Greeting All!

As I described in my introductory post a few days ago, this is my FIRST EVER build. I built plastic models when I was a kid, but that was decades ago. I appreciate the input I've received so far and look forward to learning this new skill with all y'all's help and suggestions.

Having never done this, I am starting at square one. I chose this model, in part, because of the combination package that included tools, paint, and glue in addition to the kit itself. Also, if I found I got little enjoyment or was constitutionally incapable of managing the process, my downside was limited,

So far I'm enjoying myself...unsure of lots of tasks, but having fun!

So far, I've managed to get my work space set up (with LOTS of help from my wife) and have added some tools and equipment that should help me as I proceed.

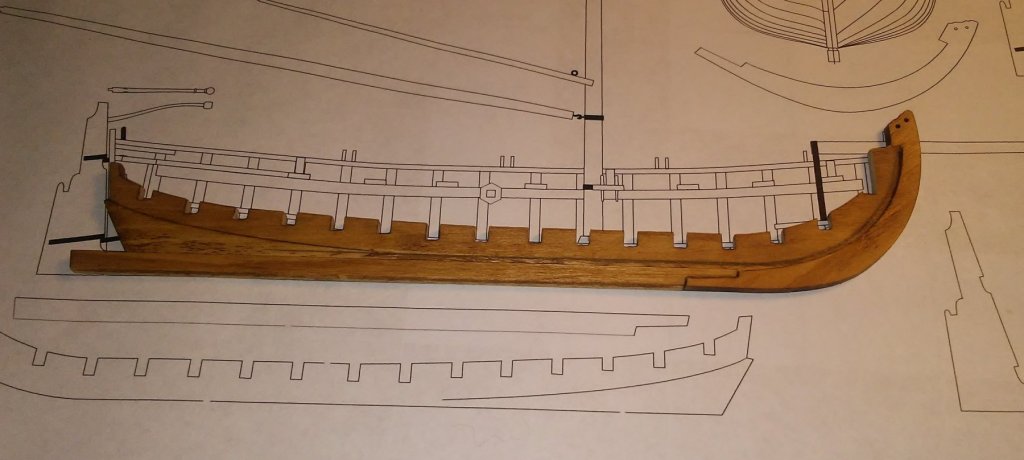

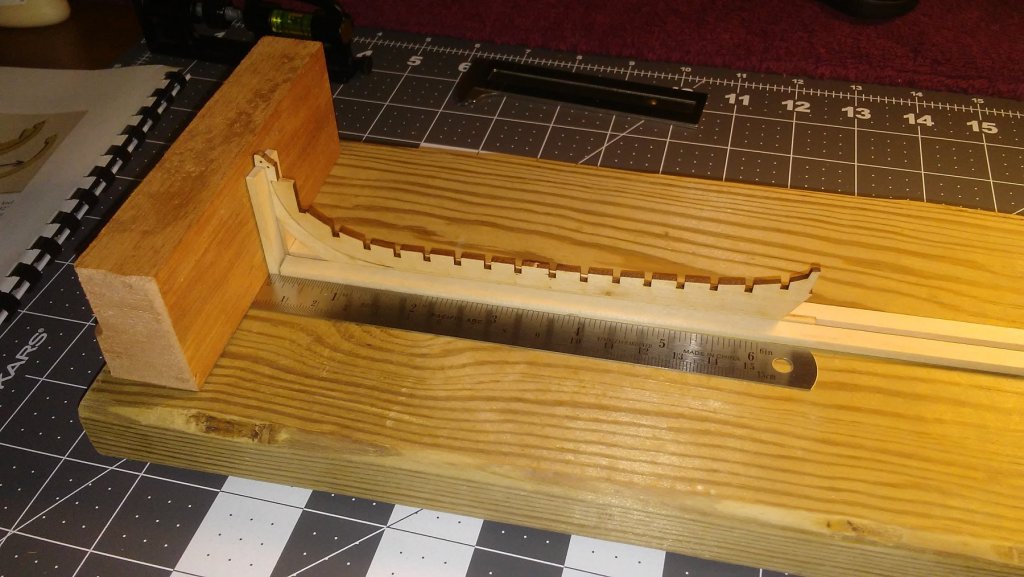

I got a little ahead of myself and removed the false keel, keel, and stem from the parts sheet and did some fine sanding to remove some of the burn marks.

