Captain Vytautas

Members-

Posts

5 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Captain Vytautas

-

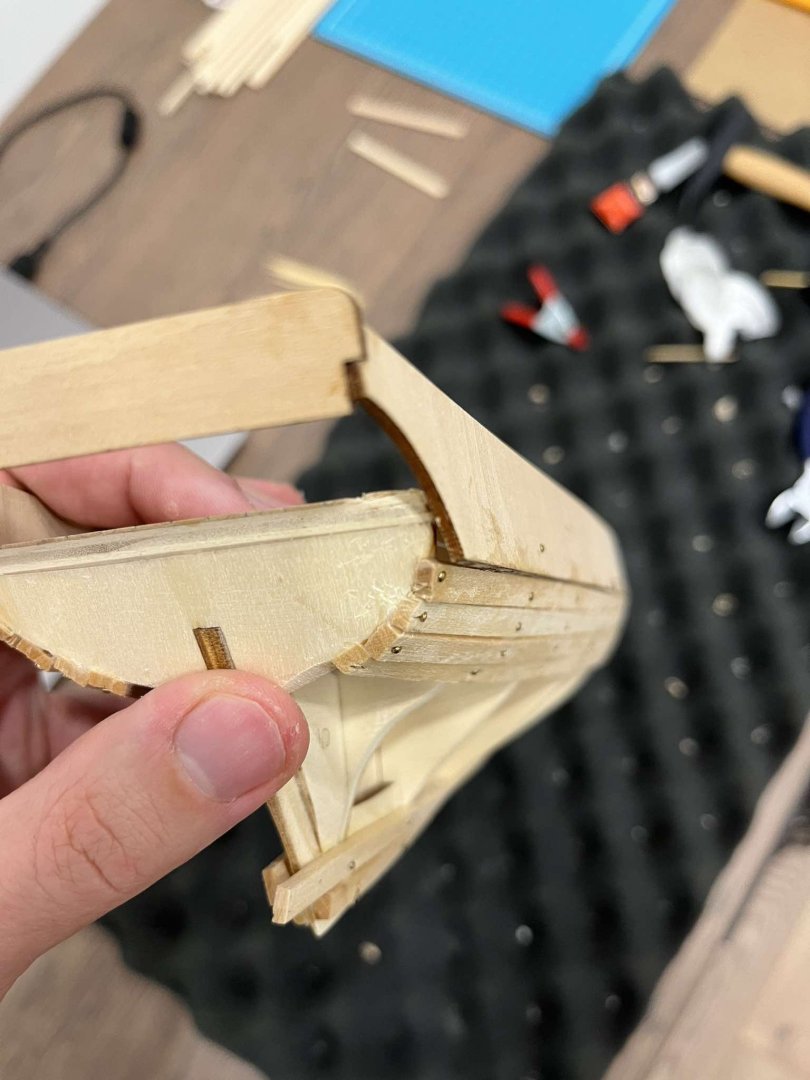

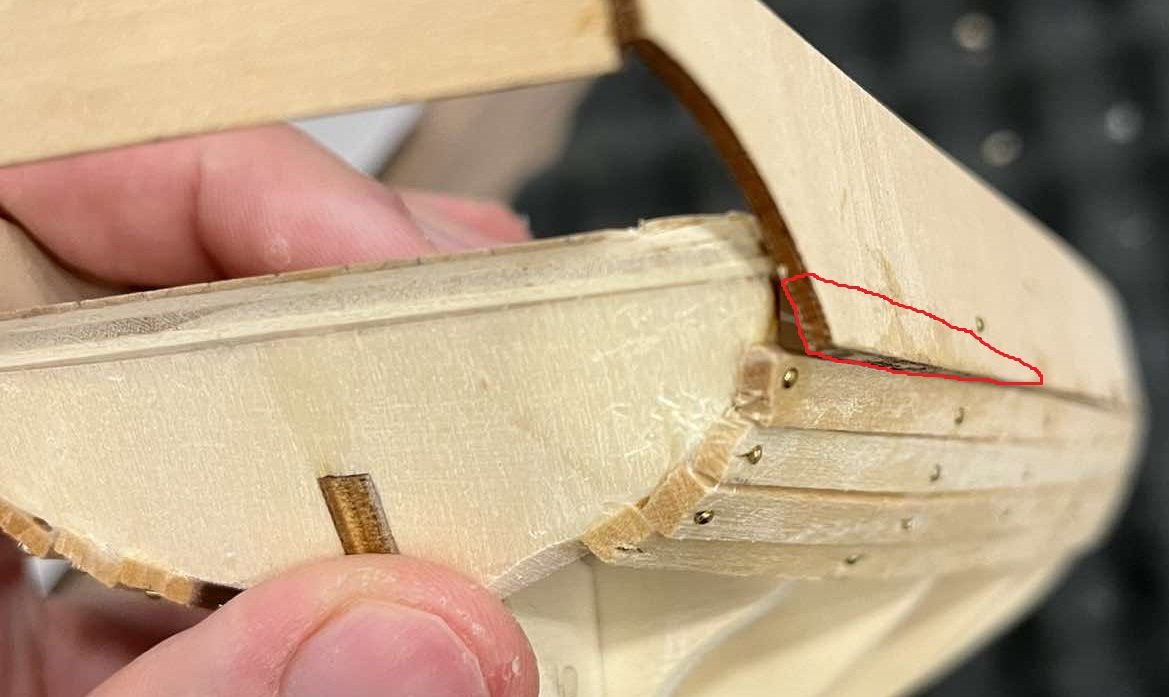

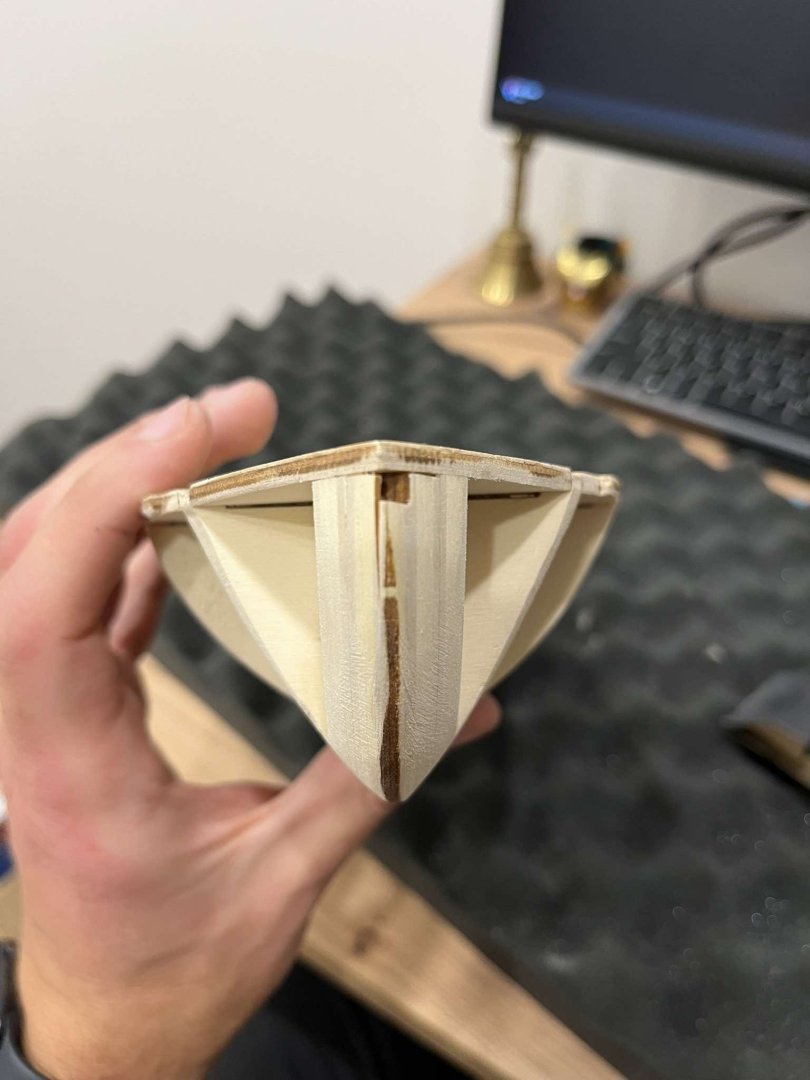

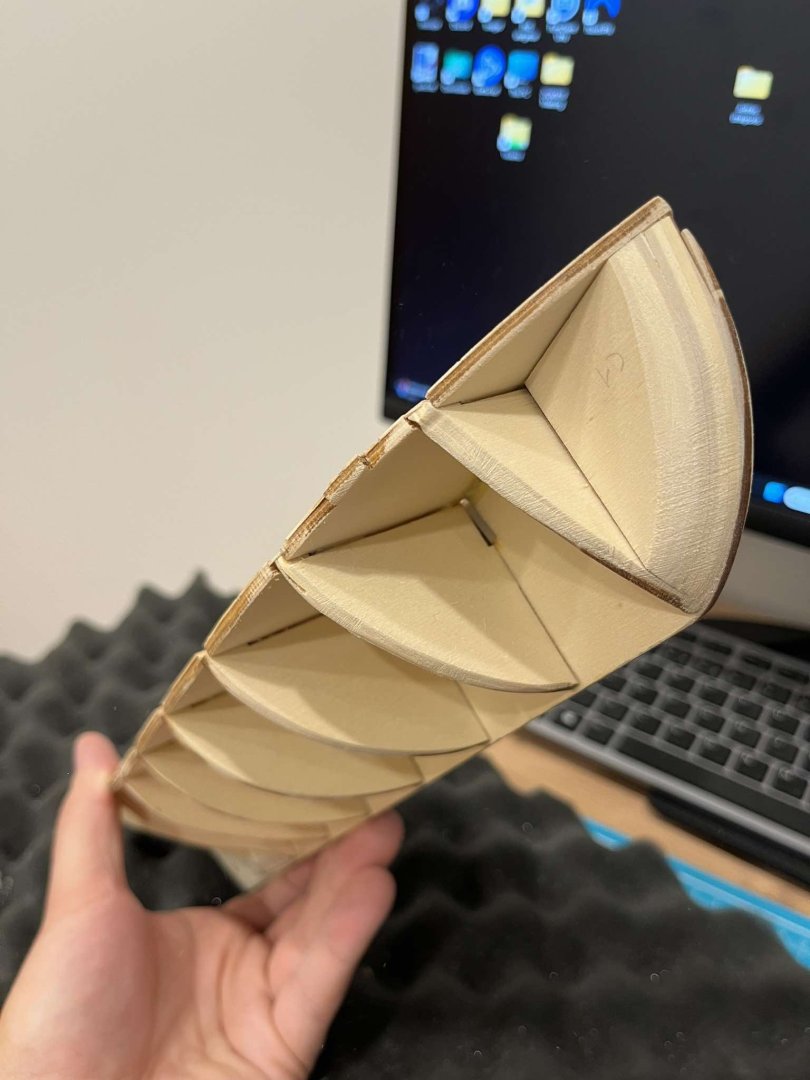

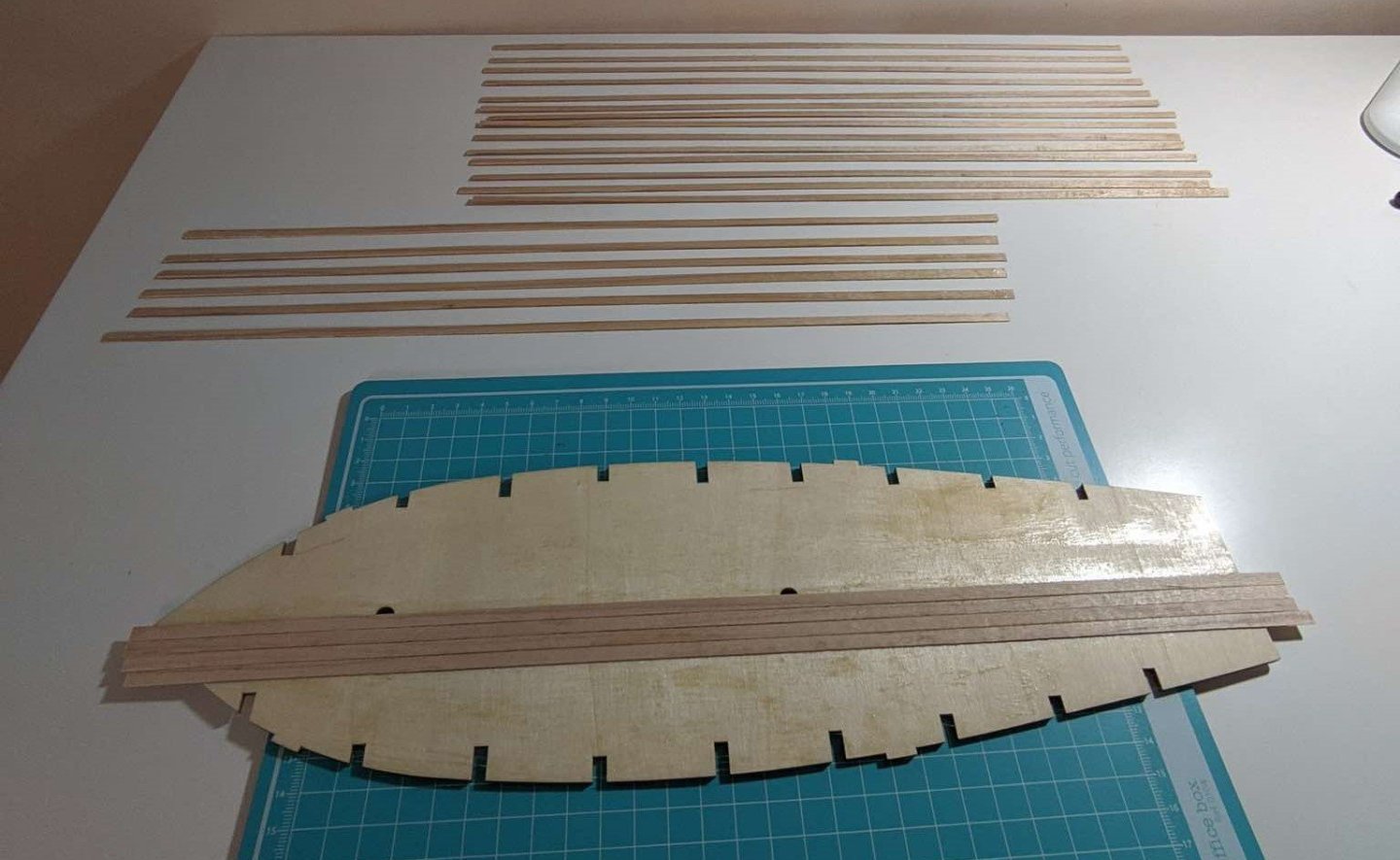

Thank you everyone for the responses. These past few days I did some work on my Polaris. Firstly, I have attached the bulwarks. Can't say that wasn't stressful, but I did it. I put them in the water for 15 minutes, then bent and dried them by ironing. Moment glue at the ends of the bulwark was a game changer for me to achieve full contact. Then I started the planking. It is both an exciting and quite difficult stage for me. Same as with the bulwarks - water, bending, ironing. What is difficult for me is pushing the pins. Half of the time it goes not the straight line that I am aiming for and through the side of the bulkheads. So far I see no damage that I should be afraid of, but it annoys a little bit. I am using a pin pusher from OcCre, maybe I just need more practice. The problem is probably not with the tool? Now I have noticed something. I should have bent the bulwarks more towards the stern when I was attaching them and glue them not within the planking area. Now there is an angle and a gap between the back of the bulwarks and the planks, but not a smooth curve: My question is - is it going to be alright and I will have a chance to adjust it by sanding, or should I cut the excess part (it is not really long) of the bulwark (I have marked it red) that is in the planking area and attach the plank instead?

