-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bnw

-

Which type of deck finish can you advise? I would like to keep the light colour of the basswood planks and no high gloss but semi-gloss/silk or maybe some kind of waxlook. @TerryPat already advised a wioe-on poly, which was new to me, but it sounds interesting! Are there other ideas and maybe an overview of pro's and cons? Or a clear website or video about this subject? I didn't find one yet.... Or maybe some images with the different looks of the different methods. Later on the second planking of the hull will be mase with darker sapelly wood and I would like those also give a transparent finish. Can I use the same product/method as the deck or do I have to use something else?

-

I was wondering: in several built logs I see that people coated/varnished the deck before going on. I do understand that it will be easier to coat the deck while there is nothing on it. But I can also imagine that it might be better to glue the cabins and other details directly on the uncoated deck, instead of glueing them on a layer of coating. Maybe more in general: at which moments can you best coat the several parts of a ship? (Deck, details, hull,....)

-

Thanks! To be honest, if you take a closer look, it can be done even more precise as what I did, but as said, this is all new to me, so I am quite happy with it. When I will do the front part of the deck, I may take some pictures how I did this. But actually I did it as per instructions. First I cut the plank as in this image: After that I placed it in position (no glue yet) and with a sharp pencil I drew the outline on the glued plank, which has to be cut. After that I cut the part away, using a steel ruler and a sharp knife. This part I found difficult to do as precise as needed, so when looking closer you will find some narrow slits, but overall not too bad. Maybe someone has an idea how to nicely fill these slits? I was thinking about a wood filings/glue mixture, but because I have blackened the sides of the planks to simulate the caulking, I am afraid that it will be worse than when I leave it as it is now.

