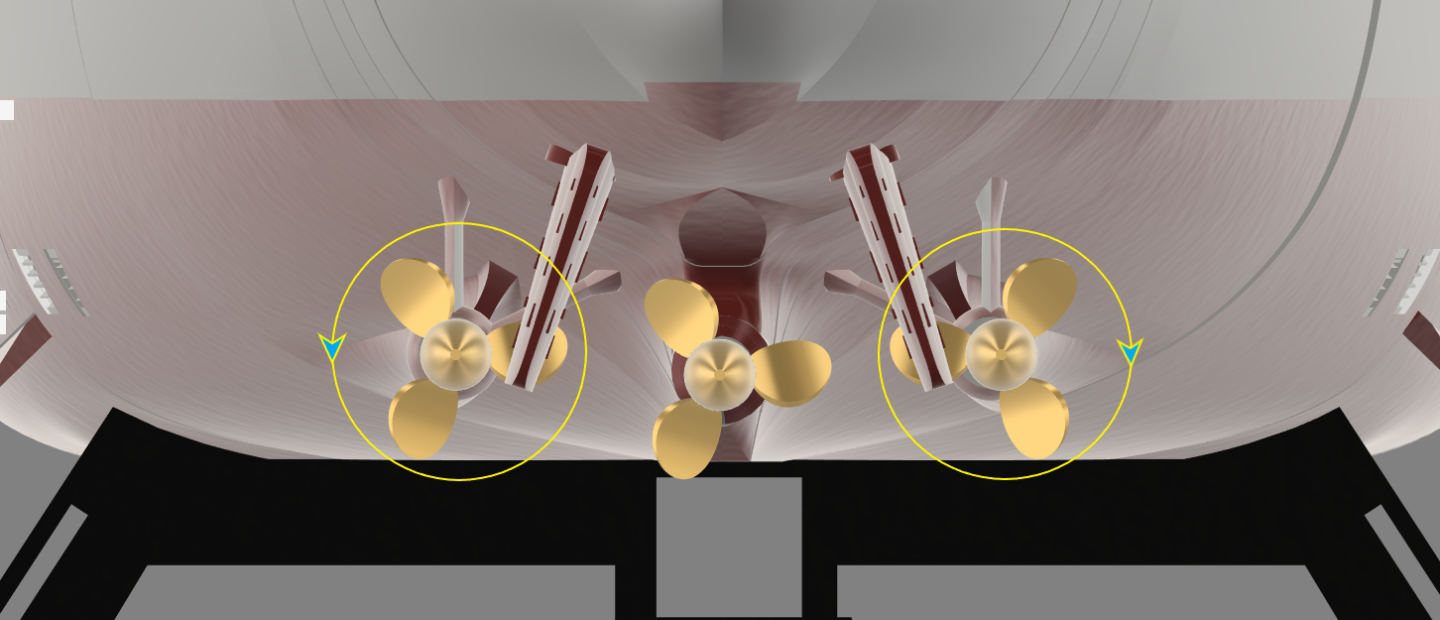

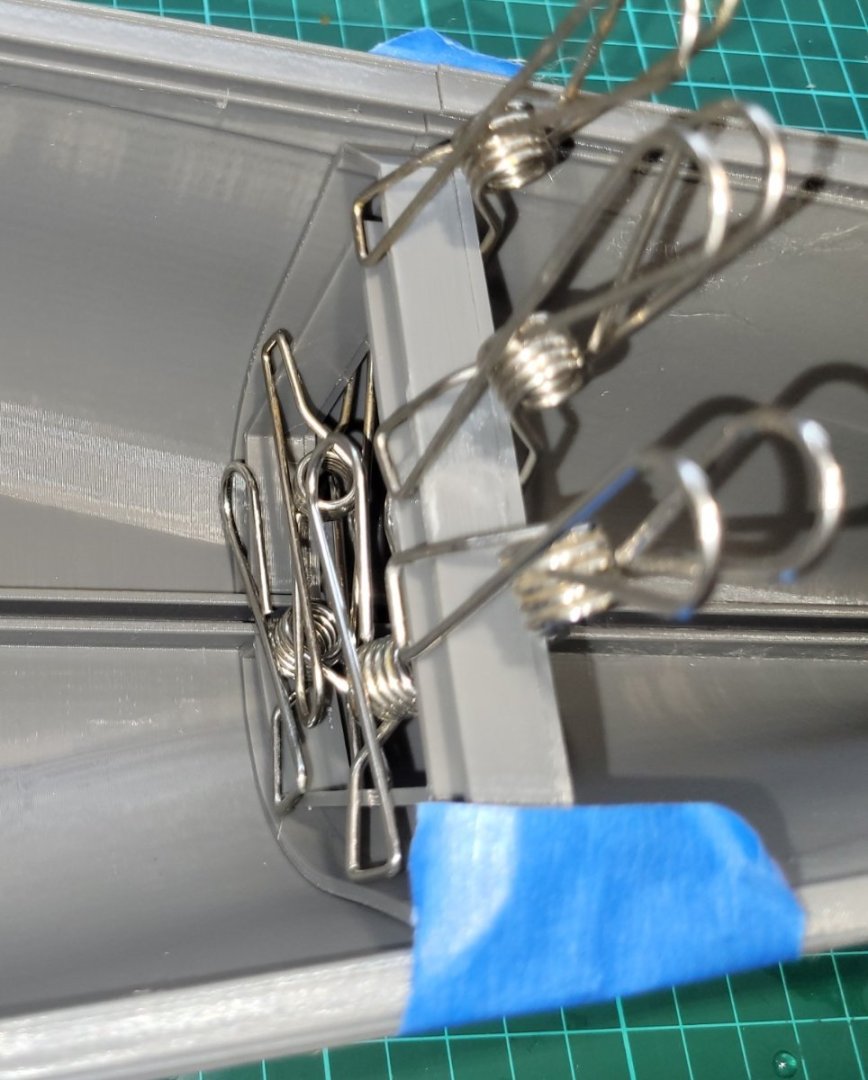

Prop shafts for this I decided on 3mm, although 4mm is an option, with a length around 440mm. An exact length I won't know until I actually couple them to the motors, so I made them 500mm for now. Each outer shaft has 4 F693ZZ 3X8X4 bearings heat fitted to the propellor support and tube, while the centre prop has just 2 of the same bearings for the tube. Doing your own shafts is straightforward but do not try it without a split HSS die (ask me how I know:)). I just did them by hand although I could have just as easily mounted them in the lathe with a die holder. If doing it by hand make sure you use a soft grip in the vice to secure the shaft while threading (Ask me again how I know, mine is just a squashed bit of 10mm aluminium tubing). 3mm stainless rod into 3mm bearings is a heat fitment. Freeze the shafts and put the bearings in the oven and after 10 minutes the bearings just slide right on. I choose to mount the shafts in a power drill and go back and forth with emery cloth to take a poofteenth off the shaft so the bearings slide on and off cold. Alternatively you could probably just use 2.8mm stainless rod. Two of the propellors (32mm) are clockwise with the port screw counter-clockwise. Typically in multi screw naval vessels looking from the stern the outer tip of the blades travel down to reduce turbulence. There are several photos of Prinz Eugen when there were 2 screws on the wreck. The ship is upside down, but the port screw (nearest) clearly rotates counter-clockwise when going forward looking from the stern. Looking at you Steam - Ship Explorer - Bismarck

-

An R/C Roman galley must be pretty unique. Amazing. I'm a software engineer that likes to tinker with electronic hardware. Sadly, I'm not retired yet which means I don't get as much time as I like working on boats. Oh well... The board in that link was made using my own design pick and place machine and is double sided. My lab also has a CNC lathe, Laser cutter, CNC Router, 4 Axis CNC Wire cutting table, SMD Reflow oven and heaps of other stuff that has mostly sat unused for the last year. Customers requirements at work, wife needing heaps done around the house, having fun with grand-children plus a continuing battle with skin cancer took care of all my time this year. I'm unsure if I will put that board up for sale or not. It is finished and the firmware mostly functioning and just waiting for a boat to test it with. It can be emulated with an ESP32 development board, LSM303 compass module, SD card board and a couple of servo expansion boards. Putting a wiring guide on that GitHub page is on my to-do list. But hopefully I will get this boat finished in the next 2-3 months then look at finalising the boat controller. After that I have a 90% completed 1:150 Prinz Eugen on the workbench as well.