-

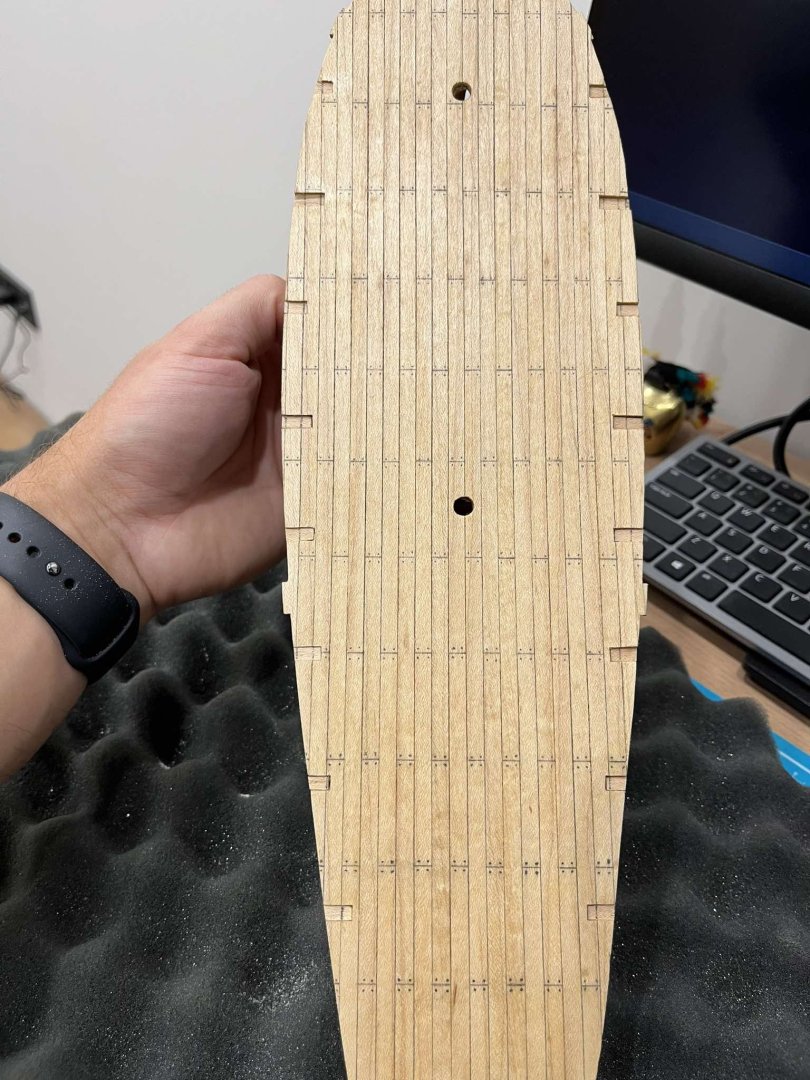

I have decided to put one layer of deck plank on the spots I mistakenly cut. Two layers would look better, but I thought I shouldn't waste too many deck plank resources since I don't know how many more of them exactly I will need in the future steps. I don't really like how it looks, but it is better than before and I believe it won't be so visible after I will glue the walls of the deck (how are they called?). By the way, I saw that people are using titebond glue. They are premium quality wood glue for more advanced projects? Also I have finished (at least I hope so) the sanding of the hull. It is hard to understand if it is enough, but I believe so.

