mediocremodeler

Members-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mediocremodeler

-

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

-

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

I cheated. I couldn’t resist the temptation of turning this in the lathe in a minute and a half. Supposed to be assembled from strips, then sanded. Shoot me. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Sorry Inches. That’s the taper. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Done, except hand sanding. .637 to .425 A LOT more demanding than aluminum or nylon or steel on the lathe. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

-

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

I just scaled up the weight from my video. Its only about 18.9 pounds in scale. I’ll put a whole gallon on there tomorrow and try to raise it. That’ll be 10 stone. 😂😁 Lmao -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

IMG_2582.MOV Single rolls smoothly. But, note to self - sheave pilot holes cannot be .001” off, or line pinch results. 😁 Not using that green garbage wire, just testing. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Single rolls smoothly. But, note to self - sheave pilot holes cannot be .001” off, or line pinch results. 😁 Not using that green garbage wire, just testing. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

I much appreciate the info I get here because I am new at this. The compliments are especially encouraging. I am a retired Porsche factory master engine tech, so when I show these things to my old school mechanic buddies, I get “encouragement” like this….. 😂 -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

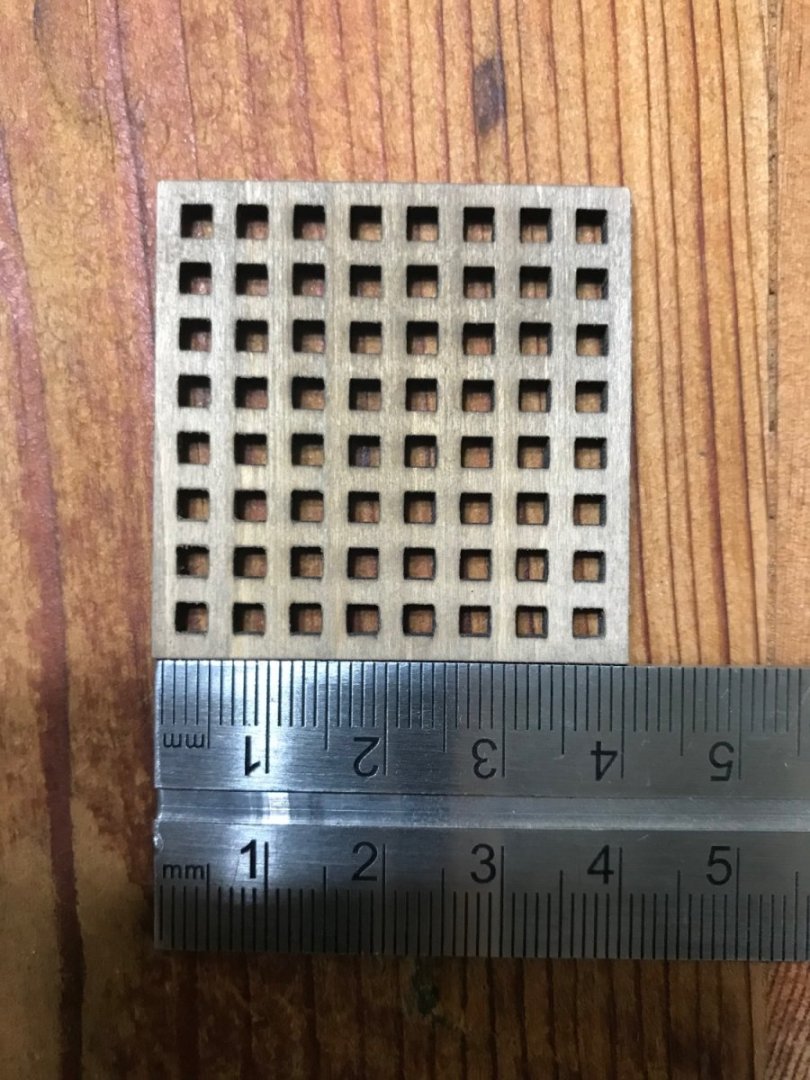

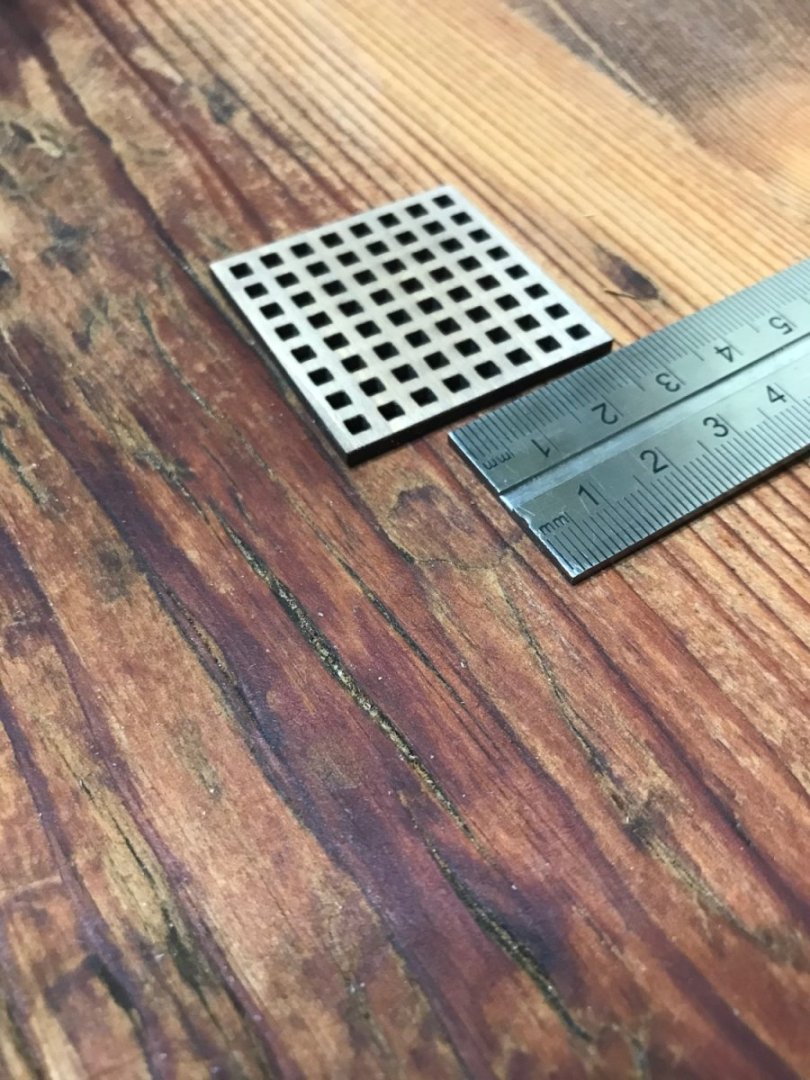

Thanks for that picture, that’s great. I did both parts in cad, then cut them with the laser. Going to draw the doubles next. Still have to taper and chamfer by hand, but that’s for tomorrow at 4:30 am while I still have 100% patience. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

I’m pretty happy with this. I can darken with Danish oil or linseed. If I can pull lines through them after I chamfer, that will be great. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

