Sterlingclements

Members-

Posts

44 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Sterlingclements

-

Just progressive sanding, with final sanding using 400 grit. Then apply tung oil with a lint free cloth, rub it in like car wax. In the above pic, the sill piece directly aft of the companion way doors (and fore the cockpit grating) is dry, no tung oil, for a good comparison of what a difference the finish makes. Both sill and companionway are made from the same piece of mahogany stock.

-

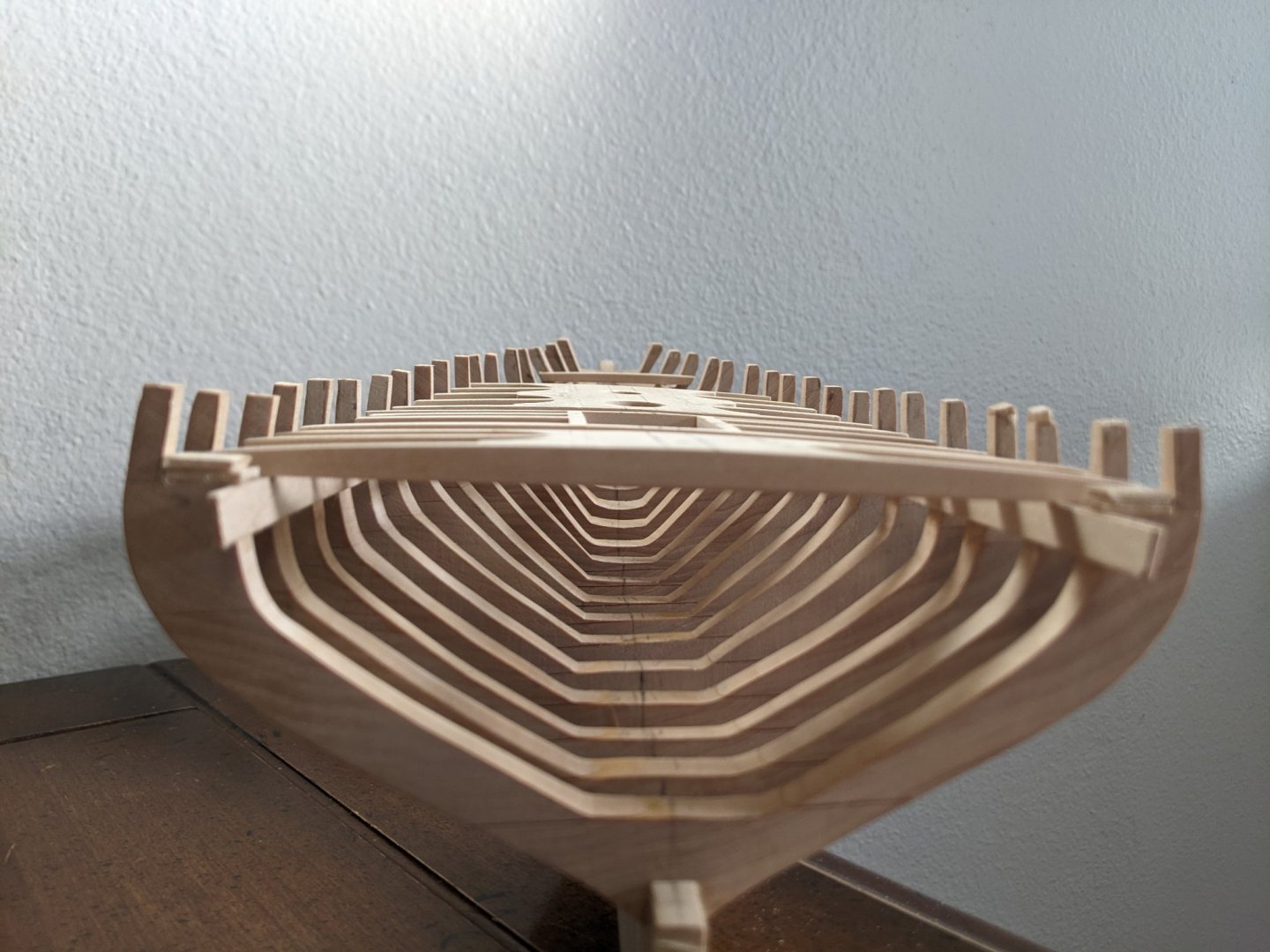

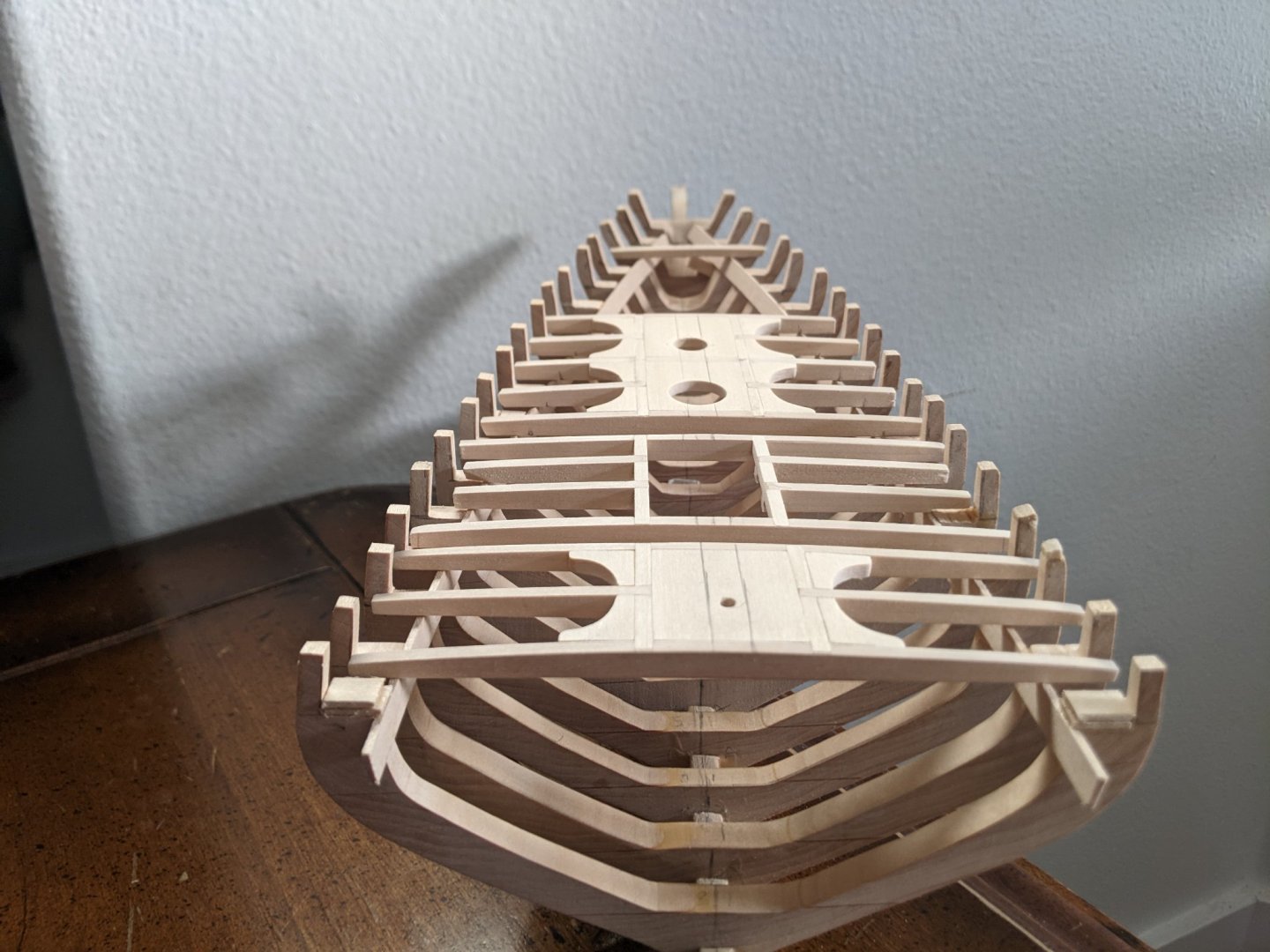

