majq

-

Posts

51 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by majq

-

-

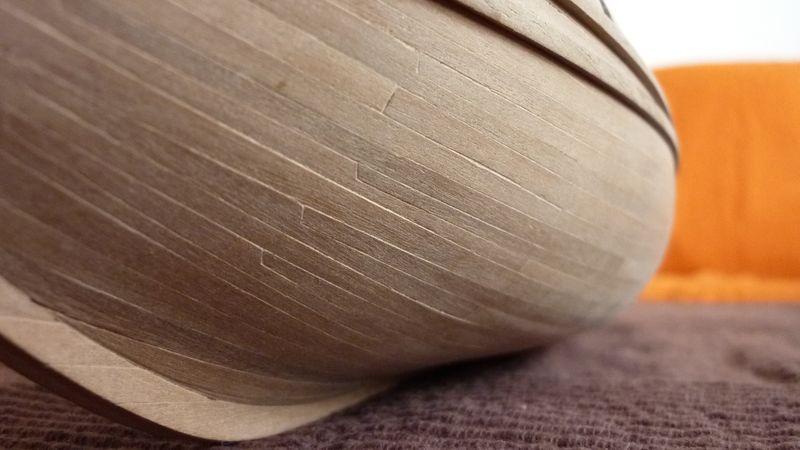

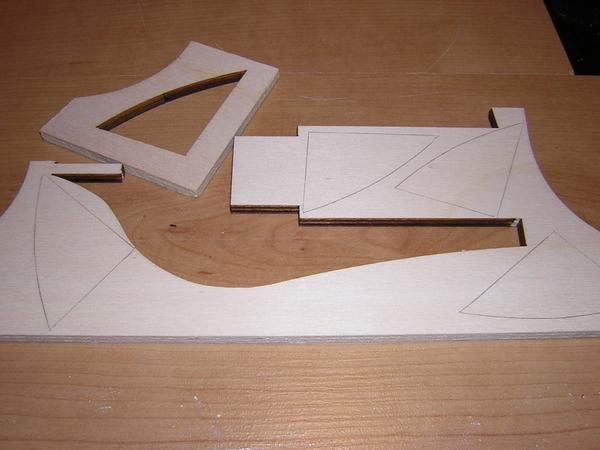

Here I re-made next piece from kit. It is deck between galleries on the stern part of ship.

On the first picture there are original piece from kit, and both sides of my piece built from scratch

(I merged then it into this one photo). Top of this piece is planked by limewood strips and

the bottom part is from walnut strips. I also bent this piece to follow shape of top most deck,

you can see it on the second photo. -

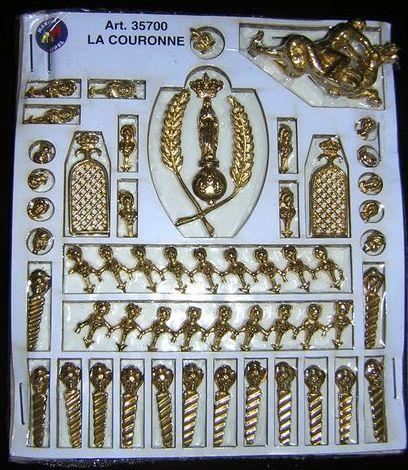

Hi all,

after a some time I update you with my progress on La Couronne. Currently she has all decks on place

and edges are shaped and finished by planks ready for making railings. I have also replicated some pieces

from kit - kit parts are made from plywood and I need them to look like walnut. Meantime I have not found any

method to paint/stain plywood parts by something to make them look like walnut, as hull is, so I had only 2

ways how to do it. Either coat them by walnut veneer, or fully remake them from walnut strips. So far I do

it by second method and I am satisfied with the result. I also prepared axial strips on hull to fit

brass decorations. Currently I am starting to make galleries on stern. So far I am satisfied with my work

and very enjoying every time spent with making her.

Enjoy few pictures from build.

Majk

*******************************

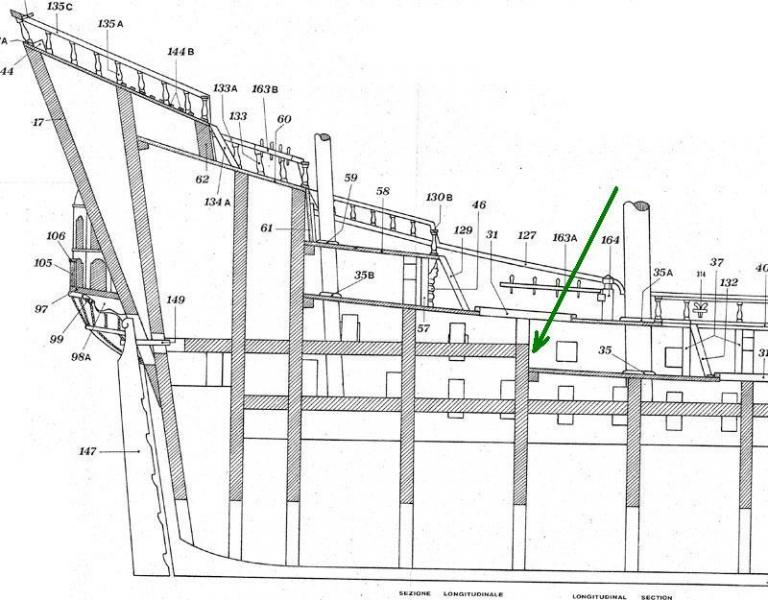

Following photo shows recasting of grating deck on the stem - I do not know what is the exact name

in sailors language, but you surely know what is it ;-)

on the left side is original piece which I tried to coat by walnut veneer, I have already finished it

and have to say that is was terrible work, but I was not satisfied with the result so I have decided

to complete rebuild this part from walnut logs. New remade piece is on the right side, it looks better I think.

