-

Posts

54 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ZevEisenberg

-

The transom, painted and with window frames and panes fitted. The window panes are a piece of clear plastic, painted black and blue, and glued to the back of the transom behind the wooden panes. The center window is, according to the plans, a false window. The plans say to “center fake window on real ship.” The instructions say to paint at this point, but other builds I’ve seen are saving it for later (or aren’t painting?). Is this because you are planking the transom? In general, do people prefer to pain parts before or after they are installed, or does it depend on the part? My dad follows the tumblr version of this log, and when I next spoke with him after he saw this one, he complimented my clever use of paint to simulate a reflection in the windows. It was surprisingly difficult to convey, over the phone, the fact that those aren’t fake reflections. That’s a piece of clear plastic, painted black and blue on the back, glued in behind the window frames.

-

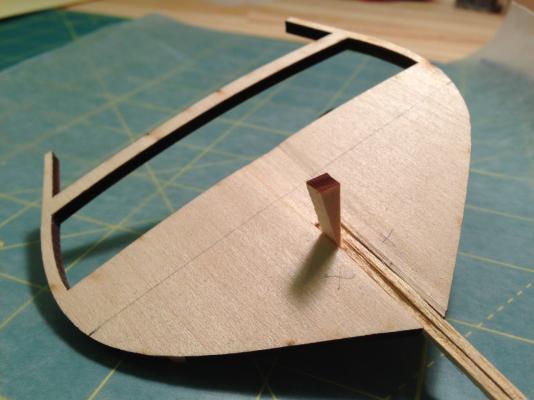

The wood transom and Britannia metal stern carving. The stern carving was not bowed wide enough for the transom, so I had to stretch it through misuse of a bench vise. After this post, I came across a post by @JPett (can’t seem to find it now) where he opted to shrink the transom itself. Since this is my first build of this scope and scale, I’m going to try to stick closer to the plans.

-

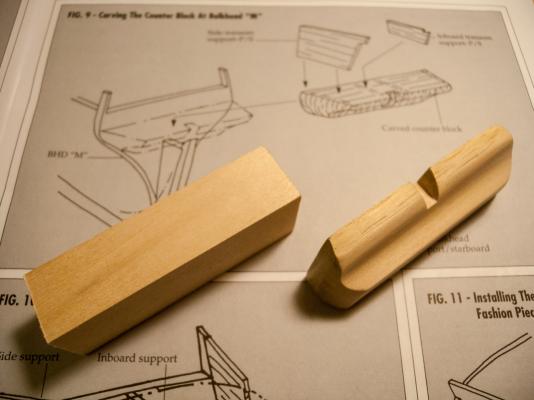

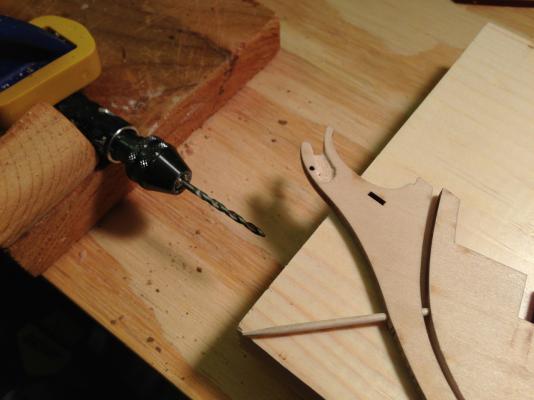

Tonight I turned a small block of basswood into the stern counter block without the use of power tools (and, some would argue, without the use of proper tools). The next time I make one of these, I will wait until I have fitted it to the keel before shaping the left and right sides, so as to ensure better alignment with the edges of the sternmost bulkhead.