-

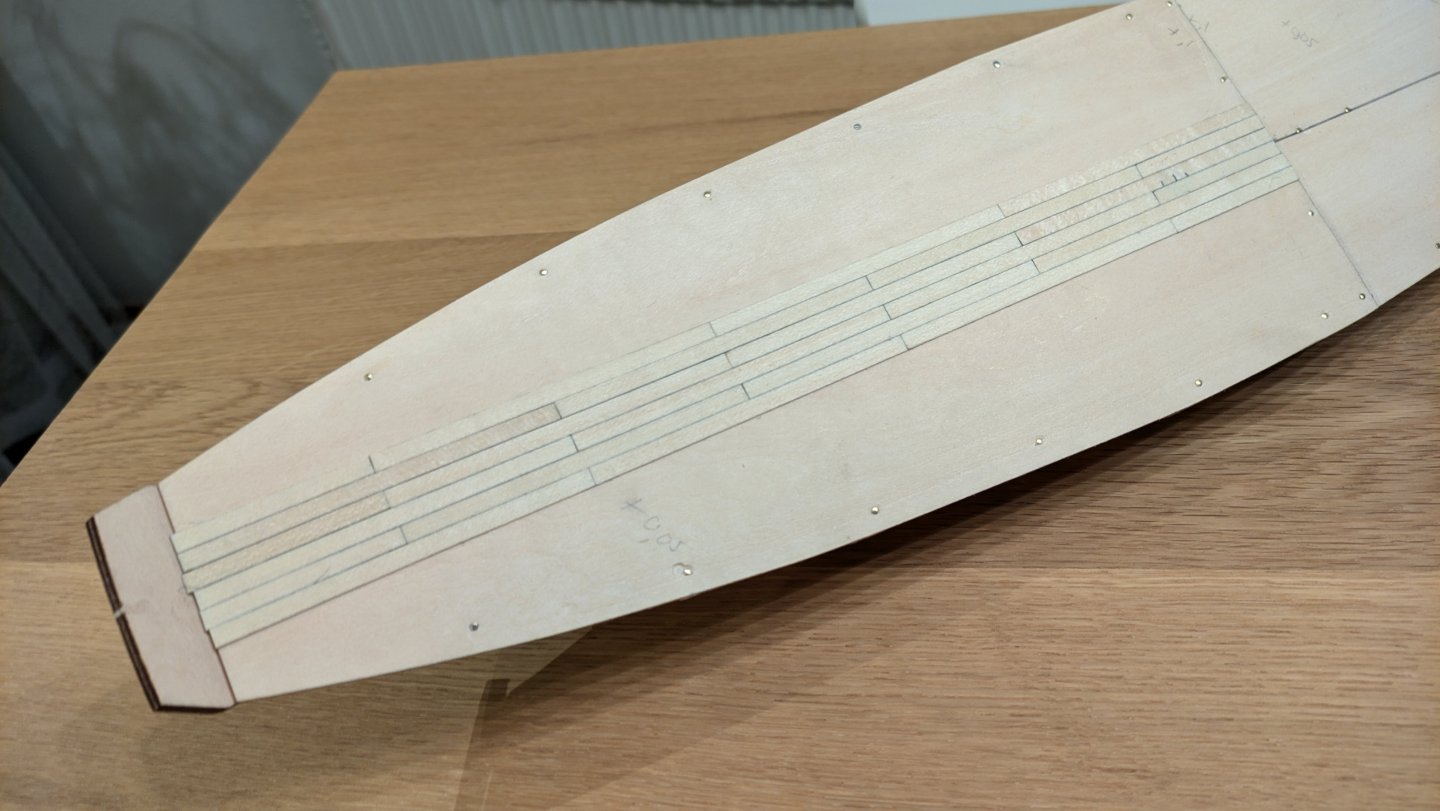

Today, I encountered the first part that I really struggled with! I am still pretty happy with the result, given that almost every task in building a wooden modelship is new to me, but this is something I still need to get better at! I was adding more planks on the deck, but as per manual, I have to make some cutouts in the curved outer plank. And that part, I did not find easy.....

-

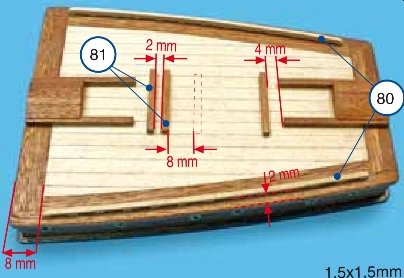

Okay, I have made my first (small) mistake, that is to say, I accidentally deviated from the instructions. The outer side of the cabin's roof should have two sapelly planks, but I accidentally placed only one. Instructions: My cabin: I'm thinking of leaving it like this. It looks pretty decent now and it probably will be quite difficult to cut away one plank-wide part of the basswood planks, because they have been glued to the false deck already.... Any ideas, or maybe best to leave it this way? There will be added some extra details but none of them will be a big problem, I think. So the 8 mm in the image below is 4 mm on my model now.

