rummy

-

Posts

122 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by rummy

-

-

Looking very good,I will be looking forward to the planking. Larry

-

Hello Aldo,I want to thank you for the link to Amazon.I did order the TFFM vol 1 at a great used price of $42 including shipping.Please let me know if you come across vol 2.Thank you again Larry

-

Guy,what amazing work.I never tought about a mill but it looks like you did in a couple hours what took me a couple of weeks.Nice work. I guess I should put a mill on my "I wish I had the money list".It is a very long list

Best Regards; Larry

-

Nice Job Aldo. Larry

-

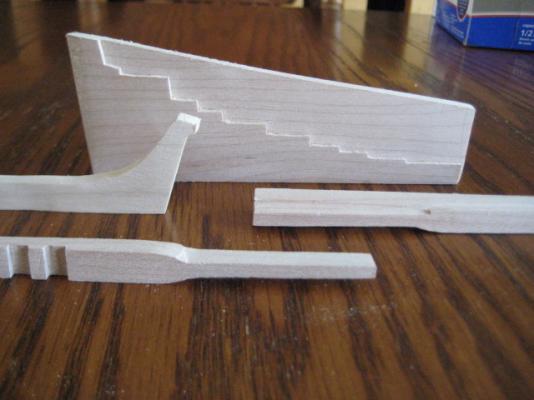

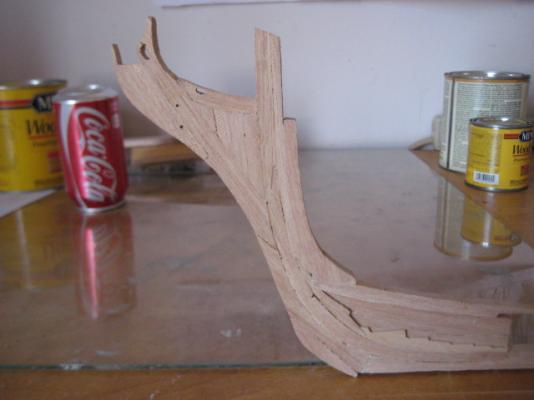

Hello Everyone.I have been working on aft deadwood #4.Why you ask? I decided that if I could not make this part and get it close to what it should look like,Then I should quit and take up plastic models.

Here is the results,made of maple this time.

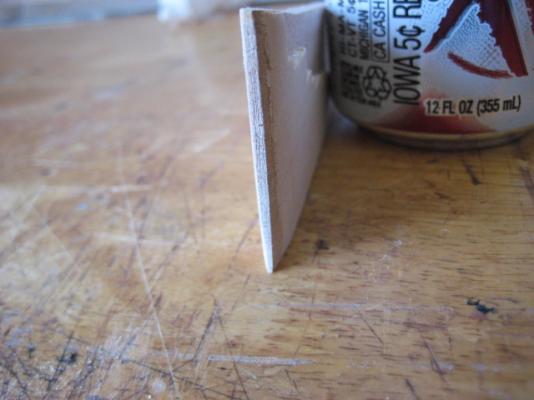

Here Is where I had most of my problem.Getting this to 3mm.I finally did and this end will be covered.

The bottom part has to be tapered also to fit the keel.The top and the knee was a problem,the only cutout I could find was the side view of with the dead wood.Wangs pictures did not show this knee being used so I tapered it also.

I am happy and can continue building wooden ships.Few more pictures Larry

-

Guy,I am going to try that thickness sander.Nice job. I have a drill press sander but I'm allways looking for something new.

I just aquired a disk and long board sander.I'm looking for some way to control the sawdust. It makes a lot and makes it fast.

Yes I am on the western side of Wi.Been here about 25 years.When it snows in May it is time to leave. Larry

-

Hello Guy,Roberts, Wi is a very small town about 10 miles from the Minnesota border and about 30 miles from the Twin Cities.

I decided to remake the deadwood again.It did come out better.This time I used maple and the finish is much nicer.I will post some pictures to night or tomorrow. Larry

-

Guy I am a novice and I do not know what you mean by 3 inch planking also how does the planking relate to the dead wood?