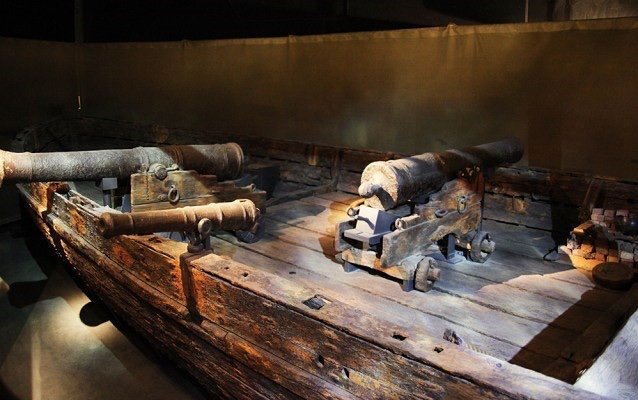

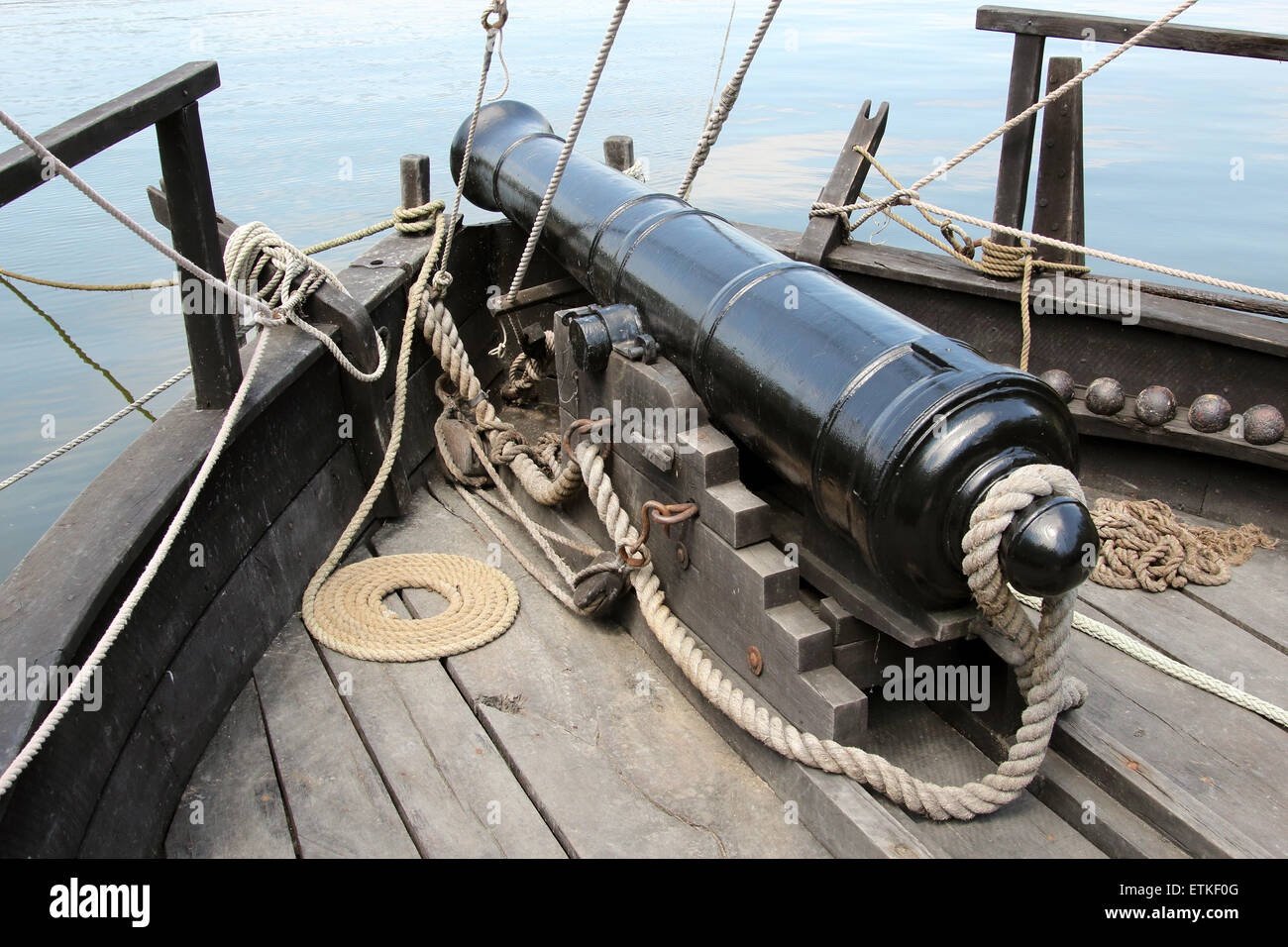

Thanks a lot for the info. Scale is 1/18 and boat was built in 1776 - US. Sounds like wood it is. Im going to go draw and burn one right now and see how it looks. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

For the sake of authenticity, there is no reference that I can find regarding whether the sheaves were bronze or wood. None were pulled up, and I don’t trust the reproductions on the reproduced boat. I can make them out of “bronze” or wood, but I don’t know which to do? -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Walnut single block blank. Hot off the press. Im going to make them functional with wooden sheaves and “forged” pins. what do you guys think??? -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

