-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaltyDog

-

I glued the deck down using Titebond Original (PVA wood glue) applied to the veneer and deck and then left to dry. Then the two were placed together and heat was applied. This method is described on various posts on this site as well as videos that describe applying wood veneer to substrates. My observations; the veneer curled width wise when drying producing some splits/separations (the veneer was quite thin), the width of the veneer increased because of the moisture in the glue, I trimmed it against the bulwarks with a scalpel. The edge of the veneer was mostly covered by the waterways. The other thing was that the clothes iron I had (the one the Admiral was willing to let me use) was too wide to iron the deck, so I used my plank bending iron. A miniature hobby iron would be an ideal future purchase.

-

My latest project is the French cutter Le CERF building the Dusek kit.The quality of the wood, veneers, drawings and instructions is excellent! So far I've assembled the keel and bulkheads, done some infill between bulkheads with balsa and started some of the planking in the area of the deck. The kit receives a complete layer of planks in the clinker fashion, a second layer of laser cut veneer carvel style planks will be added to the lower portion of the hull.

-

Thank you both for the suggestions regarding the copper tape. I'll need to get a supply of one more item, patience!

-

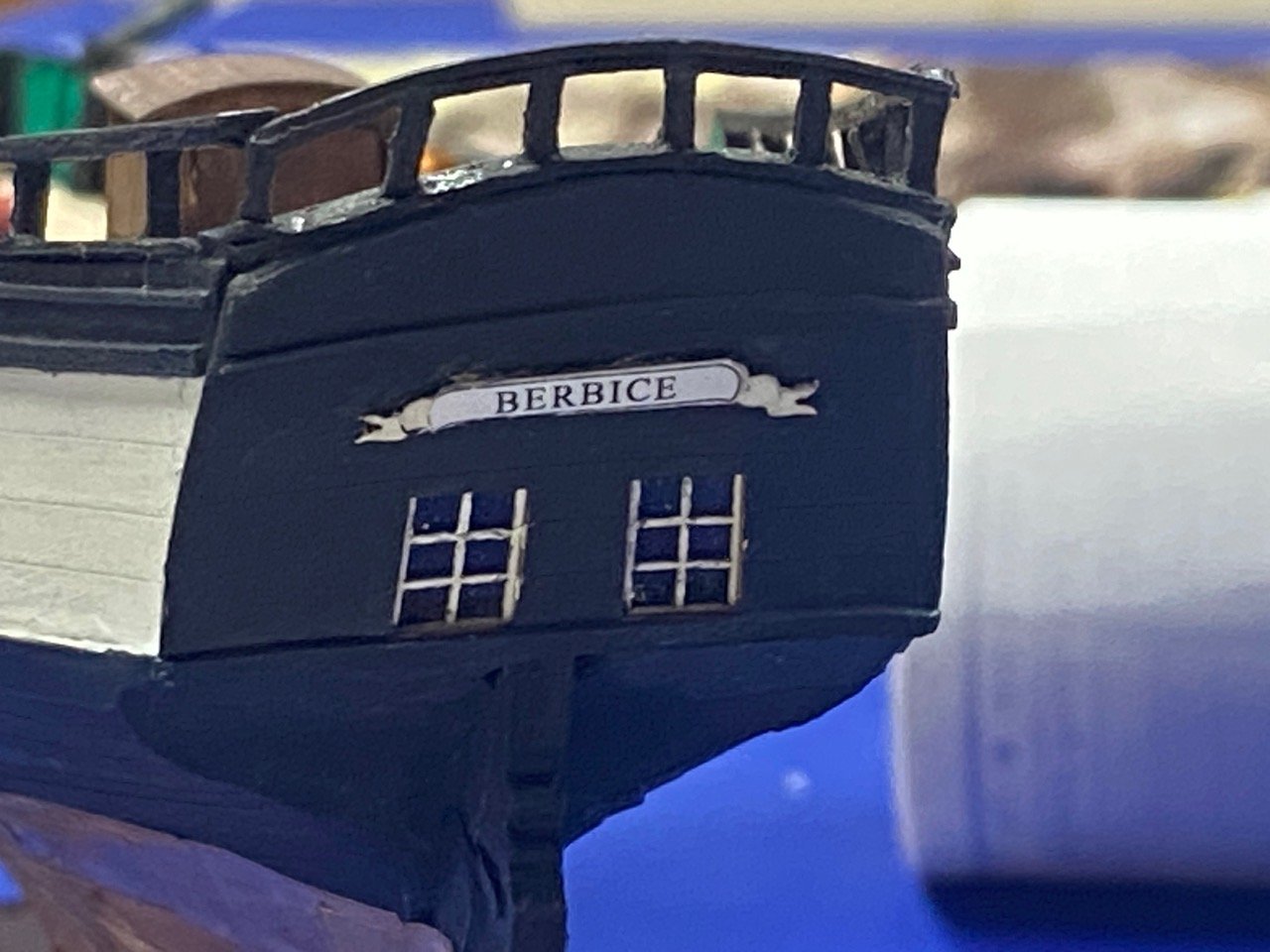

Finished with coppering the hull. It's a little too shiny for my taste, so I 'm thinking of ways to weather it a little bit. Finished the transom railing. The posts are these really malleable pieces of cardboard soonce attaching the them to the stern I applied CA to harden them and them attached the two pieces of top rail.

-

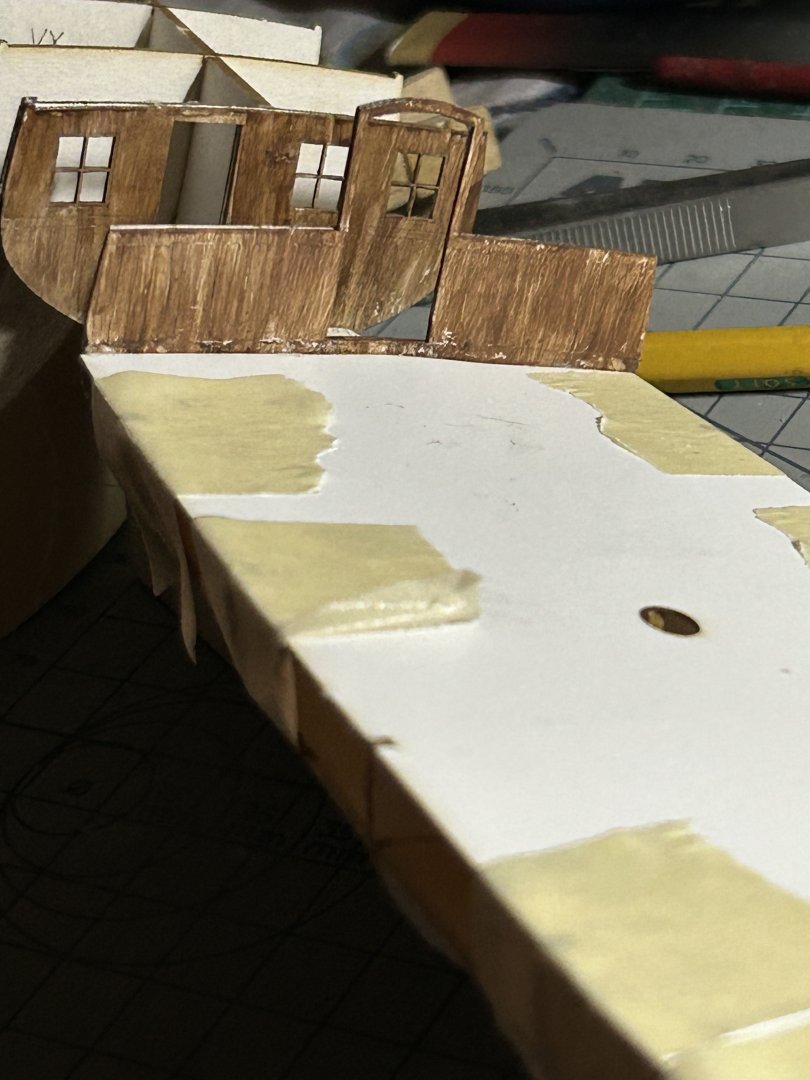

I started applying the 3rd layer of planking. The instructions tell you to finish the 3rd layer of planking before attaching the keel. However I went ahead and attached the keel so I may lay the tips of the planks at the bow to cover the small gap.