Second photo shows this piece filled by gratings and placed onto the ship. -

-

-

-

-

Hi folks,

for several months I did not update this thread, but I worked hardly on

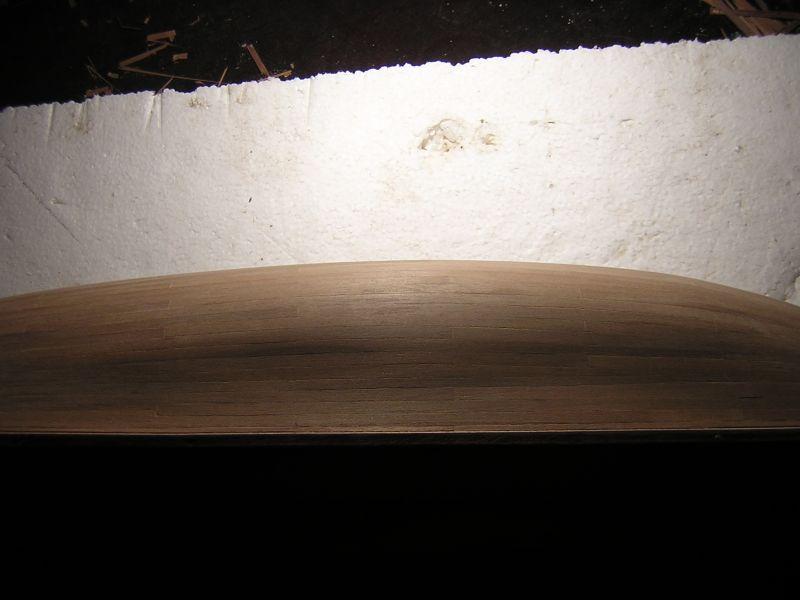

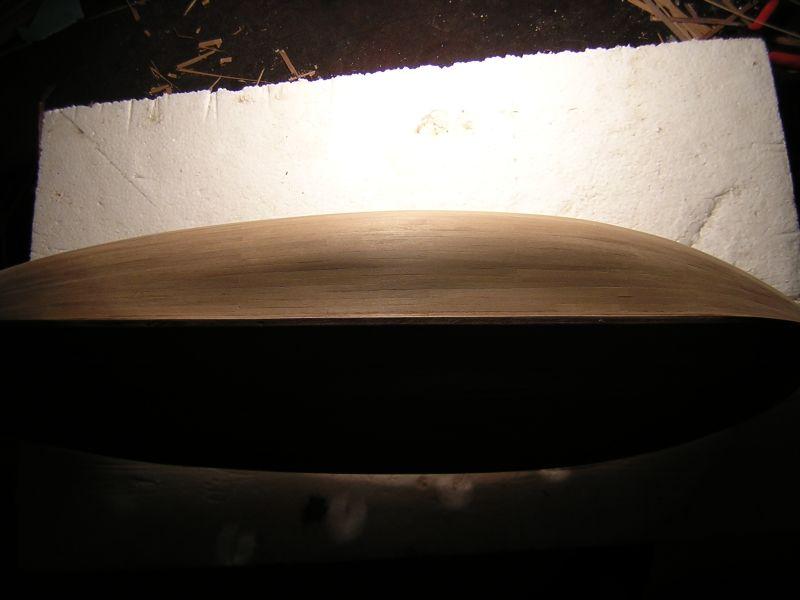

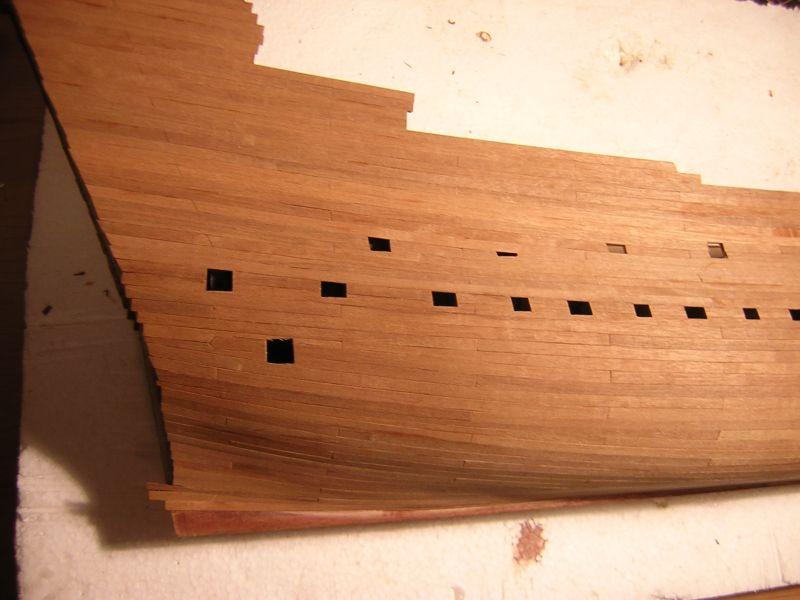

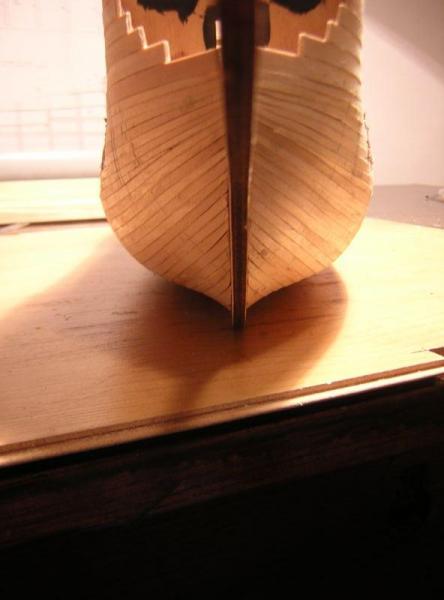

my ship. I finished second planking and although I have never did it

before, I am very pleased with my job (I know, pride is not good)

The result you can see on pictures below. Firstly rough glued on hull and then sanded in contrast of unsanded half.

I will update you soon with photos with wales installed.