-

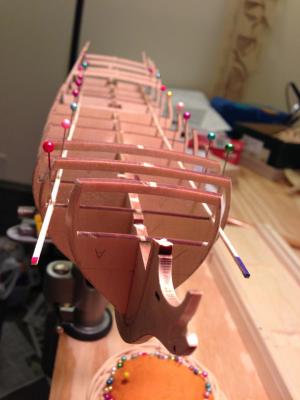

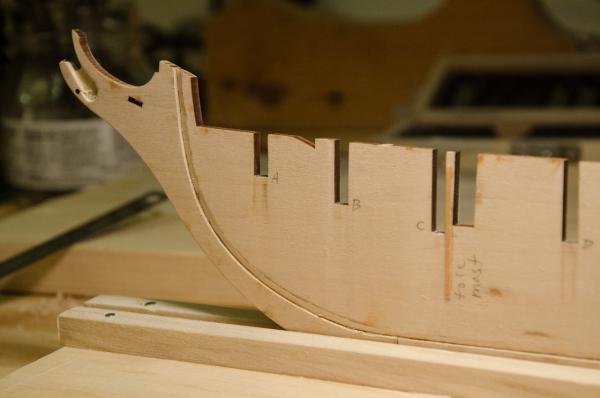

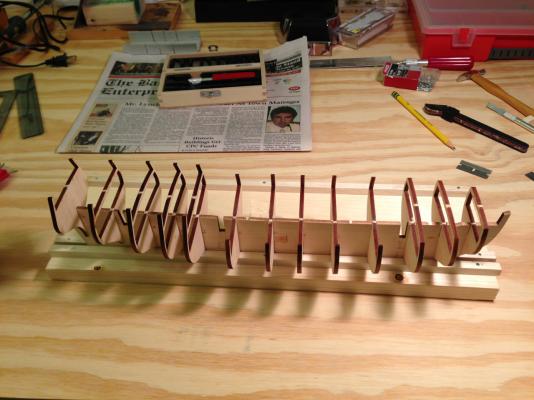

Finished fairing the bulkheads. All but three required bending, gluing, and sanding strips to both sides. This was the most difficult part of the build to date. It seemed like every time I finished fairing a bulkhead, its neighbors got worse. Some ended up having two or three layers of fairing strips added. hopefully, I’ll how get smooth planks to within a tolerance of less than a plank’s thickness, which still seems high. How typical is this level of fairing? Is this an issue of model quality, experience, technique, or some combination?

-

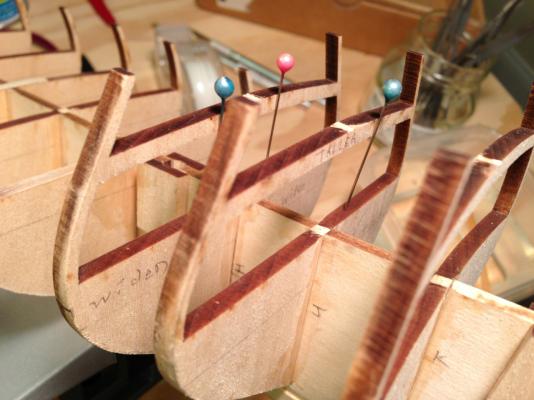

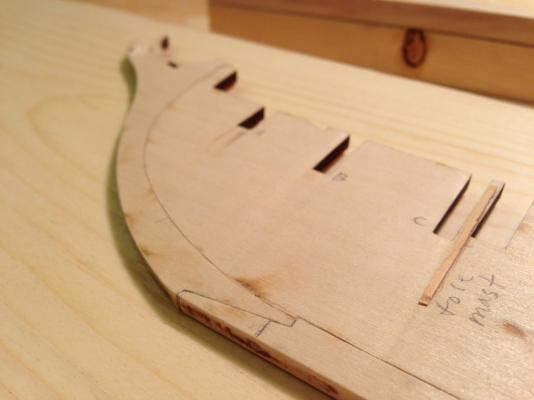

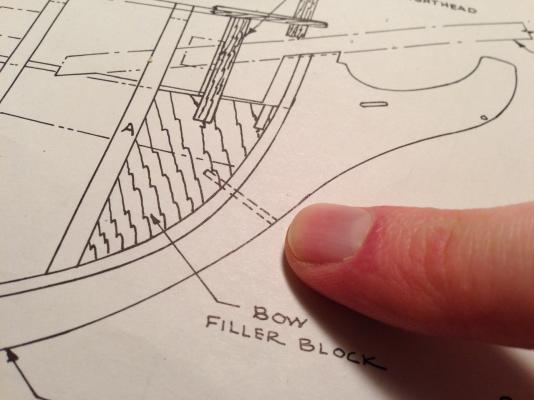

Bulkheads symmetrified. In the foreground are the paper tracings that I made of each bulkhead, folded in half, and used to check symmetry. The center slot was too far to one side in three or four bulkheads, and I had to slice a strip off of one wall and glue it to the other. This paper tracing technique comes from Frank Mastini’s excellent Ship Modeling Simplified.