-

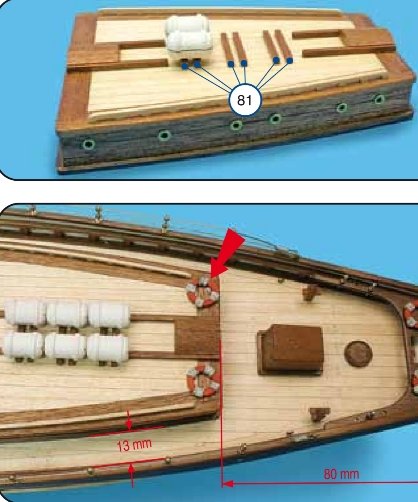

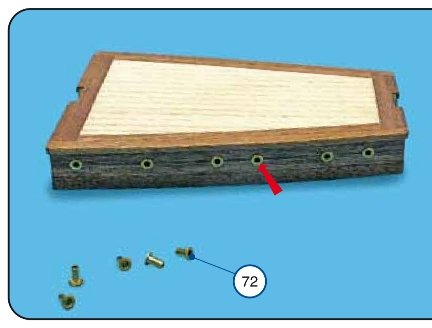

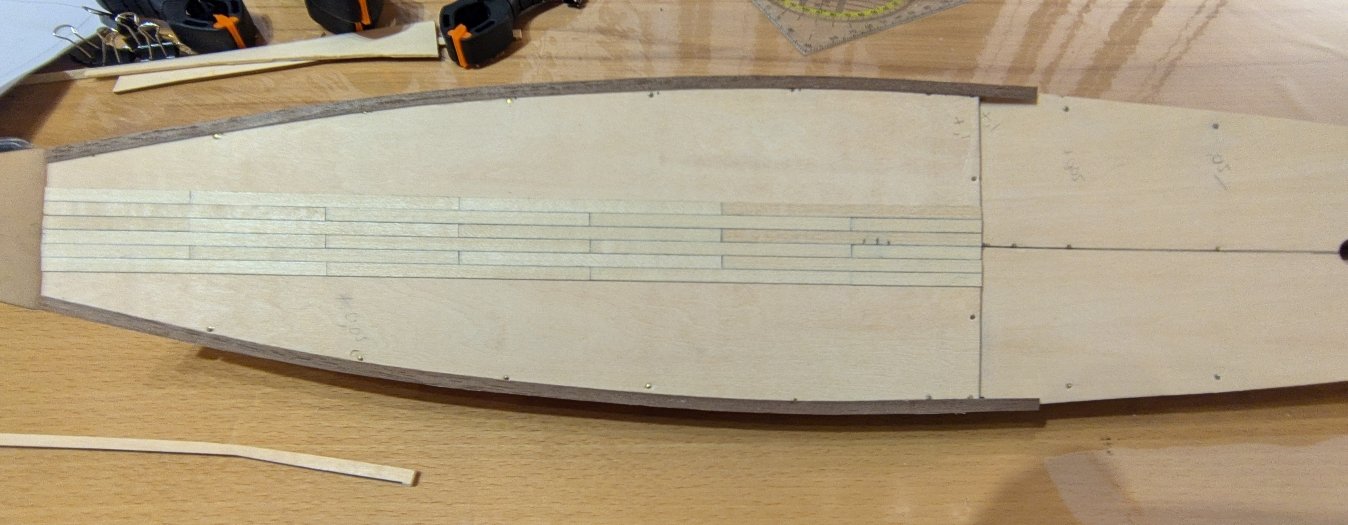

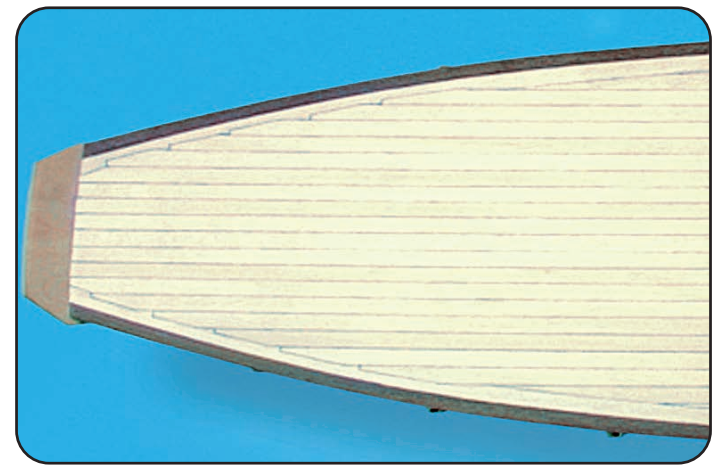

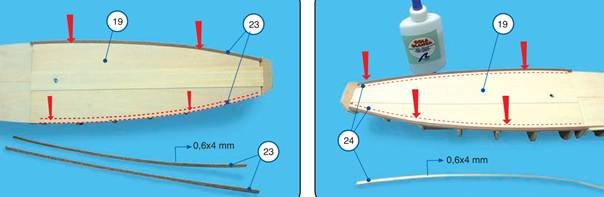

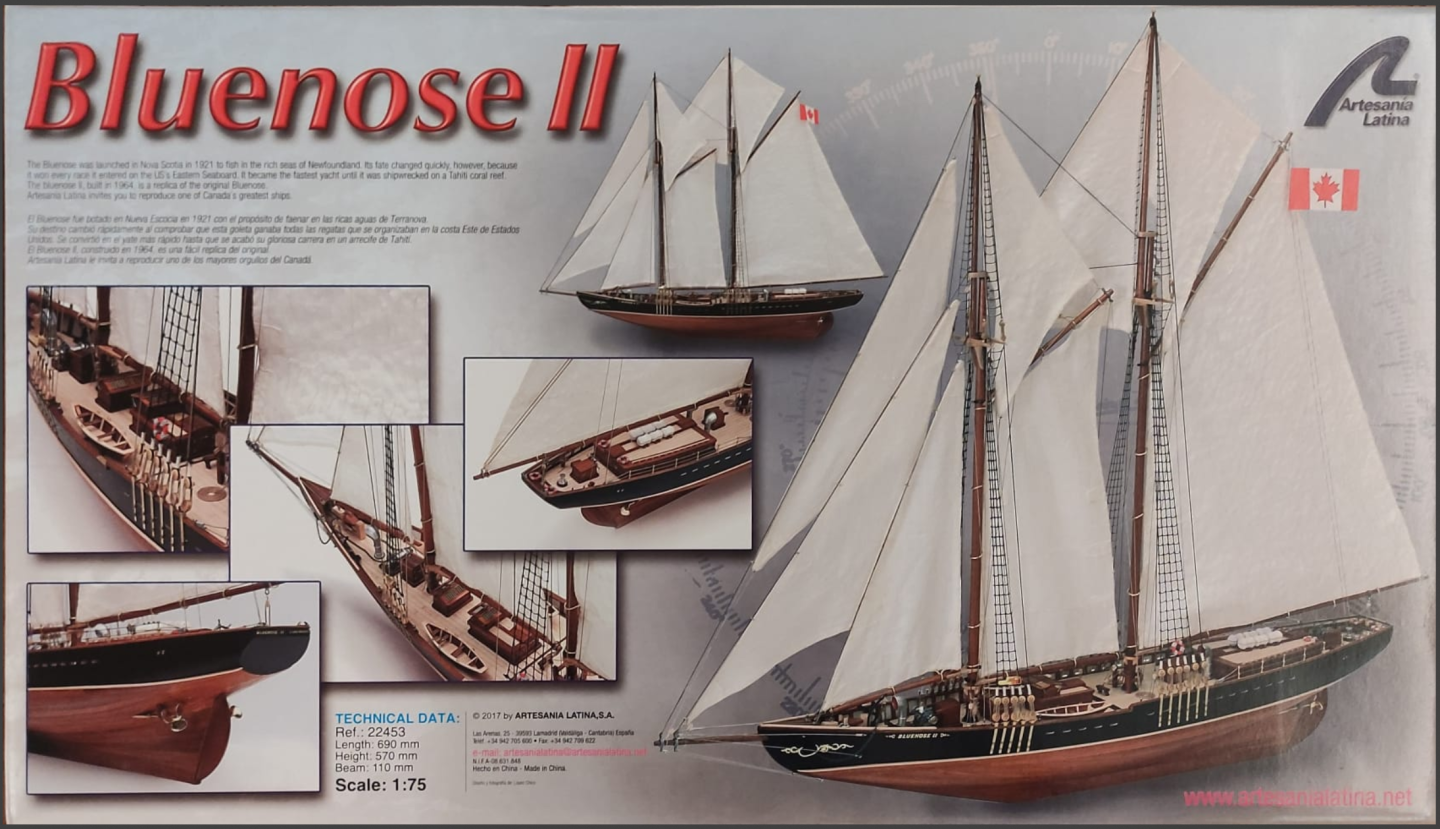

The curved planks have been glued to the deck (two on each side), so I can start filling in with the straight planks. In the meantime, while waiting for drying, I have started to build the stern cabin. There has to be added brass portholes. I assume it is best to put on the varnish on the cabin first and than place the portholes? I think I would like to keep the deck in this light colour (I know the original Bluenose has a darker coloured deck, but I like this light colour as AL also showed on the box): Is there any advice for the varnish? So as said, I would like it colourless and normally with paints, I like semi-gloss. Any thoughts and tips?