Regards,

Michal

-

-

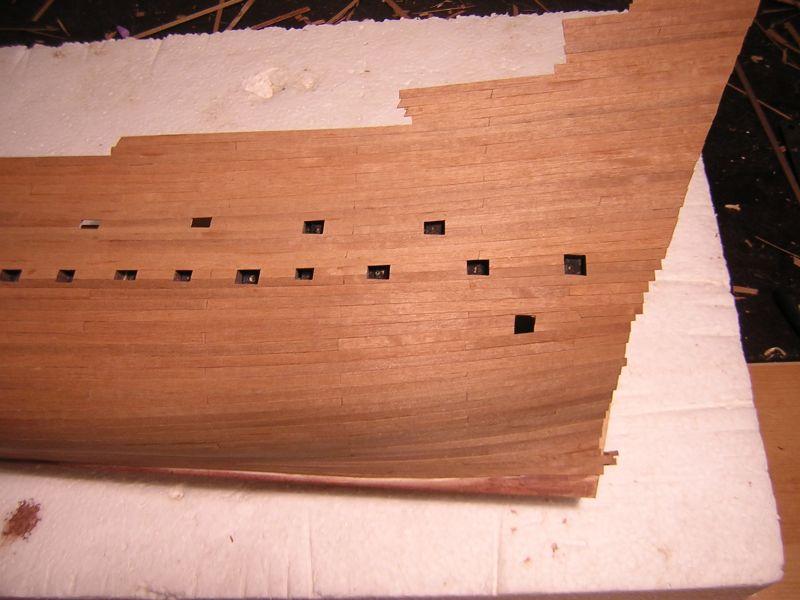

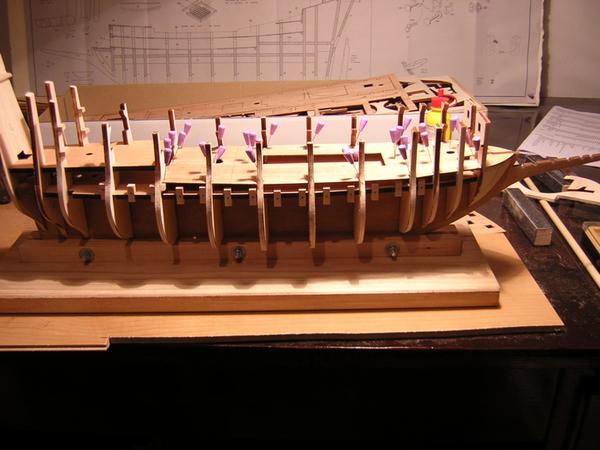

Hi all,

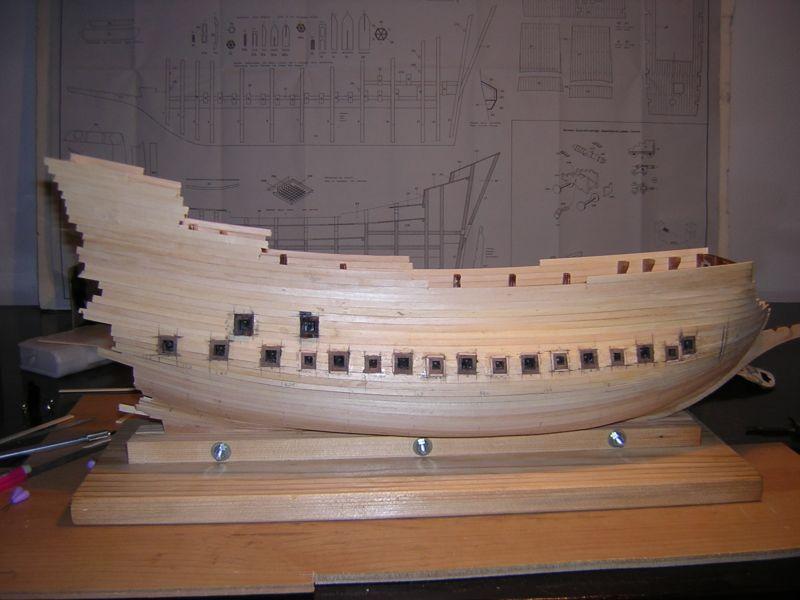

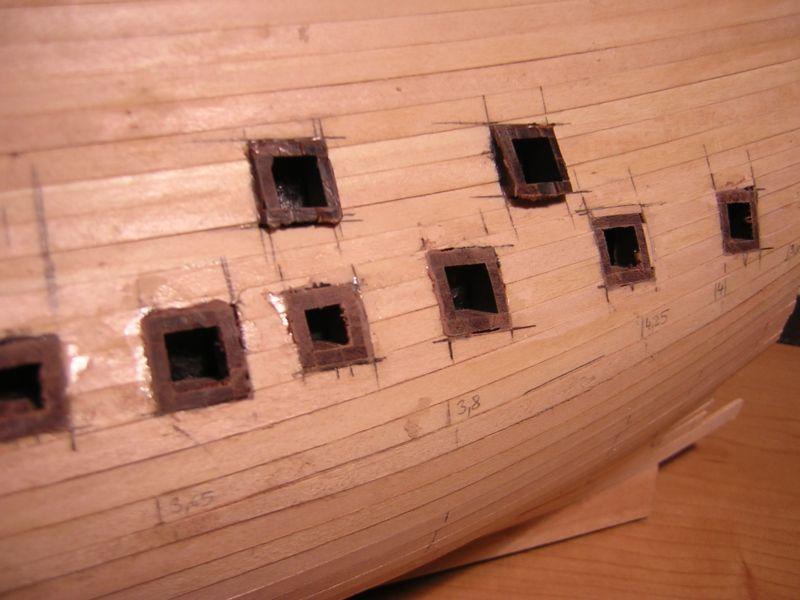

finally I have fnished first layer of planking. Although I am beginner and have not did it before,

I think that result is not so bad. Of course it have to be sanded before second planking, it should not be a problem.

Also I added gunports frames into hull and they will have to be refined as well.

Because I do not much like bright colours on historic ships and also I think that if anything is wooden,

it should not be covered by any paint and wooden texture should be seen, I decided to not painting interior

of ship by red color. Although some books mentioned that red interiors and guns were correct

for 17th century ships, I decided to make them from natural wood. Because I planked my 1st layer from

limewood and second planking will be from walnut, I had to imitate walnut in interior.

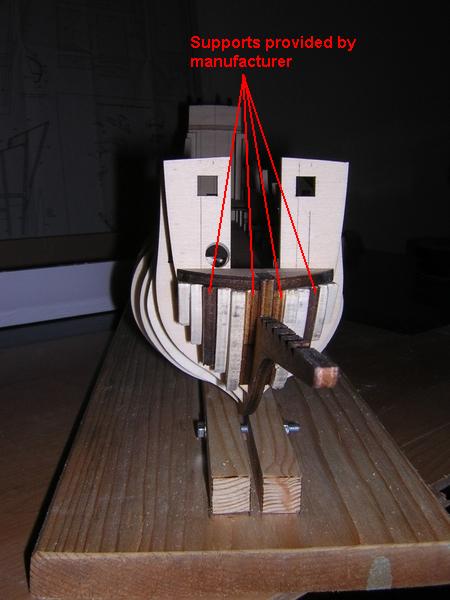

So I planked it by the same strips which I will use for second planking of hull. Terrible plywood supports

for other decks I planked as well. There were a little gaps between that planked supports and deck,

so I enlace them by 1x1mm walnut strip. The result is fine, I think. I believe it will be even better

once I finish it by any varnish.

Below are some photos.

I would very appreciate any response from community, otherwise I am

feeling here like lonely shipwrecked person, when I am writing build log

for myself only

Cheers !

Michal -

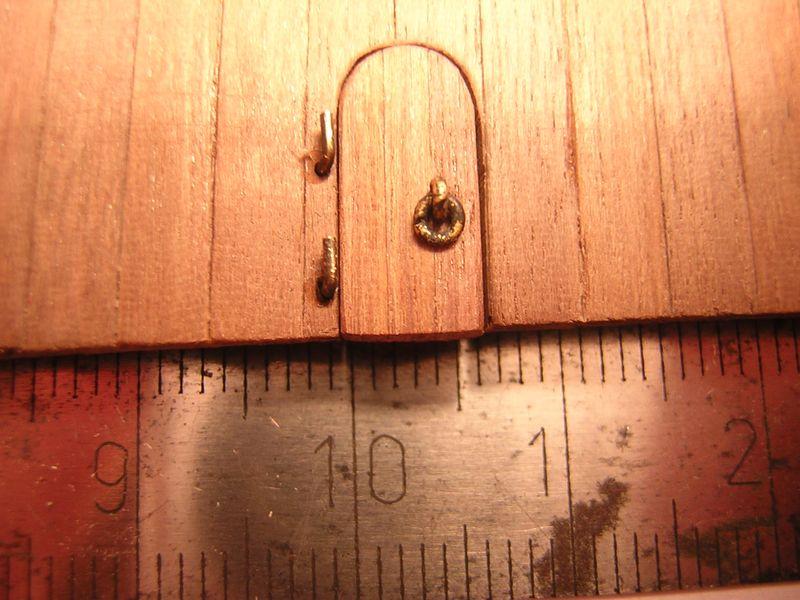

Hi,

today I happify you with some progress on my ship. It is not originally

designed by Mantua, I saw this improvement on the same ship who is

building "marcjp" who has build log on this forum as well. As it is not

provided in kit, I had to build this part from scratch. Fortunately it

was not so hard, but it was a fiddly job. I think that the result is

nice at least for me.

I made the wall from wallnut strips 2x4mm, doors are from 2x2mm strips,

handles and supports for hinges are made brom brass wire, and hinges are

etched brass plate. I described producing of hinges in previous post.