-

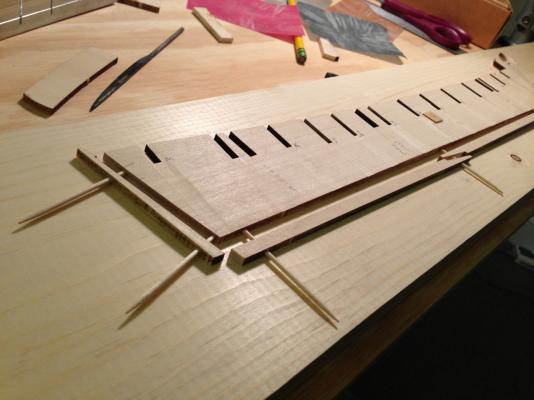

The plans suggest using dowels to help align the keel. The keel pieces are 5/32nd of an inch thick. I tried using a 1/16th inch drill bit, but I can’t seem to find any dowels that thin. I tried a ~3/32nds drill bit, which seems to work perfectly with some round toothpicks I picked up for $1. Pictured is an experiment on a bit of scrap wood. I drilled the hole, inserted the slightly-sanded-down toothpick, and cut and sanded the end. Looks like it will work perfectly, provided I can construct a jig to align the Dremel to ensure I get a perfect hole through both pieces.

-

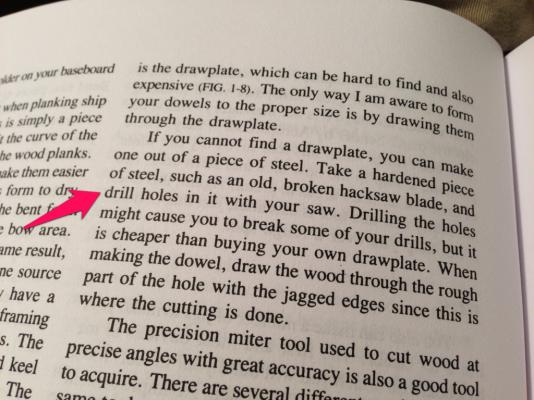

I also picked up a copy of Planking Techniques for Model Ship Builders, since the planks on my last model came out pretty uneven and required a lot of cleanup with wood putty. I won’t really get into the book until I actually get to planking, but I skimmed it, and this passage jumped out as not inspiring confidence.

-

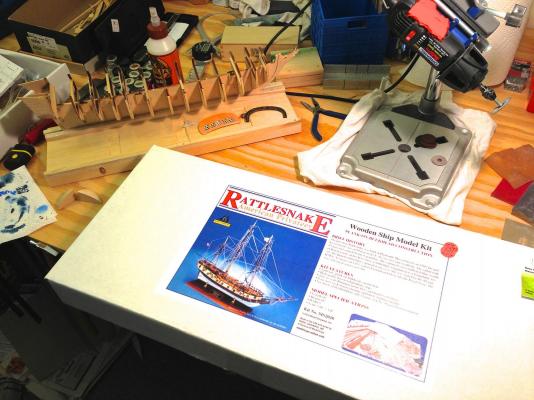

My workspace circa October 21, 2012. In addition to the included Model Shipways instructions, am referring to Ship Modeling Simplified by Frank Mastini. It has great tips on making a build board and assembling the keel so that it comes out flat. The dremel in the picture has since been promoted to a stand that turns it into a drill press or grinder. It’s also a bit messier now, but not so much that I can’t find anything (he rationalized).

-

I am new to the Model Shipways community, and I suspect I am one of your younger members (born 1988 - anyone younger?). I grew up on an island in Maine and was always around boats, and my whole life I have been doing something boat-related in one way or another. The neighborhood kids had tree houses; I had a rowboat in the yard that my dad had turned into a kid-sized lobster boat. When I was growing up I made many simple boats from kits (the kind with a solid hull and like ten simple blocks that you glued on for detail). I had a Titanic phase some time before middle school: plastic models, paper models, and high-pitched lectures about waterproof compartments and buckling steel to anyone who would listen. In the last few years, I made two small plank-on-frame boats from kits, the first with my dad and the second on my own, after a crash course in plank bending from a neighbor who I wouldn’t be surprised to find on this forum. Last year my parents called me from a weekend getaway in a small town and said they had found the Rattlesnake kit, on sale, in a hobby store, and wanted to know if I would like it for my birthday. I thought it would be fun to get back into model ship building. At the time, my main hobby was an iPad app I was writing in my spare time, but that’s also partly my job, and it was a bit of a programming overload, and I wanted to do something in the real world for a change. I built my last models when I lived with my parents, so I had fun setting up a work bench in my apartment and getting new tools. I started with more or less nothing, and have bought tools only when I actually needed them. I didn’t know about the Model Ship World forums when I started my build. I wanted to document my progress, so I set up a tumblr account for this and other projects that I work on. I only found my way here when I started googling around with questions about this particular model, and discovered at least two other build logs for the same exact model. What an amazing resource! The first bunch of posts will be reposts of the same photos from tumblr, though I may embellish the text with technical details better suited for my fellow pintsize shipwrights. It seems customary to start with the box, so I will as well, along with a sneak peek of my current progress: I look forward to interacting with and learning from all of you as my build progresses. I welcome your feedback and questions, and I will have many questions of my own.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.