-

It has been quiet at the shipyard for a while.... Because there was work to do in the maintenance of the house. But today I have laid my first deck planks. I was wondering whether to do the calking or not, but I have chosen to use a pencil to add some little black on the sides of the planks before gluing them on the deck. The next step will be my first bending of planks for the outer planks. For my first modelship I am quite pleased with the result. Maybe I have to do one or two wipes with sandpaper. I am wondering one thing. My "biggest fear" is getting stains of the graphite when sanding the deck planks. How big will the risk be for that? Any tips to avoid that? One thing I can think of is sanding in the length direction of the planks.

-

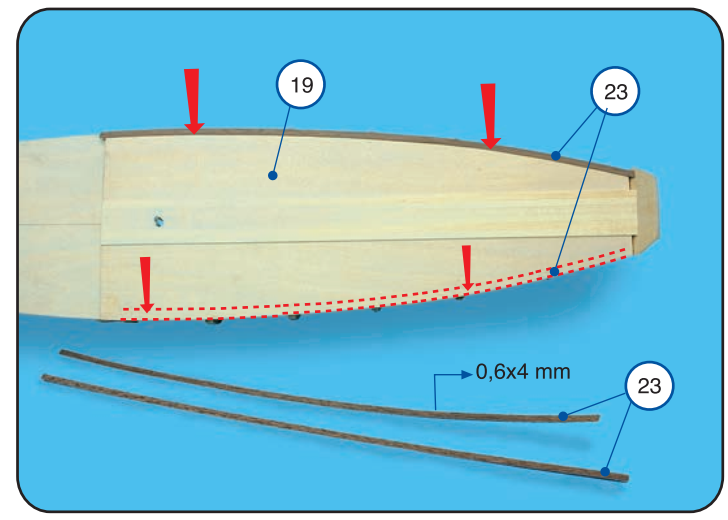

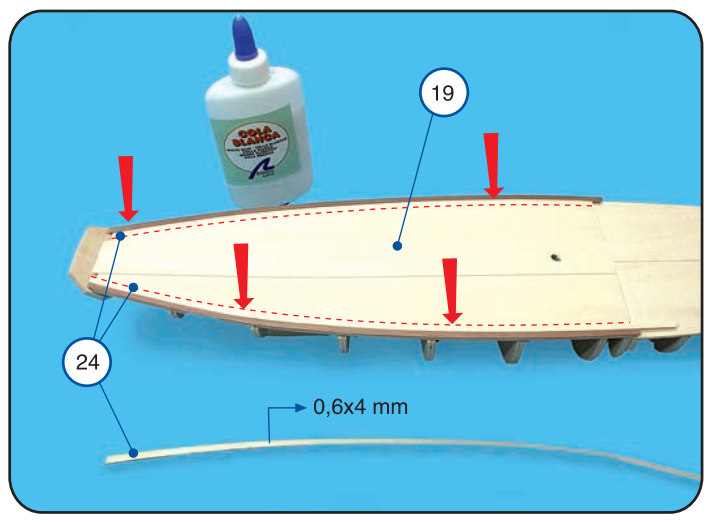

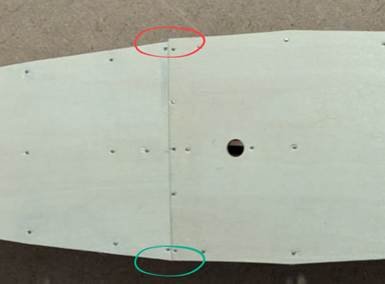

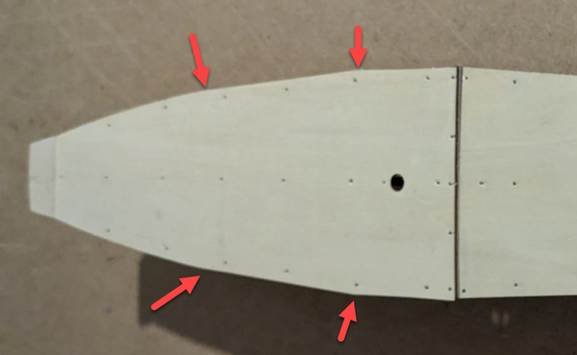

Planking the deck.... wondering how to start.... I am at the start of planking the decks, but I am wondering a few things, because of a small inacurrance in my work and a thing about the lasercut decks. Maybe I am thinking to much before actually start, but I would like to try to get the planking as symmetrical as possible. Next image is from the build log from @Penfold Bluenose II by Penfold - FINISHED - Artesania Latina - 1:75 When finmishing the planking, he noticed there was a small asymmetry in the pattern of the planks, because he sanded the contour of the deck after drawing the centerline, but before planking, as I did understand it well.: I hope to avoid that, but as a newbe, I have a small asymmetry in the position of the higher deck at the red arrow, because I was a bit inacurrate when assembling the frame. The hogher deck protrudes a maximum of 1 mm from the lower deck on one side. As per manual, next steps has to be made: Add 6 planks in around the centerline Add a walnut plank: And a basswood plank along the contour: Then fill in with the other basswood planks: And after a few other steps, sand the right shape in the bulkheads: But there are a few questions. At the red arrows, the higher lasercut deck has two obvious sharp points. Along the two green lines, the countour is a straight line and only the blue edge is curved. The walnut plank and later on the bulwarks will have to follow a nice curve. As told in the instructions, the curve will be sanded after placing the planks on the decks. That means, when attaching the outher plank, you need to stay inside the contour and will see the sharp points