-

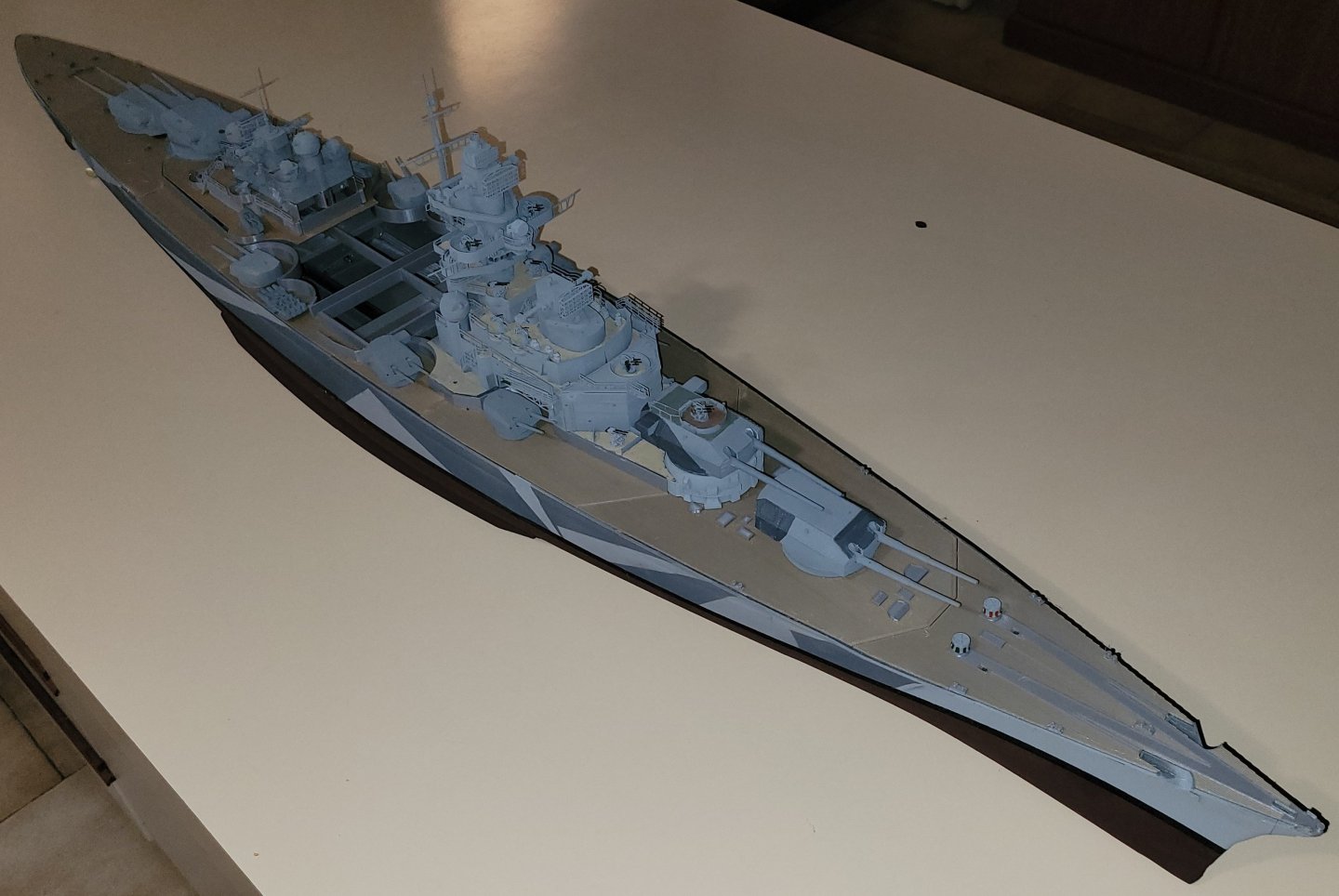

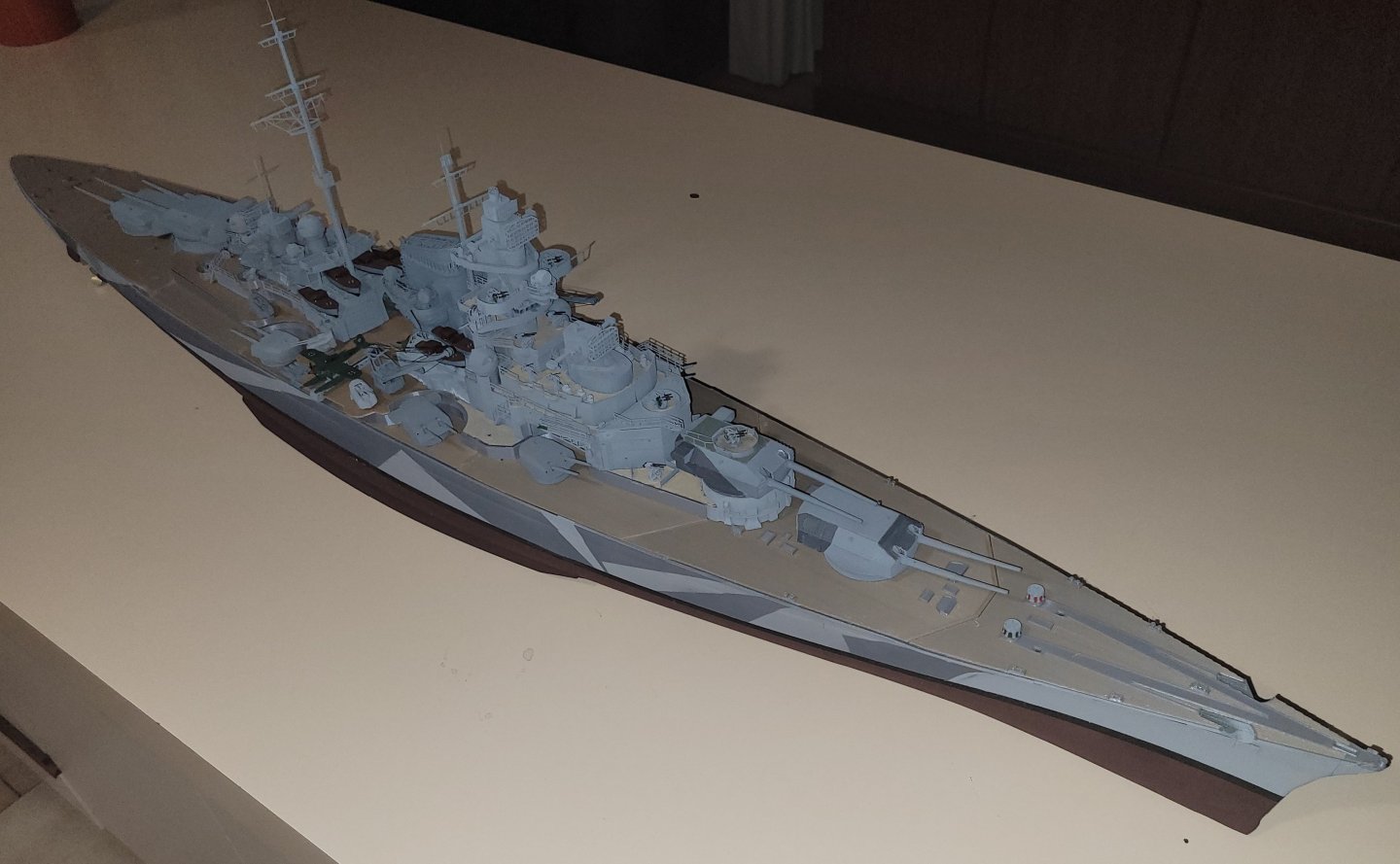

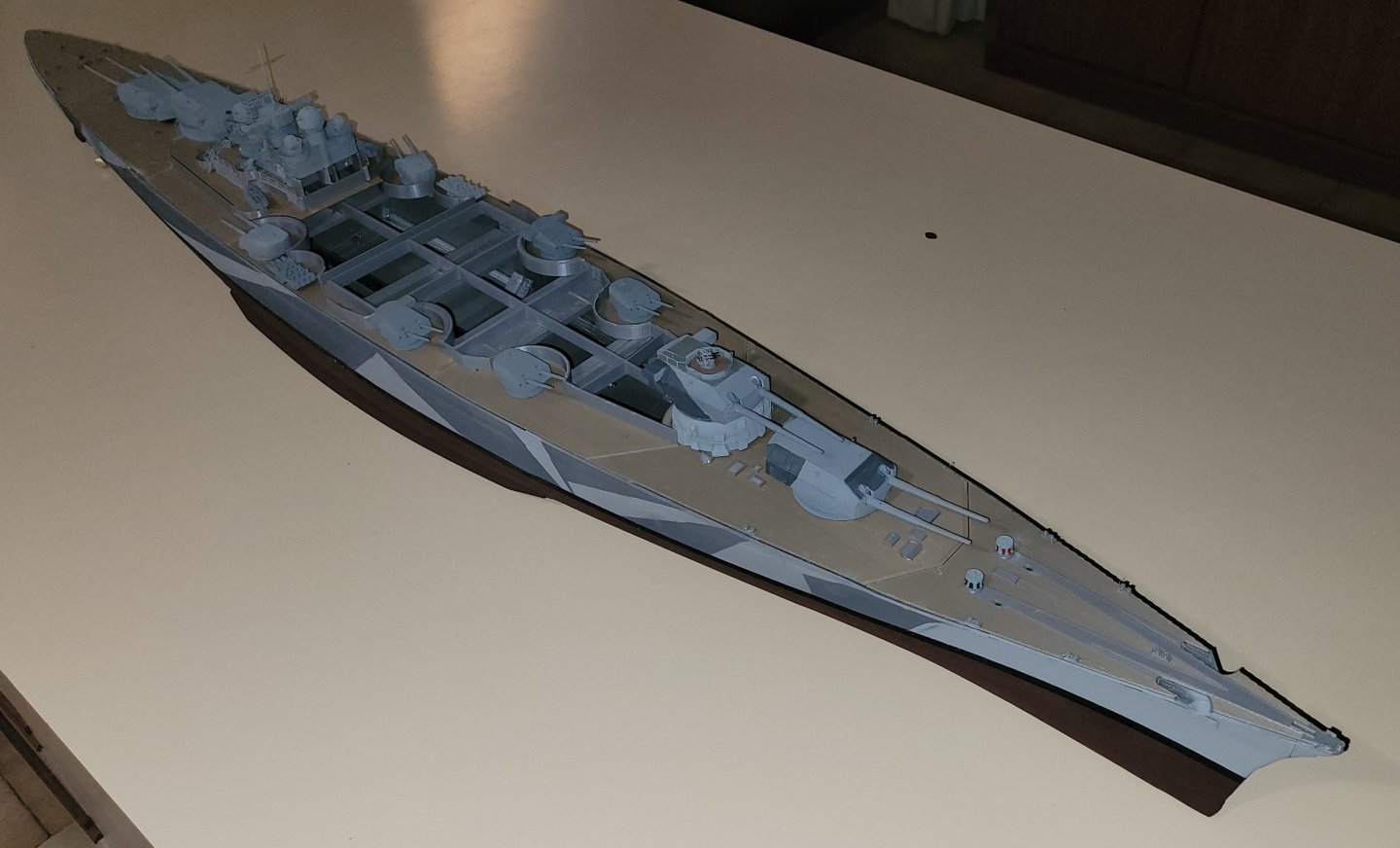

In the lead photo: Tirpitz is 1:200 = 125.5cm=49.4 inches Bismarck is 1:150=167.33cm=65.9 inches Maybe not 30 servos. I can definitely see 27. I will be using a 3 channel controller Rudder/Throttle and Main Fire control director. Everything else will just follow that based on compass input.

-

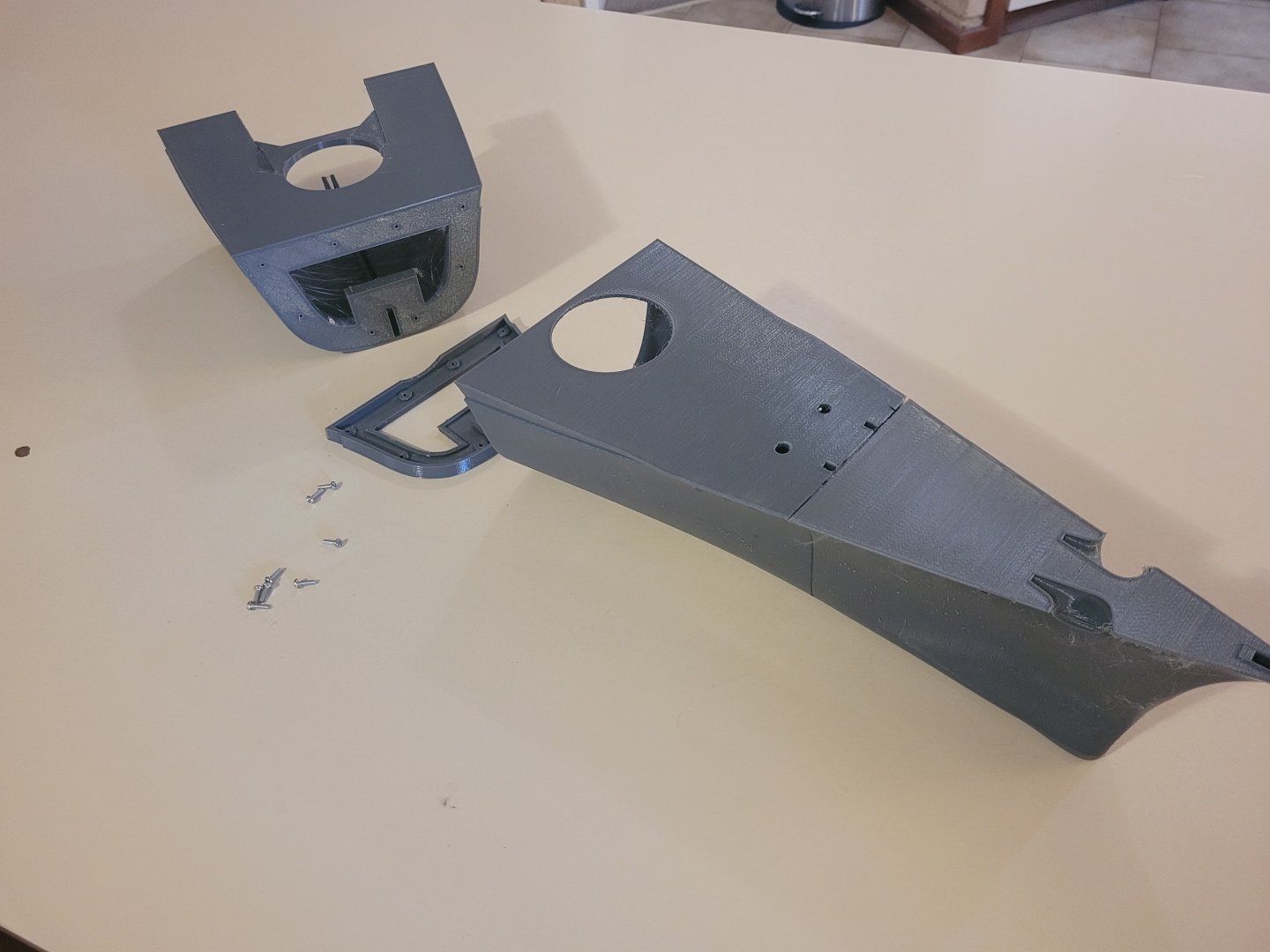

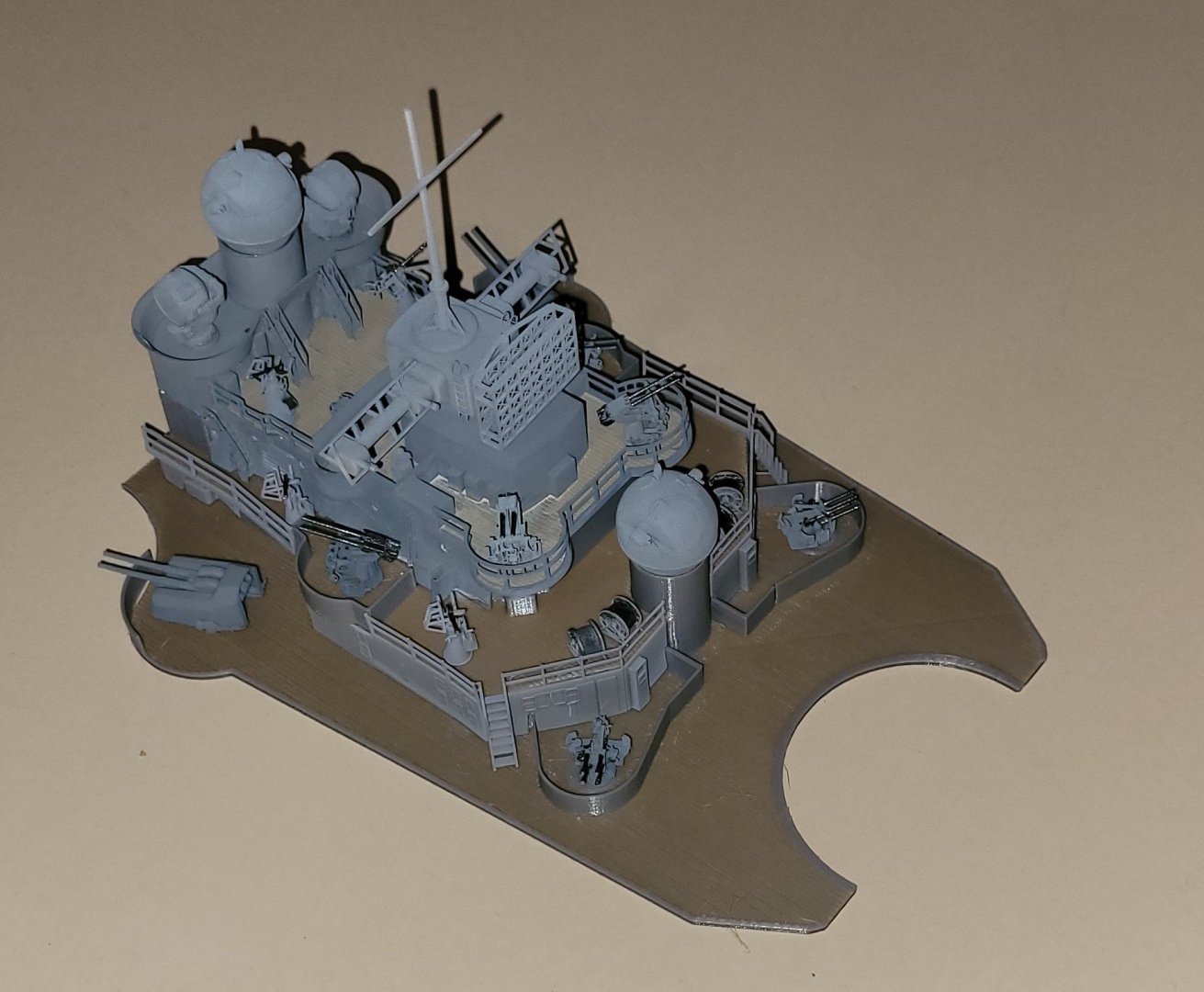

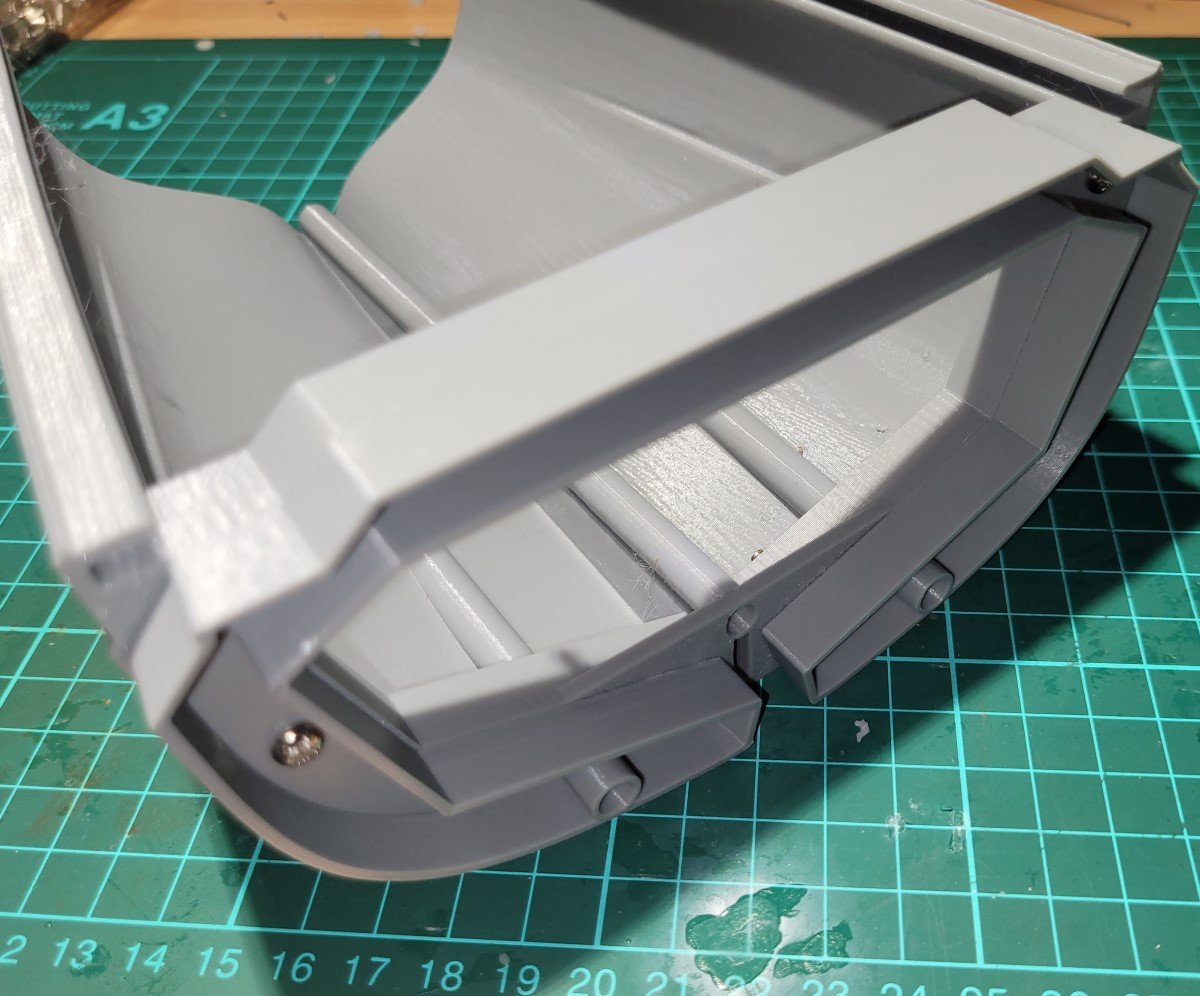

Hi Ian, A lot of work goes into designing the models so that they print well and look OK. This one will be a mix of resin and FDM prints so its a case of PETG where strength is needed (even though it looks stringy and rough) and Resin print where detail is needed. I printed the hull pieces at 0.3mm layer height so they don't look as good as they could but largely this will be covered with PLA deck veneers and filler/paint. The appearance could be improved by printing at 0.2mm but then your time for each section goes up. I think the longest one on this was 18 hours, but at 0.2 it was over 24. My easy solution to cutting my print times in half was to just build another MK3s One difference between the Tirpitz Model and this model is that the main deck structure is incorporated into the hull files. The Tirpitz model has a tendency to warp until all the deck plates are glued in. This one is rigid as anything and apart from one piece lifting slightly from the bed I haven't encountered too many issues. The turrets are already done, I just haven't detailed them yet. The mains have traverse and elevation, the secondaries just have traverse (considering elevation in the 150's but there is not much room in the turret). All up it will be around 30 servos. The bulkheads/joiners have large apertures in them so passing wiring should not be an issue. I did have an issue with one pair of 150's where the bulkhead is directly underneath it and while I put in relief for the turret into the bulkhead I did not put enough to actually fit the turret. (The servo, by necessity due to the turrets size, protrudes outside the turret basket.) I have since altered the bulkhead file but for this one a dremel was my friend. Mike