-

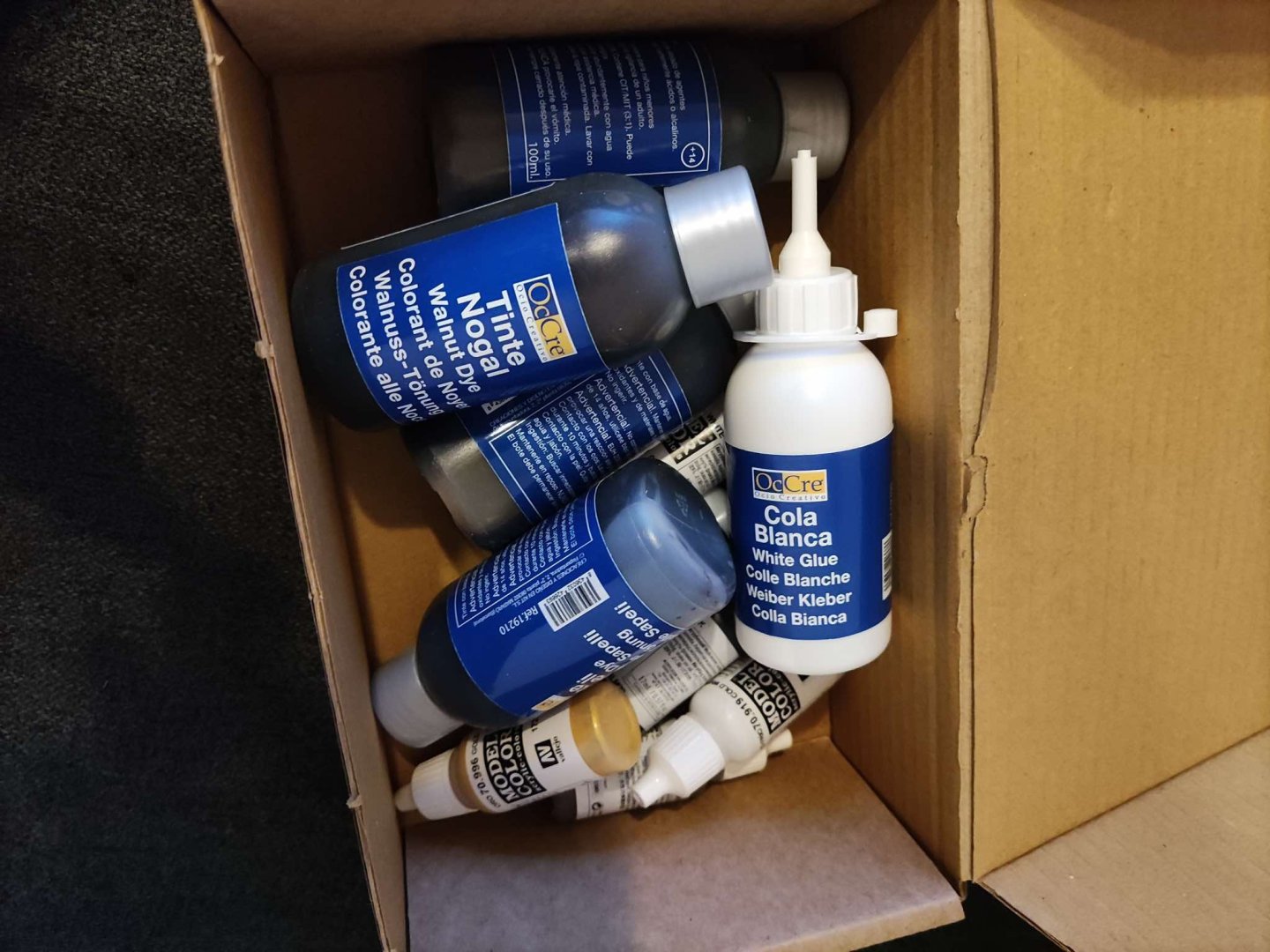

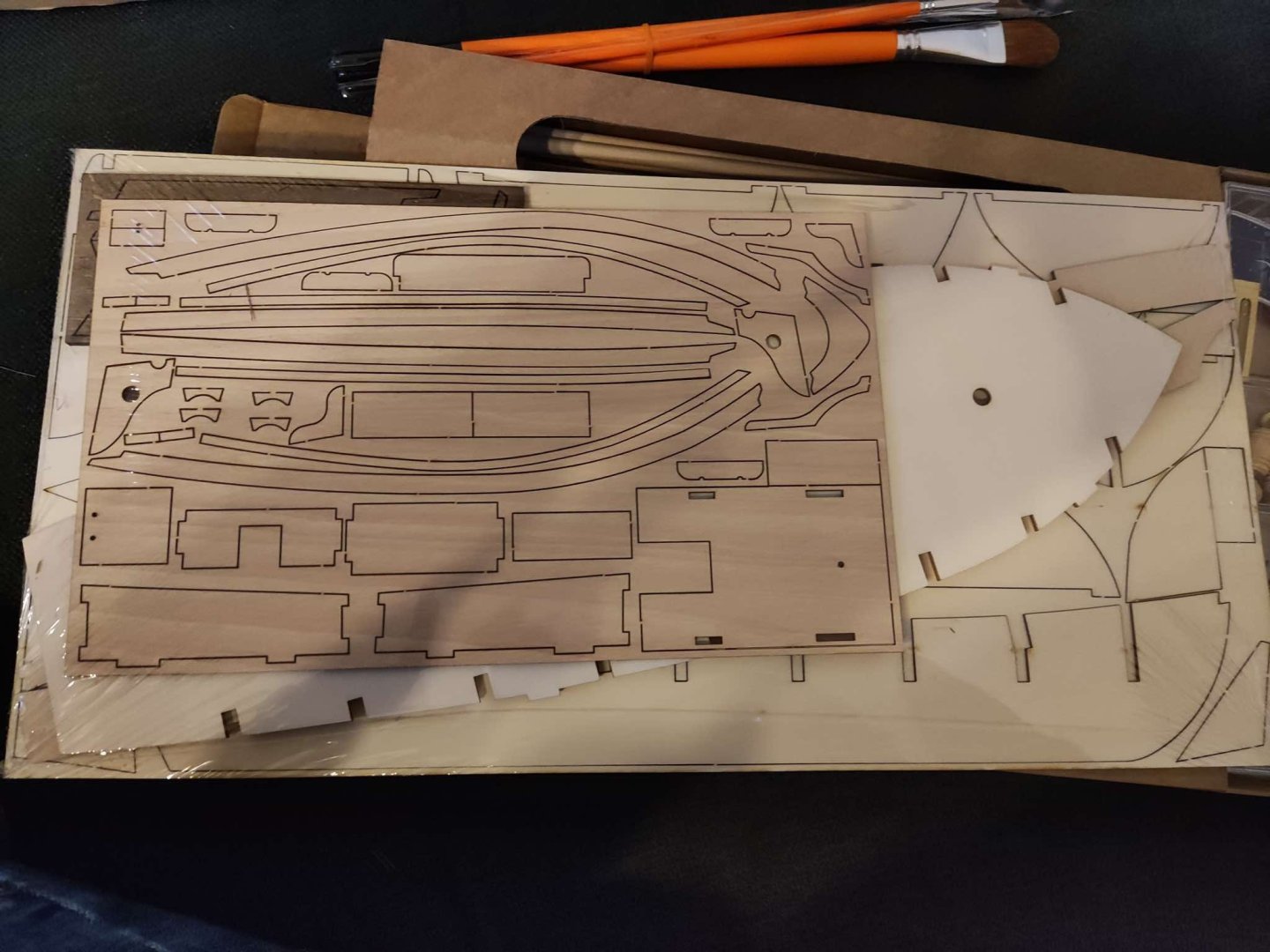

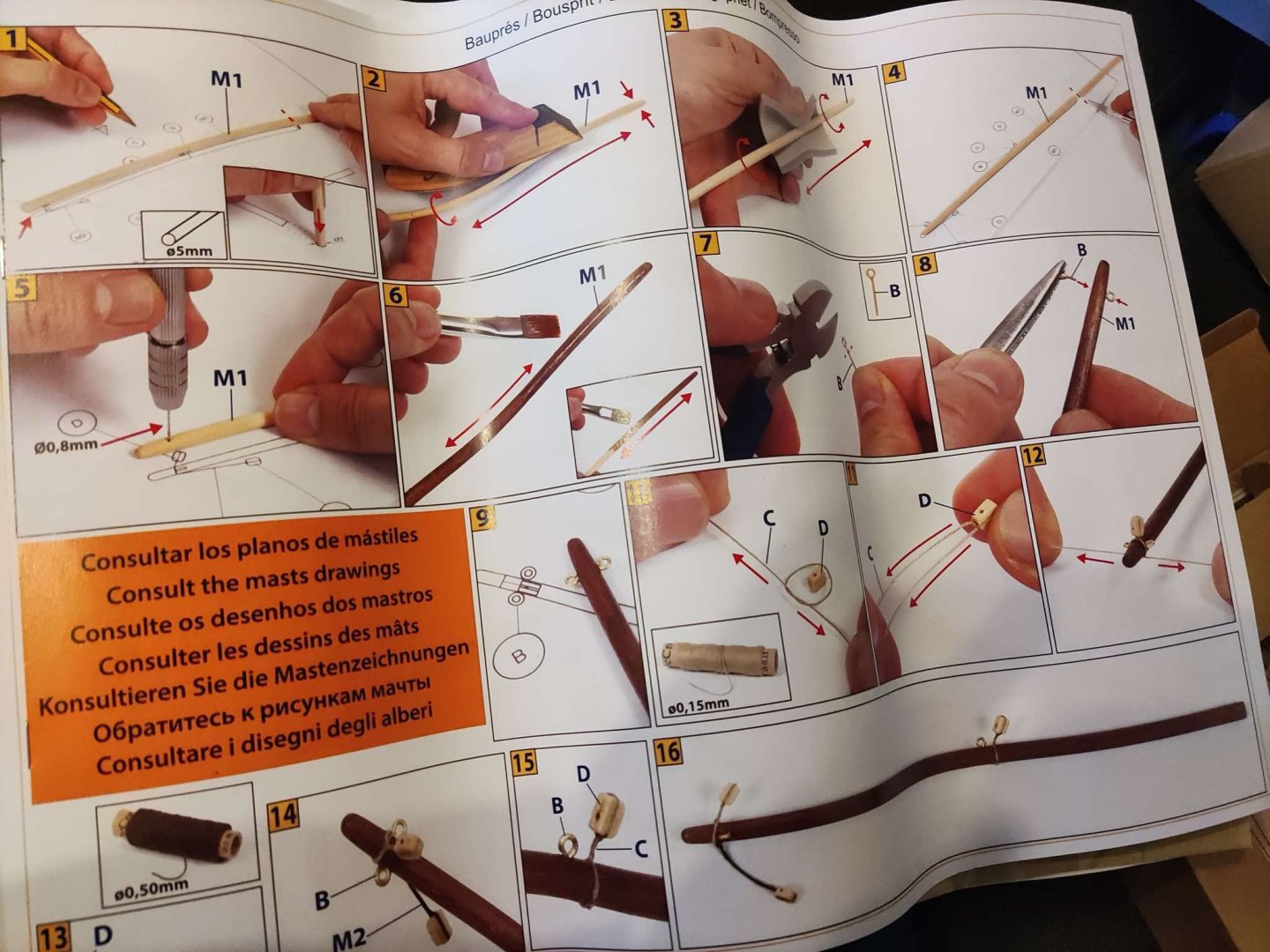

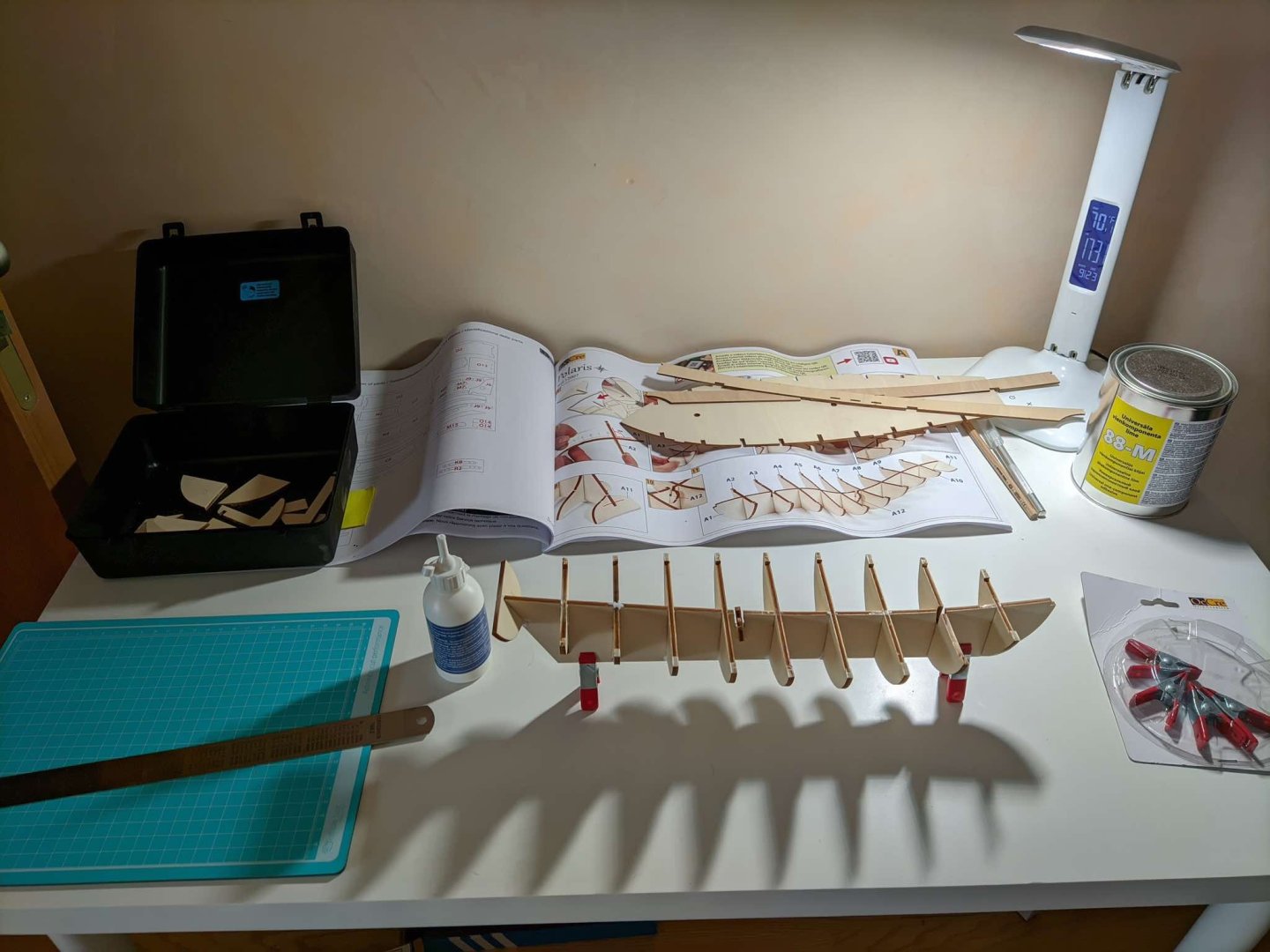

Hello, Here I start the log of my first build - Polaris by OcCre (1:50). I have purchased this kit in 2020, but started it only around 2022. Then took a long break again and now I am looking forward to finally returning to this build and finishing it (I promised my friends that I will finish it before my 30th birthday in January 2025 ...). I ordered a starting package together with the paints, glue and starter tools. Even though I don't have anything to compare with, I like the quality