of the deck and other parts of the deck protruding, which will be sanded away at a later time: Another consequence of this is that the with of the walnut plank may vary because of the sanding. The other way might be to sand only the contour of the deck (not the bulkheads at his moment) to get the nice curve and place the outer walnut plank against this sanded curve. I can than sand and measure both sides as close as mirrored to get a nice symmetrical layout of the planks and draw the centerline after this. To be honest, the deviation between left and right is only in this incircled area; the rest is symmetrical: But I can imagine, because of the cutouts, a small asymmetrical area will be visible in asymmetrical cutouts/planking: The other thing is, because I will need to correct the little inaccuracy at the step from the lower to the highter deck, the hole of the mast will also be a little offset to the centerline (about 0,5 mm or <1 mm). So the lines between the planks will also be not completely symmetrical to the hole of the mast, but maybe that will be less visible? Can you guys tell me which way I can do this best? Or am I being too picky now and do I simply have to start planking? I hope I made my questions clear, but someone told me: ask before gluing!

-

Tnx guys for the interesting info! @Snug Harbor JohnnyLooks like an interesting book! thank you for the tip! @KenchingtonThank you so much for your story, I was really impressed by it. I have never been to Canada but hope to visit this beautiful country one day. I like that my first ship model is actually a Canadian ship. Reading a story from someone who lives there, who actually saw the Bluenose II and has been aboard her, really touched me. Especially what you told about the moment she passed by when you were aloft. When I started this hobby a few months ago, I didn't realize that building the model is only a small part of it. Talking with other enthusiasts, learning the history and specifications of the real ship, and listening to stories about her and the people around her, is at least as satisfying as the building itself!

-

Me too like the nice lines of the Bluenose! I think the shape of the hull will be nice to work on and to follow while sanding and planking. I have found the videos you mentioned. I have watched the first few minutes, and it looks like clearly spoken and explaining videos, so definite worth watching! Nice, you not only can spend a lot of time on building, but also on watching videos, tutorials, reading modelshipworld.com, etc....