-

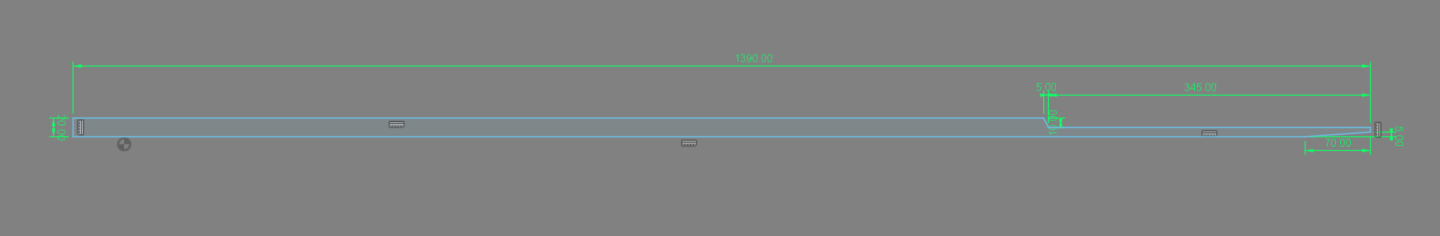

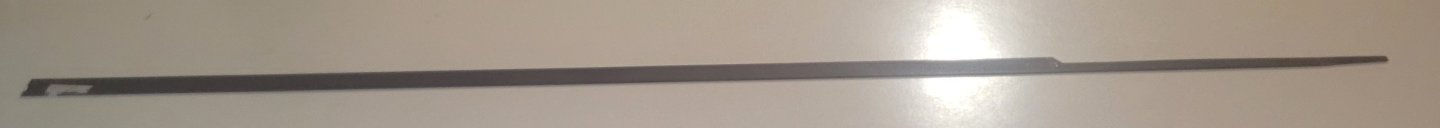

The keel stringer is a simple black steel M3X20mm flat bar with some angle grinder cuts to get the correct profile. Measurements of this are not critical. If its 5-10mm shorter or has the corners rounded to get a comfortable fit it is of little consequence. Weight is not an issue. This thing will need a ton of it to settle at the right level. Here is a pre-oxidised version of it:

-

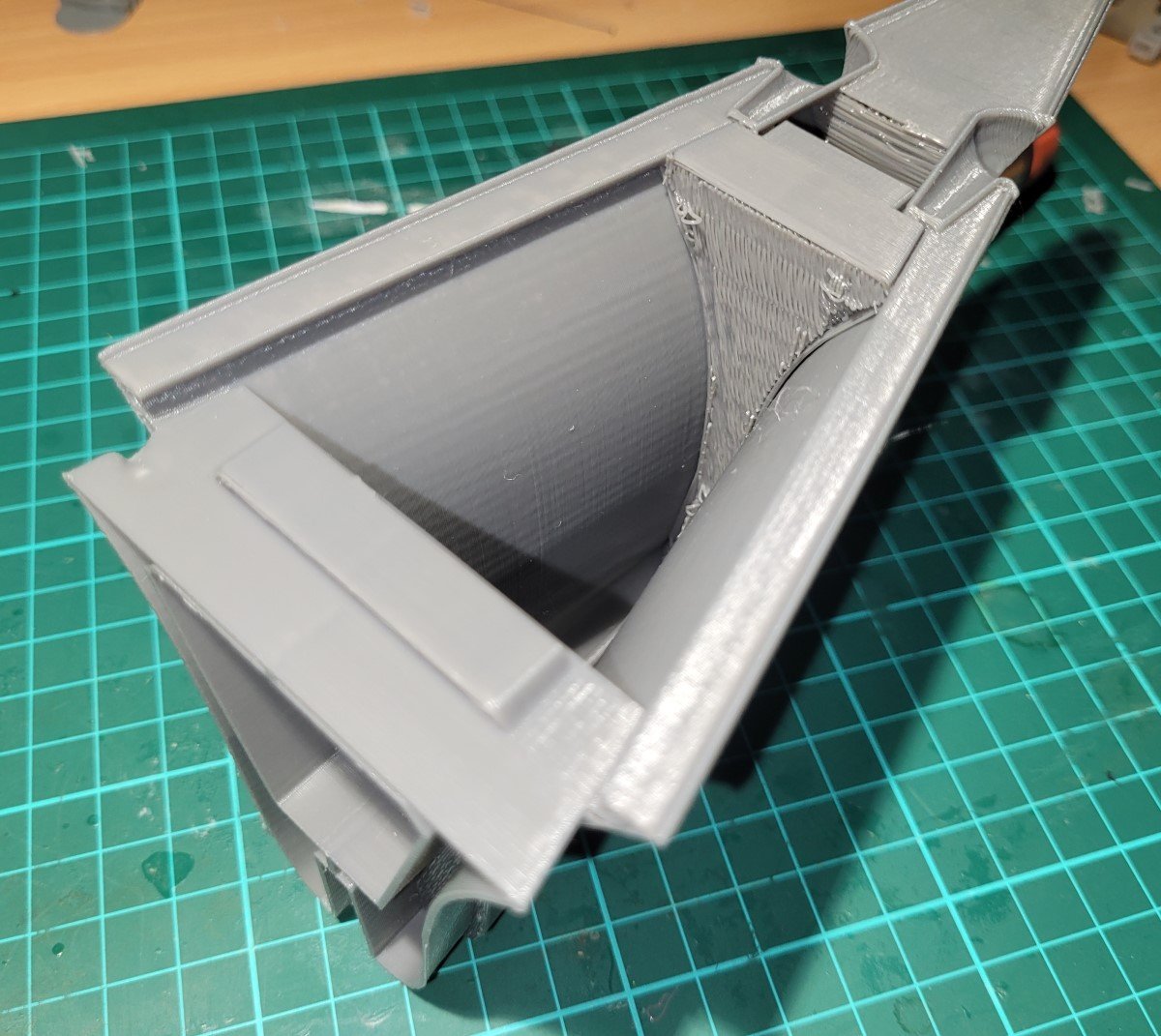

Hulls 4 and 5 were right at the extent of my printers bed in width so I elected to split the pieces with PrusaSlicer vertically using 1.75mm dowel joiners. There is steel keel stringer epoxied into a channel at the centreline when the hull is fully assembled so the chances of this join leaking when assembled is low. Hull 6 Bulkhead has an oil reservoir for the prop-shafts that will feed into the prop tubes which needs to be glued into position.

-

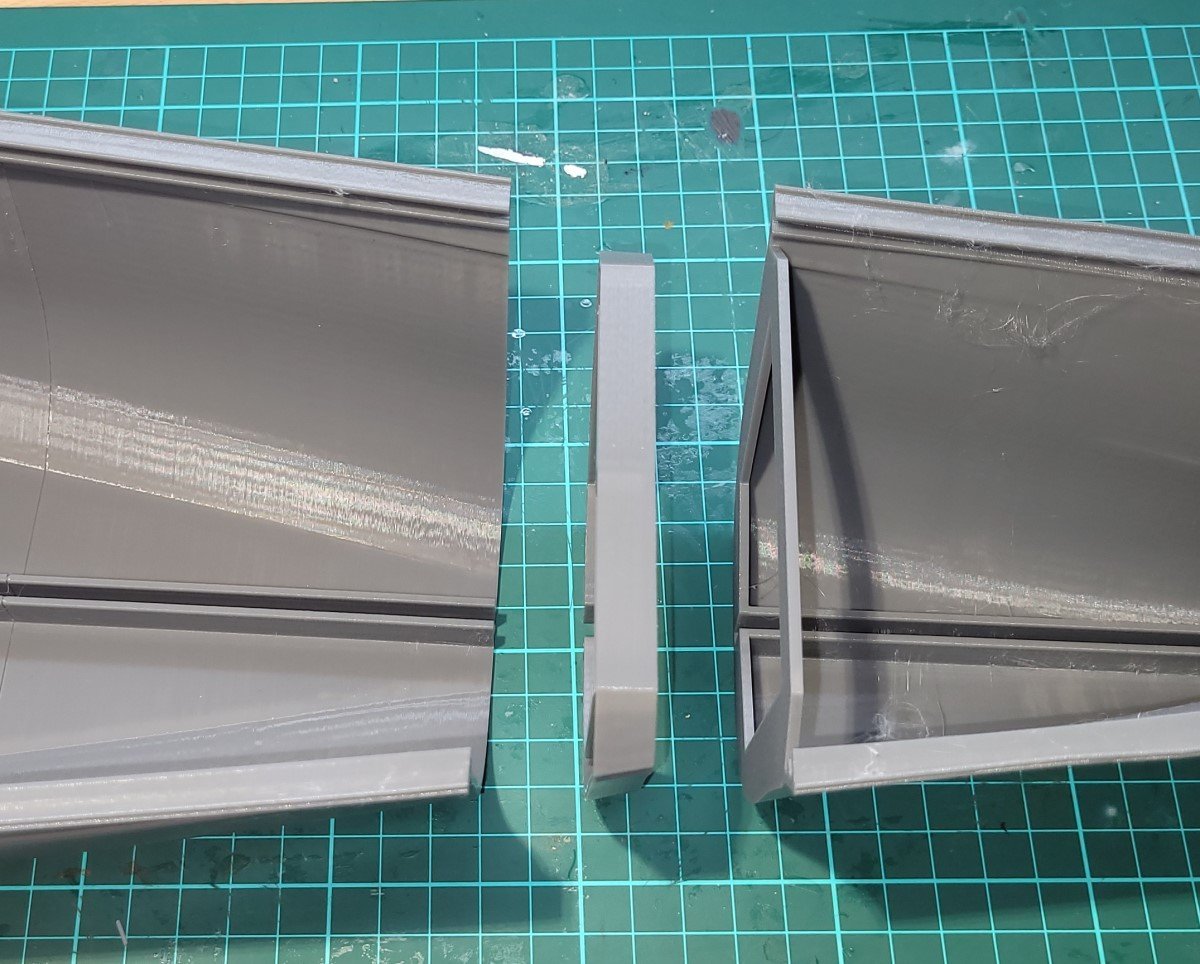

Hulls 4 and 5 are connected by a double sided joiner as the print direction on the hull pieces changes direction. The joiner is attached to Hull 5 with JB-Weld and aligned using the tabs printed into the hull piece.

-

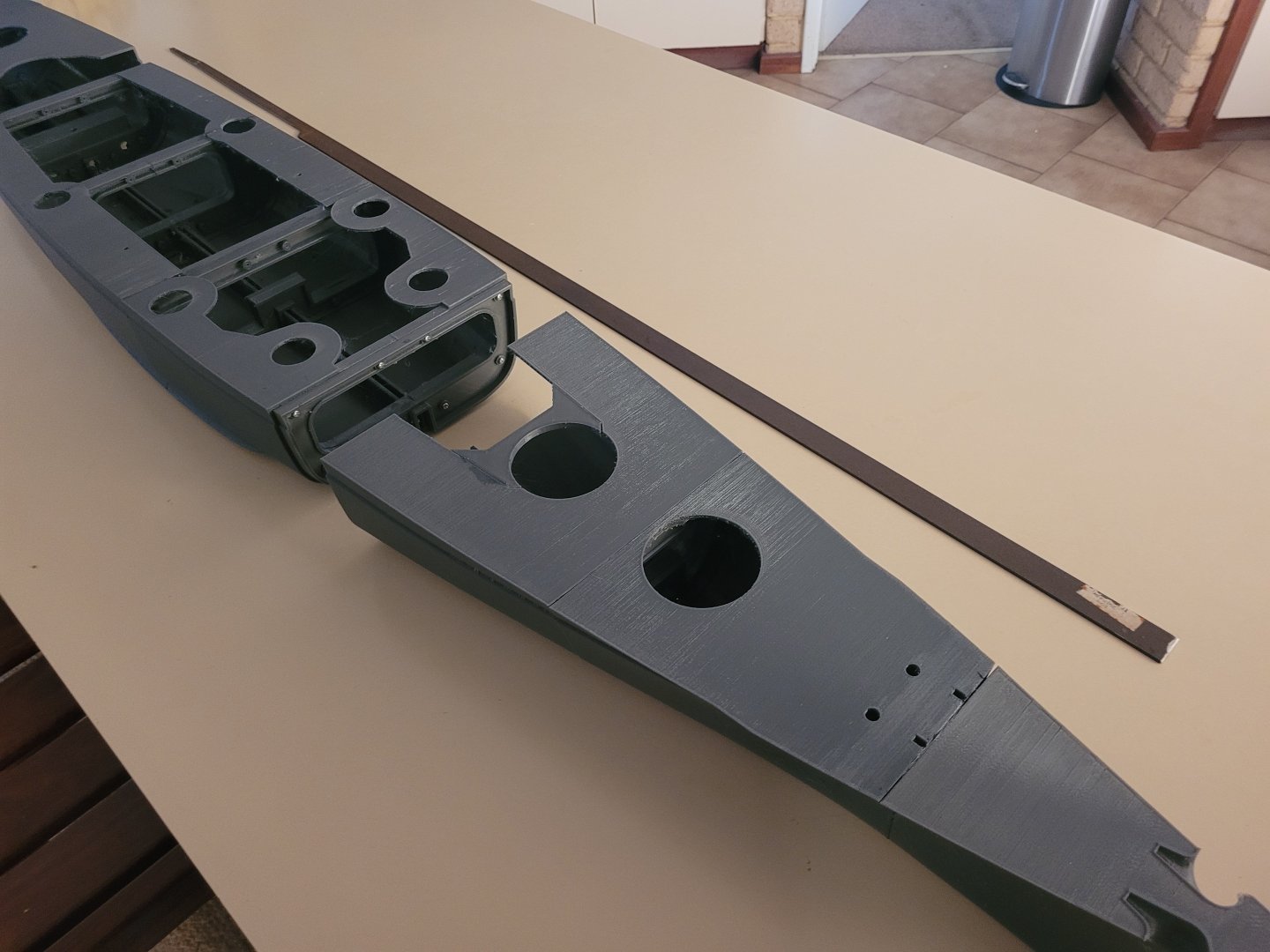

The hull is printed in PETG, I used a layer height of 0.3mm with organic supports on hull 1 and 8. I don't recall using supports on any of the other sections. The hull pieces are printed from the bulkhead upwards so there is no issue with build plate adhesion even though some parts taper out from the first layer (Like Hull 2 in the picture below) Hulls 1 and 8 are printed from the open end so there is a risk of instability due to the small amount of bed contact. I did have an issue with Hull 1 lifting slightly, you can see the gap when it is glued to hull 2. This is easily filled and the deck will be laminated with a detailed deck plate so should not visible going forward. Mating hull parts have a joiner that is attached to the bulkhead on one of the parts using JB Weld and M3X10mm machine screws. This is then JB Welded to the other part Etc etc..

-

Hi, It's been a while but I have been doing stuff since completing the Tirpitz model. Bismarck and Tirpitz are brother ships (German navy ships are male whereas most other navies ships are female so grammatically not a sister ship). So making a 150 Scale model of Bismarck should be no harder than upscaling the Tirpitz Model 133% and modifying a few parts right??? Wrong This is a complete re-design correcting some minor issues in the hull and making it more friendly for remote control use. 1:150 versus 1:200 doesn't sound like much of a difference. My wife is quite displeased. Where are you going to keep that?