All brass pieces are blackened by some chemic dilution. I varnished the

wall by teak oil and I think the result is not bad. I am not able to

find any reseller of Danish oil in my country

I found only one and he wants 6$ for 10ml of Danish oil. I checked

foreign shops and it is normally price for 250ml, not for 10ml.

I am waiting for little nails which I want to use for fitting hinges on

the doors, but they are almost 10th day on the way to Europe, I hope I

will get them soon.

Enjoy my photos !

Michal -

-

-

-

Hi all,

I have not updated you a long time about my build progress. I had not

much time for ship building, because spring and summer was time for

working on garden and around house. Of course a lot of time I spend with

my son and wife. But I was not idle in shipbuilding and now I can

update you with some photos I made during almost last half of year.

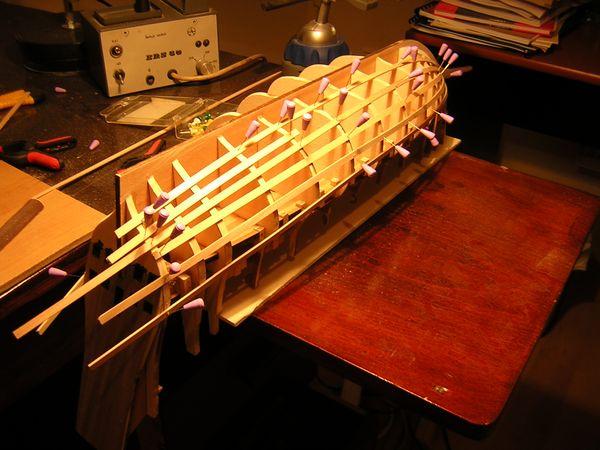

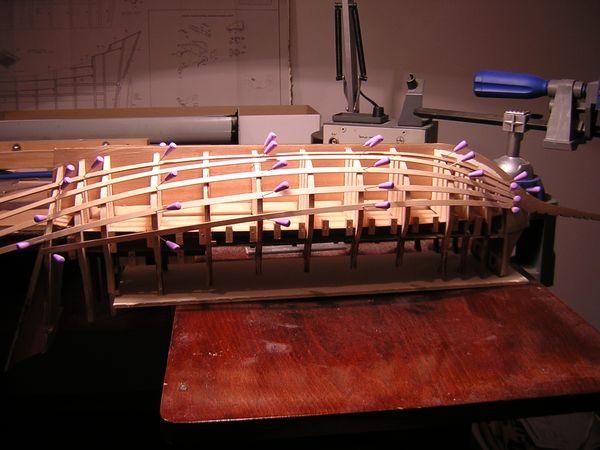

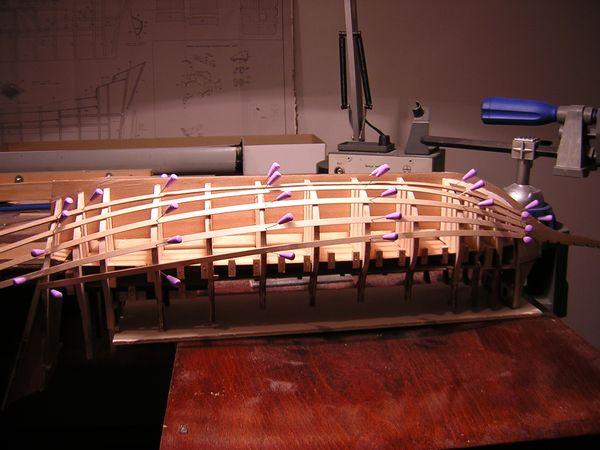

Last post was about assembed hull and main deck pinned onto it. Then I

decided to start planking lower part of hull, because in this section

was nothing to do more.

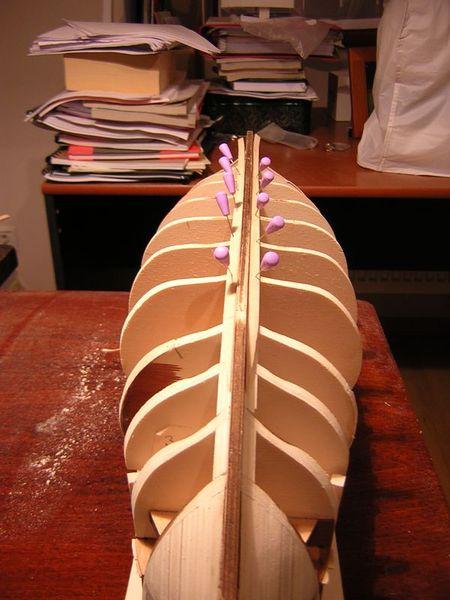

Firstly I made some fillers between foremost bulkheads near keel. It is

for support the lowest planks, they will be ended in this section and

have to be glued to something. I think I need not explain it to you,

experienced modellers, besides it can be seen on first few photos.