-

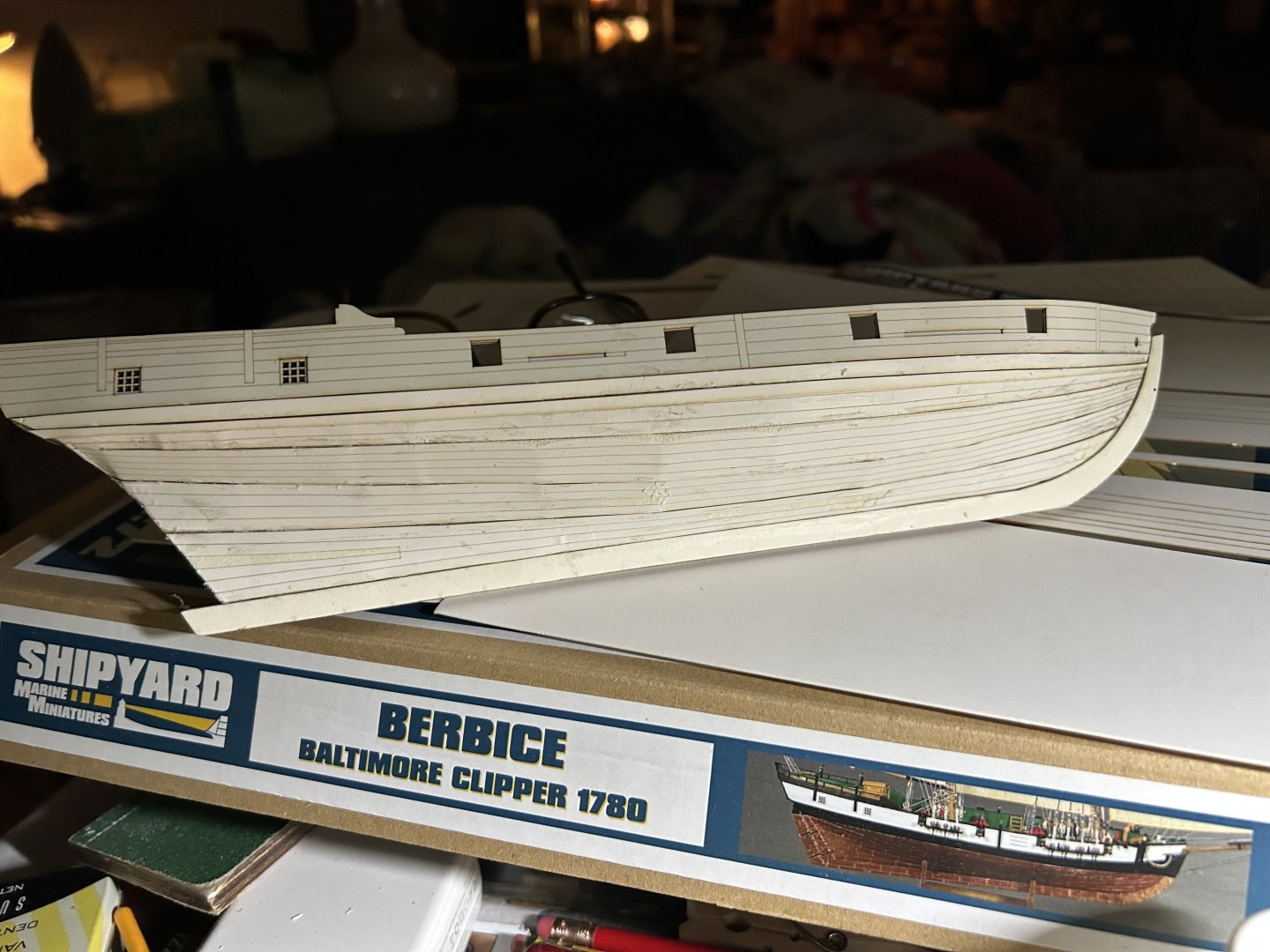

I thought I'd give paper ship models another whirl. Decided to go with a laser cut Shipyard model to make it a little easier. I purchased the Berbice 1780 Baltimore Clipper. The kit is great - great instructions - wonderful parts, resin cannons, paint and a couple of paint brushes. I made some pretty quick progress.

-

Hello I've been lurking on this website for a couple of years and building ship models to various levels of completion but thought it was actually time to build something to completion and post it on this website. The frame and bulkheads went together nicely and I am putting on my first layer of planking. I did some rabbet work and a bearding line down by the keel, stem, and post rather than following the kit instructions to the letter.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.a535f921341975feee55bce5d11e80fc.jpg)

.thumb.jpg.5d4a2eec7980eacd7806aa6ddd41ddda.jpg)

.thumb.jpg.cac390c4ff7ff1b0969b03dffa2a0099.jpg)

.thumb.jpg.61885209614852192d9410740aa6ea8a.jpg)

.thumb.jpg.ce4acaf96e2b573a2e3d7b4ba02ceb96.jpg)

.thumb.jpg.911163fefac02a6c2f5bd00998d68a96.jpg)

.thumb.jpg.a5ea4ae58f1db6111830faf20665ab9e.jpg)

.thumb.jpg.55ac79dffeb13acd497f61ce627ceaa3.jpg)