Iro

Members-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Iro

-

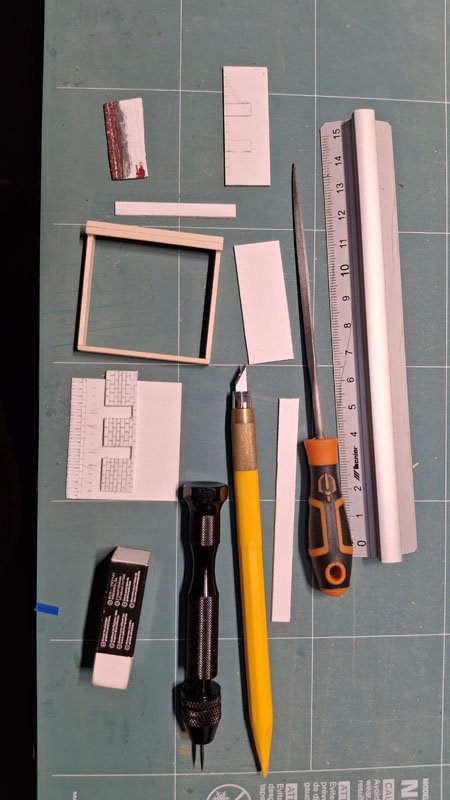

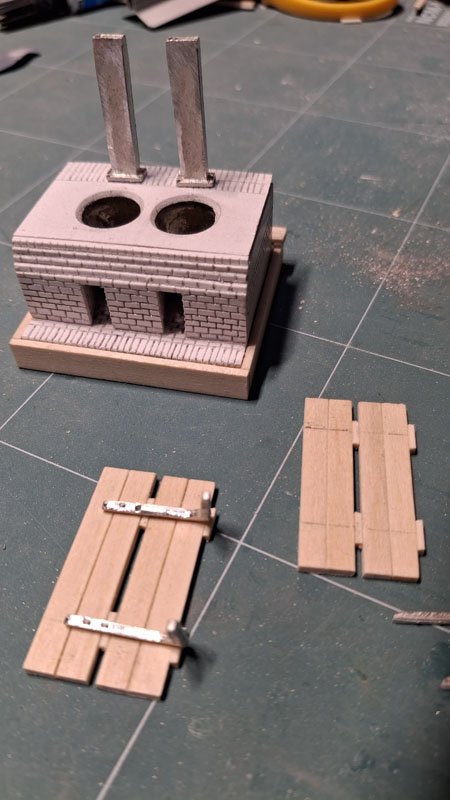

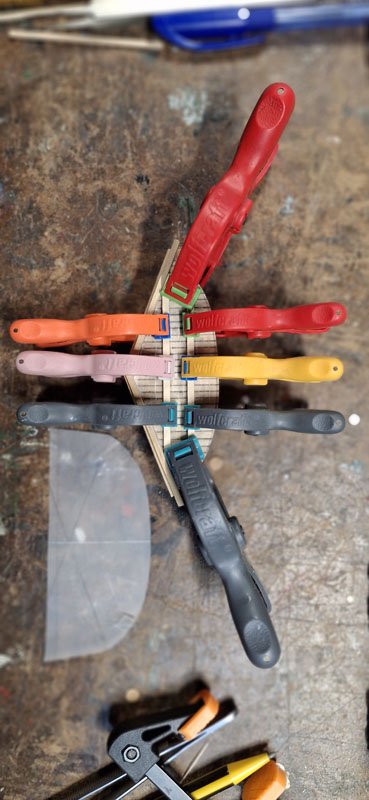

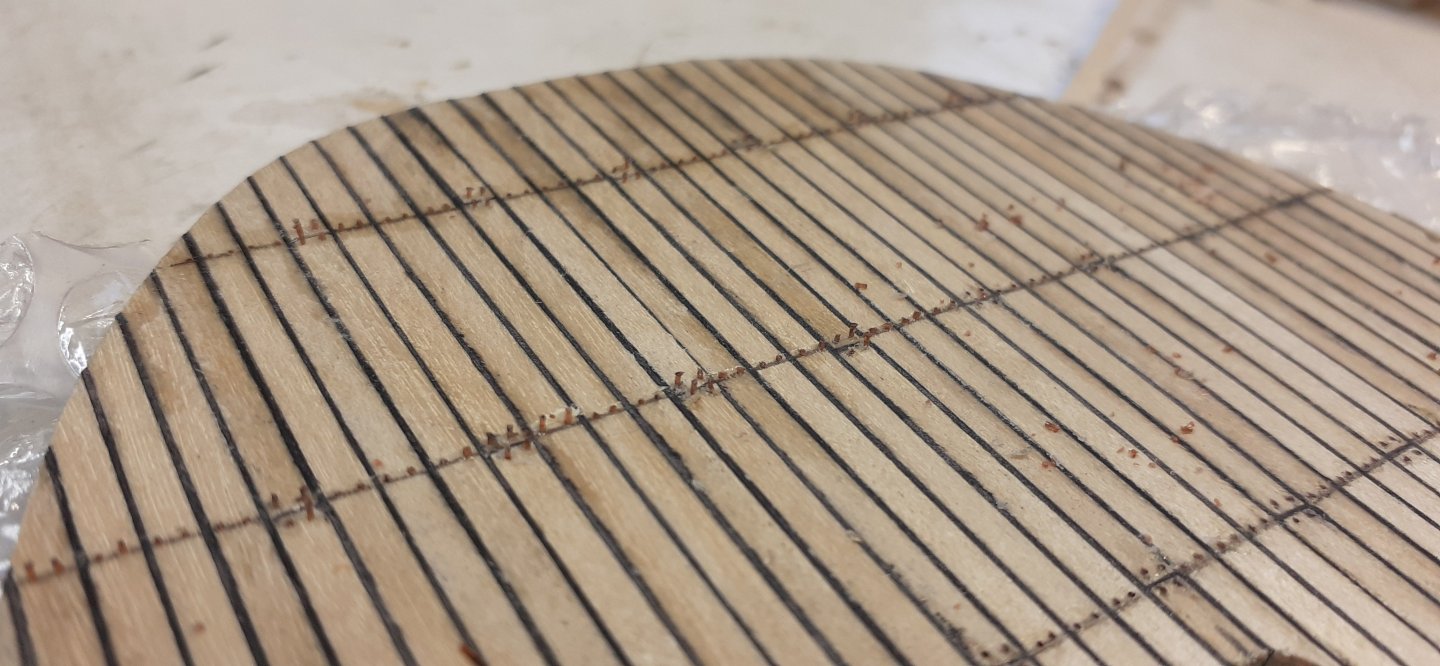

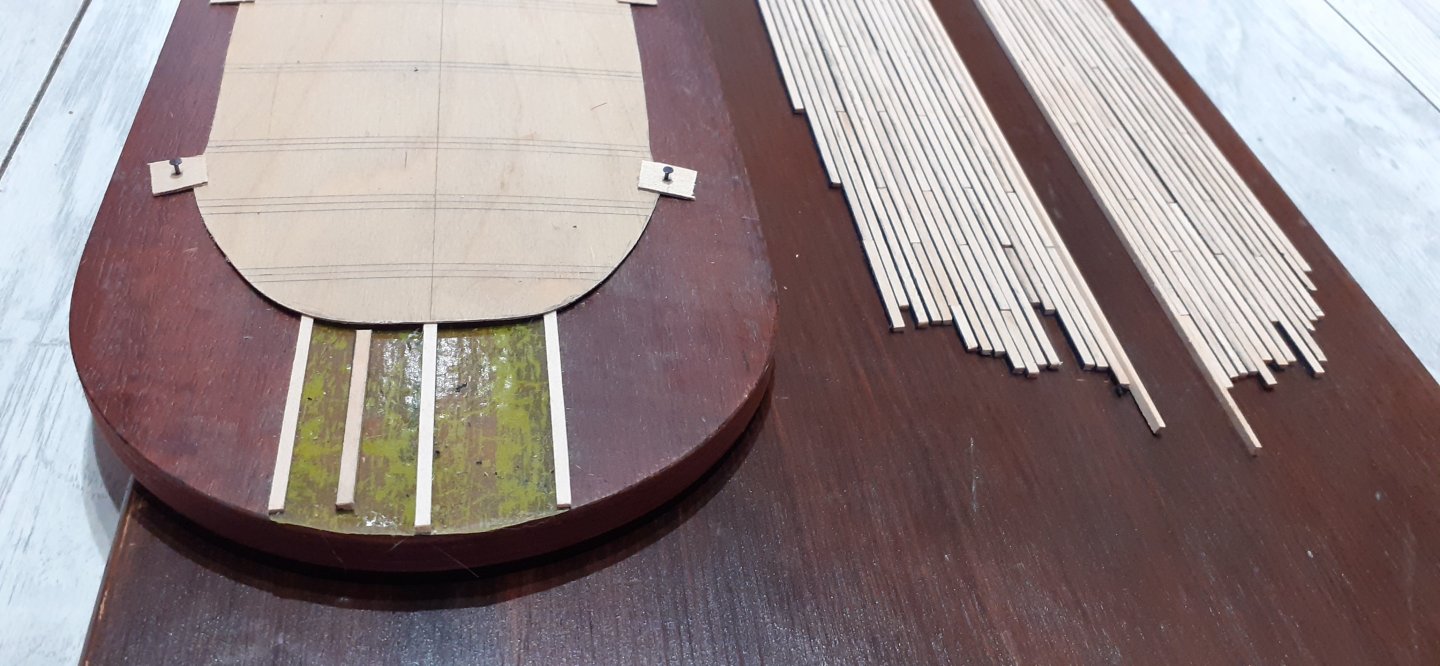

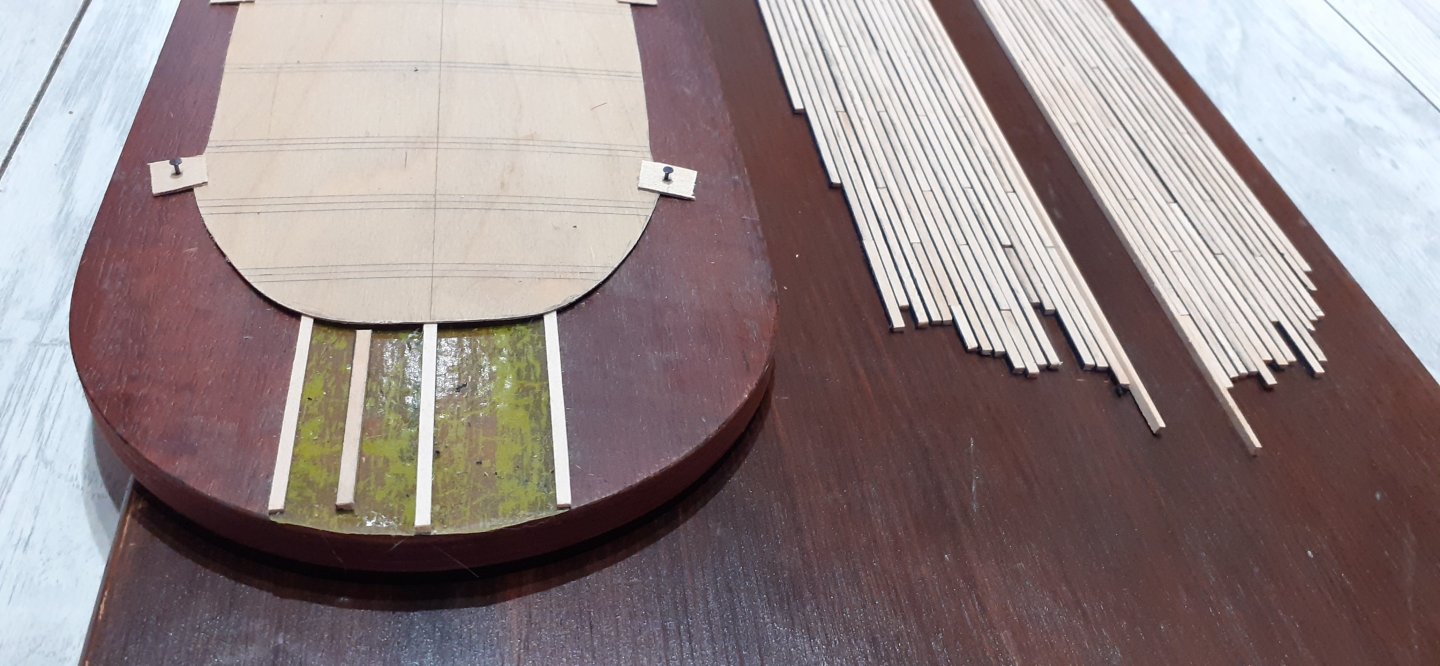

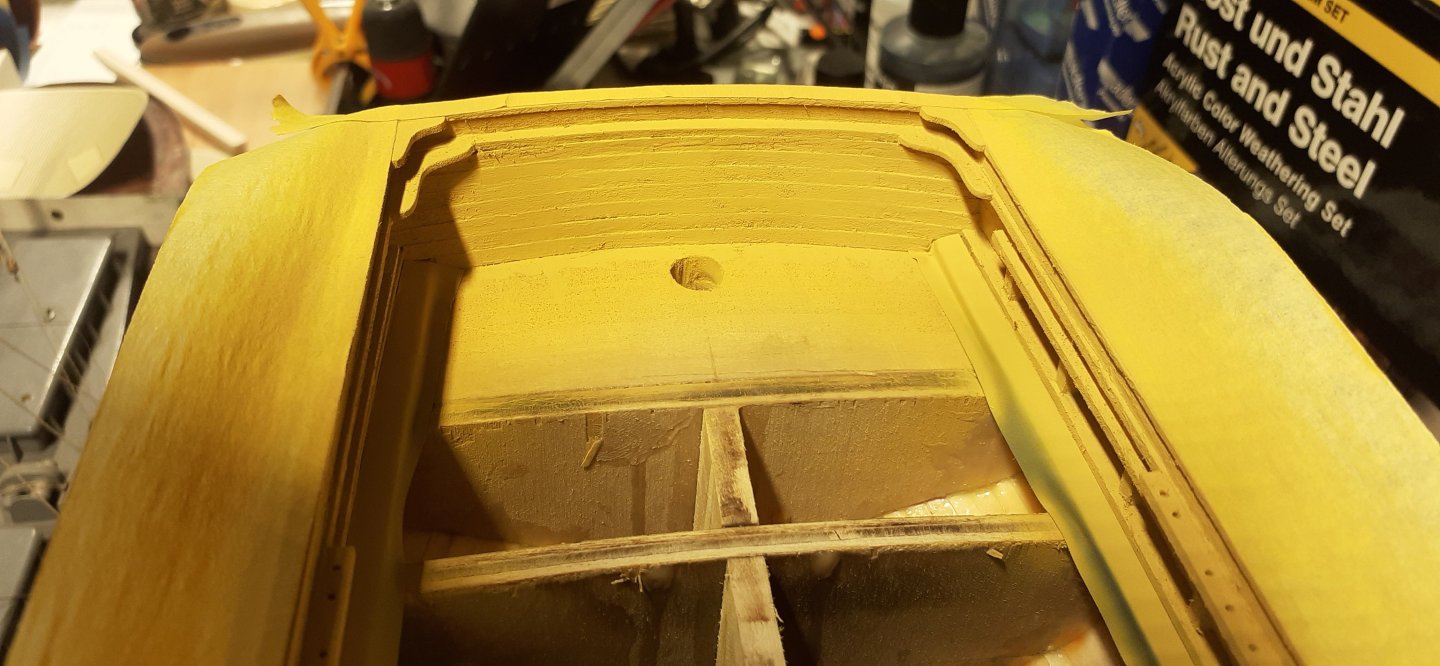

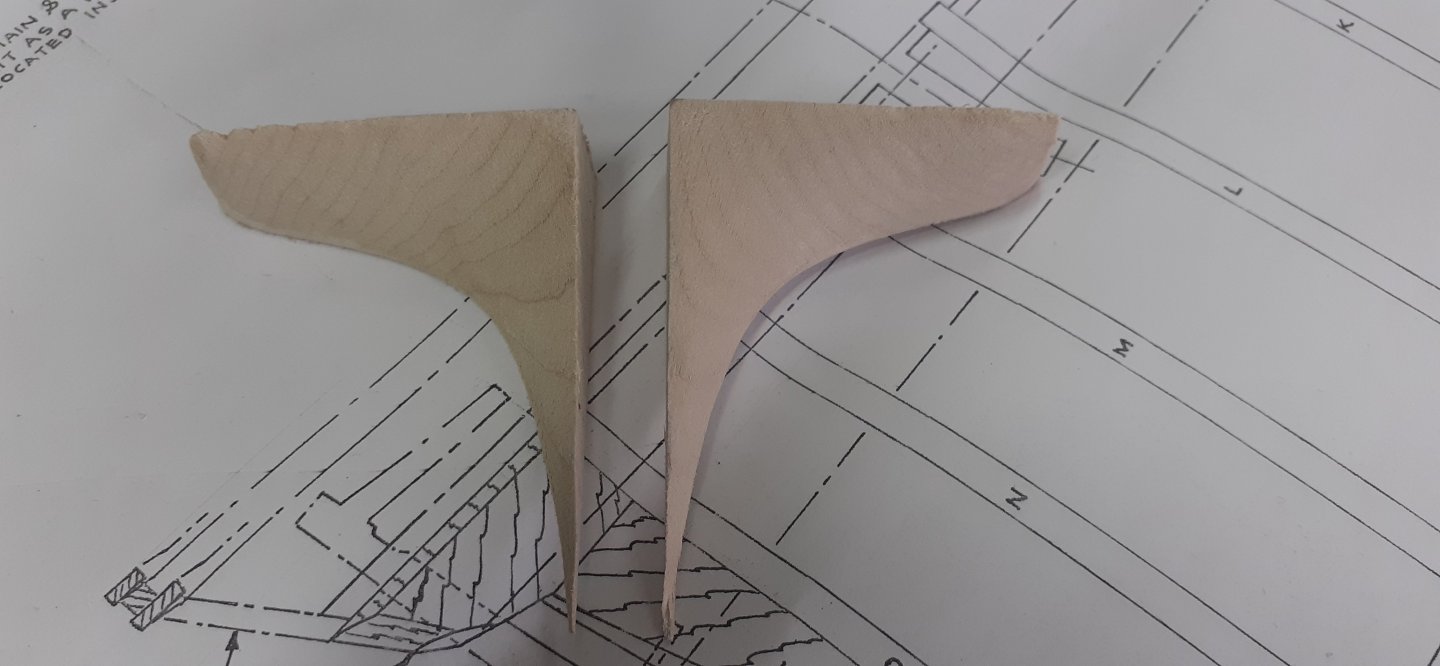

Some parts from the set are unacceptable to me. I am forced to make them myself. I still have a dilemma about choosing the color of the deck, whether it should be more bluish gray or maybe bluish brown. In different photos in Real Charles W. Morgan looks slightly different colors. I think bluish brown will be a better solution for painting the deck. I would be happy to hear some advice from other experienced modelers or those lucky ones who have visited the ship in person.