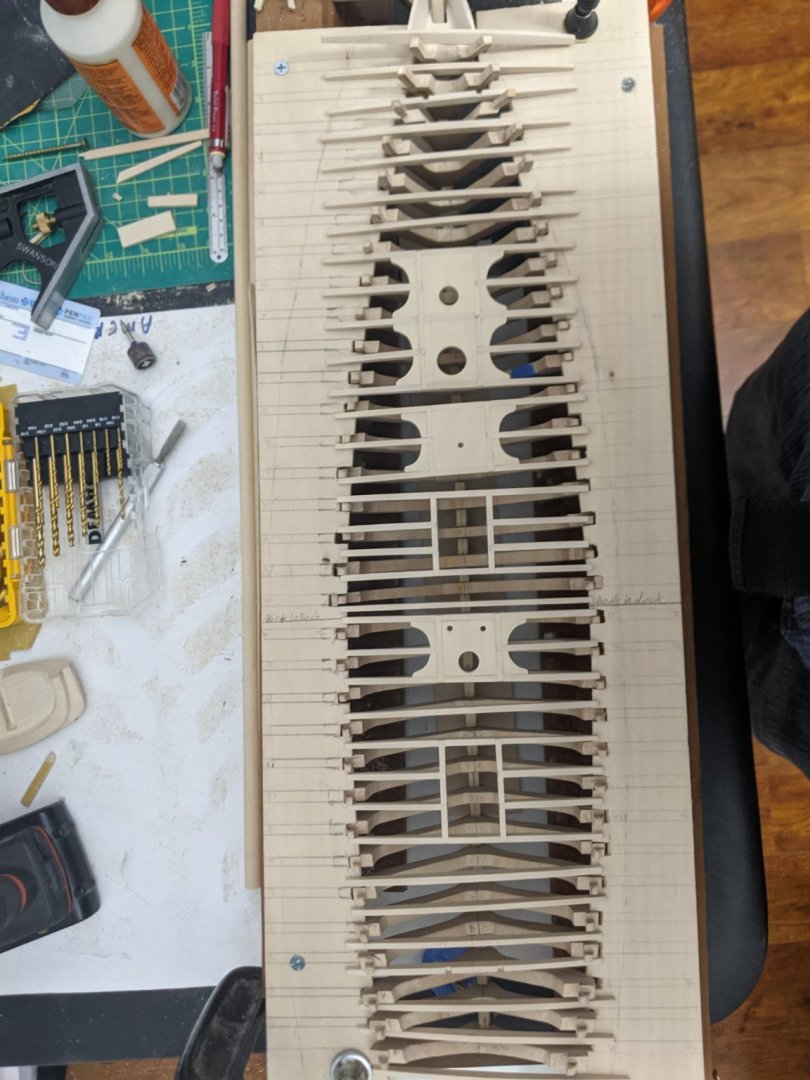

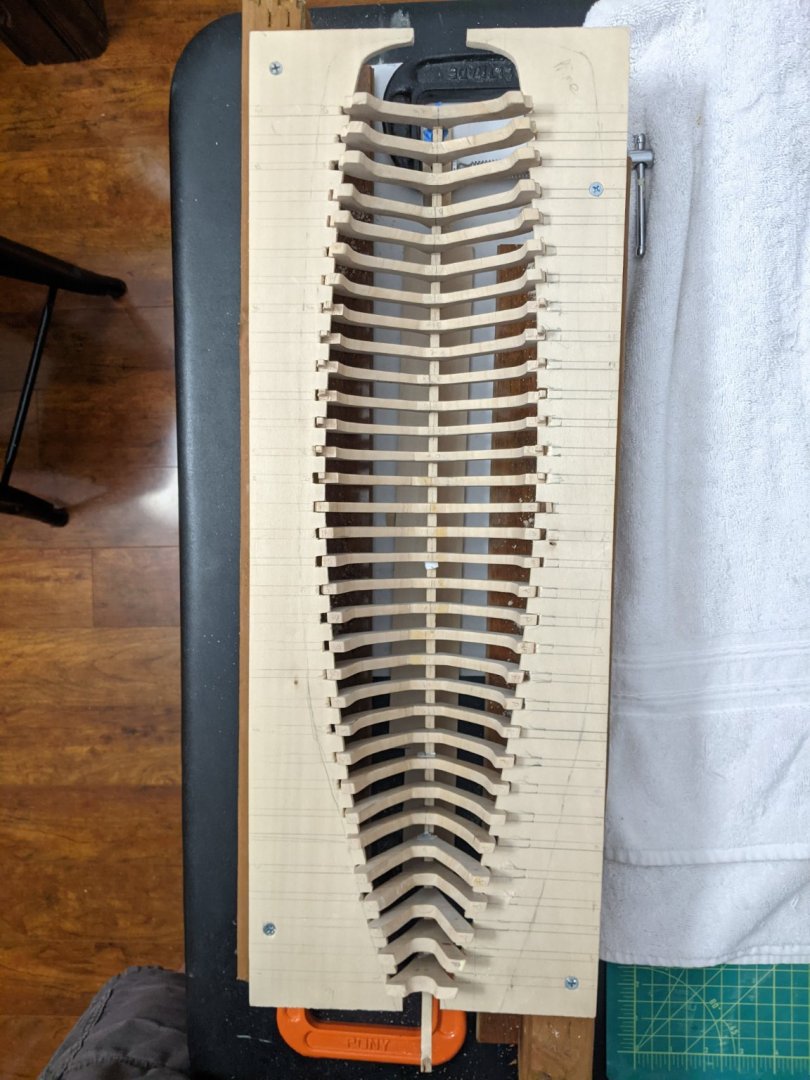

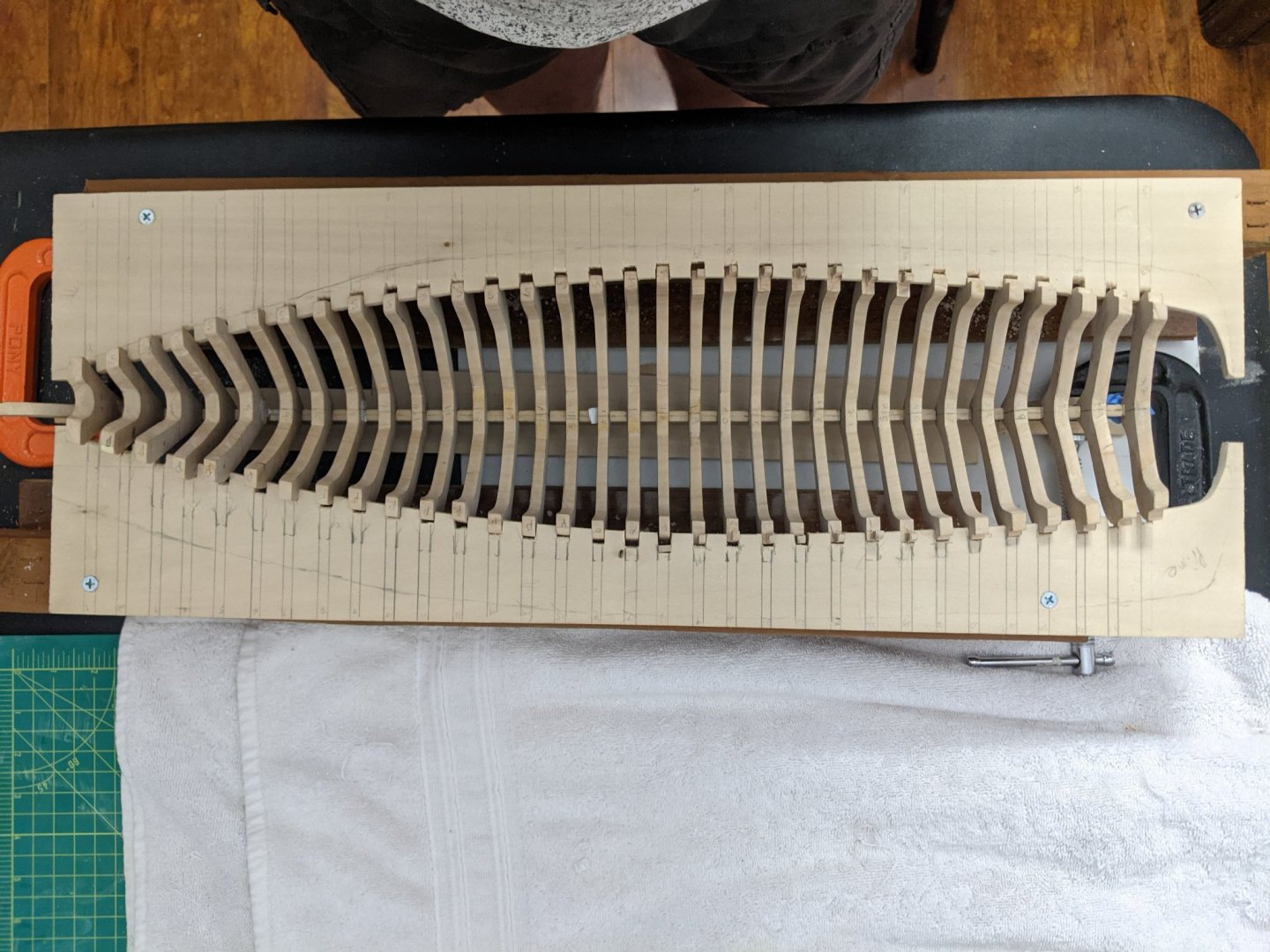

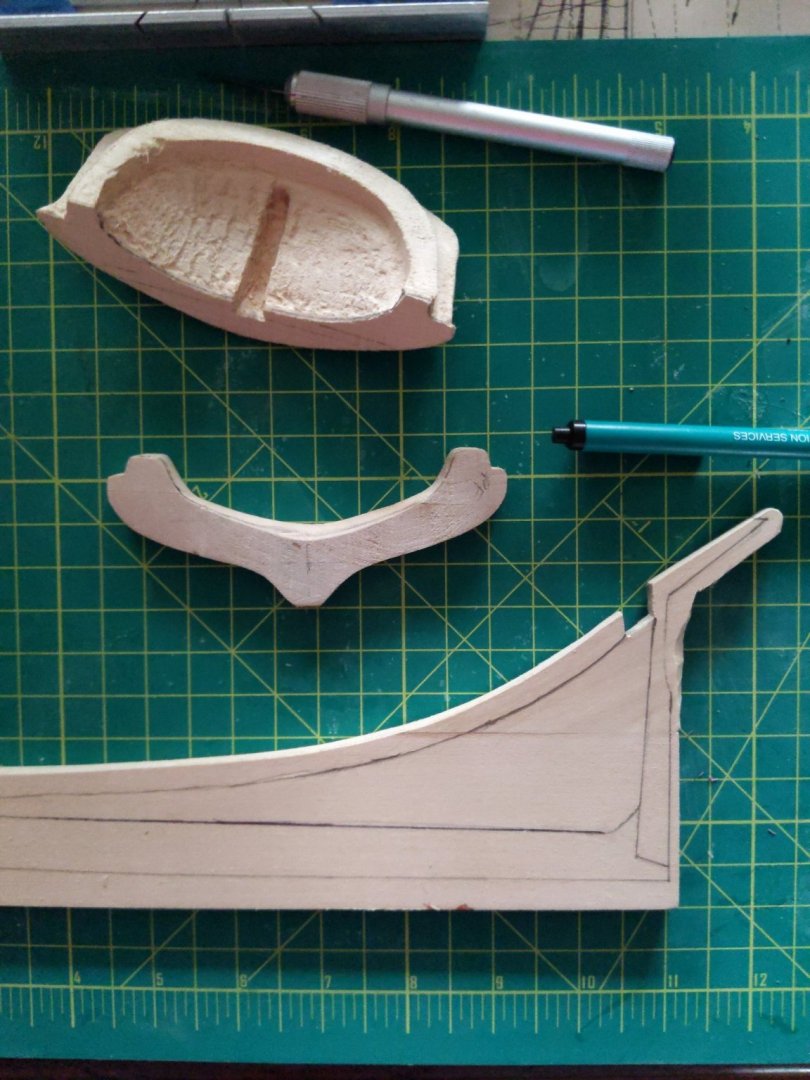

At long last, after checking each measurement multiple times and dry fitting deck-beam assemblies to verify timberhead heights, I began glueing the frames to the keel. I started with frame 18, just fore the break in the deck, and worked my way forward through frame 1. I took my time making sure that the frames were not only square to keel/horizontal but were also symmetrical in height port/starboard and in width from center line to outboard edge. Results pictured below, including temporary installation of sheer clamp so I can further check planking fit and complete any touch-up fairing as needed. I also included pictures dry fitted deck-beam assemblies and a few keel-line views.