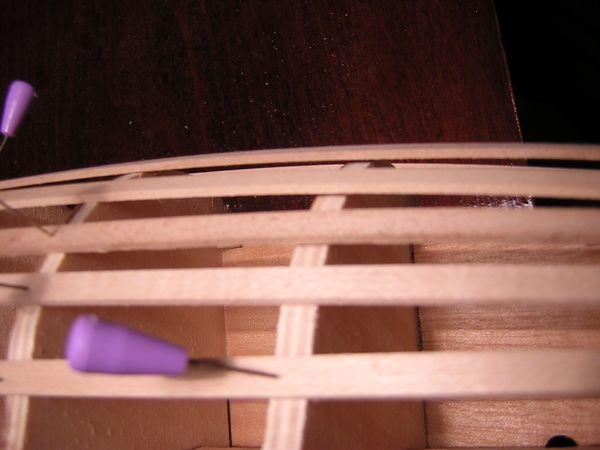

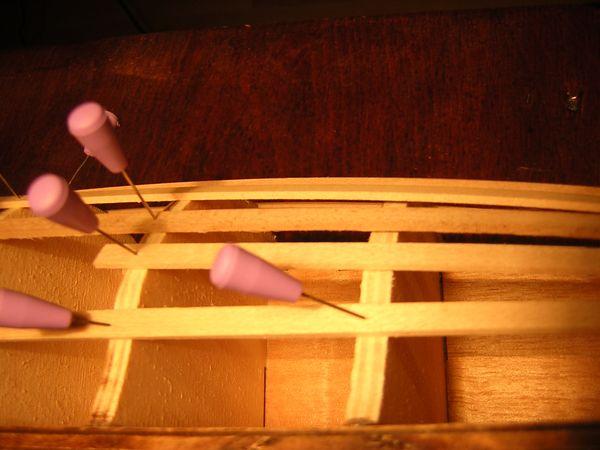

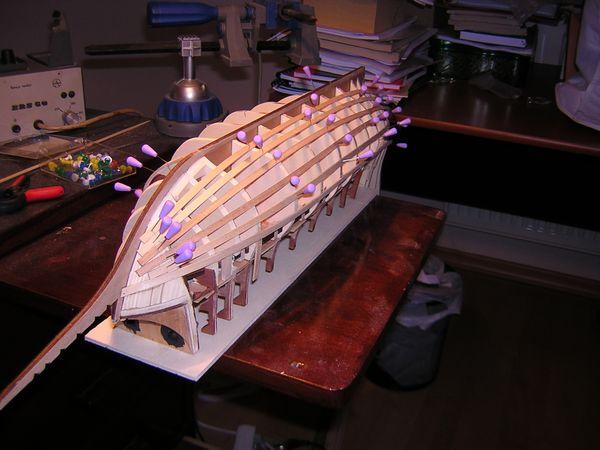

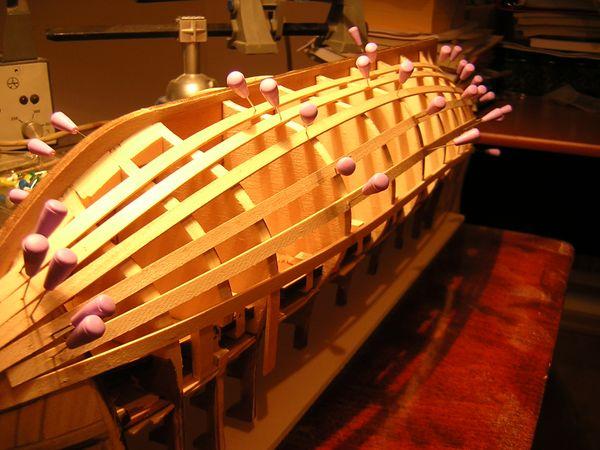

Then I placed firts plank and found out that shape of hull is not

accurate, it was bumpy. I removed plank and made zeppelin from my ship

I pinned few planks to bulkheads, leave gaps between them and look along

hull shape. I found gaps on few parts of bulkheads, marked them, then

removed planks and put "filler" from plank on that place. Then I sanded

that parts and repeat the whole process again. I repeated it several

times until I was satisfied with hull shape. I had to say, that it is

lengthy process, but is important for the final result of planking.

Although I will use double planking method and thus first layer can be

adjusted by sanding/filling before applying second layer, I decided to

have fine shape already on the first layer. I am adding few photos of

adjusting of frame process.

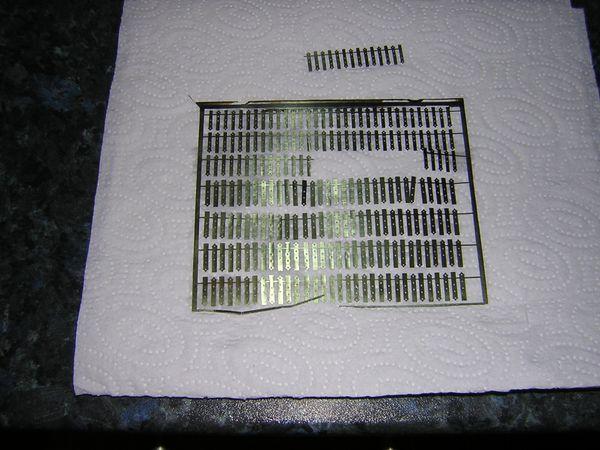

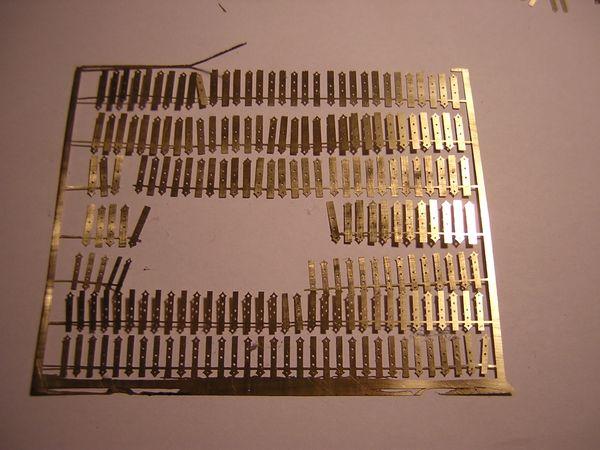

Mantua provides gun port lids made from some brown metal, with moulded

planks and hinges. It is easy to fit them to the hull without much work

and every piece have the same exact size, very comfortable I think.

But in my opinion it looks very horrible and also is not much authentic.

I think that on vessels from the first half of 17th century was not

gunport lids made from steel

Mantua should replace that crazy metal lids in kit by brass hinges and

few planks, modellers then can make more authentic lids by their own.

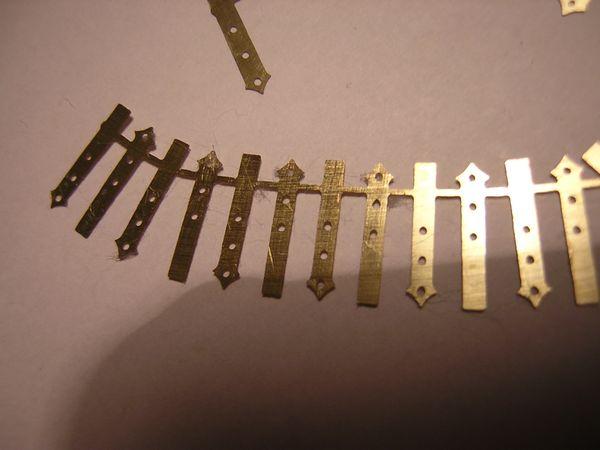

I decided to make gunport lids on my own. Fortunately on MSW web in

Tutorials, there is nice guide for making photo etching. All chemical

stuffs are available in my country and brass plates too. I decided to

use 0,01mm width brass pate for all hinges. I draw hinges in AutoCad and

print it on foil. Then I had to cover brass sheet with photosensitive

varnish.