-

The planking of the deck will need some bending of planks and this will be the first new thing to learn for me, so I am still looking into it first and I am investigating how to do this. The most outer plank is walnut: And the second row is basswood: the rest will be filled with straight planks: Is this the right way to do the bended planks: put the plank in (warm) water for a while. How long? A few minutes, an hour? Bend the plank and place it with clamps in the right position onto the deck. Let it dry in this bended position. After drying, take away the clamps, put some glue on the bended plank and position it back with clamps to let the glue dry. Will this work in this way?

-

Part II Planking the deck. Next thing is the planking of the deck. It consists of basswood and some walnut sheets. I have seen several methods of planking the deck, adding the caulking seams, imitating the nails. - I was thinking of using a pencil to add some caulking at the sides of the planks. - I also think not using complete planks in one piece (front to end), but devide them in shorter lengths to get a better scale. Do you have any tips how to get the best planked deck? Is a pencil a good way for the caulking? Can I get problems with stains from the graphite or how to avoid that? Do I have to use a soft pencil or a harder one? Use the same pva glue for wood? Other ideas and tips before I start with this step?

-

Part I – keel, bulkheads and decks I have already done some things, so this build log starts a few steps in the process. I have removed the lasercutted parts from the plywood sheets and sanded away the irregular spot where the parts were attached to the sheet. After dry fitting I glued the bulkheads to the keel. Because the laser cutting, the bulkheads were almost 90° to the keel without even using tools for it, but I decided to use the Lego brick method to ensure the right angle. Next step was attaching both the decks parts. I have used glue and nails. With a drift punch I made sure the nail heads did not stick out. I am actually quite happy with my first keel-bulkhead assembly! I only noticed one inaccuracy, which I was a little bummed that I had missed, but it is solvable when sanding the edges of the bulkheads to match the planks of the hull. There is a jump halfway down the deck. When you look at this point in the topview, the contour is interrupted at one side. I also noticed that the higher deck did not have a rounded/smooth contour shape, but it has two sharp edges. This is not a “fault” from me, but it was lasercutted that way. On this edge I have to add a walnut sheet, which will follow the contour. I suppose those have to follow a smooth rounded line, not the sharp edge? Following the instructions I have to add those walnut sheets first and sand the bulkheads later, but maybe it is wise to round the contour of the deck before adding the walnut sheet? At the same time I can also correct my small inaccuracy.

-

I am new to building wooden ship models and keeping a build log, but after making the first steps, i discovered, it will be helpful to ask some questions now and than to people with more experience! And because those will be small questions sometimes and maybe not worth it to create a complete, separate topic for, I decided to start my own build log and hope some people might read it and can help me, when I am stuck or hesitate the next step! Some words about me: I am living in The Netherlands, somewhere in my 50s 😋and whole my live, I liked to build and create things, do all kind of handcrafts, electronic projects, make drawings and so on. this continued in my work as an Industrial Product Designer. Things I did: plastic model airplane and car kits, styropor sailboats, RC airplanes and gliders, model railway, and so on.... but I have never built a wooden ship! I think it will be quite a challenge, but on the other hand, you just have to do new things to learn them! My goal is not to make a ship that has to be 100% accurate in detail as the original, but a model that looks nice and giv me a lot of fulfilment when building. I have chosen to build the Bluenose II from Artesania Latina. I like the the slender hull and definitally wanted a model ship where I have to do and learn planking of the hull! I have already delved a bit into the history of this ship and have watched several videos of this still sailing ship. Reading articles on the internet gave this intro on this ship: The Bluenose II is a famous schooner and a proud symbol of Nova Scotia, Canada. She is a faithful replica of the original Bluenose, a legendary racing schooner and fishing vessel. Currently, the Bluenose II serves as a goodwill ambassador and a training vessel, maintaining the maritime heritage of the region. As said, the kit is from Artesania Latina, scale 1:75 I cannot say if this is a good quality kit, but some people told me, they are okay. I do not know how long it will take for me to complete this kit, but I do not set any deadlines. I will take the time and try as much as possible to enjoy building it! I will also have to learn a lot of new words, because this is a completely new jargon for me!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.