-

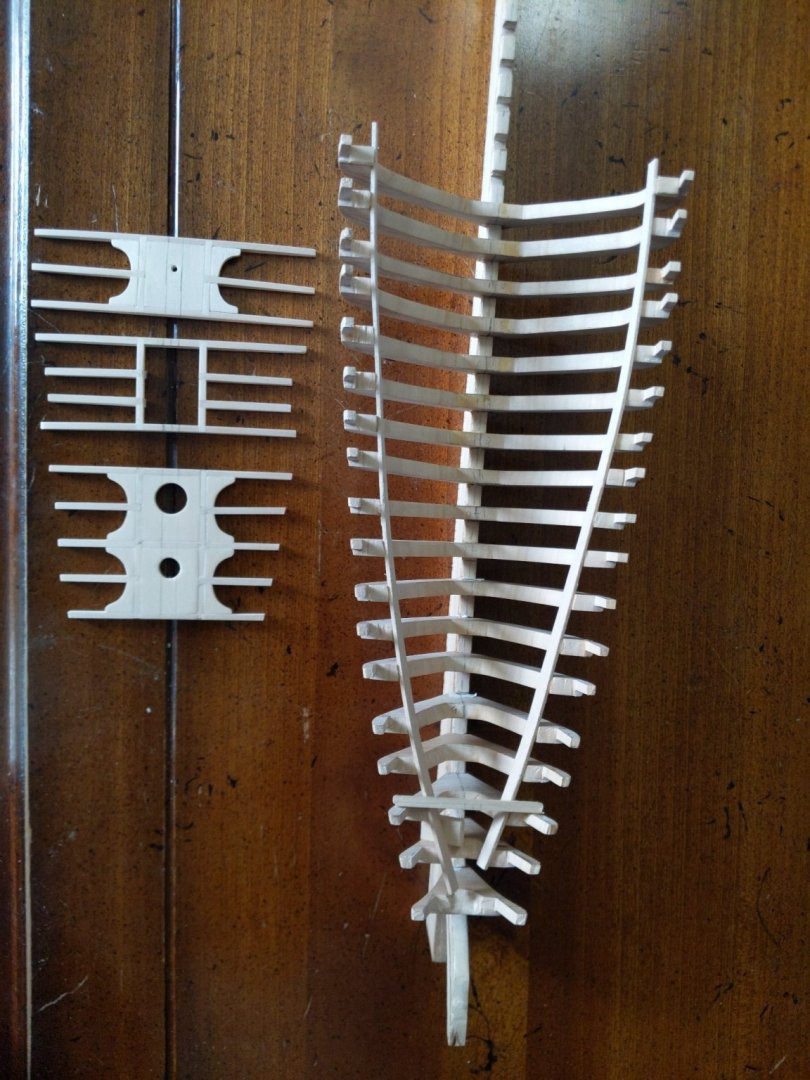