-

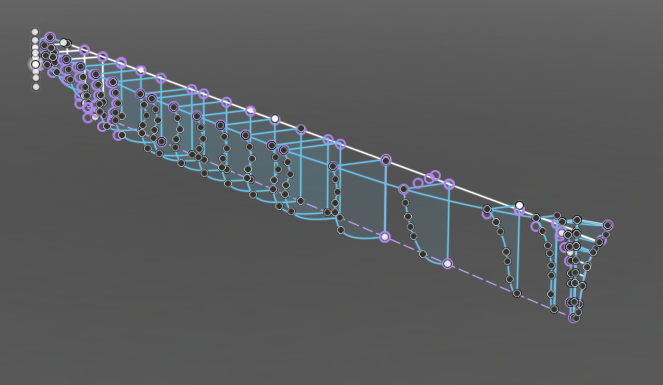

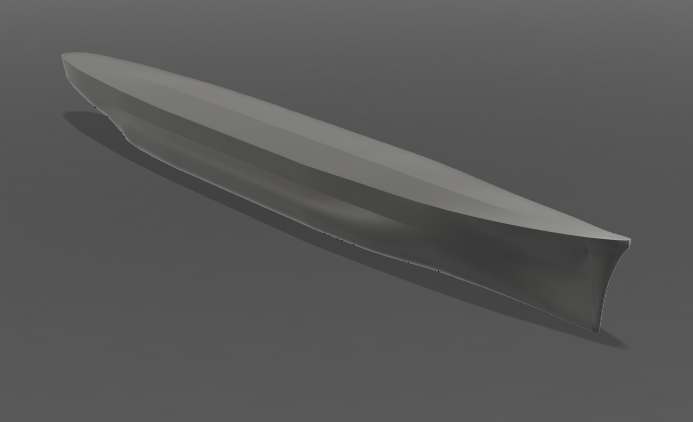

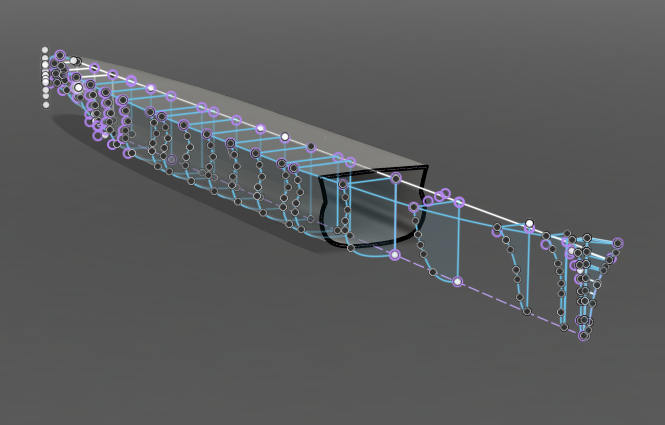

Hi, Whichever way works Having the hull line drawings is key. My preference is stem to stern lofting between the frames and using the hull lines as rails on the loft. The stem is a separate piece lofted from top to bottom. This creates a solid which can then be hollowed. The Tirpitz hull would simply not hollow so I resorted to modifying the frames to have an inner and outer profile and lofting the already hollowed hull. I would not recommend this method as it creates too many issues with mirrors and slicing later down the track. I'm doing a Prinz Eugen at the moment and am struggling with a lack of hull line details available. It appears a lot of the plans available are modellers interpretations of the hull outlines from 30 to 40 years ago. Prinz Eugen could not be hollowed from the last stern section forward (Fusion 360 had a hissy fit) so I sliced the model into 2 at origin and hollowed the 2 halves then joined them back together. So, this is the Prinz Eugen hull. It has largely been modelled from a reasonable plan and profile drawing and some very sketchy hull lines. You will note that there is not a ton of lines and to be honest, I could lose about half the centre frames without affecting the model. I prefer to let the lofting tools do the work and draw as little as possible but make sure that all the profiles connect correctly so the loft works better. So far I have about 20 hours invested in this, next we add the prop shafts, rudder, port holes etc then start work on the superstructure. Having said all that, I am not an expert by any means, more an interested amateur. So its basically whatever floats your boat Hope that helps some.

-

I didn't time them but it was not really appropriate. As I was designing the files virtually every one is print first one, test fit, check appearance, place in bin, adjust drawing and reprint. The parts were designed in 1/50 then rescaled to 1/200. The rescale has to then be adjusted to produce a printable part. Some detail is lost, other detail exaggerated to get it to print OK. When I am designing the files I tend to not have the luxury of being able to add lots of parts to the same print job, they tend to to be small jobs with one or 2 parts (remembering a lot of them go into the bin) Now that the parts are right, you can load the Resin printer with as many parts as can be fitted to the build plate as the print time is always the print time of the tallest part. That dramatically speeds things up a bit. Not so with the filament printer, extra parts means a longer print time. A straight up print with the current files would take around 2 weeks on 2 printers (One Filament, one Resin), around 1.5kg of filament and 2 kg of resin.