-

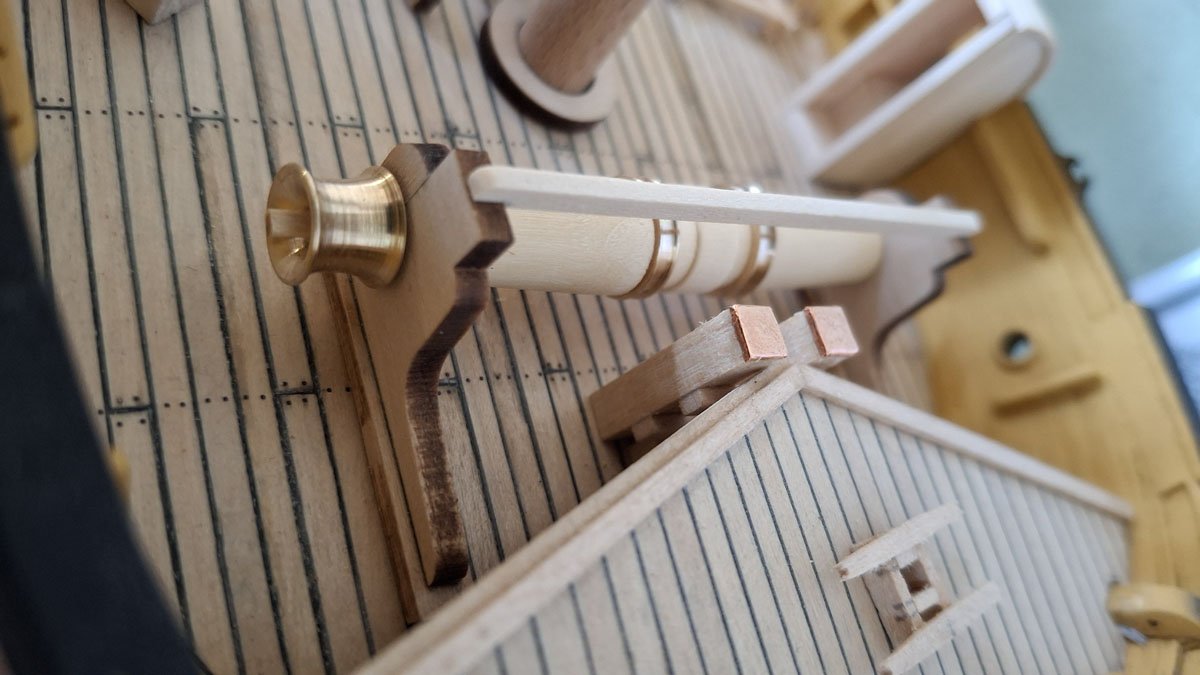

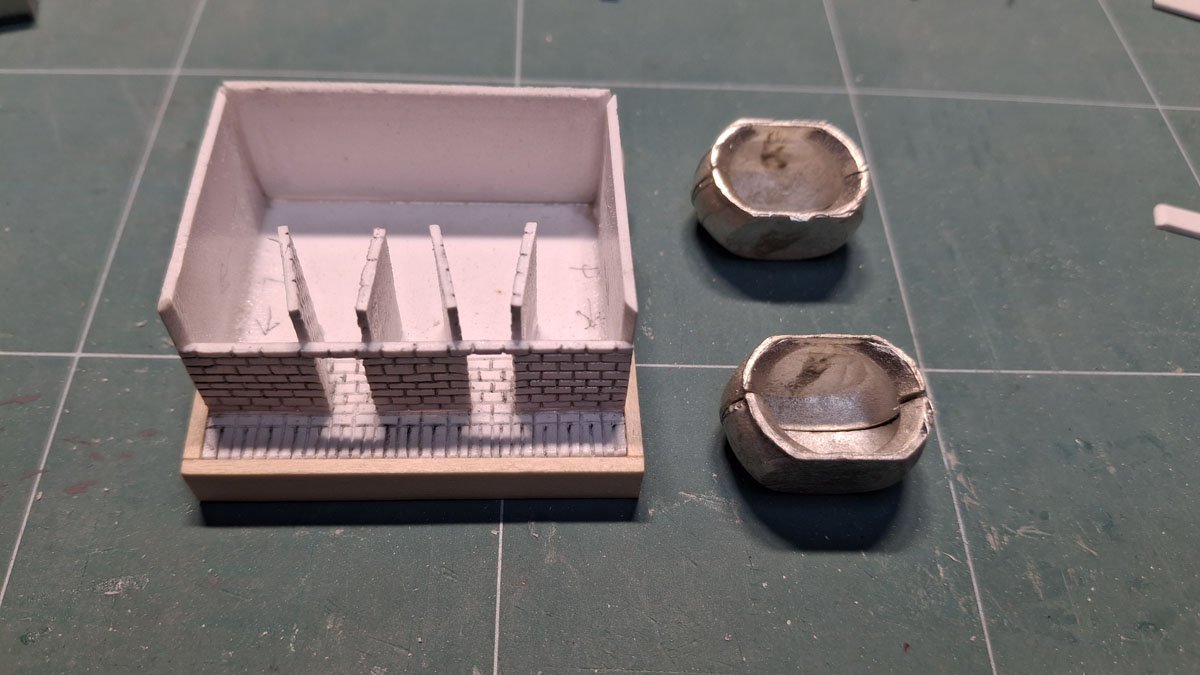

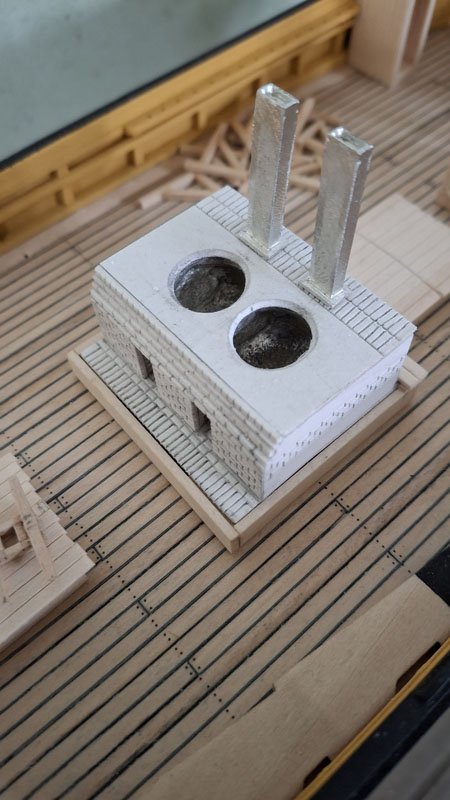

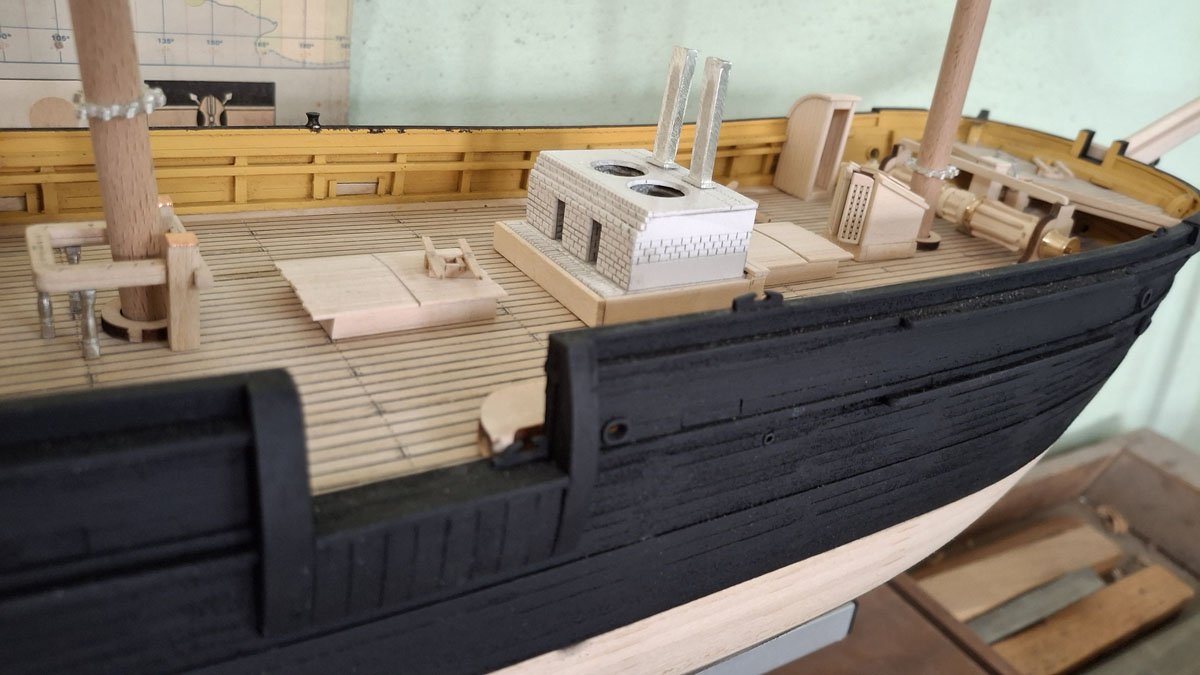

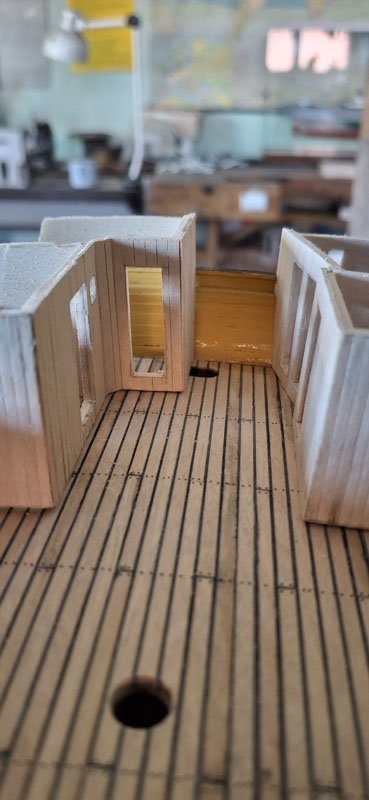

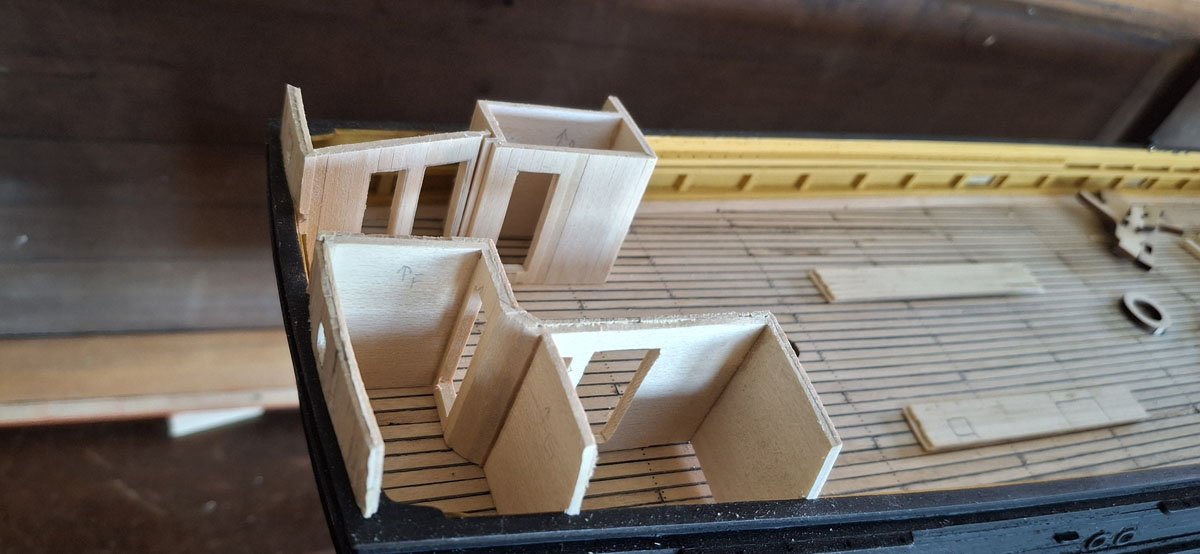

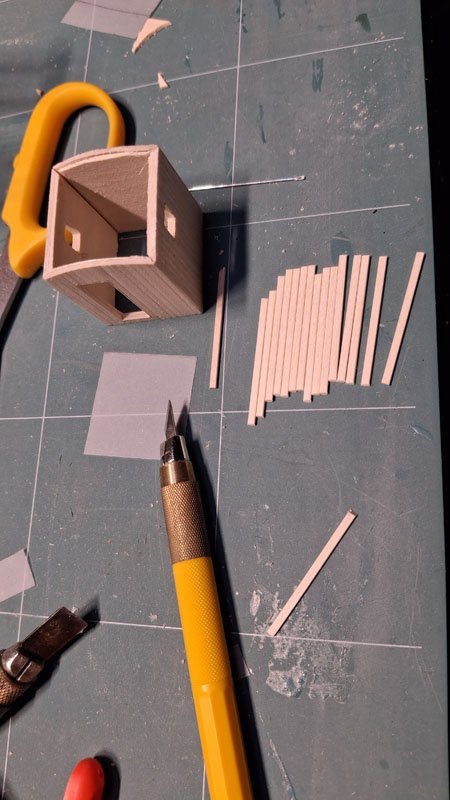

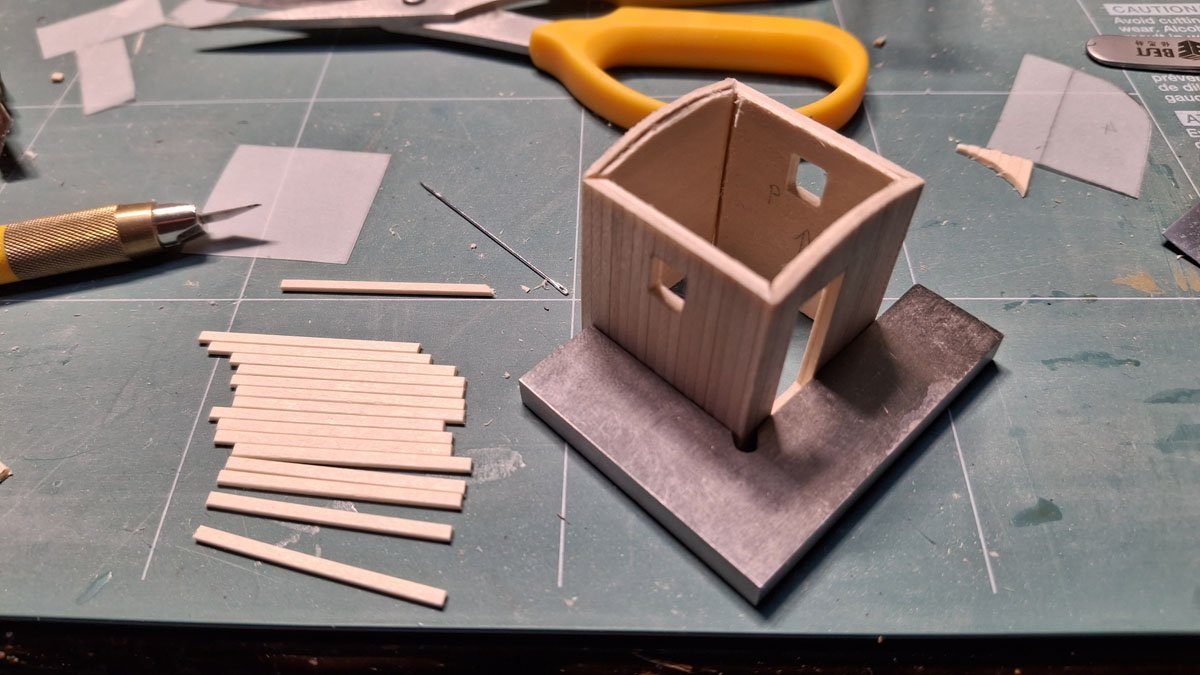