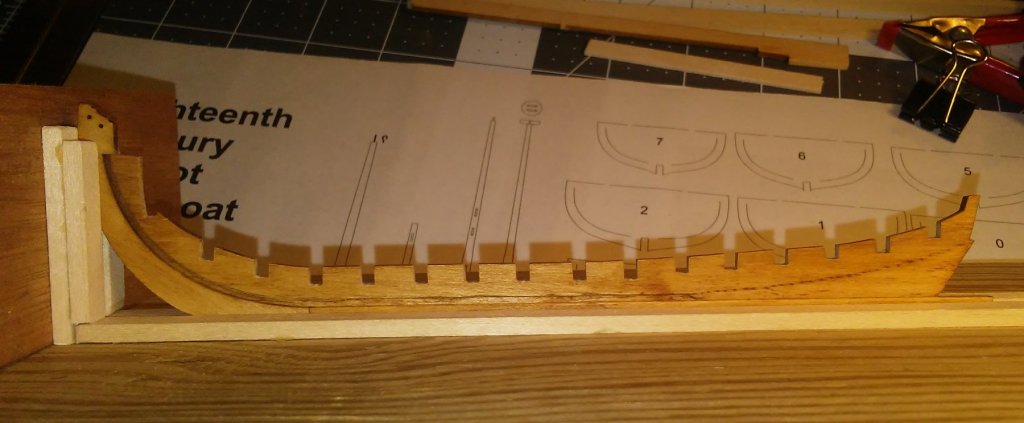

A trip to the hobby store got me some spare basswood pieces so I can practice techniques to improve my skills. I also built a jig to set the hull into as I progress. Nothing fancy, but adequate (the keel pieces are fitted together but not glued):