-

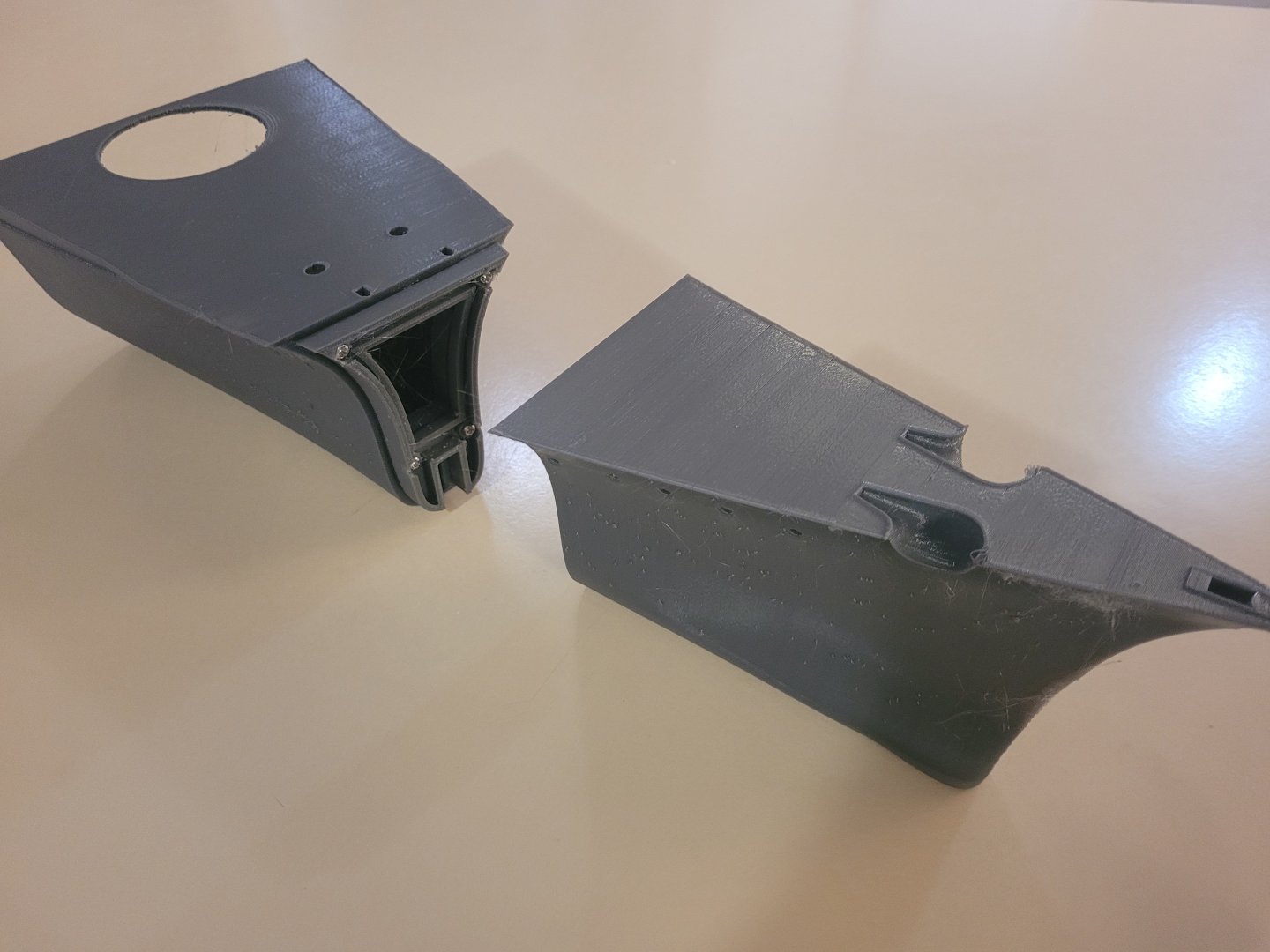

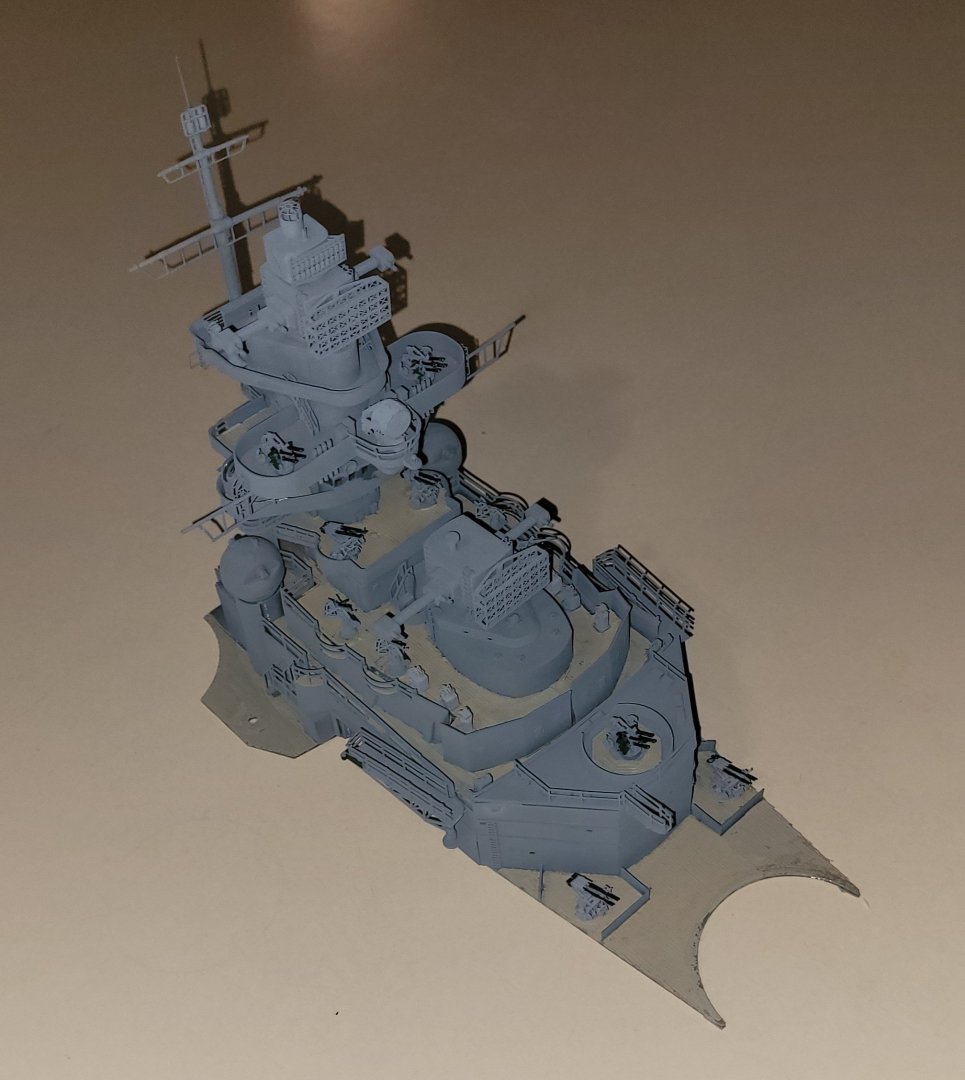

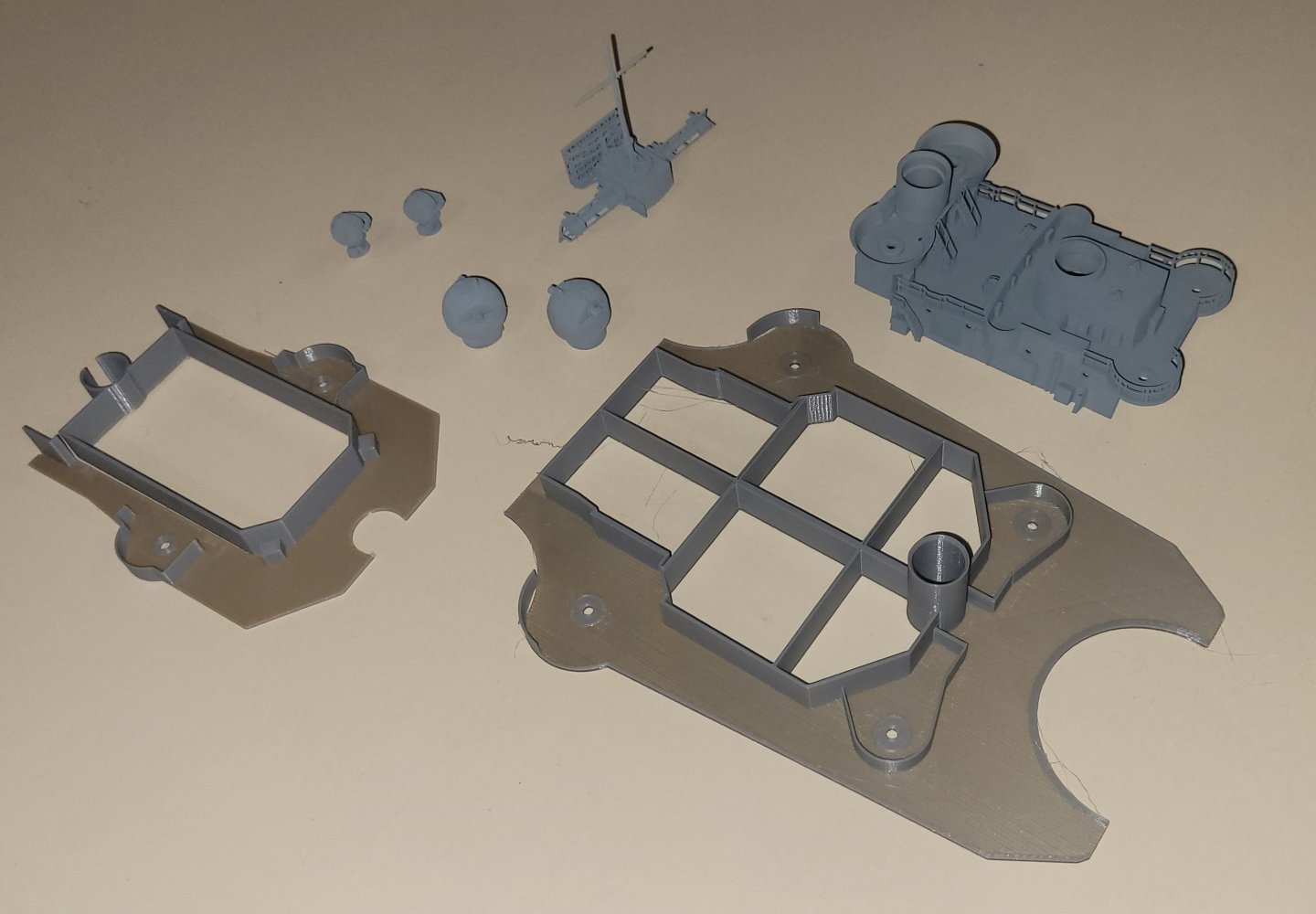

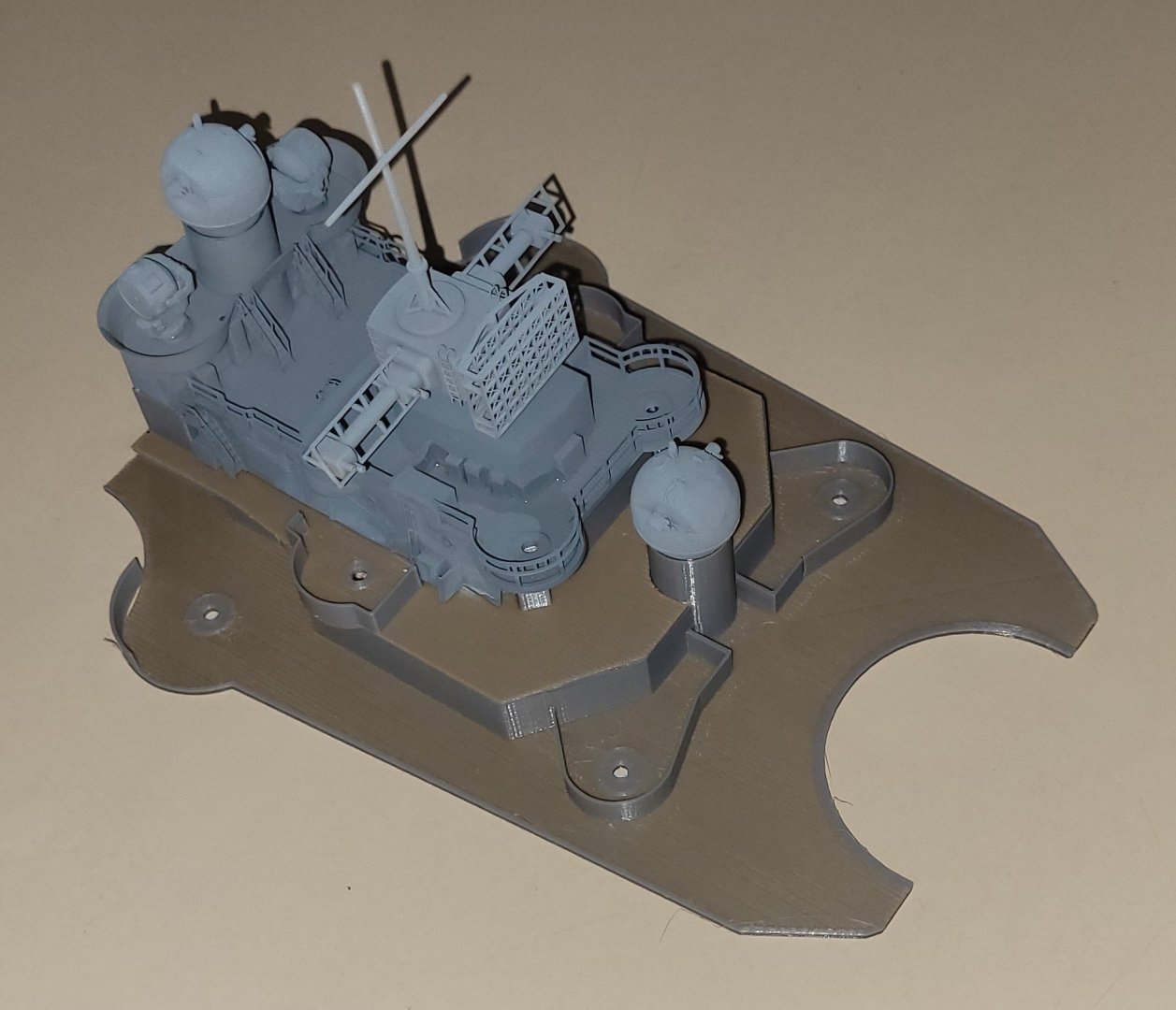

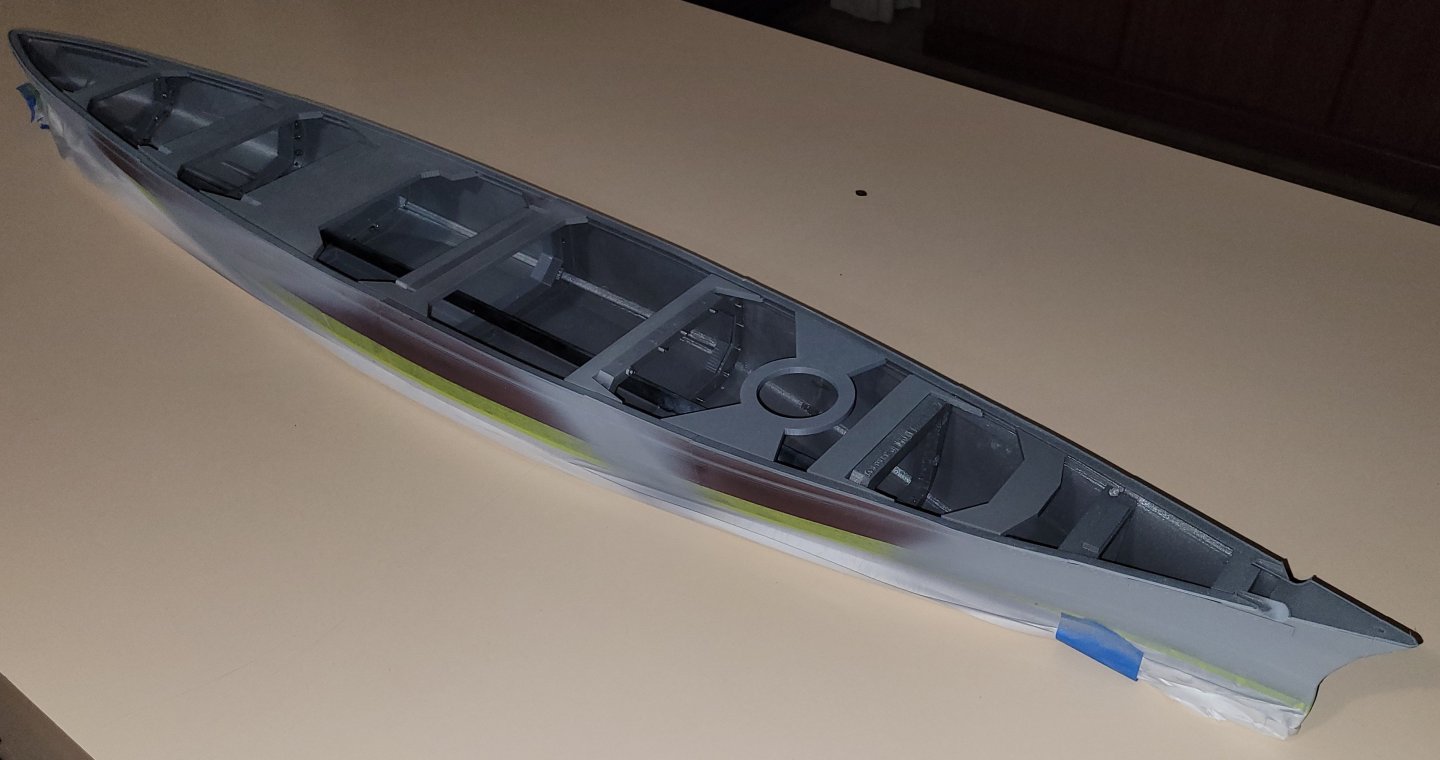

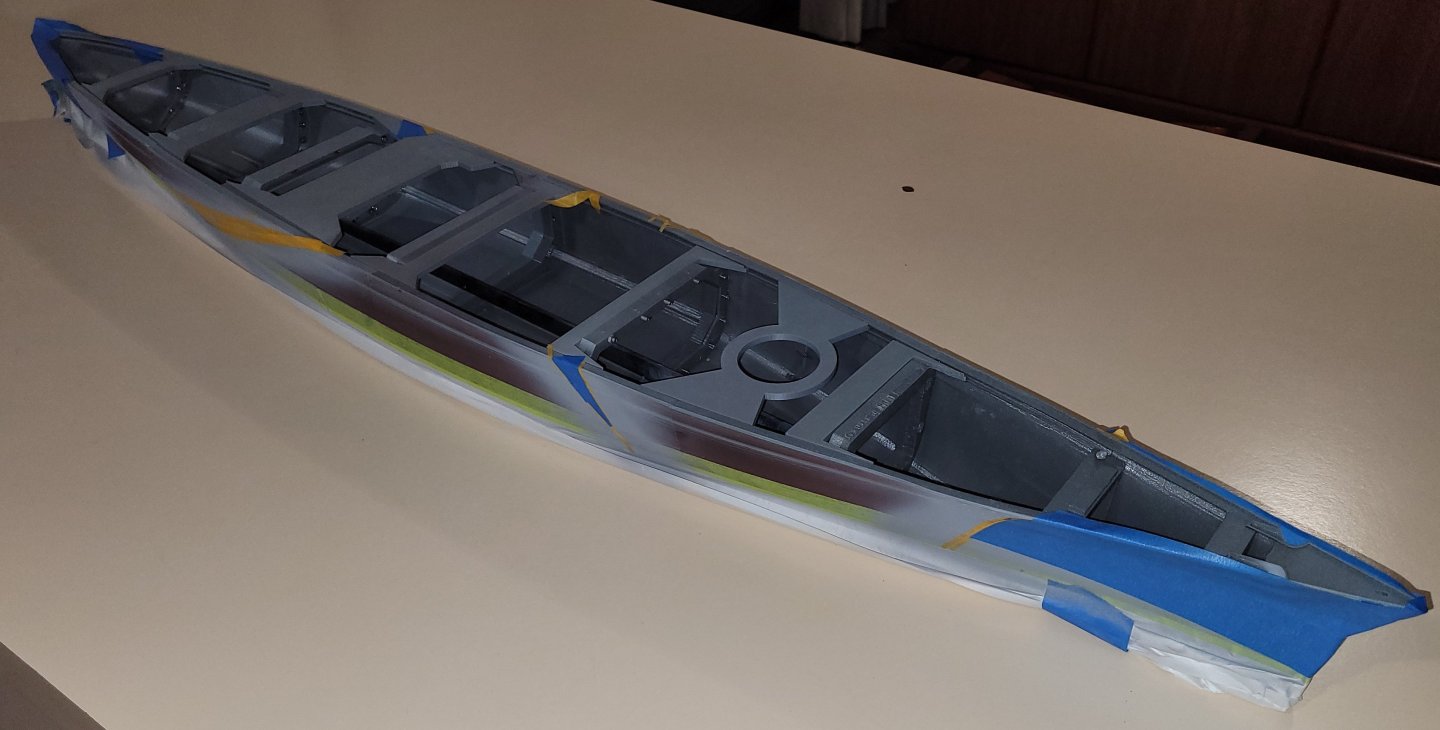

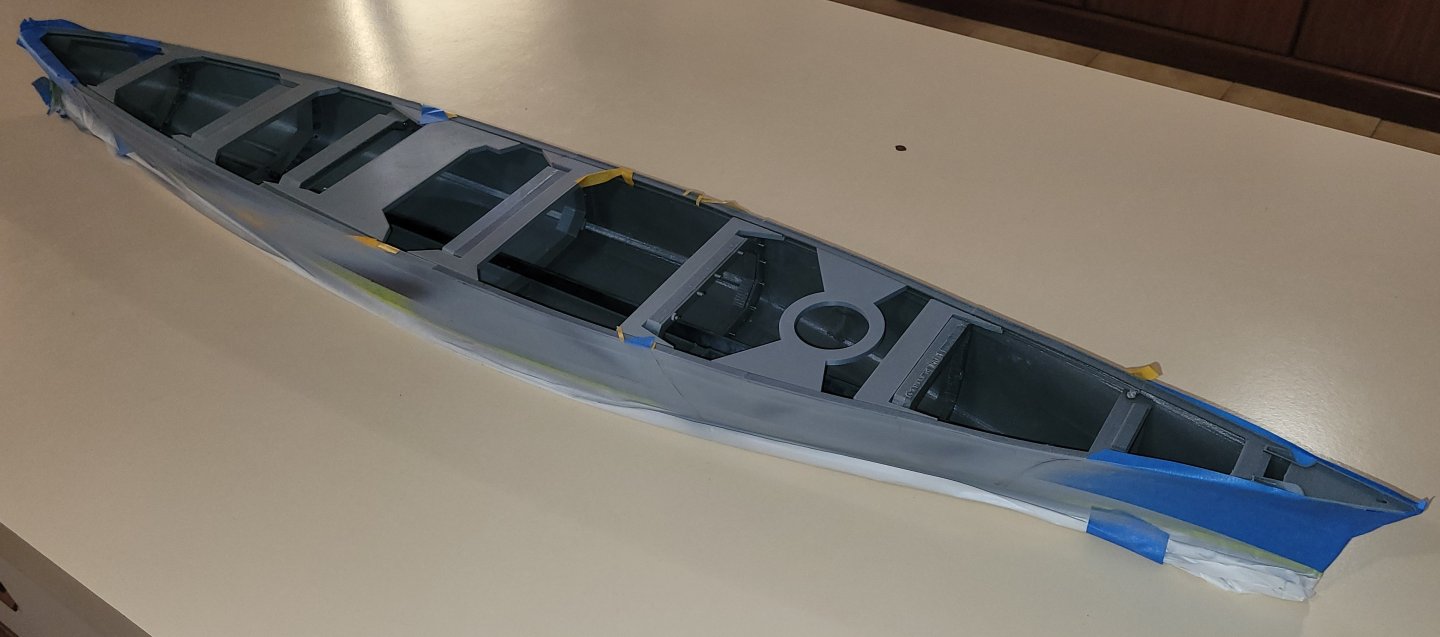

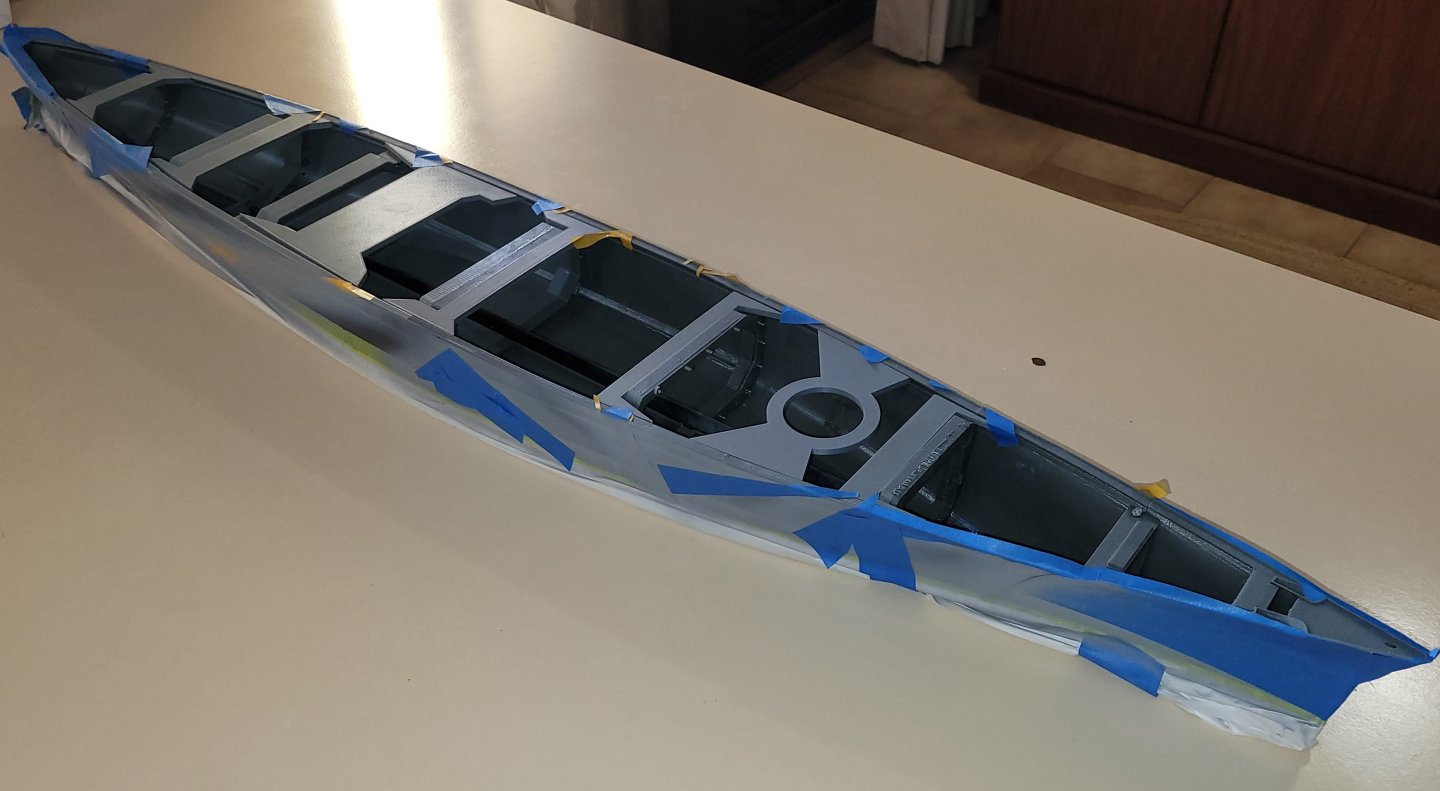

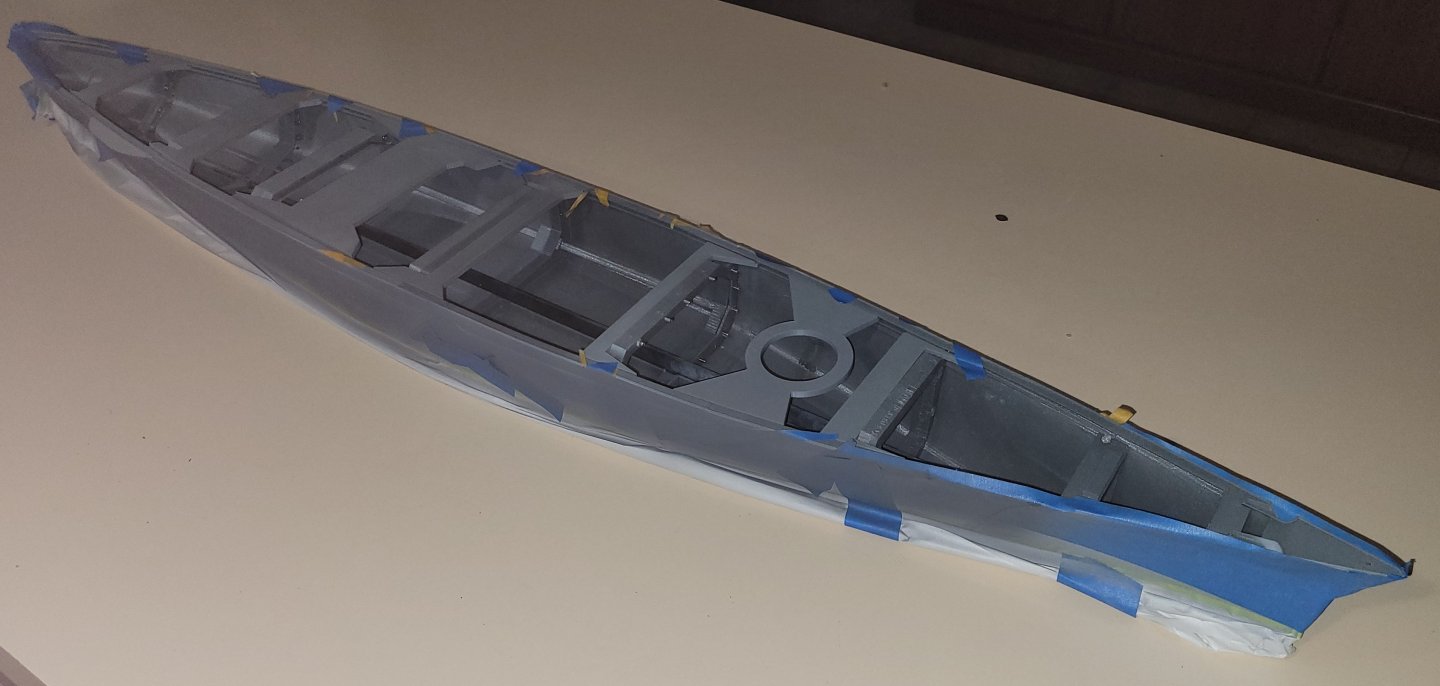

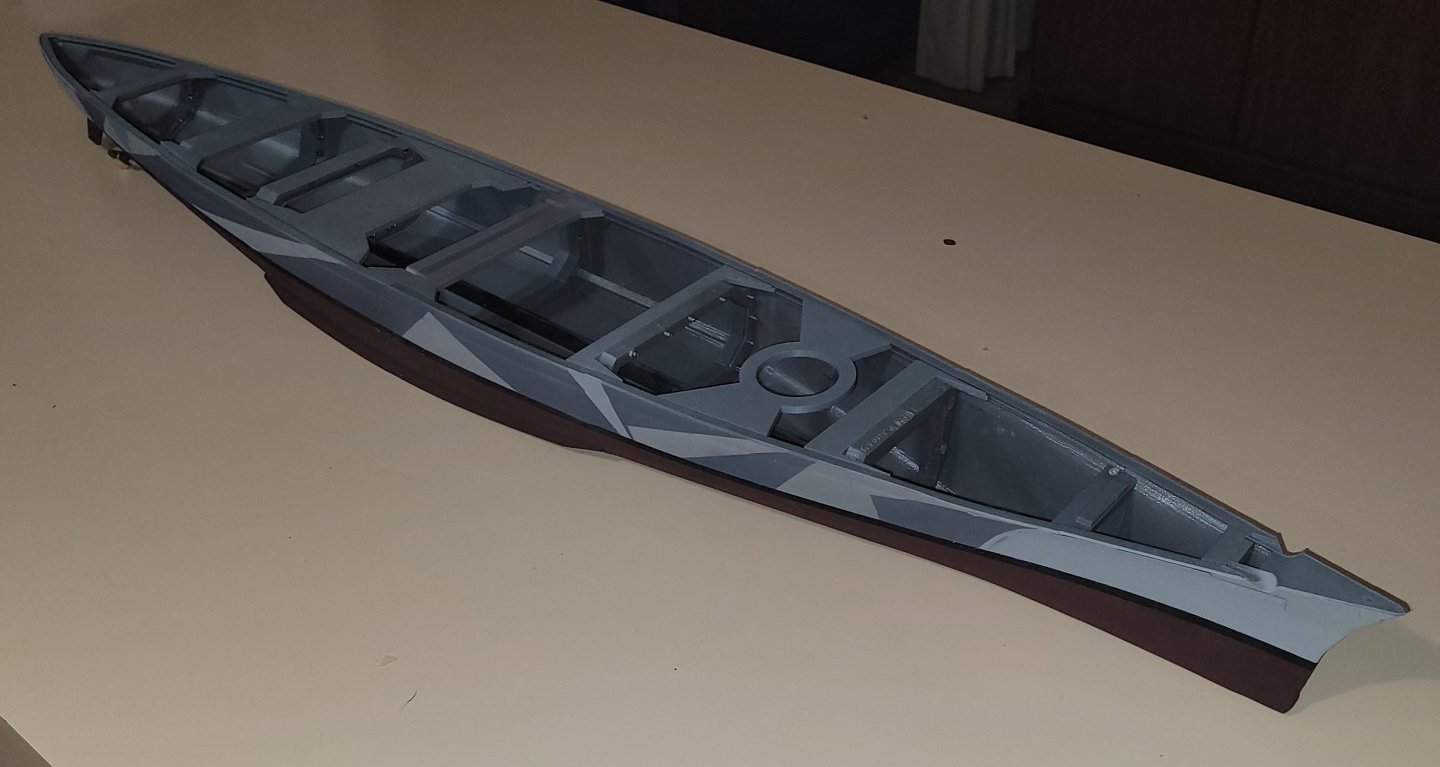

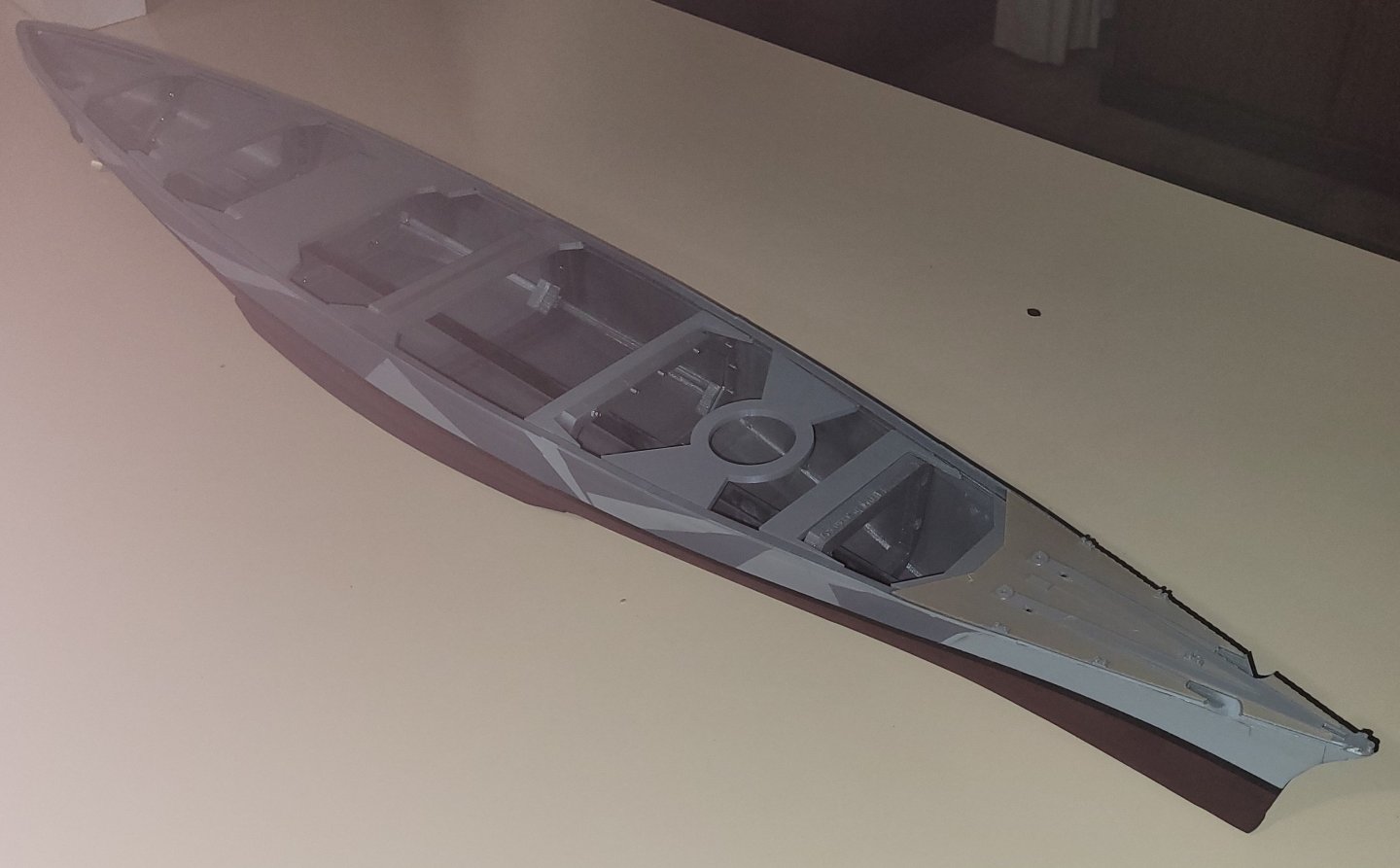

Basically, the model is done in four parts. Hull Rear control superstructure Hangar Deck superstructure Forward control Superstructure The hull is assembled after a bit of adjustment and some sanding and reinforcing steel bar added to the keel for support, I finally have a hull ready to go. Cross members and deck supports added to hull. First touch of paint is for the waterline stripe. Just a touch of black covering at least the required area: Then a careful application of masking for the waterline: Then a shot of red anti-foul: Mask of the red, don't need to be very careful here as I just masked onto the previous black masking. First gray tone: Then mask the bits I want to keep: Second gray tone: Then mask the bits of that I want to keep: Finally shoot the last gray tone: Then finally I can unmask it and see what I have: Glue in the first deck plate: Then the second piece and so on until they are all in place:

-

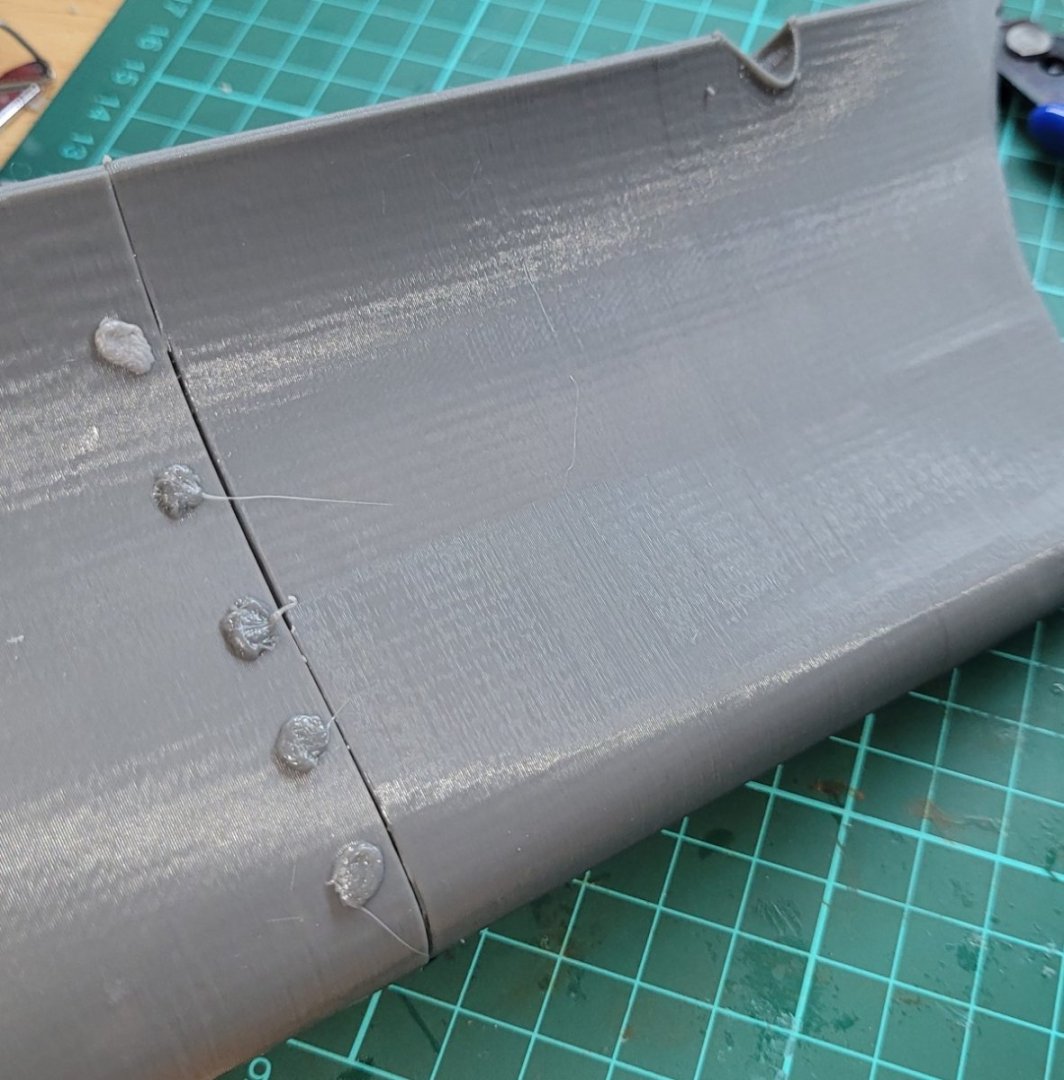

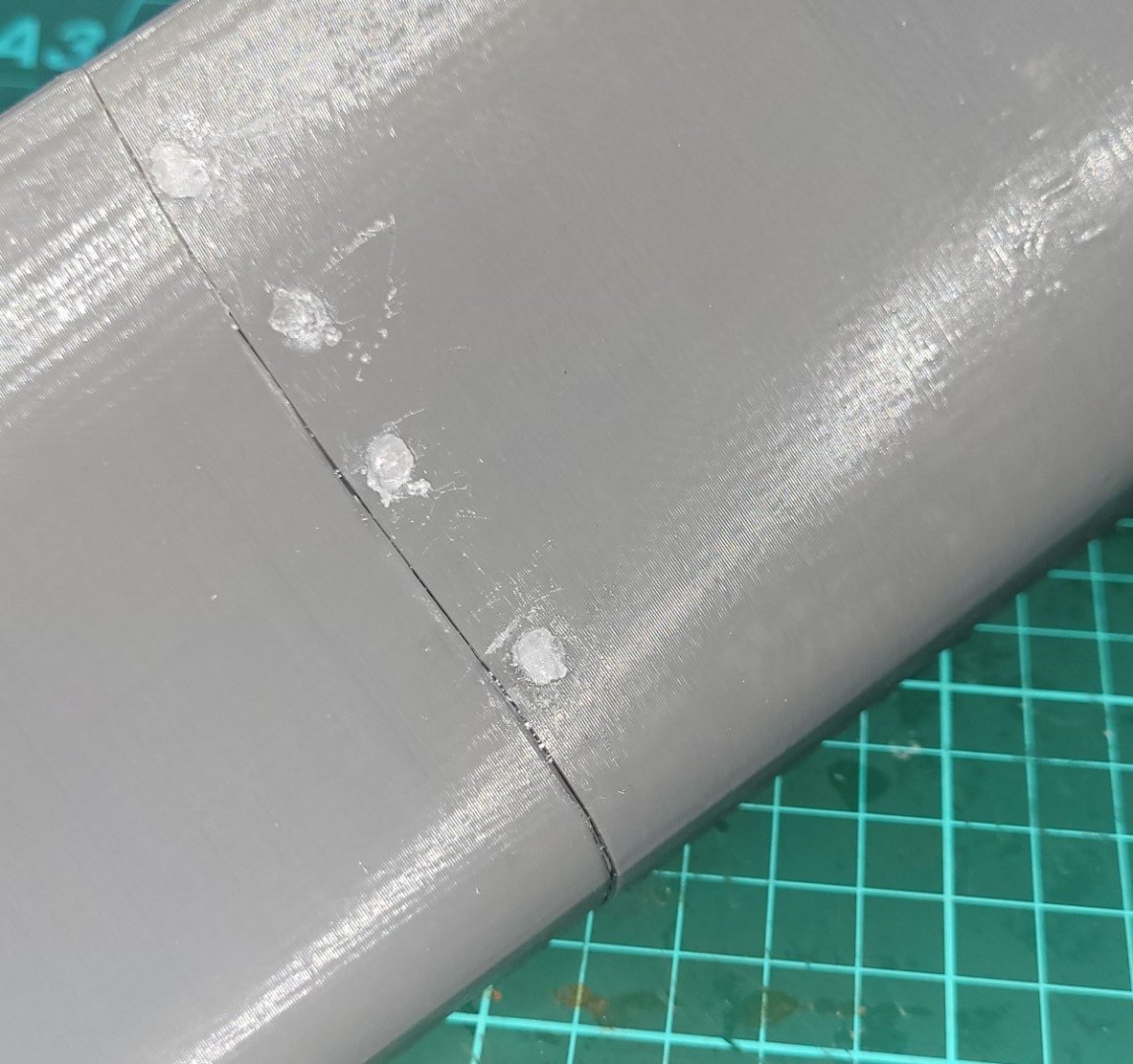

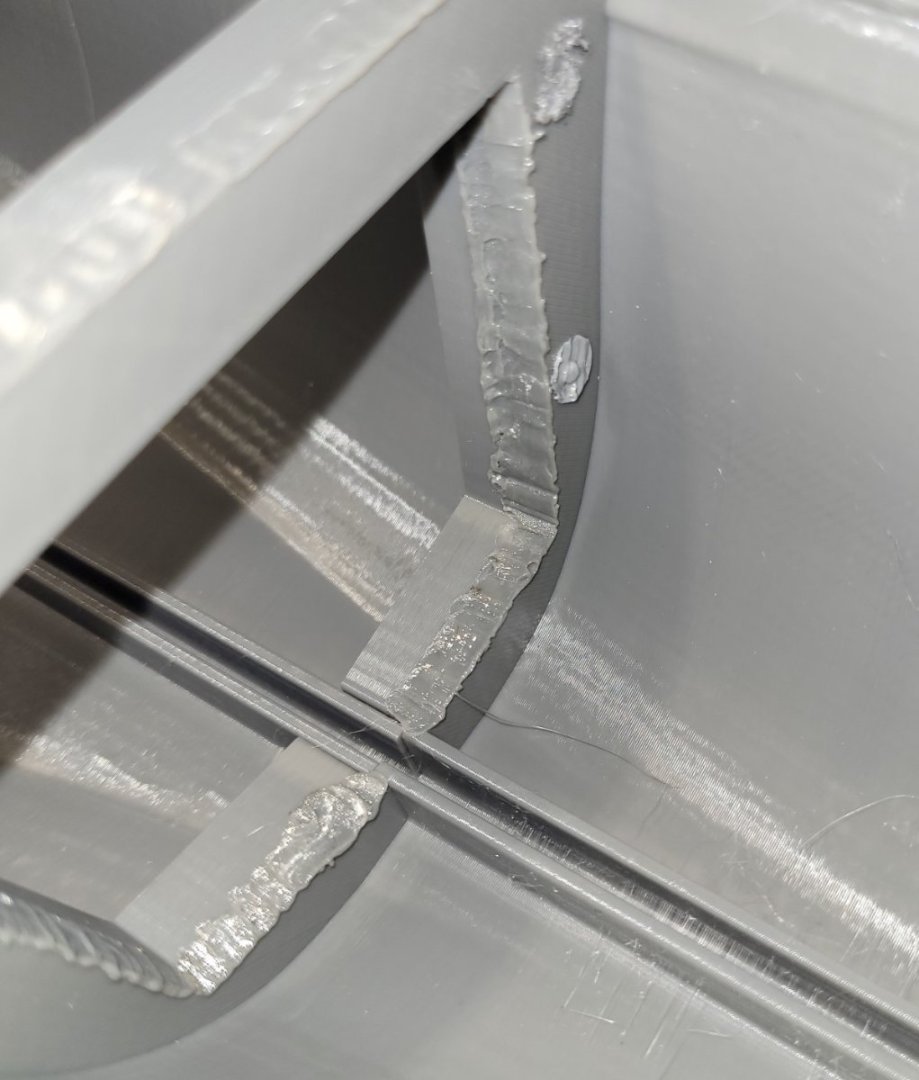

Hull welded rivets: Cover the interface joiner with Epoxy Resin and assemble the 2 parts to be joined. Align the parts as best as possible and drill a 2-3mm hole through the outer hull and the joiner wall: I use a 3D pen to then flood the hole with melted filament. Slight pressure can be applied where appropriate during application to get a better alignment of the 2 hull surfaces. "Rivets" can then be trimmed with flush cutters and join is ready for final seal with epoxy before final sanding/sealing/painting. These 2 pieces were the experimental parts with the joiner printed directly with the hull piece, the poor quality of the join is obvious but should fill reasonably well.