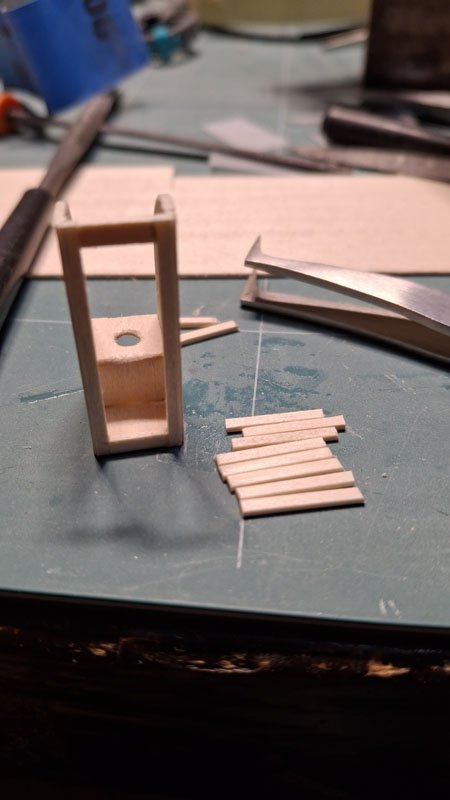

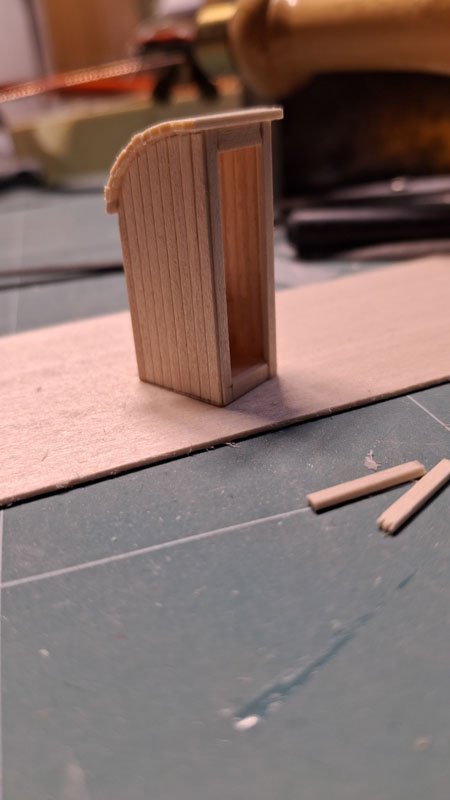

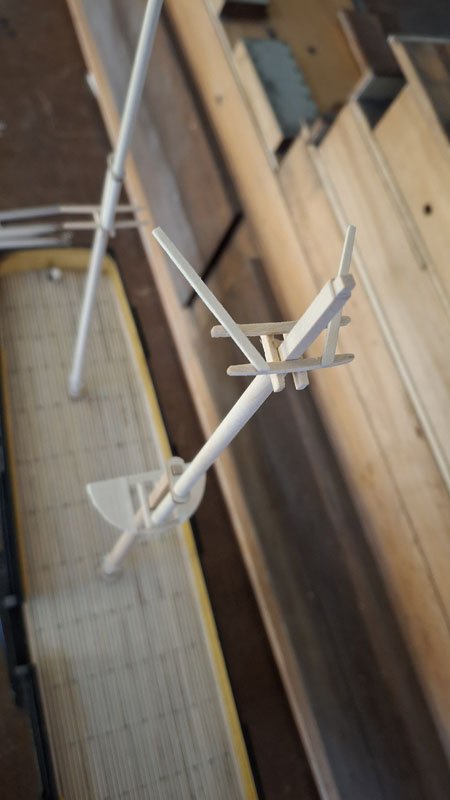

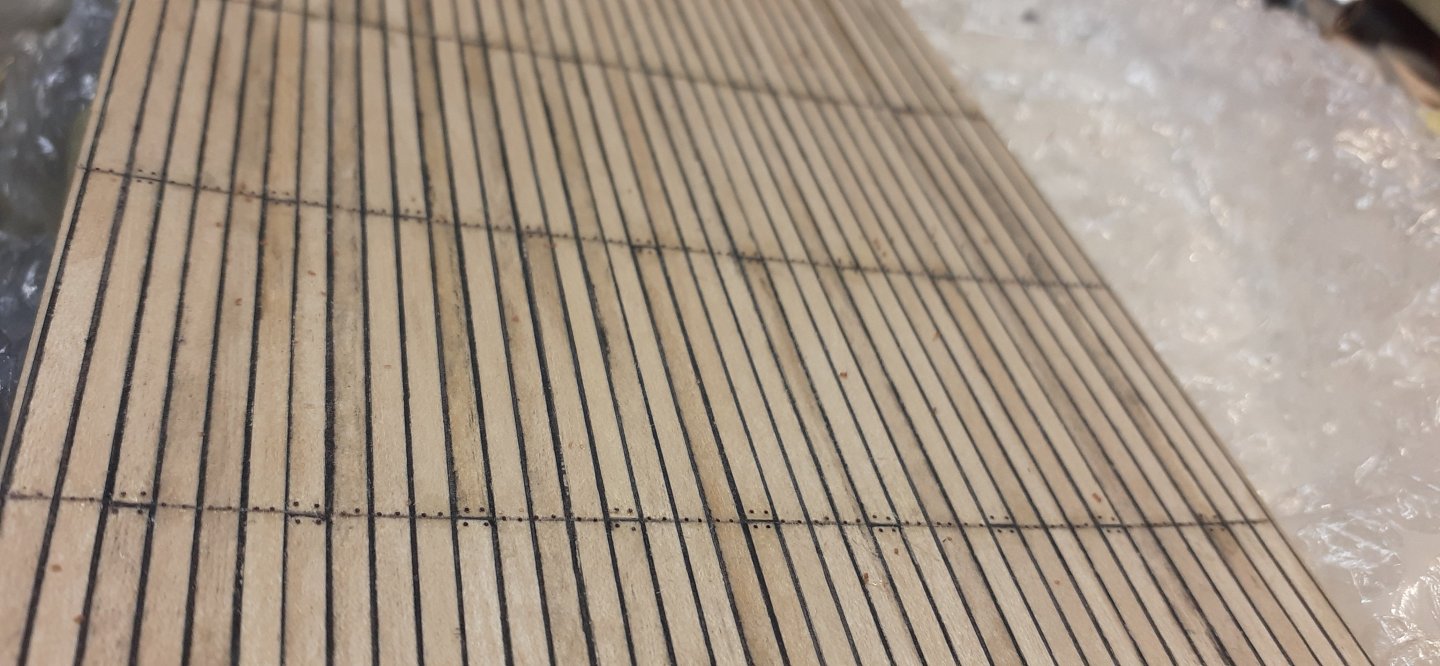

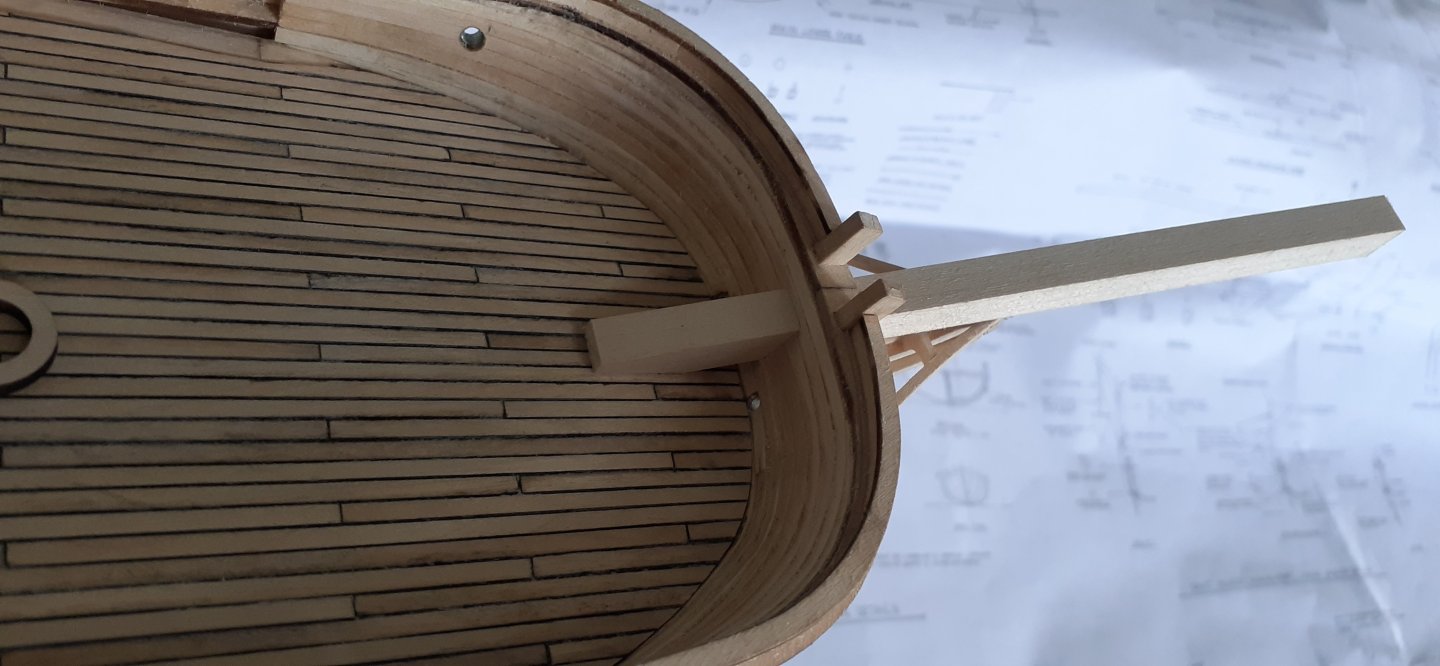

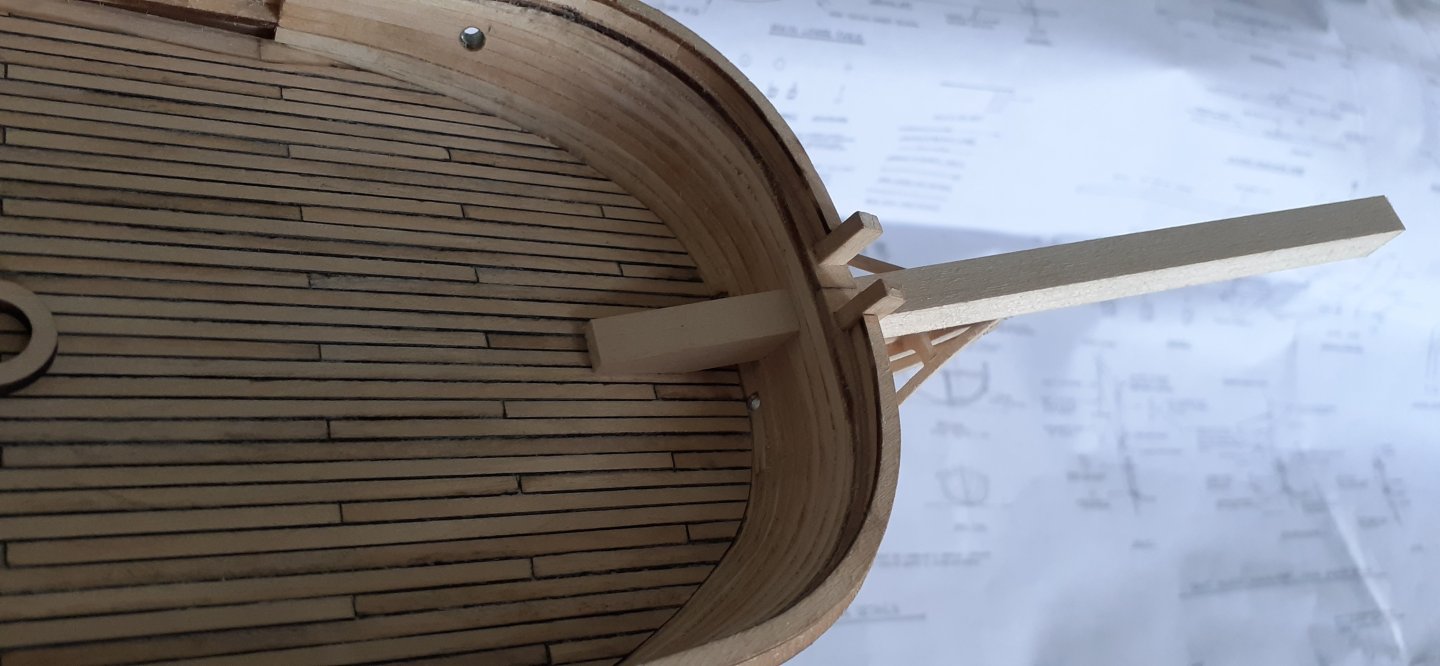

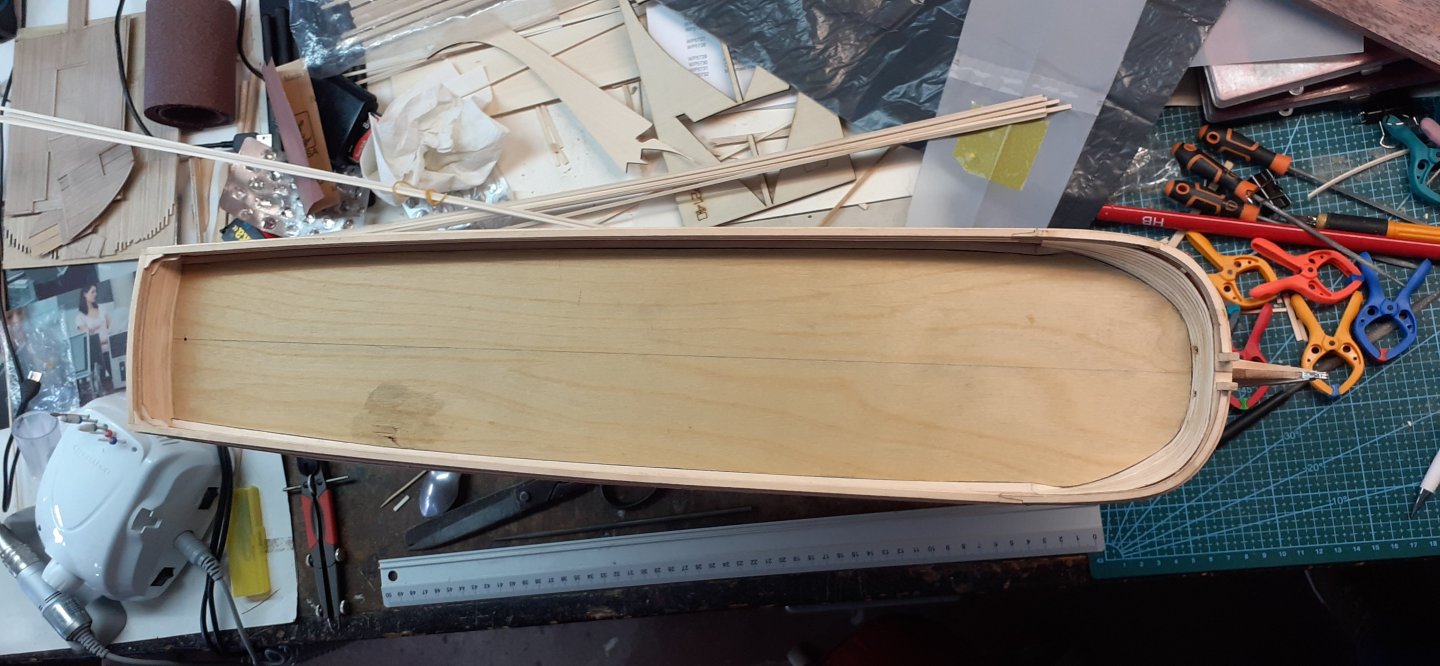

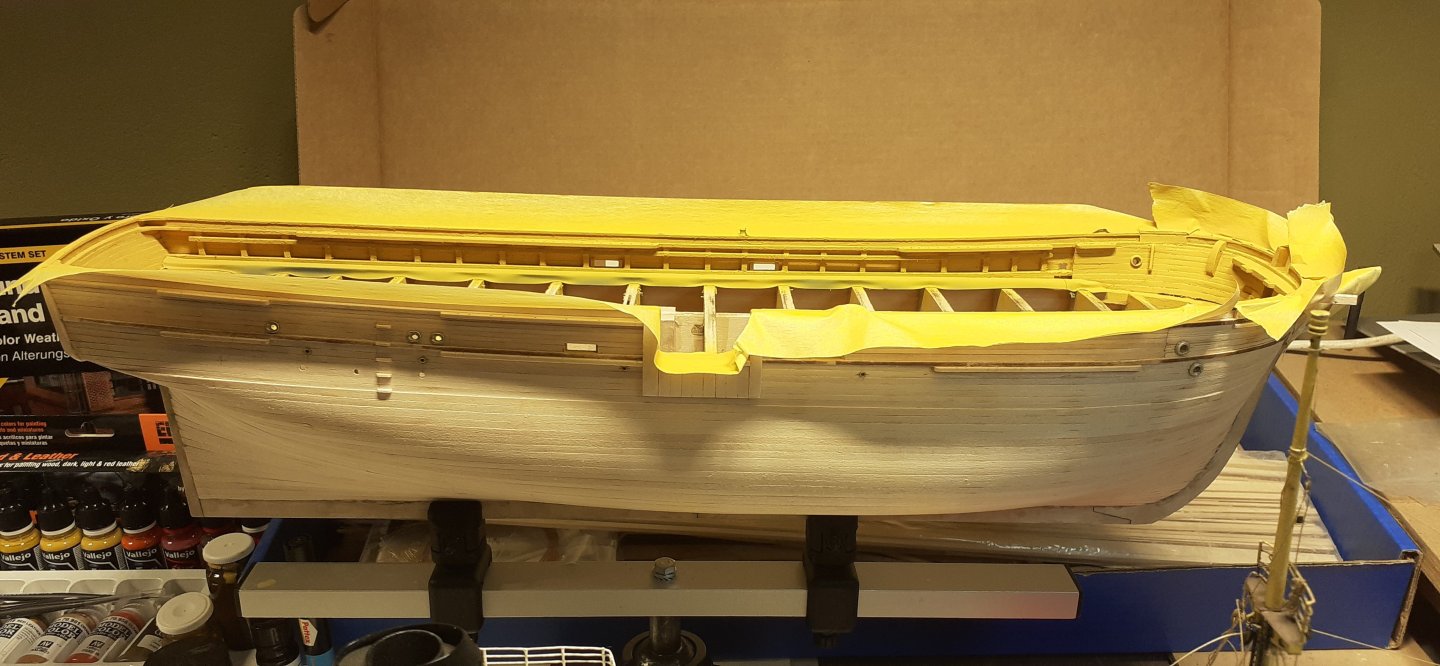

The deck is in place, glued with epoxy resin. I had plenty of time to place the finished deck in the right place. This did not protect me from epoxy leakage in the hole where the rudder is. But every cloud has a silver lining. I started producing all the parts on the deck one by one. For now, in raw form, so that when the time comes, I can paint and polish them.