Thank You for any help. Larry

-

Hello Guy,I did the aft dead wood 3 times.I have it ok but not the best.The mohogany is to soft to get a really good edge.I hope you do a better job than I did.

Best regards Larry

-

Looking very nice Richard.Keep up the good work and keep posting, Larry

-

-

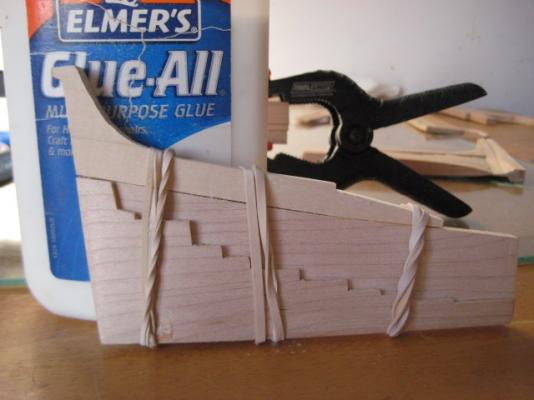

Hello Everyone,I'm having a heck of a time with my stern deadwood.

Christian here are a few pictures of my problem.

This is a picture of the of the keel which measures 6.5 mm and the rear of the deadwood which is 3mm

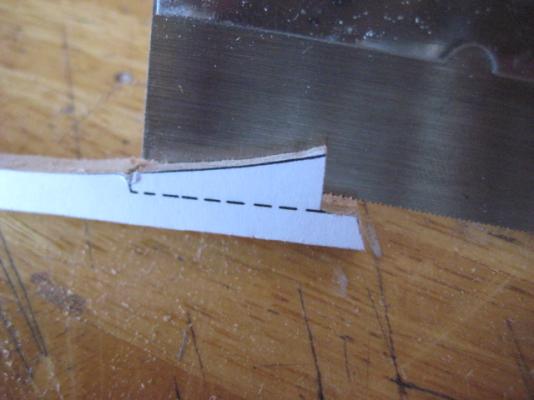

On the 3 piece steps the center wood would be 1mm and the steps at 1mm each at the rear of the deadwood.How do I make the keel and deadwood agree

Here is the way I did this.

Thanks for any help Larry

-

-

Welcome Richard,I'ts nice to have another person to gain knowledge from.