In this step I would like to notice, that the best way is hold brass

sheet vertically and apply varnish, then hold it in vertical possition

until it dry. Otherwise the varnish make stains and cover is not

compact. In instrustions there was mentioned that drying of varnish take

24hours at 20°C and 15 minutes at 70°C. I got great idea - use owen for

drying to avoid waiting whole day for drying. In this step I had a

little bit difficult task to persuade my wife she allow me owen in our

kitchen. At last everything went fine and my brass sheet was ready in

few minutes

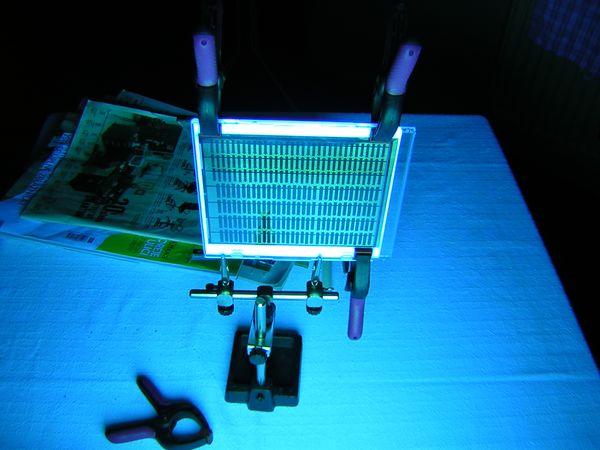

Then I lighten both sides of brass sheet by ultraviolet light through

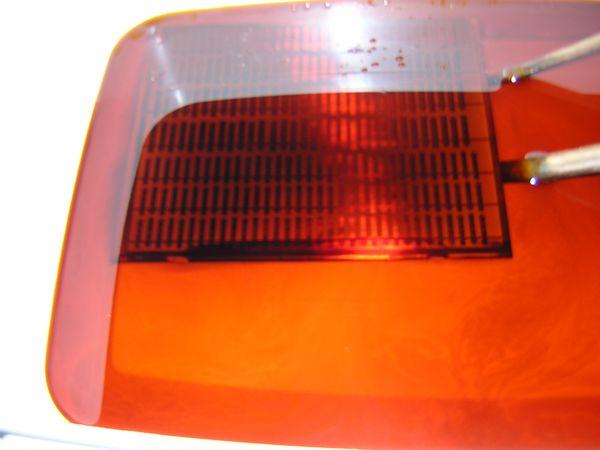

foil and then put the sheet into solution of NaOH. I had to calculate

right concentration and can confirm that there is correct dilution 5g

NaOH/1l water in tutorial - it worked fine for me. After few minutes in

NaOH I washed brass sheet in water and put it into FeCl3. It took

several minutes and hinges were ready. I am very satisfied with the

result as I have never did it before and waited it more complicated and

more worse result.

Enjoy few photos from this stage below.

It is almost all what I can share with you now, I hope I would be able to give you more updates soon.

Cheers !

Michal -

Hi all,

at firtst please excuse my long absence here, but 29.2. my son was born

and so I had (and still have) other worries and have not much time for

modelling. Nevertheless I made some progress even if it is not so fast

as it was.

I have sanded bulkheads to have correct shape for planking

(unfortunately I forgot get photo for you, I will send some next time).

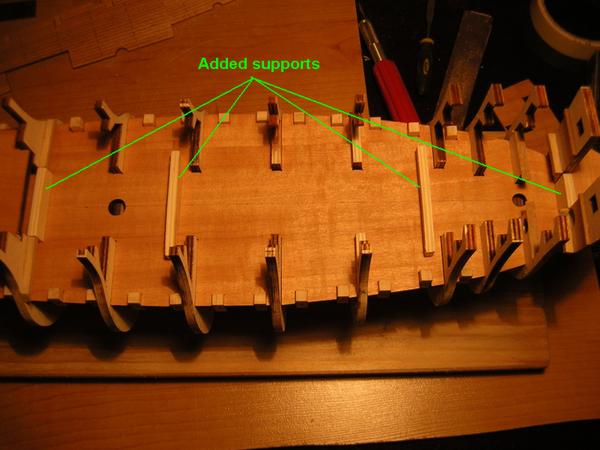

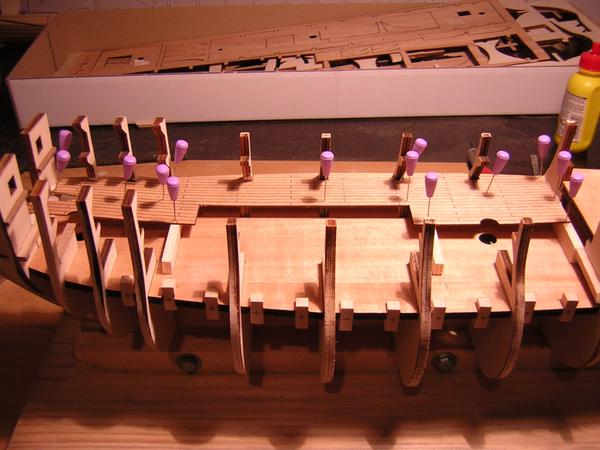

Then I started thinking about decks, because it will be seen I started

to be more careful and thinking twice before cutting and gluing

I started with the lowest deck, where gratings and lower line of cannons

are located. Unfortunately some humidity or dryness twist my deck

pieces and it looked as screw. I think that it is also caused by small

thickness of decks. To fit the deck to hull in proper shape I had to

make some additional supports.

Then I drew lines for deck planks on both pieces, it will help me once I

will make deck planking. Afterwards I glued deck to the hull and fit it

by modellers pins. I will plank it and make gratings gefore start

planking the hull.

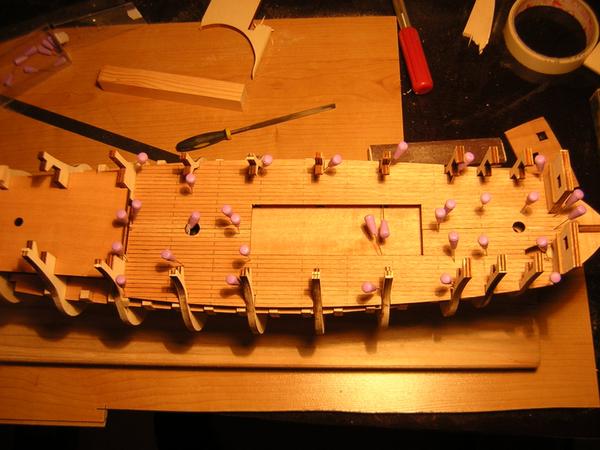

Deck planks are from limewood and it seems to me very shiny in

comparison with planks for hull, which is from walnut. Thus I decided to

paint decks (and other limewood pieces) by some varnish. I still not

have chosen any, but I would like either similar color as walnut or at

least some more yellow to make deck more old-fashined. Fresh limewood

strips looks very modern, I think

I will try make caulking by painting with pencil on one side of plank, I

think it will be well visible even if I choose walnut varnish for deck.

Though I will make some tests before start planking.

I also think about making nails on deck planks. But this deck will be

planked by 3mm wide planks and thus it would not be so easy to make

nails properly. Either I can mark them by any very thin pencil, or I can

try make tree nails, but in this case I am afraid will not be

successfull, as treenails would be very thin. Have anyone any suggestion

about this ?

Ok, stop talking and lets see any pictures.

Cheers !