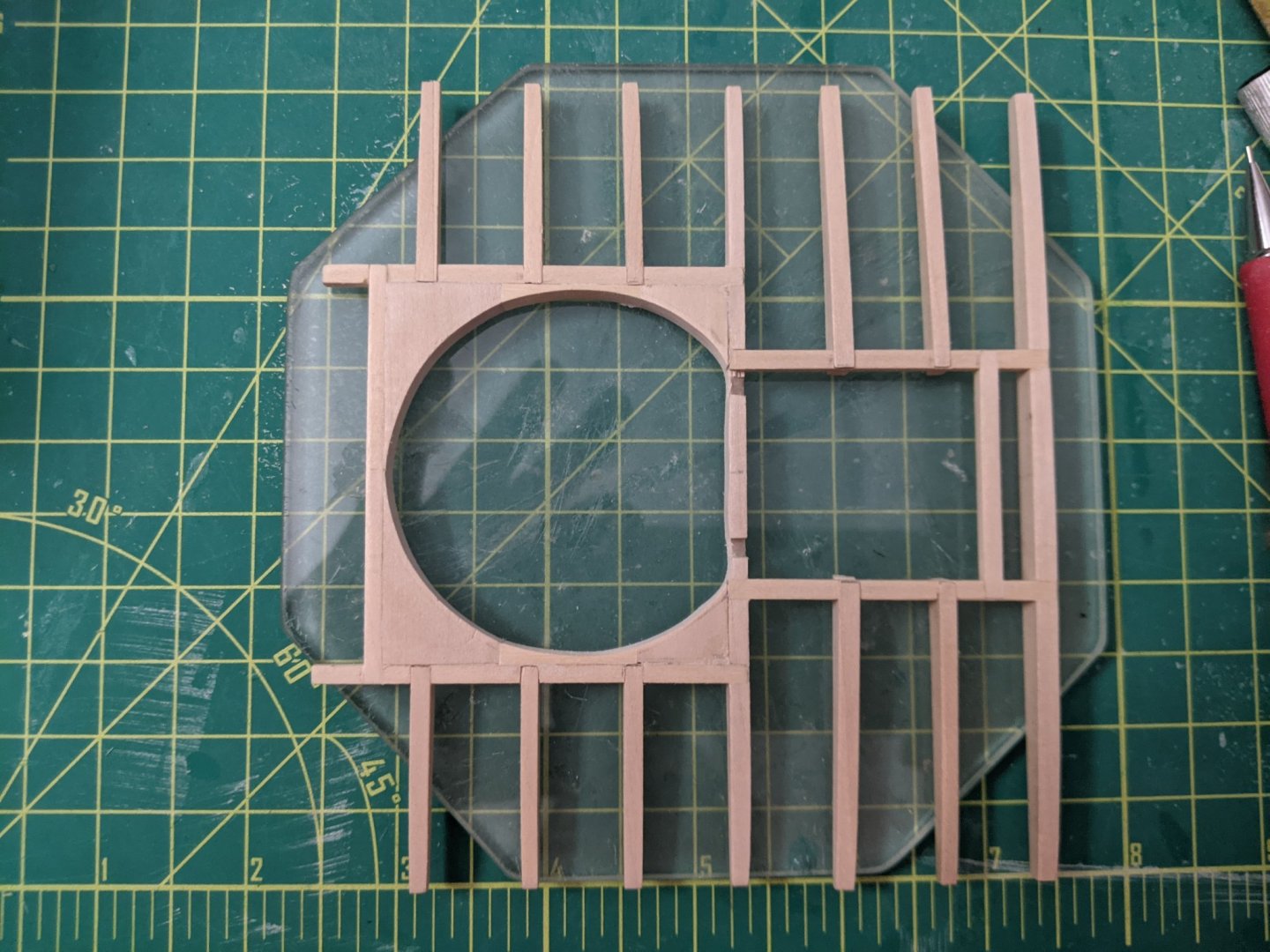

