-

Posts

112 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by altalena18

-

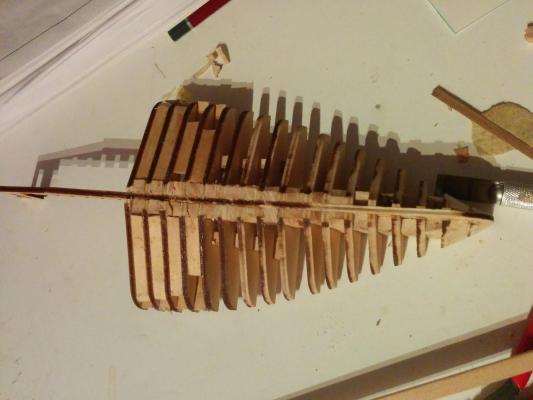

I gotta say, I'm shamelessly proud of this little jig here. Pictures of progress on that ratchet to follow

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Well, grinding the part out of brass stock it is! I couldn't find any brass strips at the jewellery store, but they had some thick wire. I had someone there put it through a vise to get it a bit flattened. Once I got home, I tried carving the notches. I kept not really succeeding until I built this jig- which I'm quite proud of! Now the part is almost done...

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

I agree- and that was the point of teaching myself scratchbuilding using a small boat- just enough detail to get enough new skills and experience, but without having to turn 36 guns and rig 25 sails or whatever. So it's off to buy some brass stock!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

I thought of using plastic or evergreen (i bought a whole bunch a while back and still have some) but I was trying to think of a way to make it out of brass. I guess it'll have to be the old files and brass.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Oh well, I was hoping to avoid that, but it looks like i'll have to nip down to the jewellery supply store and see what sorts of brass stock they have...

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

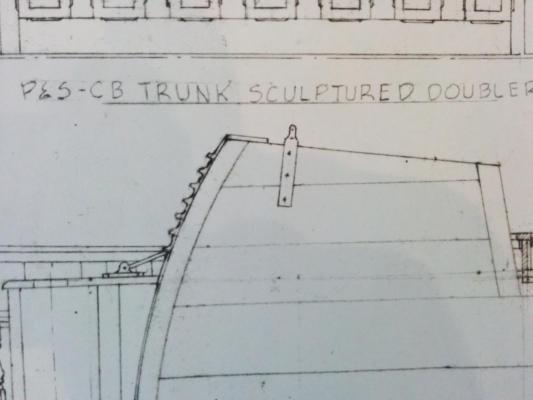

So I need some advice- the daggerboard has both a sort of ring with tongues to tie the rigging that lifts it up, and a ratchet to hold it in place. Does anyone have any idea how I can craft that ratchet? Any common parts or something, or any other method? I guess I could try to carve it out of brass stock with my Dremel but I'm nervous that it'd be difficult and messy and not look neat.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Well I don't know how much time I do have, I guess that's what weekends are for. Buildin the model helps me relax, so I try to put in an hour or two as well in the evenings after work... Anyhow, anyone have any ideas for making that ratchet?

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

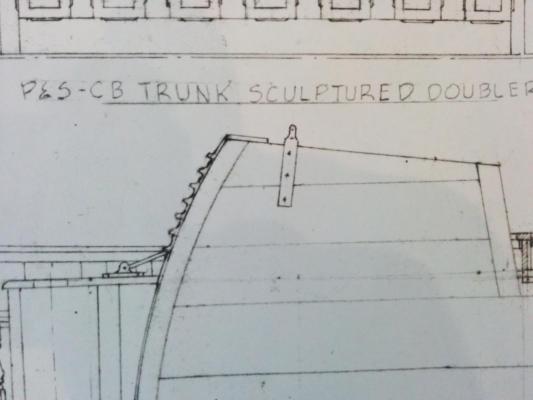

Here are some pics with the keel and the floor dry-fitted, showing the daggerboard going smoothly through all the parts.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Haha that's really something! I still wonder how only 4 men could handle such an enormous sail in any kind of wind though. Anyhow everyone, here's today's progress. I've made a hinge for the dagger board by drilling through 2 pieces of wood and putting a short length of brass tube in between with the board in the middle. I think I might have installed it too early though, because i've just realized that I've forgotten to install all the daggerboard's fittings! oops...

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Wow Jasco, I hope you realize that your magazine is 2 months older than I am... And if you ever build a full-sized sandbagger, you'll probably need an enourmous crew, what with all that sail area and that puny hull!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

I used basswood stock from the hobby shop on Annie, and balsa on Fair American. I think basswood works better because it's easier to carve and not as soft, and the best thing is to find or cut billets that match the width between your bulkheads, so that they come out decently exact and don't warp the hull. Even still, it takes a lot of work and a sharp eye to ensure that everything is straight and plumb!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Thanks, anything helps. Honestly in my opinion, if you plank a solid hull, or, as I do, use a lot of wood as filler in between bulkheads, planking is not that difficult a chore. I planked my Fair American pretty easily, although all the work is now hidden under copper plates and paint!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Although luckily I don't have to buy turnbuckles, Annie has deadeyes

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Wow, Jasco, that is mindblowing and inspiring. I hope mine looks a tenth as good!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Hi all! I have just completed a very stressful and delicate operation on the model- I have cut out the boat's backbone in order to have a slot for the daggerboard!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

I've almost completed installing all the bulkheads. Eventually I'll get to sanding and fairing everything, but first I had to straighten out the hull. Even though I'd steamed and pressed the keel TWICE and let it dry in between two glass shelves, it still managed to warp. I'm pretty sure I've got it straight now but we'll see...

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

So here are some updates. I've installed more bulkheads, and reinforced them with wood to strengthen them. The bulkheads where the open deck is are particularly delicate, and I'm hoping this will help strengthen them and prevent them from cracking.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Wow, I'd love to see some photos of your model! when I first started doing research, I found almost nothing on the Internet about sandbaggers, and I'm surprised that so many people even know what type of boat it is. Laser cutting wood should be pretty cheap. I paid about $40 for lasercutting.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Hi Rob, I'm glad to meet so many caring and helpful people! If you do go to mystic, please feel free to take pictures of Annie, especially of small details like fittings and rigging, and post them to this thread. It will certainly be helpful to other people who want to use my build to help with theirs, if they ever build Annie as well.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

Oh how lovely, Gary! It's so nice to hear a real story like that that connects us to history. It must have been sheer joy just to speed on the Hudson on such a beautiful boat. I think a lot of what is behind our hobby is the sheer beauty and romance of these machines.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

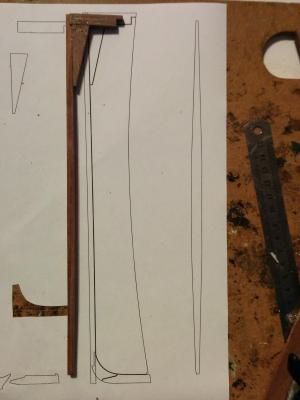

I drilled out a slot in the keel for the daggerboard. I was really nervous about this step, because it is pretty delicate work, but I maaged to make a pretty even slot without breaking anything. And the daggerboard fits with room to spare!

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

-

So I've worked on the keel. It was really hard to cut really exact scarphs- I don't know how all those folks building plank-on-frame build things like this by the hundred! My keel fits together fine but it is by no means perfectly accurate, and makes me appreciate all the more a lot of the more sophisticated builds I've seen on this site.

- 103 replies

-

- annie

- sandbagger

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.