Michal -

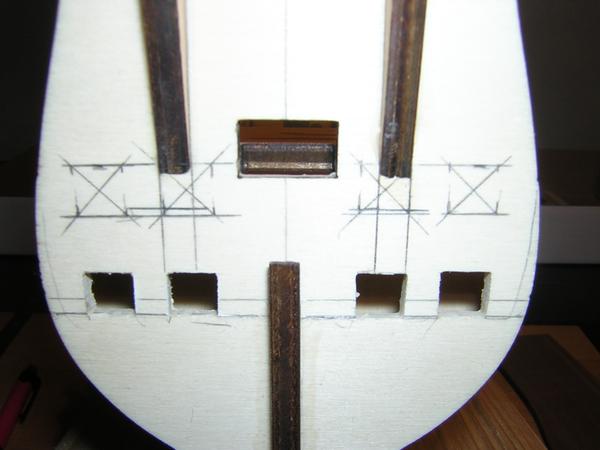

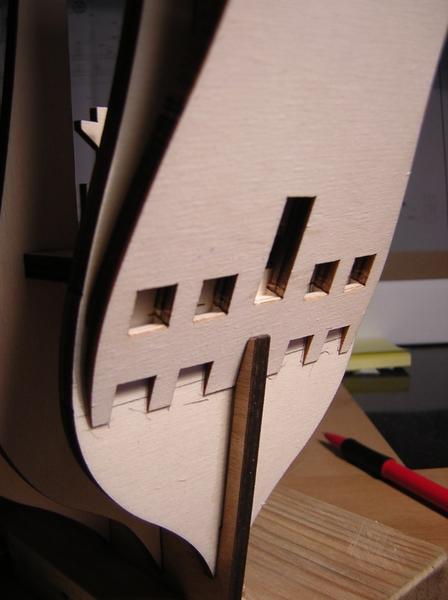

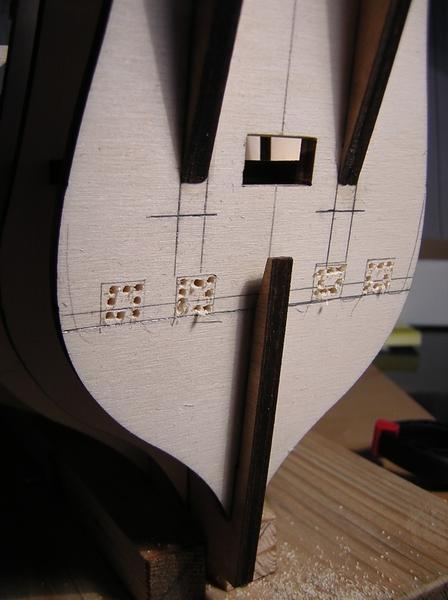

Yesterday I worked on stern part, be specific on

gunports. As I said previously, I decided to position lower line of guns

deeper by 6 milimeters into the ship. Now I proceed in this idea.

I marked centers of gunports, drilled and place support for lower line

of cannons. The result is much more better than Mantua provided

originally.

I will have to paint holes by black matt paint before I glue the last

frame covered by wallnut veneer (I avoid possible spotting veneer by

paint).

Again, some pictures from this part. -

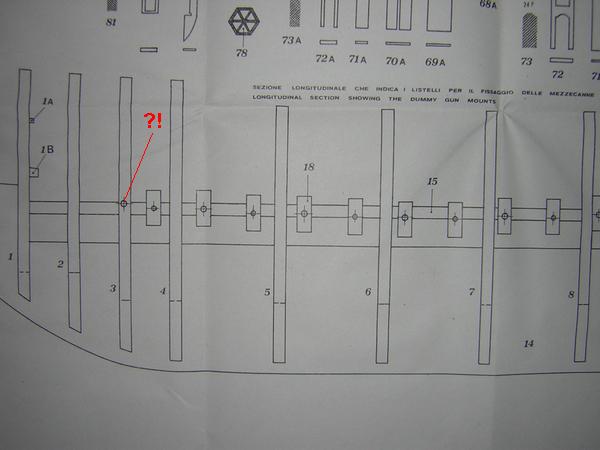

Supports for dummy barrels are created from

6x6x15 strip pieces, each barrel is possiotioned differently on the

strip and each strip is placed differently on the false deck

I cut 32 strip pieces and measured each strip on plan and made each pair

separately. It was monotonous work, but finally it is done.

Anyhow I think the installation of dummy barrels are poorly designed by

manufacturer, so I did not glued supports yet and thinking about making

full gunports as should be (box shape around cannon). It would be

important for planking support near cannon (planks would not be fixed to

anything around hole for barrel without this box).

Again very funny is placement of 1st barrel, which Mantua designers placed directly on the frame.

As the other supports are fixed to false deck and so these cannons are

a little bit deeper, the result would be that 1st barrel will protrude

from ship and others will be deeper. Also very interesting would be

planking around this cannon

Few pictures about this: -

Thanks to all for contribution, it is very encouraging.

Chris, thank you for warning, I read your log about Victory, it was helpful.

I will contact you via PM if I will need consult anything.

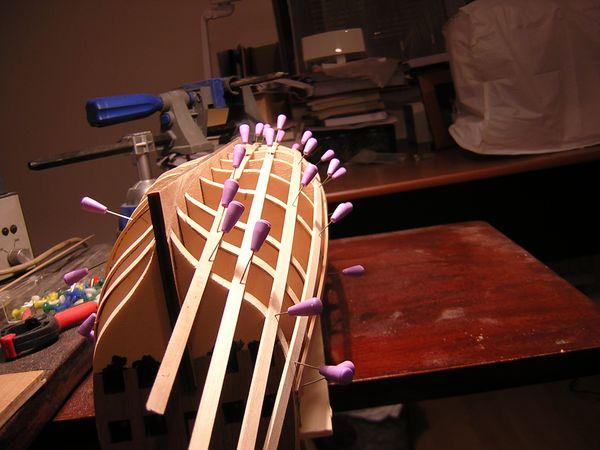

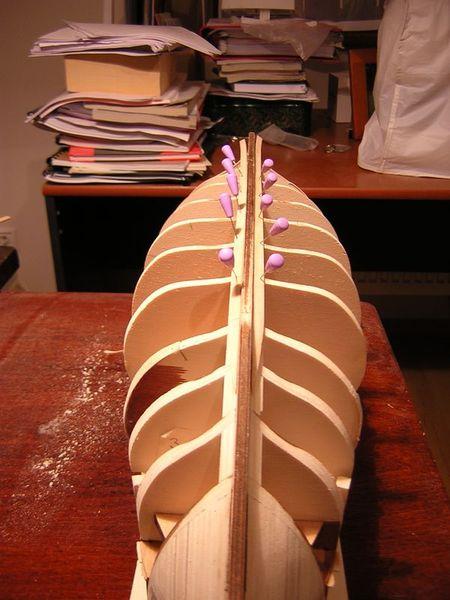

Now about my progress in building. Mantua provided only 4 pices (2 for

each side of ship) for support planking on the bow. As I read some books

about ship bulding and planking, I found out that all modellers make

bow and stern parts (where planks are heavily bended) from block of wood

and sand it along with hull shape before planking. I decided to go by

the same way, I cut similar support frames and glue all of them together

at the bow. I think that on the stern it is not needed to fill gap

between frames by wood, because planks are not such bended there.

All is illustrated on following pics. -

-

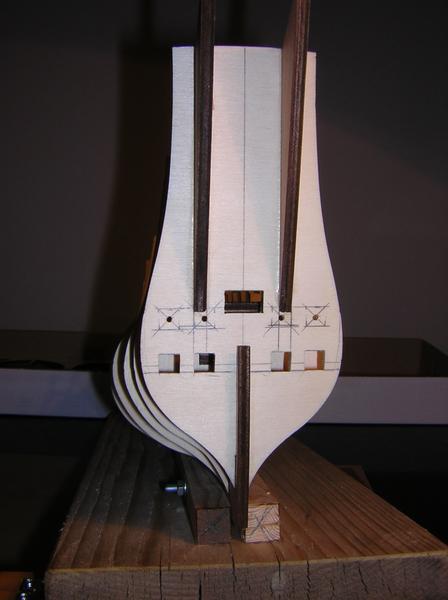

Hi Francis, thanks for compliment, I am still trying do my best

Here is described work on the last frame. Because this frame will be

visible as the stern, I was very careful with it and it is still not

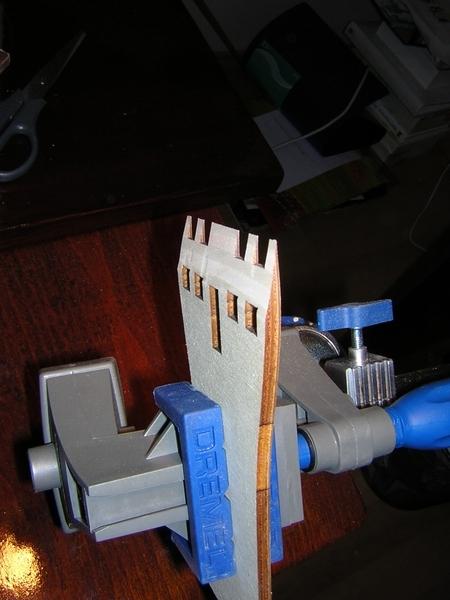

glued onto the keel. The last frame had to be sanded to sharp angle.