-

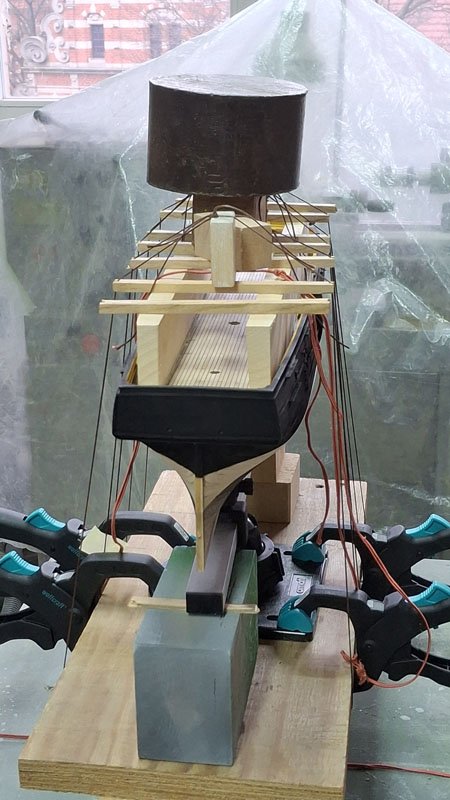

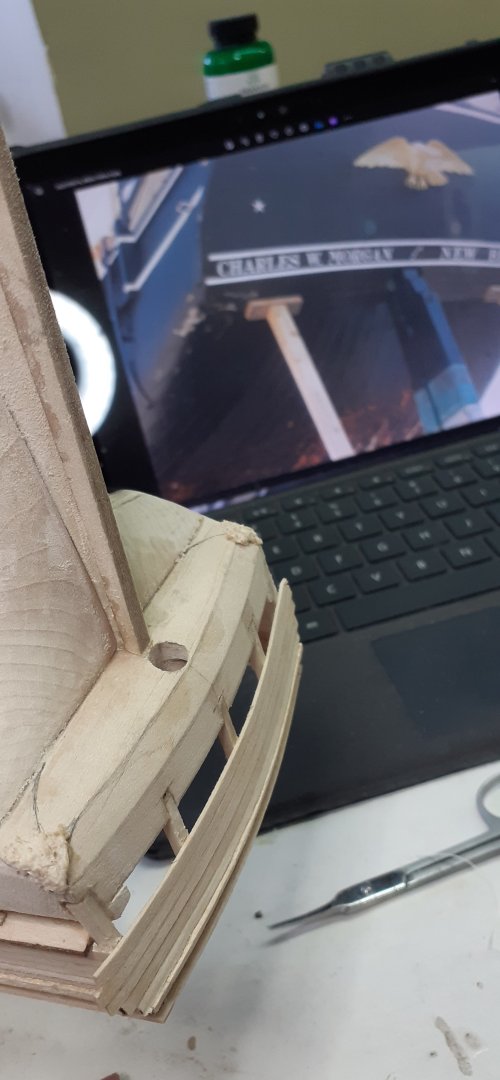

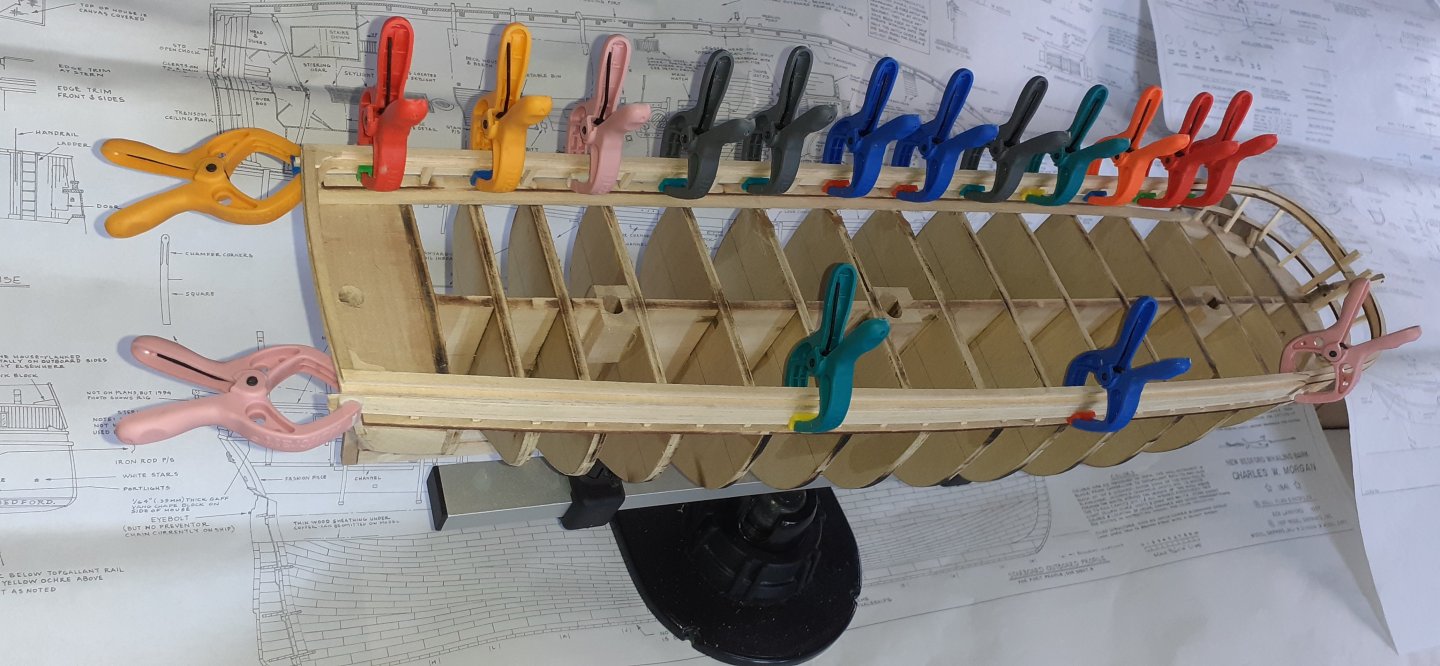

Hi Paul. Thank you very much for your kind words. Thank you also for your understanding and patience, I made a bit of a mess in the post. Oh my. Now I think I have the situation under control. First attempts at gluing the deck, the effect is satisfactory I think. I used epoxy resin to glue it, thanks to which I had a lot of time to adjust it calmly, about two hours for the resin to harden. Attention! You have to watch out for resin leaks, think carefully about planning the gluing and prepare everything in advance.