-

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

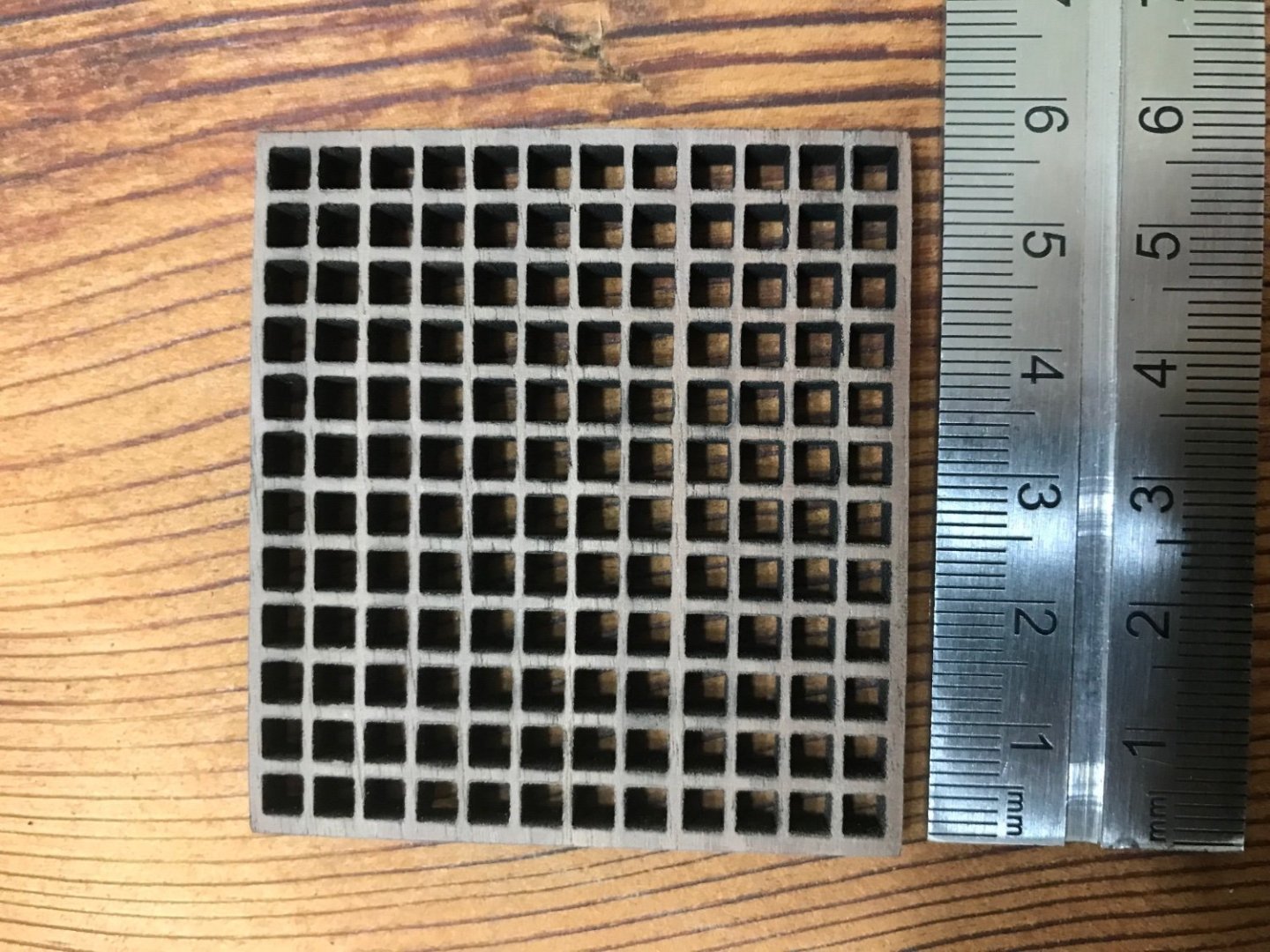

Oh Here is the decking with the “scrolls” as they appear on the plans. I guess this is broadside reinforcement? -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Swivel gun brackets balanced. Copper not “brass blacked” yet. pretty close to original, close as I could solder anyway. Only took about 6 hours for both. 🤣 -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Ugh. Now I have to make my own switch hitting serving machine. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Hadn’t considered it, but if you want some for the Rattlesnake, I’ll make them. Send me dimensions and what kind of wood you want. I have: oak, honey colored pine, walnut, spruce, and balsa. Mortgage is paid, don’t need money. 