Fortunately my dremel sanding drum made a lot of this work and the rest

has been fined by hand. I tried put the last frame on keel and found out

that dummy barrels on lower line should not be placed enough deeply

into ship. Otherwise the upper barrels will be in correct possition and

lower barrels will stick out more from ship. So I marked barrels

possitions on last but one frame and cut holes for cannons. Thus I will

put lower cannons by 5mm deeper. Fianally I glued walnut veneer on the

last frame (better to do when the frame is free than glued on the keel )

)

All my work is shown on following pics -

-

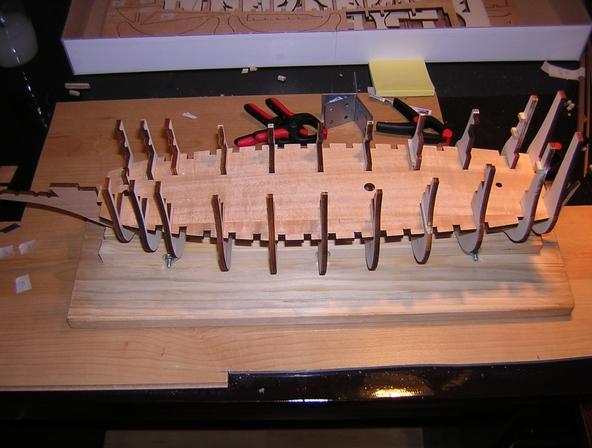

Thanks for post Ghostman, wish you the best with your build ! And a lot of patience with Mantua

Sending some pictures where I started glue frames on keel.

I let me inspire by some posts on this forum and made keel holder by

myself from board, 2 wooden strips and 3 screws and thus saved 80$ for

original keel clamp by Amati Idea -

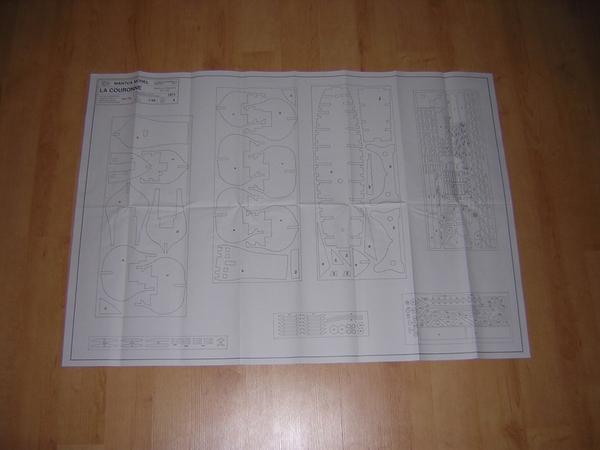

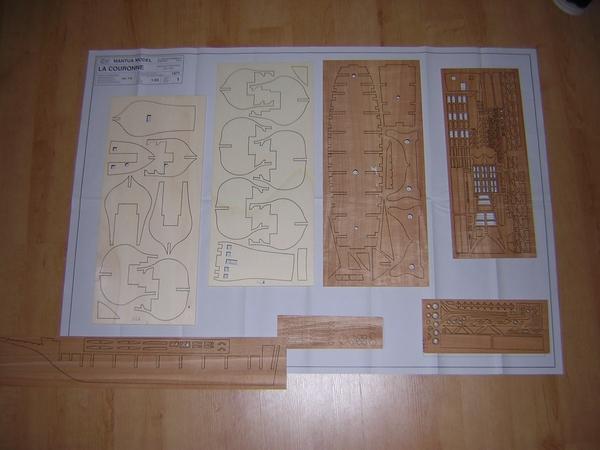

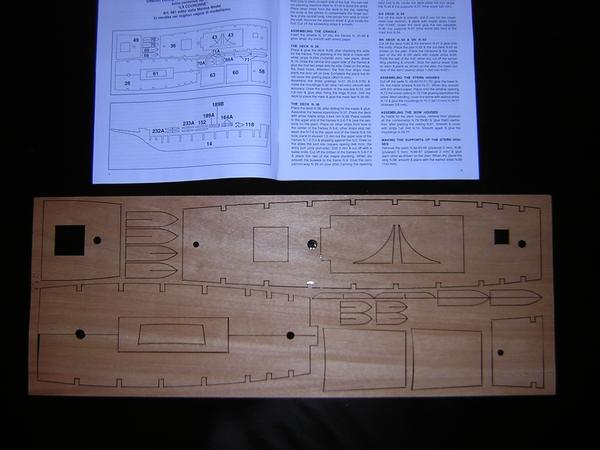

First of all I studied plans and assembly

instructions for understand parts numbering. I have to say, that

assembly instructions are very poor, only text without any guidance

picture. But it did not surprise me, I read some reviews on web and it

seems that it is any Mantua's speciality to provide poor instructions.

Adding some pictures, not much interesting at this stage

-

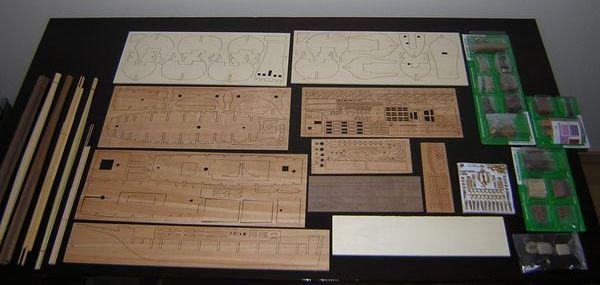

Hi all,

finally I finished my family house, refurbish my work table, bought

tools and now I can start build my 1st wooden ship. Even if I am newbie

in this hobby, I chose La Couronne which is designed for more

experienced modellers. But I like this ship, she is very nice and I did

not want to waste time with models for beginners

Almost for one year I studied books about ship modelling and also read

web stuff. I think I am well prepared now for building

I hope I will be success with this build and will very appreciate your interest, opinions and advices.

Well, lets start:

La Couronne by majq - Mantua - 1:98

in - Kit build logs for subjects built from 1501 - 1750

Posted

On these photos you can see my bending art :-) I bent this 1x4 mm walnut strip almost to right angle.

To be honest, I broke one strip at the beginning, this second try is better ;-) Next photo shows

this strip cut and placed on ship