-

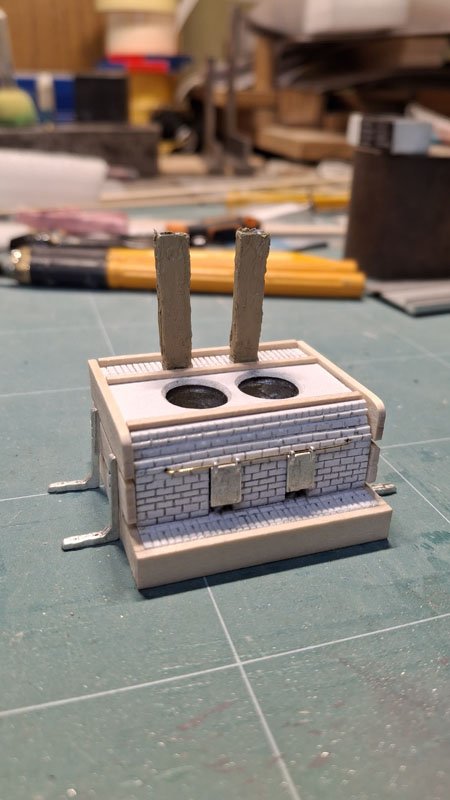

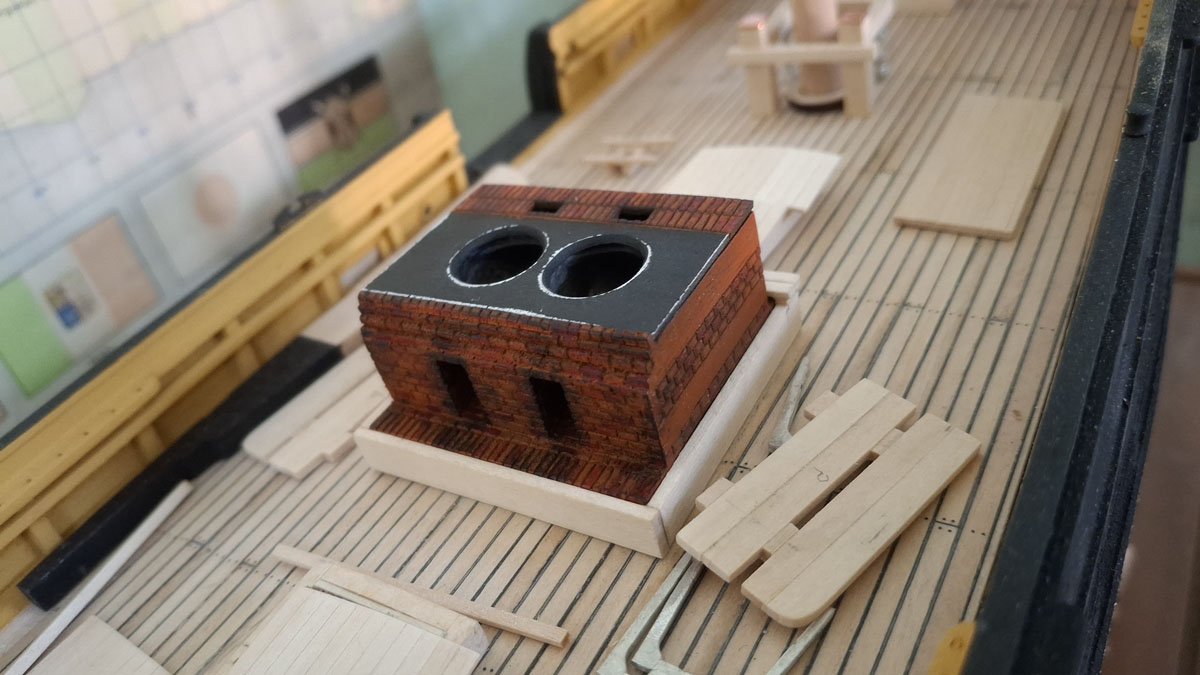

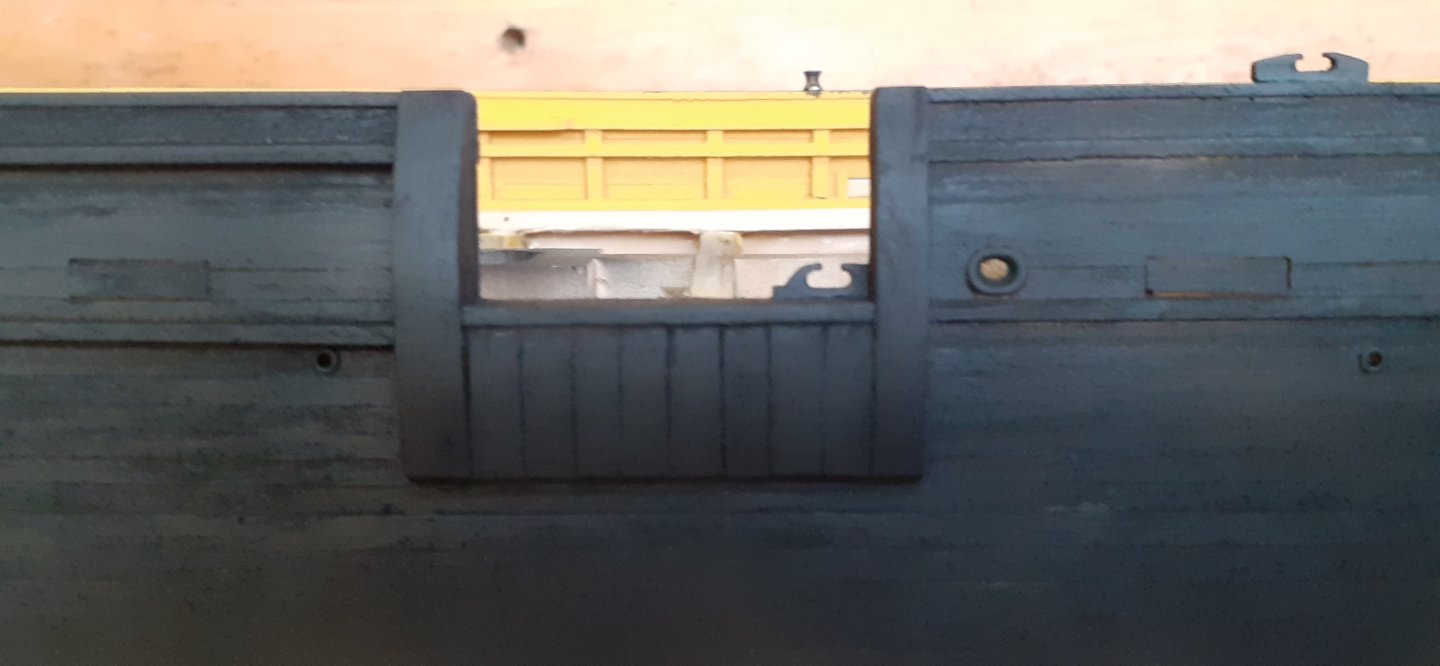

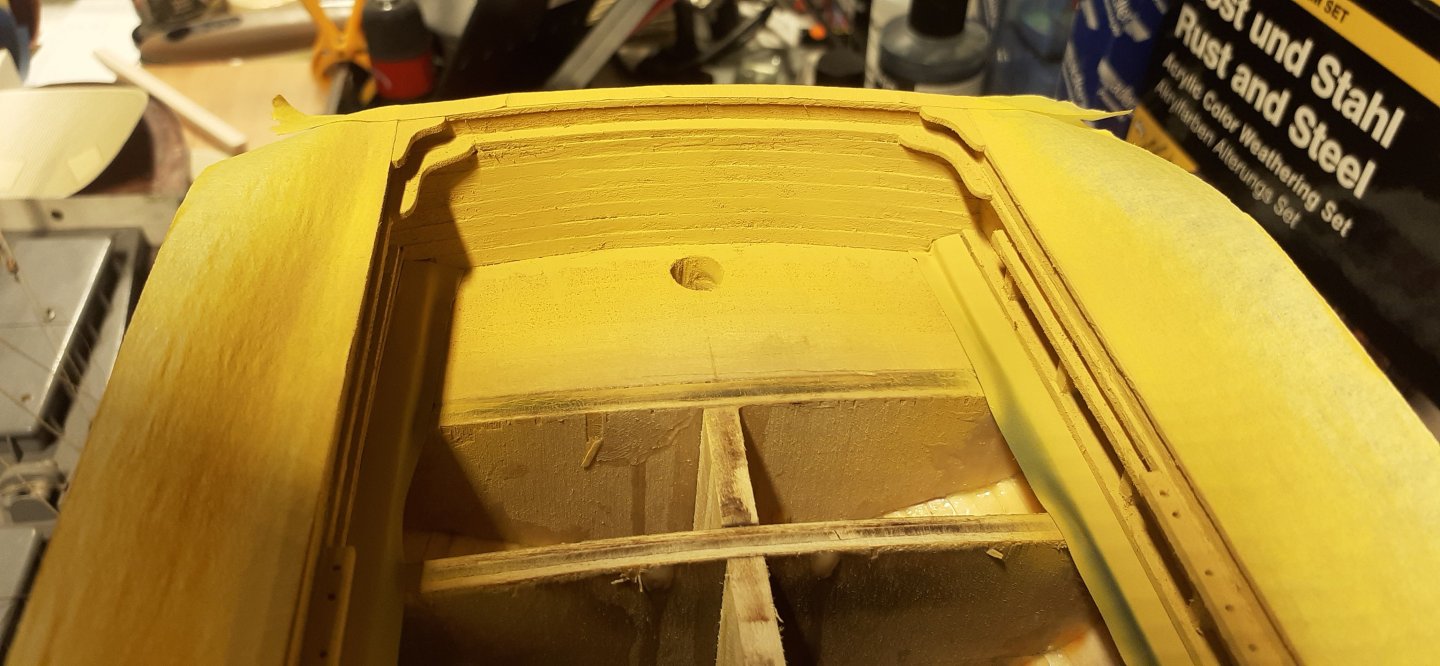

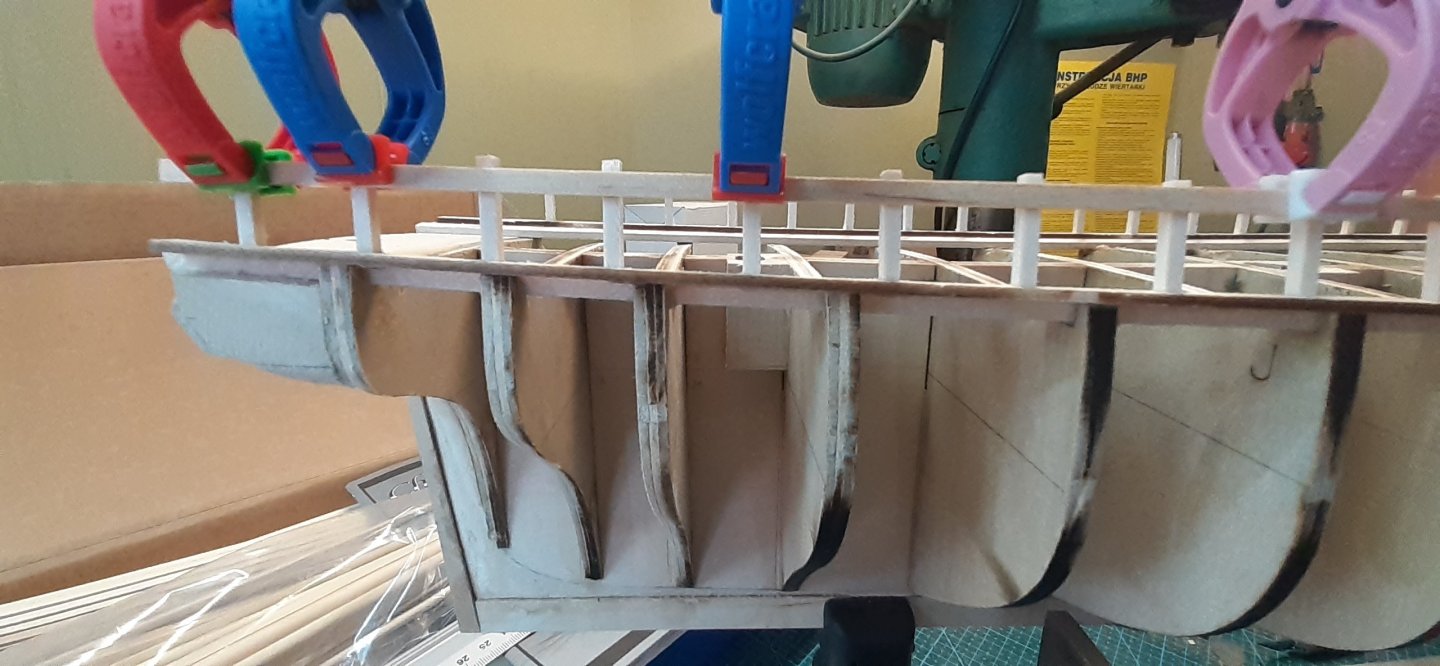

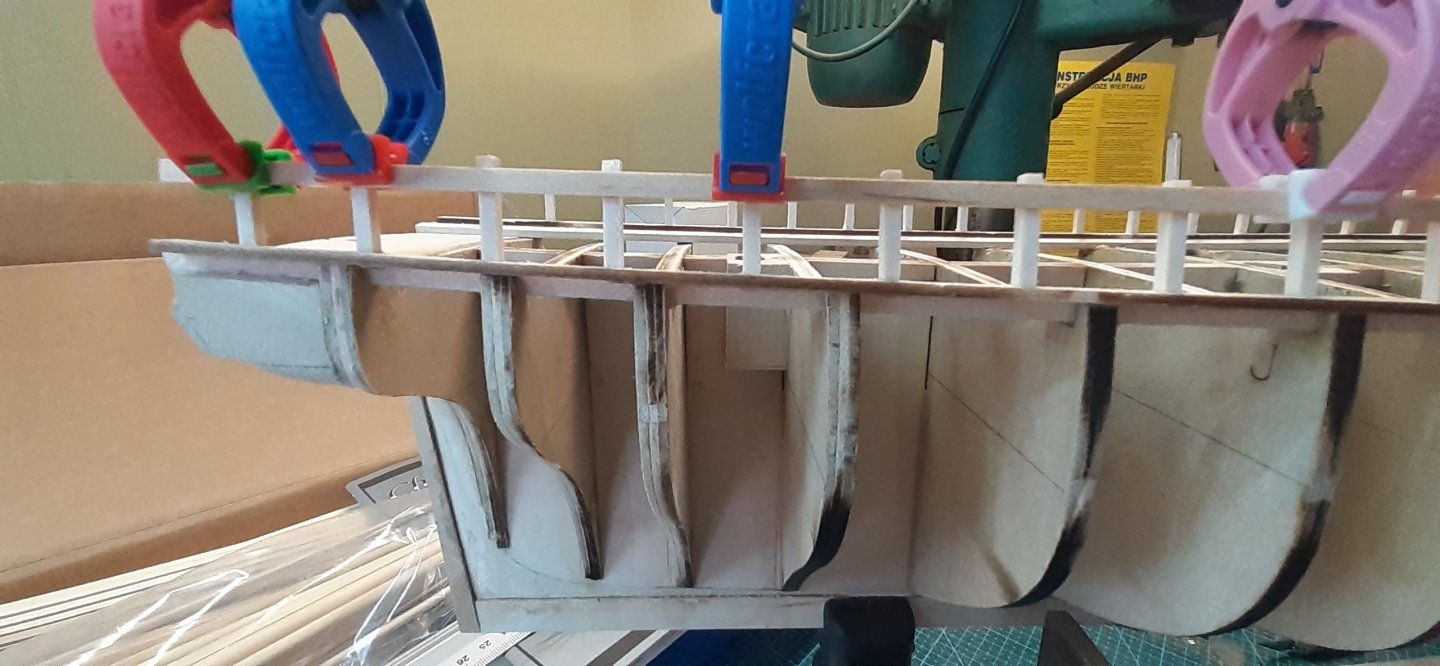

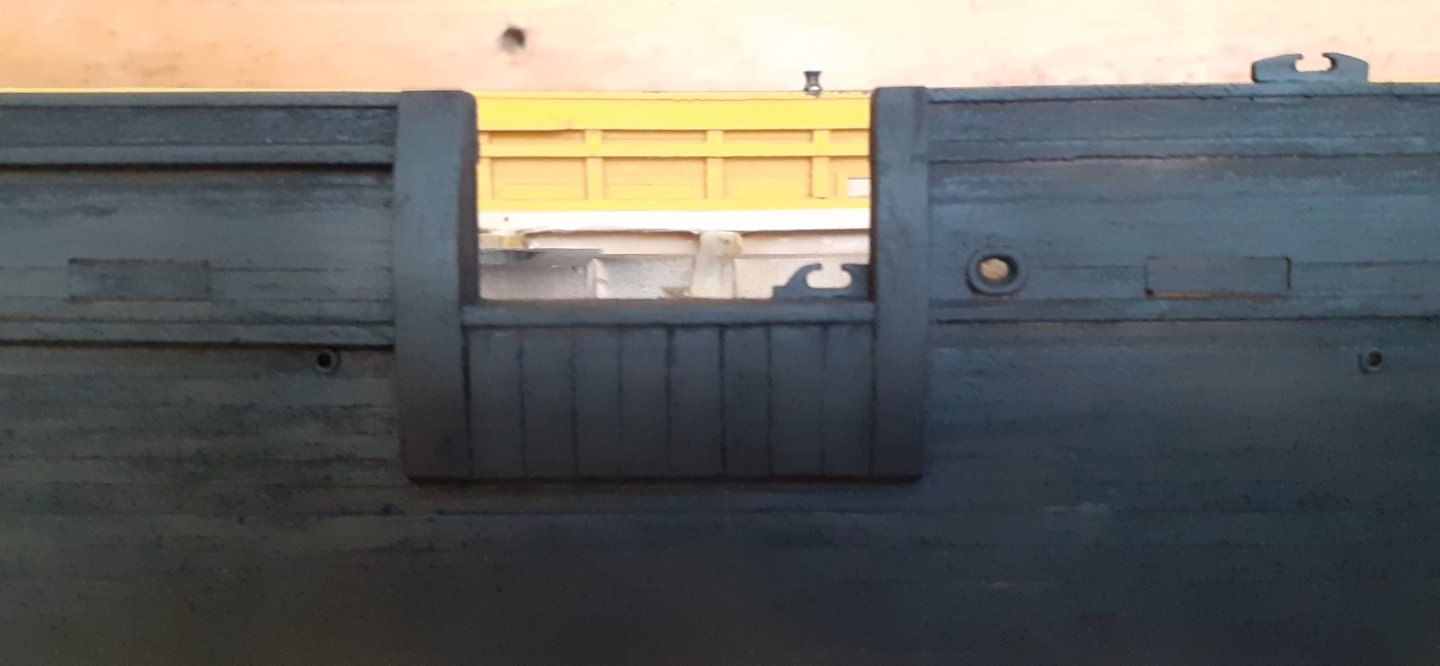

First painting after previous cleaning and checking for glue residue. I wanted to make the hull skin elements visible as much as possible and the detail of the plank structure as visible as possible. To achieve this, remember to dilute the paint and use a drying retarder. Good and careful preparation of the masking for work with an airbrush is half the battle.

-

And more elements are arriving on the ship, the shipyard is working at full speed, although in reality it is painstaking tinkering and corrections to elements I was not satisfied with. I decided to make fasteners, I made the device by making a 0.4mm hole in a flat bar and a 0.3mm drill. I knocked them out of an aluminum can, making small circles.

-

Thank you for your kind words. My work with this model began with this very portal. Searching for information about this ship led me to this place. Charles W Morgan is the history of America, so I found the most information about this ship here and in the process I discovered many fantastic modelers who struggle with the subject of its construction. I am from Poland, I hope that my sentences are quite legible, my English is not the best and I am forced to use a translator.