🙂 Btw, does anyone know what size a pulley block for a 1776 cannon was in actuality?? -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Bought some line from that guy “Ropes of Scale” in Toronto. Awesome stuff. Looks even better in person. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

-

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

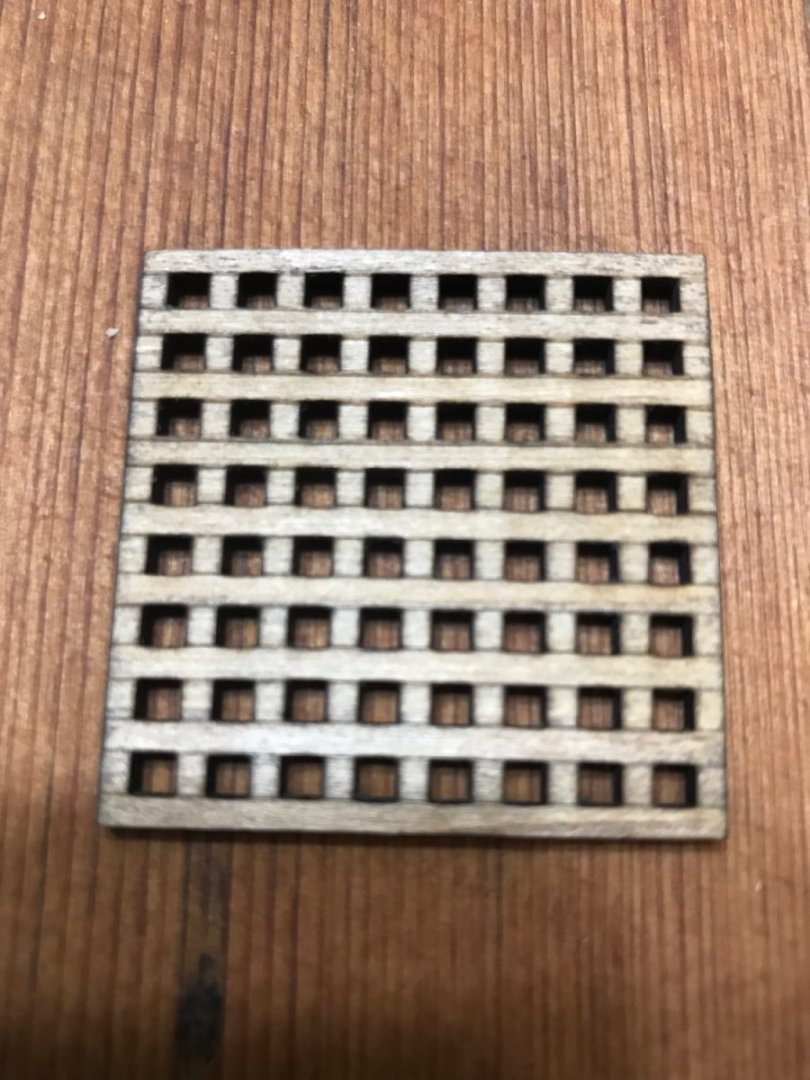

Allanyed- Okay, first revision according to your advice. These proportions are the same as your diagram, but without head ledges and coaming, which (I believe) is framed on the ship. The “basketweave” can be delineated with a knife and ruler in a minute or two. Please let me know if this is good, in thebin with it. Thanks. 😁 -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

Great info. I’m going to model the “correct “ version. 😁 Also 3 or less, got it. -

Laser cannon bracket

mediocremodeler replied to mediocremodeler's topic in CAD and 3D Modelling/Drafting Plans with Software

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.