-

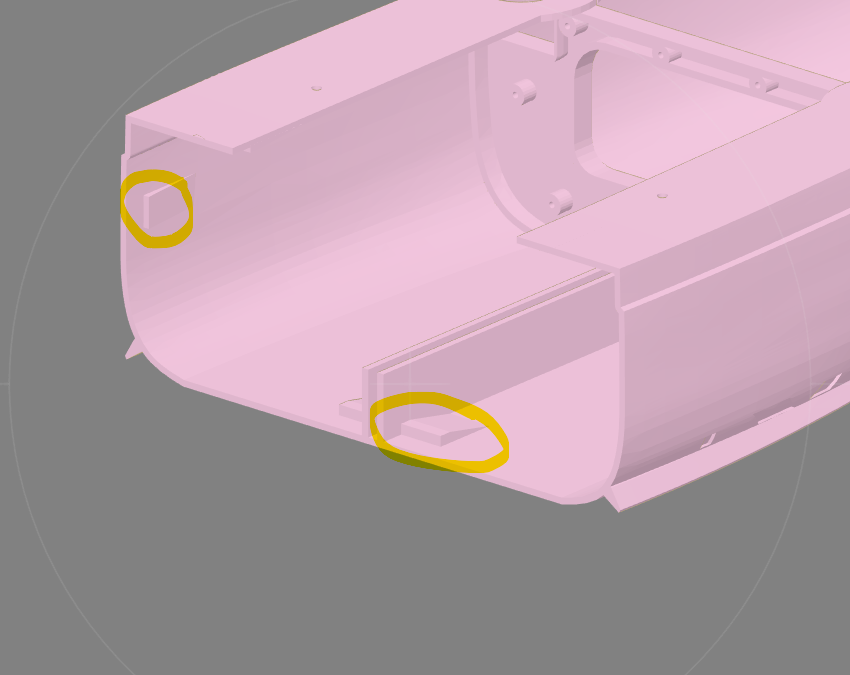

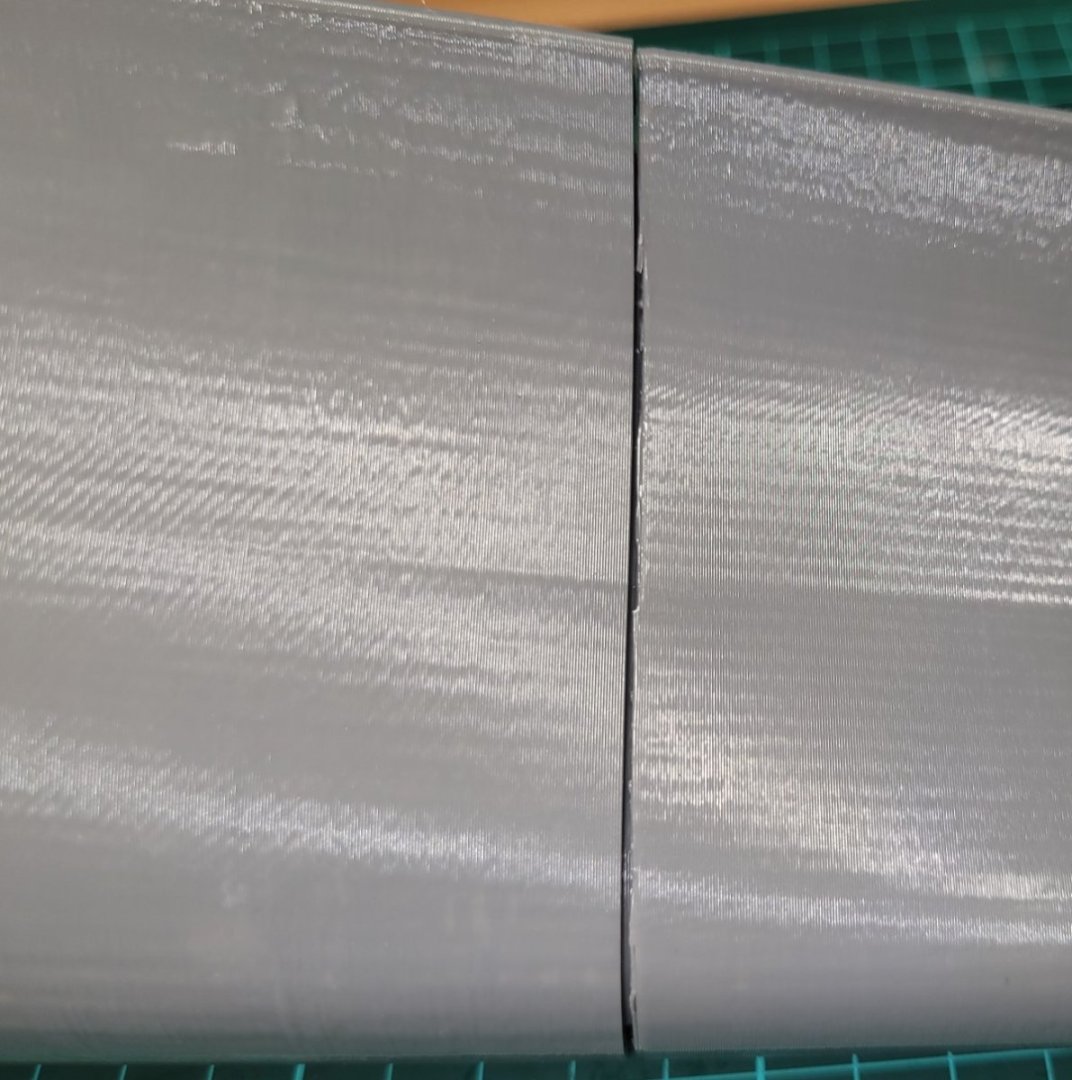

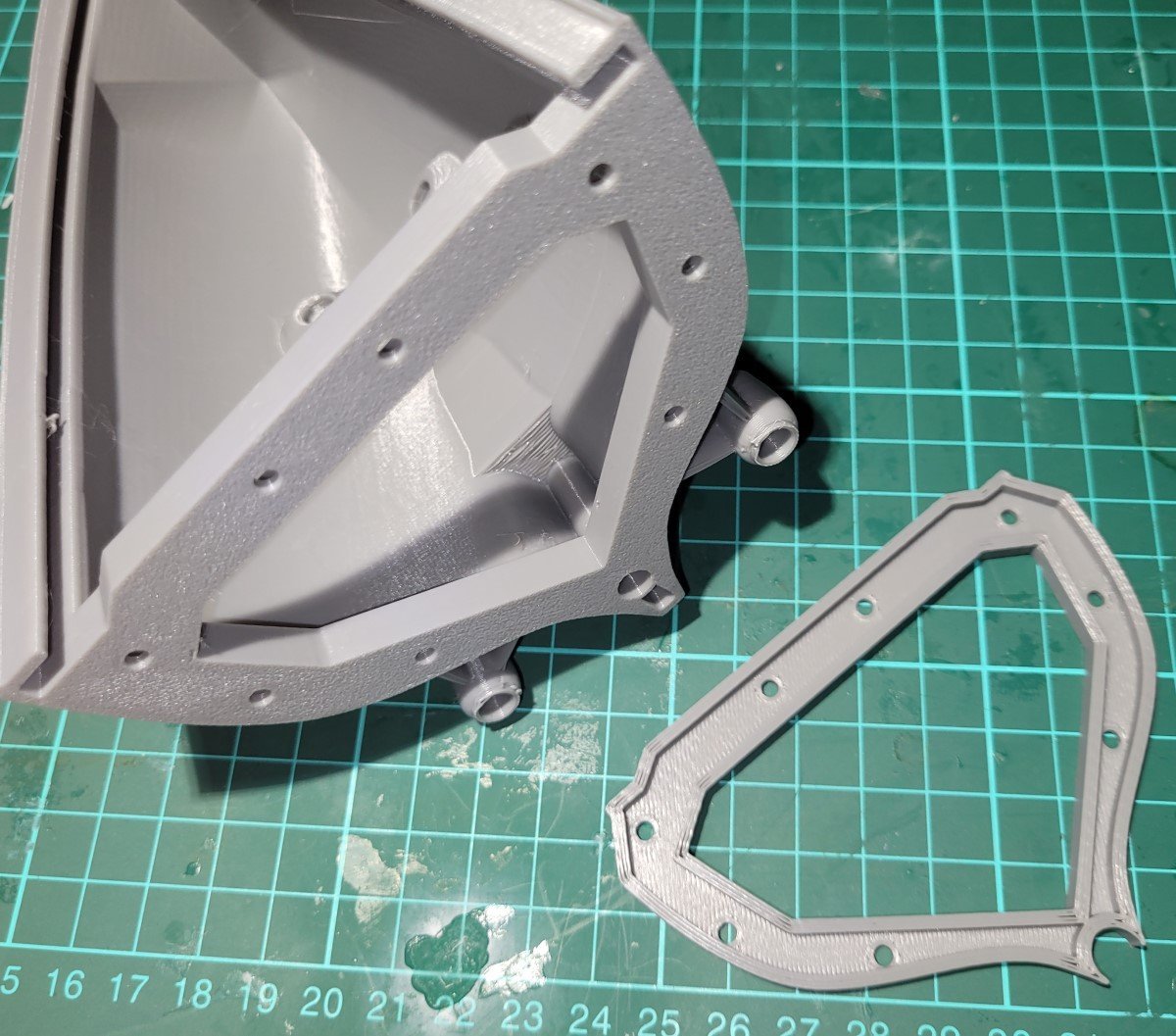

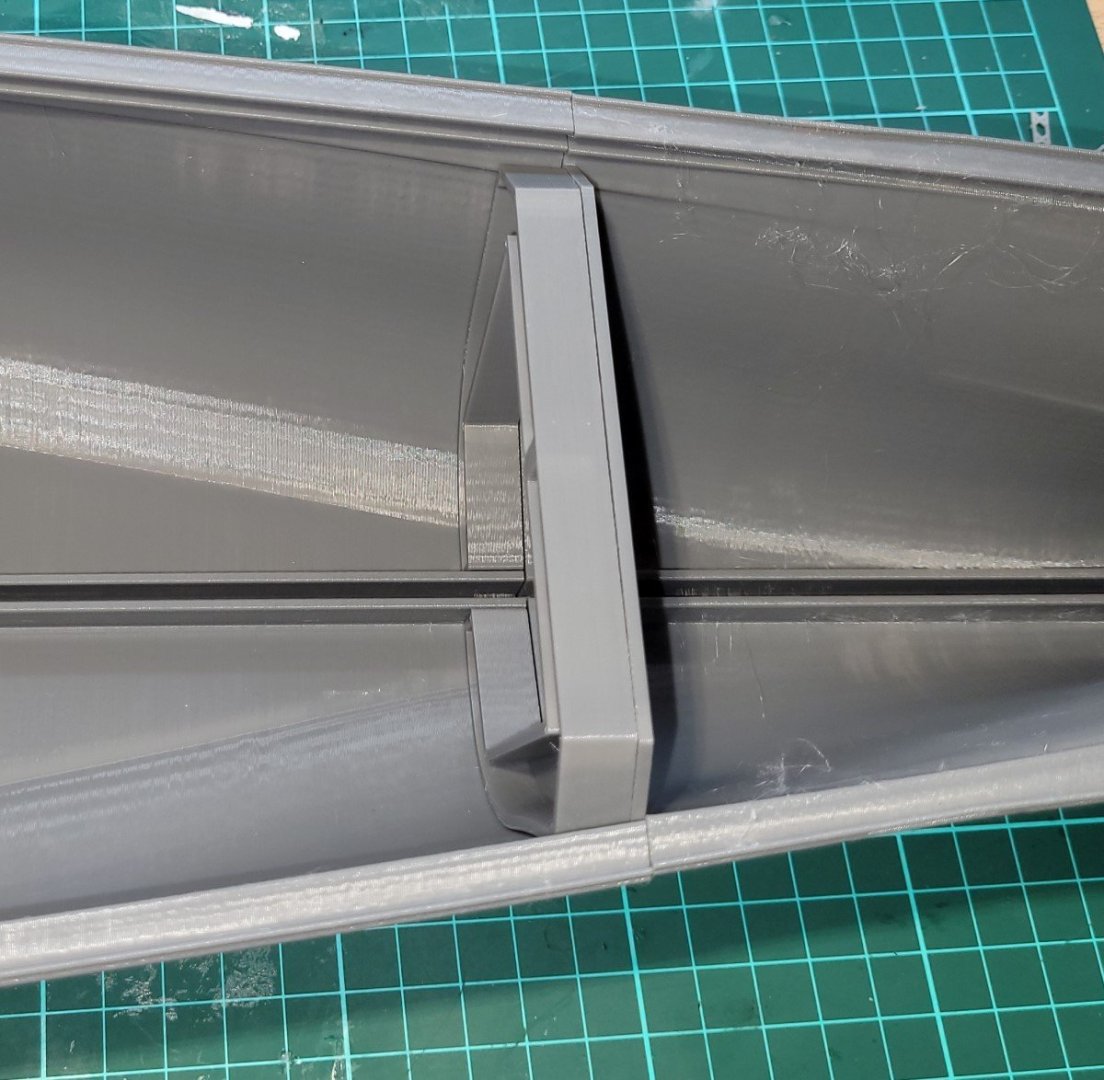

So, for the last week I have been trying different methods of joining the hull sections to make assembly as simple as possible. While the original method works fine, it is a bit fiddly getting all the parts to line up perfectly so I have been searching for a better method. First I tried printing the Interface directly onto the bulkhead hull section. This requires extra supports while printing the part and does not produce a really good seam between the two parts when connected: Then I tried printing the joining holes on both the bulkhead and the interface to allow them to be lined up easily. I also beefed up the bulkhead to provide extra support: This provides a much better join line between the two hull pieces. This is also the easiest method of assembly by quite a ways. Your print the 2 hull parts and the interface, super glue and screw the interface to the bulk head using the holes and some kebab sticks to keep everything lined up, then the hull section snap locks onto the interface and is mostly self supporting. Reinforce the join with epoxy resin on the interface and welded rivets between the hull and interface. This works with the original hull parts as well, but is easier on the revised hull parts as the holes on the interface and bulkhead parts are pre-printed.

-

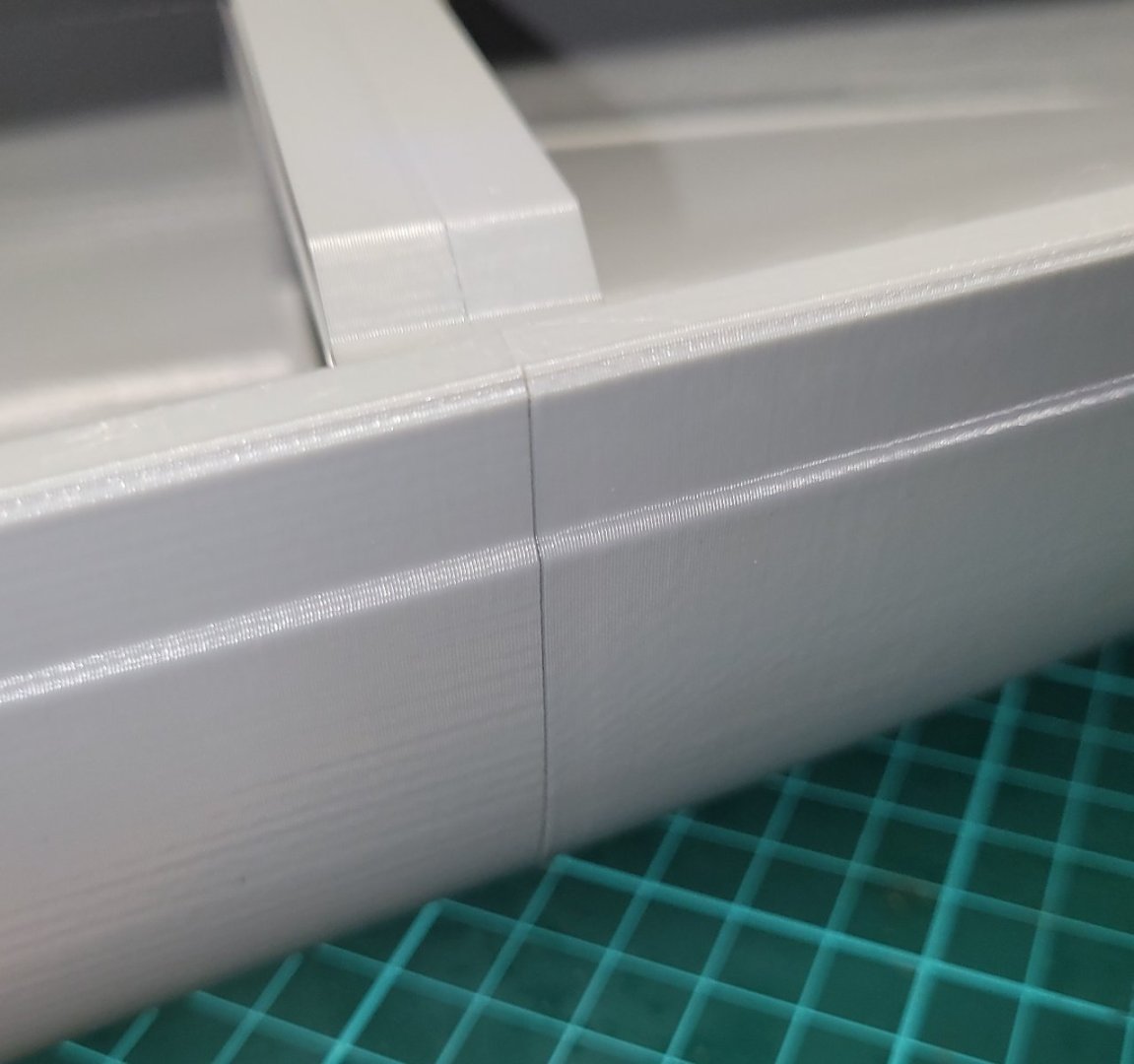

Next is the hull. The hull parts will keep your printer going for some time. I print them at 0.25mm layer height for all layers with a 0.4mm nozzle. You could go a bit coarser to reduce time, but I haven't got much else on (Said no-one..ever) The hull sections comprise 2 sections and an interface part in the current design. It occurs to me that the interface could simply be printed directly onto the bearing part to reduce effort, I will investigate this. Dry fit the 2 hull parts together and insert the interface. It is handed to follow the contour of the part being joined, but typically the hollowed section faces away from the join surface: Once happy with the fit, remove the interface and apply enough cyanoacetate cement and re-install the interface firmly to it to the part with the bulkhead. Don't get glue onto the hull part being joined as we want to remove it to reinforce the interface join. Hold parts together liberally with masking tape and pegs/clamps etc. When set, separate the now hopefully 2 parts and reinforce the join with soldering iron welding to fuse seams along with holes drilled through the bulkhead to create "rivets" where appropriate to strengthen the join. Once complete, the 2 parts can now be permanently joined with glue, more rivets through the hull side into the interface join and sealing compound on the interface seam with the bulkhead part to keep things nice and dry. The channel at the bottom of the hull is for a 20mmX3mm steel flat bar that runs the length of the hull to give it a bit more longitudinal strength. This bar has a cut-out towards the stern to accommodate the center propeller shaft. It does not have to be tight-tight, if you have problems inserting the bar into the propeller section, trim the bar appropriately (and with safety gear of course) to get a comfortable fit (the steel flat bar into the hull, not the safety gear :-<). There are extra channels along the hull at deck level to add further re-enforcing as deemed fit.

-

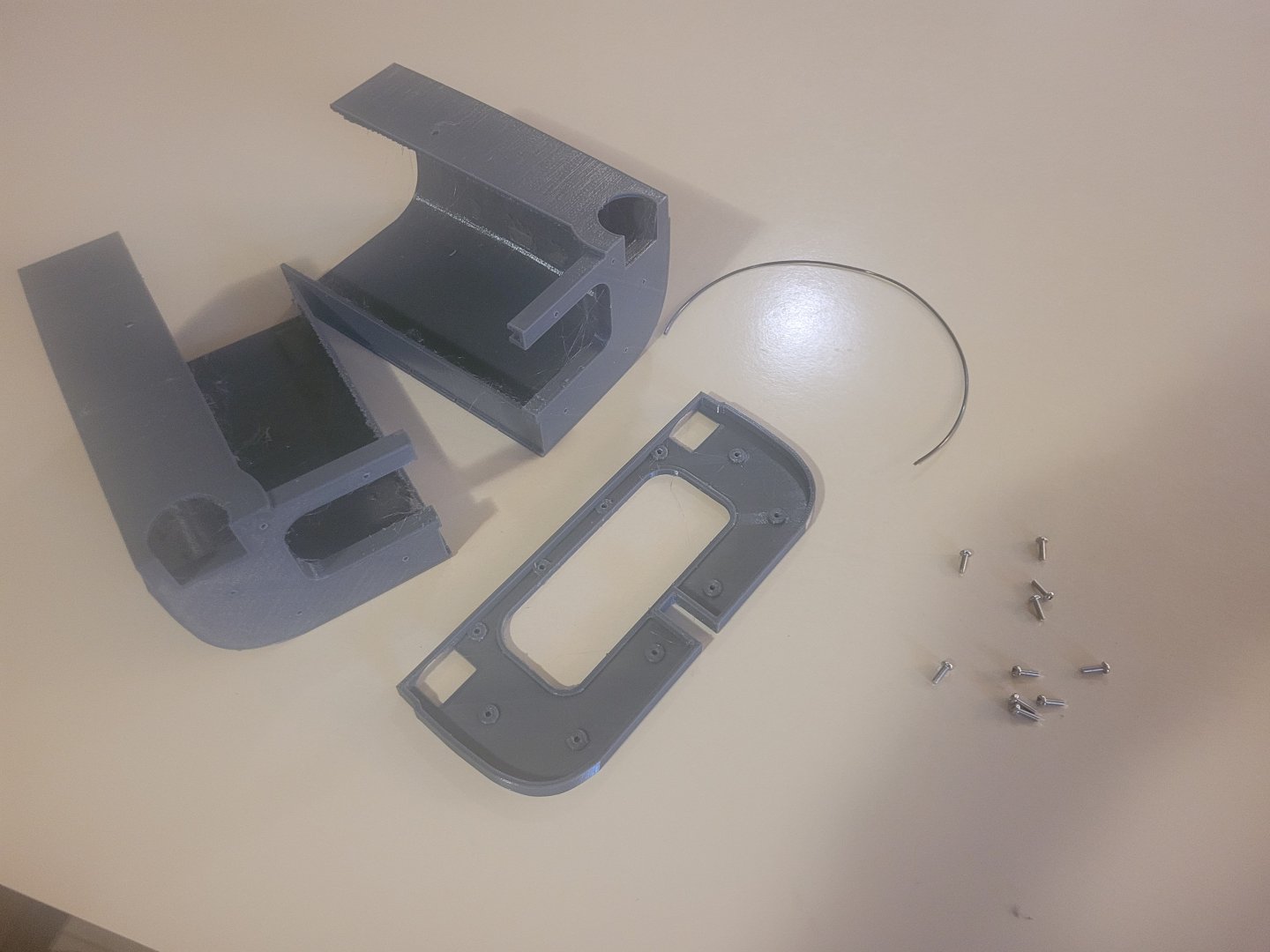

So, we will start with the stand. Fairly simple sort of affair, print out the bits and they just clip together. Files included for Bismarck and Tirpitz, just not sure of the Bismarck Name plate. Fonts... Whatever. Nameplates are printed with a filament change from black to 4.45 mm then a swap to gold silk filament for the remainder. I printed these in PLA with an initial layer of 0.25mm and following layers of 0.15mm, but this could be increased to 0.25mm for speed if required. The stand ends are handed. One end is for the bow, the other is for the stern. The name plate and name plate support orientation can be switched to allow for display in either direction.

-

No great objections. So it begins.. I have published the build files for this project here. I have worked on and off 1/200 scale models of Bismarck and Tirpitz over the last 30 years. I have completed a 1/200 Hatchette Bismarck, a Scratchbuilt 1/200 RC Tirpitz in MDF and Cardboard (Yes...MDF), and am currently working on this 3D printed version. I started this model based only on FDM printing, but after some time realised that I could not get the level of detail required with FDM alone so started shifting parts to SLA resin printing. This model is therefore, a hybrid SLA FDM 3D printed model. Equipment used is, but not limited to,2 Prusa MK3S printers, both Bears modified and one with the extended Z Axis height, a Protech RPE1 Resin printer and an Creality Wash and Cure station for Resin printing. I also have an assortment of cutters, sanding medium, Air brushes and Dremel tools along with various other bits of hobby grade tools and equipment. Nothing too fancy (apart from possibly waaay too many 3D printers, you could probably get by with just 1 FDM printer) I have access to Laser cutters, CNC routers and lathes and a full custom PCB Lab with photo etch facilities and an SMD pick and place robot, but these are a bit excessive and will not be used with this model. I think.. maybe the Photo Etch facility, but I will try not too.

-

Hi, I am not sure if this is a scratch build or a kit. Since I am the creator of the files used in building this model, I suppose it is scratch built, but as the files are available for purchase, it could be considered a kit. Unless told otherwise, I will proceed on the basis of scratch built and will wait a a day or two before proceeding for input.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.