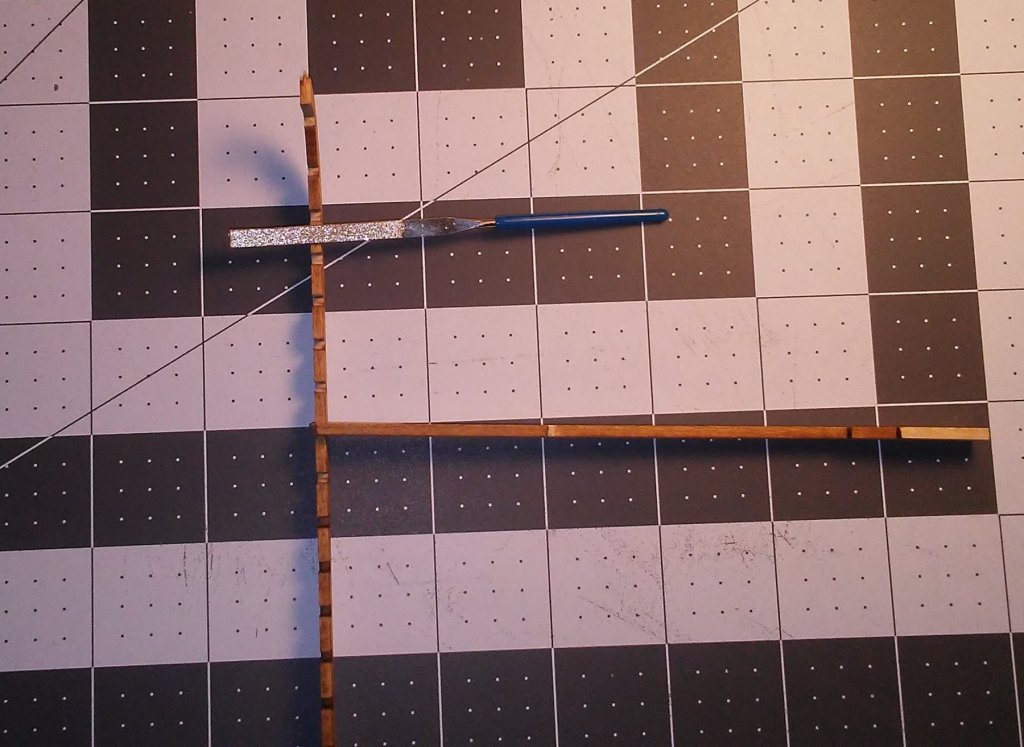

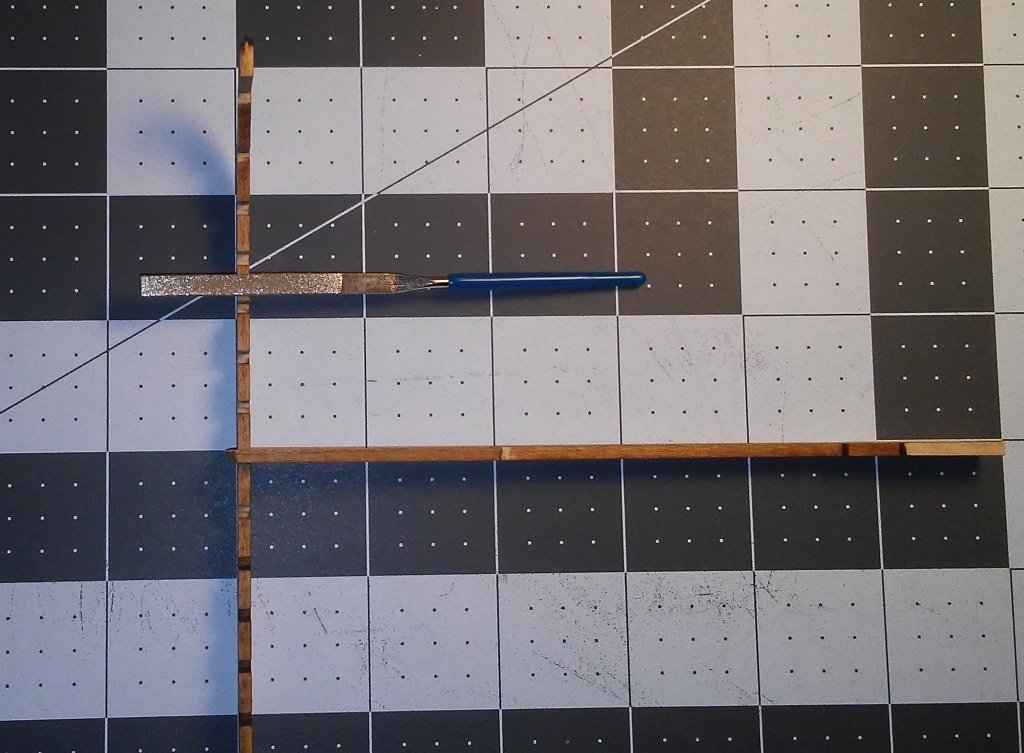

In preparation for bearding the false keel and cutting the rabbet I practiced on a spare piece of 3/32" basswood. I found sanding to the required thickness at the stern is my best option. I will have to cut the rabbet with a knife.

I transferred the bearding line to the opposite side of the false keel by making a photocopy of the plan. After being sure that it was properly scaled I placed it on the part and marked the keel by making pin pricks every couple of millimeters. I finally used the pricks to draw the curve using a french curve.

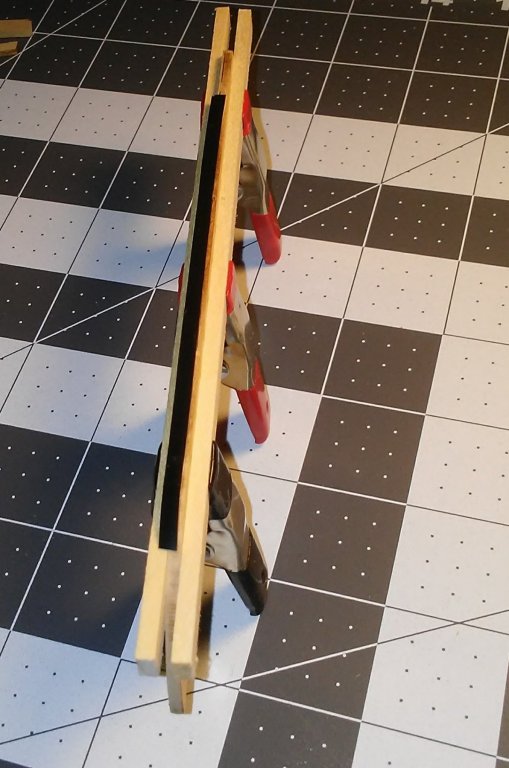

In preparation for cutting the rabbet, I masked the bottom of the false keel with 1/16" art tape and verified my dimensions before cutting down to the appropriate depth. I believe if I cut too deep anywhere I can regain structural integrity when I get further into assembly. I then masked the other side of the false keel. Lateral cuts on the sides were done after completing the length-wise cuts.The picture below shows the masking:

I'm currently sanding the stern from the bearding line to the edge of the keel and stern. I'll update after I complete the false keel and combine the three keel sections.