of the materials and all the accessories. As for a new guy, the instructions are clear and there is also an informative step-by-step build guide on Youtube from the OcCre itself. Then I started to build. I really enjoyed the process, the hobby seems interesting. The sanding takes a lot of thorough effort, but I believe it takes time to understand specifics and grit sizes. And here I made a mistake I cut the extra deck planks (if call them correctly?). What would you suggest to me? Try to apply small deck planks? At this moment I am finishing the sanding of the bulkheads and false keel, which seems like a long and thorough process. The next step is going to be attaching the walls outside the deck.

-

Hello from Lithuania

Captain Vytautas replied to Captain Vytautas's topic in New member Introductions

It would be super nice! I remember good old days I was playing Magic: the gathering in 2006-2008 and there was a Lithuanian forum and community of this game. It was a nice way to communicate in the forum with like-minded people, but nowadays social networks, like Facebook or Instagram, are filled with toxicity and hate. This is why a forum feels nostalgic for me. Lithuanians love the Baltic Sea. Did you get a chance to visit Lithuania? -

Hello, modelers around the world! I am a new builder from a small and beautiful country - Lithuania. Looking forward to this hobby as it seems calming and interesting, especially for long and dark evenings that are right around the corner in autumn. Some time ago I bought my first ship model kit - Polaris by Occre. I have started building it, but then, of course, the lack of time kicked in. Now I feel that I have more time, also my big new work table is on the way to my house, so I want to continue my build. I have photos from the beginning of the building and also I have lots of questions so I am going to start the build log. Hope to receive the feedback! Vytautas

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.