Larry

-

-

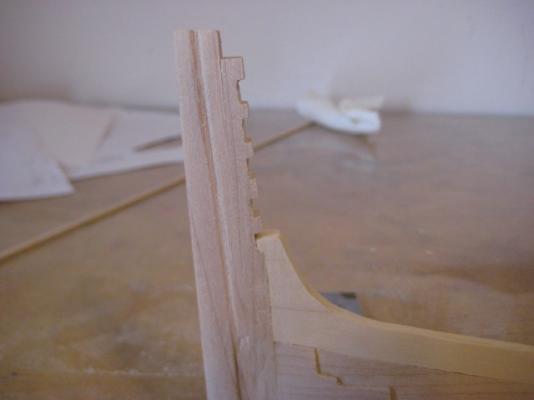

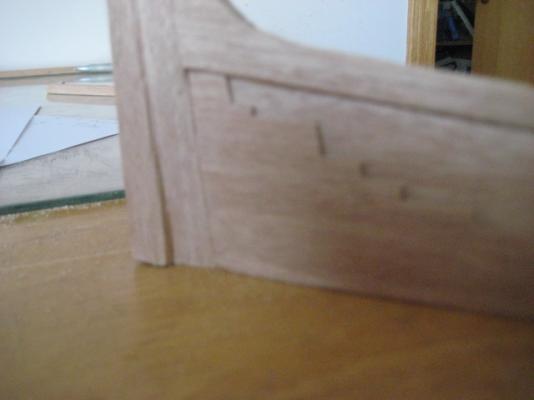

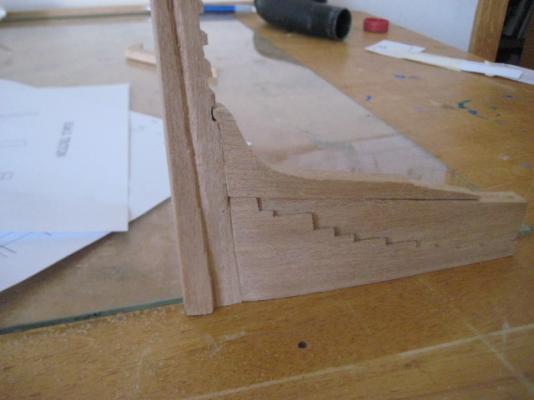

Hello one and all.I finished most of the bow pieces.A real challenge to say the least.The whole thing I did over again,some parts I did Over 3,4,and one piece 5 times.

On this part I used the saw seemed to be easier.Yes and up side down.Dang camara "smile"

This is the steps cut in three pieces.

The rest were cut,sanded.fitted and sanded some more.It takes quite a while to get the fit right

Does anyone know where to start the taper and what the final size is on the bow?

Where to start next?Maybe the keel? Have a nice day/night Larry

- st george, harvey1847, Paddy and 1 other

-

4

4

-

Hello Muggle,What is the name I should call you? Are you in China?

My name is Larry And I started this build a short while ago.The thickness of the Bobstay and the Eaking is 8 mm.They will be tapered later.

Your picture of the chocks shows only 3 and there should be 4.The timber you chose is nice

Best of luck Larry

-

Thank you Mark and Guy,I did change wood for the keel and bow pieces.I went with mahogony.I will still do the frames in maple.I changed my building technique.Now I am cutting fitting and sanding one piece at a time.It takes a little longer but the fit is better,at least on the bow.Only one picture.

Good Night Larry

-

Nice show Paddy Keep up your great work.Nice tree nails. Larry

-

Thank you everyone for the warm welcome.

I have been cutting bow and keel pieces.I took a look and decided to go with a darker wood for these parts.Back to the hardware store.Thats ok for I need practice.There is one piece I was dreading and that was the fore dead wood steps.So I took the easy way sanded the fore wood down to 3/16 inch then added 1/16 Bass wood steps.

This made a nice clean steps

Best Regards Larry

-

Nice tip Rusty.I was wondering the best way to do thoses. Thanks Larry

-

Hello Pete,I like your work it is very nice.I do like your tools.I have been looking at the Byrnes saw and thickness sander.Trying to convince my self I need to spend $ 900.I also like your noodle sander.That is one of those why didn't I think of that. Larry

-

Very nice Paddy.Progress feels so good. Larry

-

Hello to the few, the brave,and the crazy.I have now joined you and I must be crazy to try this build.

I am almost done with the Triton Cross Section.I took a look at this build and saw the bow and all the pieces I knew if I could build this I could get threw with a lot of help.I am milling my on wood and the frames will be made of maple.Parts will be cut with a band saw and finished with a home made drill press thickness sander

So on with the show Larry

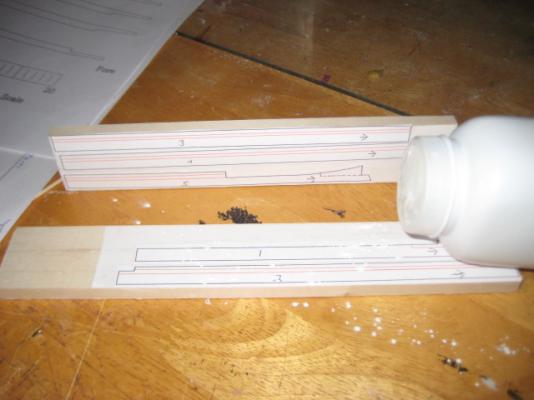

The first picture shows how I mount my templates to the wood.Double sided carpet tape then a little baby powder to remove the sticky.There are other ways but this works for me

SaturnV's 1:48 Full Framed Triton Build

in Build Logs for the Full Hull Version of HMS TRITON

Posted

I will be going to Montana this summer and I will harvest some Russian Olive if I can tell between it and a pine tree

Thanks for the link, Larry