-

-

Thank you for your kind words. My work with this model began with this very portal. Searching for information about this ship led me to this place. Charles W Morgan is the history of America, so I found the most information about this ship here and in the process I discovered many fantastic modelers who struggle with the subject of its construction. I am from Poland, I hope that my sentences are quite legible, my English is not the best and I am forced to use a translator.

- Show previous comments 1 more

-

-

-

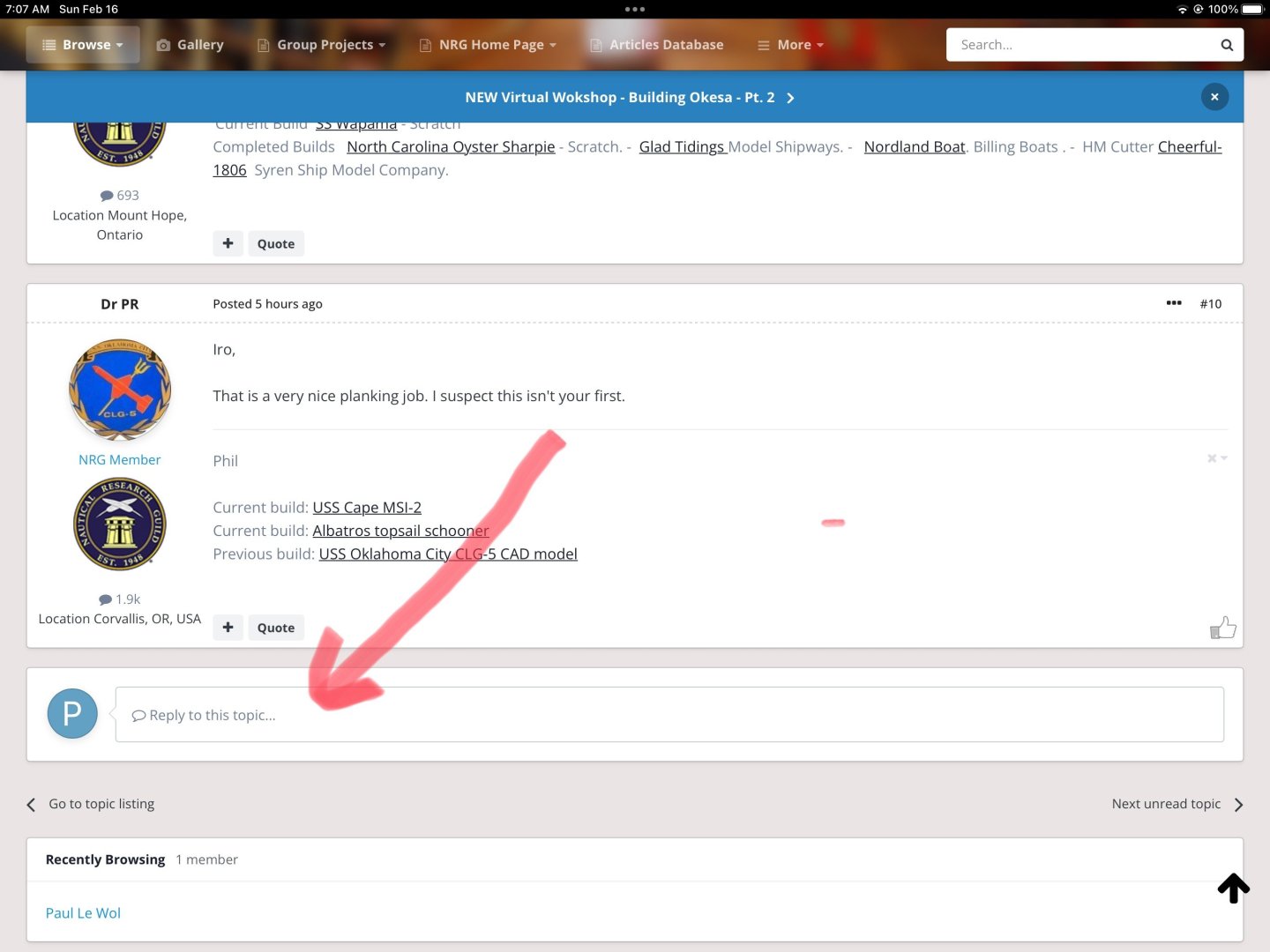

Hi Iro, here is a screenshot of your build log.

Make sure you use this box when you want to add to your build log.

-

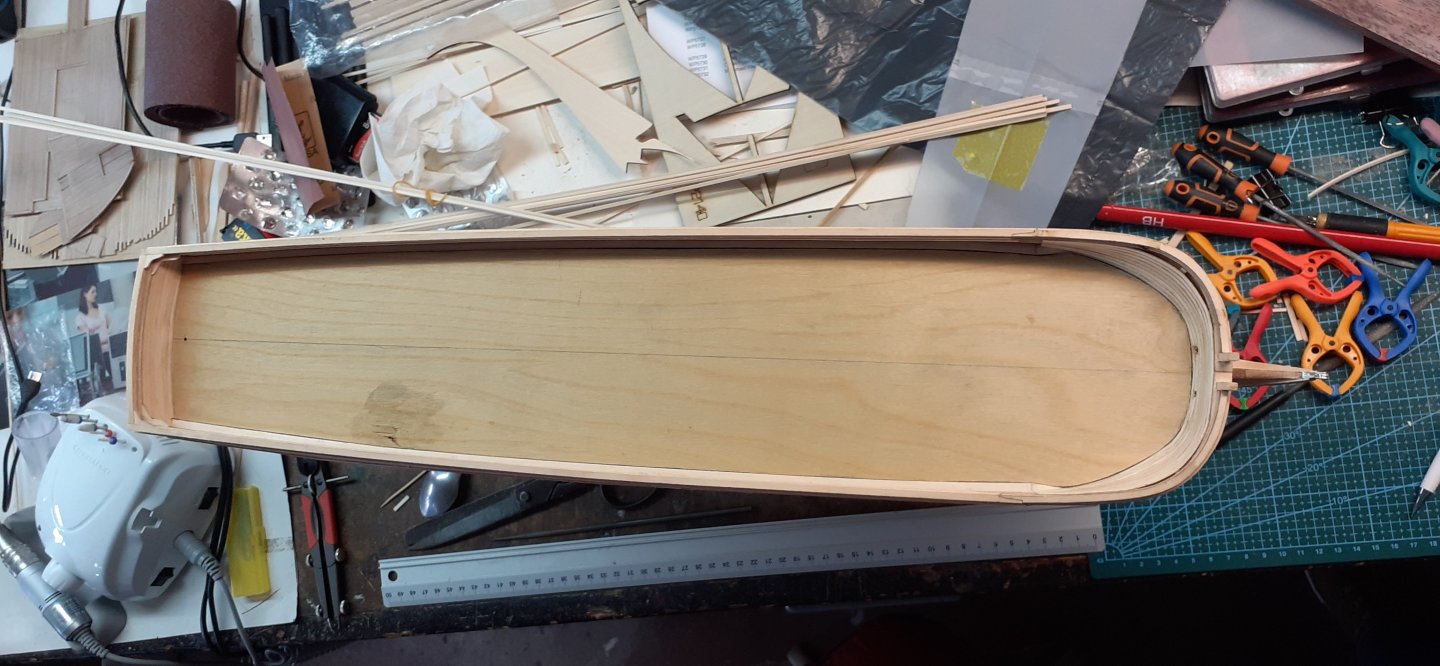

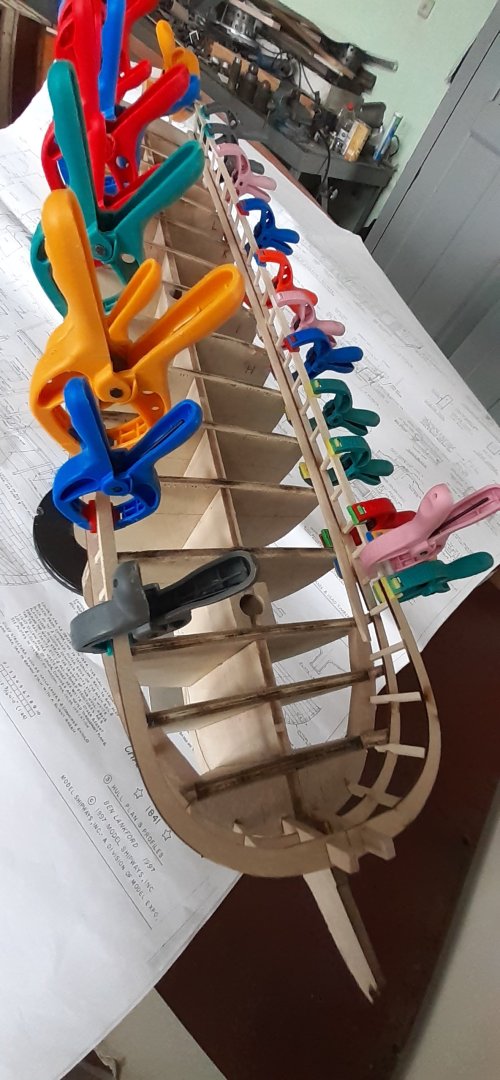

My Charles is supposed to be an aged model, linden wood is perfect for this project, it adds a natural age to the model and the atmosphere of those times. The lower part of the ship is made of copper, which makes it easier to make the planking, which does not require so much focus. The modeler should focus his energy and precision on watching the hull axis and symmetry, controlling rotation and uncontrolled deformation while the glue is drying. At this stage, there is still a lot that can be fixed.

-

The model is very interesting in terms of rigging, it has a whale suspension system and a gangway on which sailors worked. It does not have a large number of cannons, its weapons are seven boats for harpooners, buckets, barrels and a furnace for rendering fat. When building the model, you have to constantly watch the axis of symmetry and the delicate curves of the deck and bulwark, which define the beauty of this hull. All lines are curves that you have to focus on, in addition to this there are elements of hull reinforcements that have to be rhythmically set vertically, preferably in relation to the level (line) of the ship's draft.

-

A few words about the kit itself. Since I am not one of those who complain, I will focus on the positives. Although not the best, linden wood offers great possibilities. This type of wood behaves a bit like a sponge, it can be crushed, flattened, bent and formed almost like plasticine. Warning! You have to be careful about its delicacy, because an inadvertent scratch with a fingernail can carve an unnecessary scratch in the material. Modeling plans made with care, although I often have the impression that there are no lines that would make the task easier. Fortunately, there are many photos of models already made by other modelers and photos of a real ship, which greatly helps to check the correctness of your own interpretation of reading the executive plan, thus helping to protect yourself from making a mistake.

- Show previous comments 2 more

-

And more elements are arriving on the ship, the shipyard is working at full speed, although in reality it is painstaking tinkering and corrections to elements I was not satisfied with.

I decided to make fasteners, I made the device by making a 0.4mm hole in a flat bar and a 0.3mm drill. I knocked them out of an aluminum can, making small circles.

-

First painting after previous cleaning and checking for glue residue. I wanted to make the hull skin elements visible as much as possible and the detail of the plank structure as visible as possible. To achieve this, remember to dilute the paint and use a drying retarder. Good and careful preparation of the masking for work with an airbrush is half the battle.

-

Another painting and masking. This time I used Vallejo 70913 and 71057 paints, yellow ochre and workshop black according to the RAL sampler.

-

Hello to all interested. This is the journal of the Iro shipyard, from the construction of the Charles W. Morgan ship. My adventure with matter, the struggle with patience and the passage of time. Since childhood, I have been fascinated by travel and the world that has passed. Explorers of old times, fantastic travelers struggling with the power of nature, brave people full of passion like modern astronauts sailing through the spaces of infinity. With sailors greetings Iro

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.