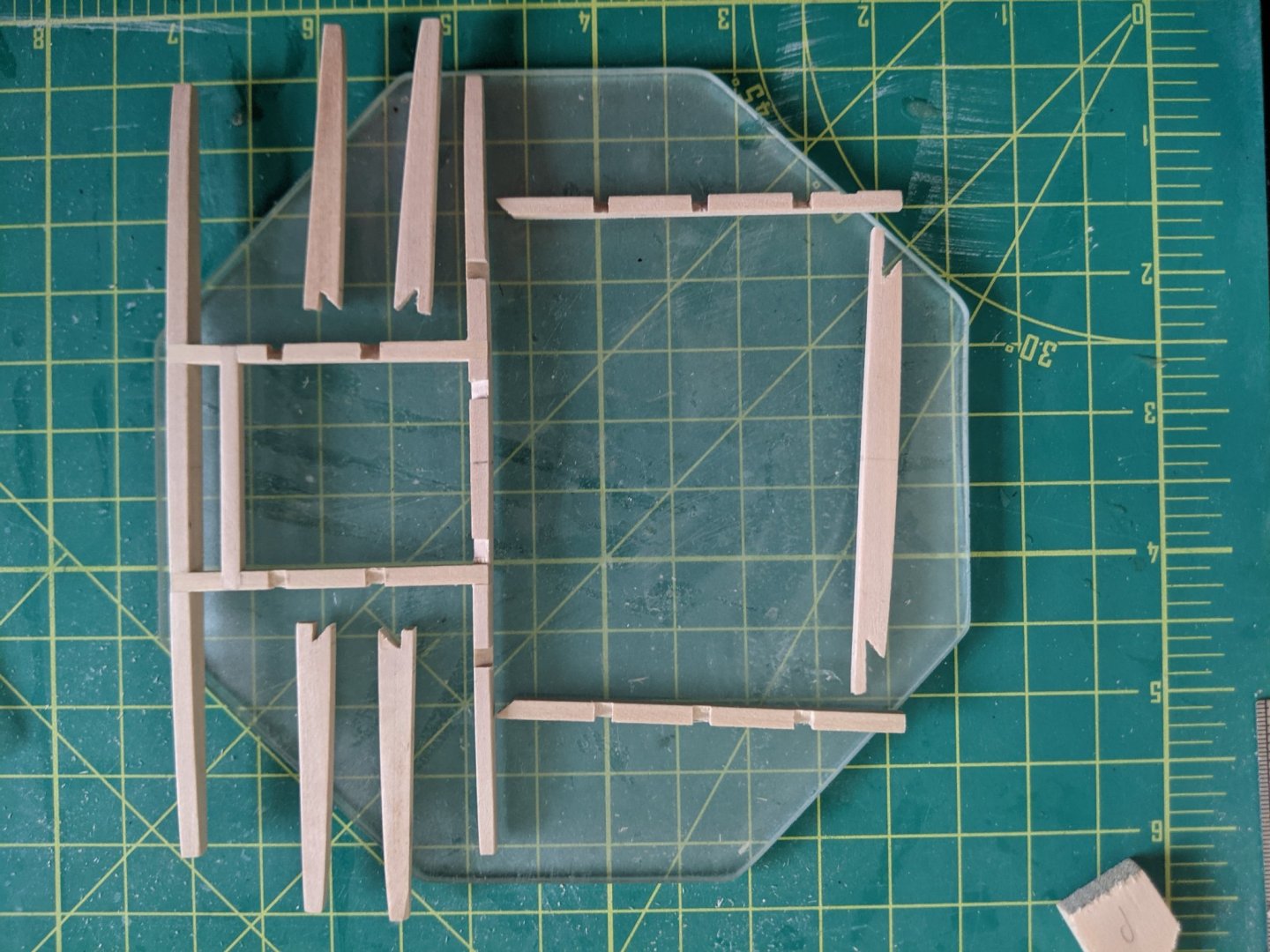

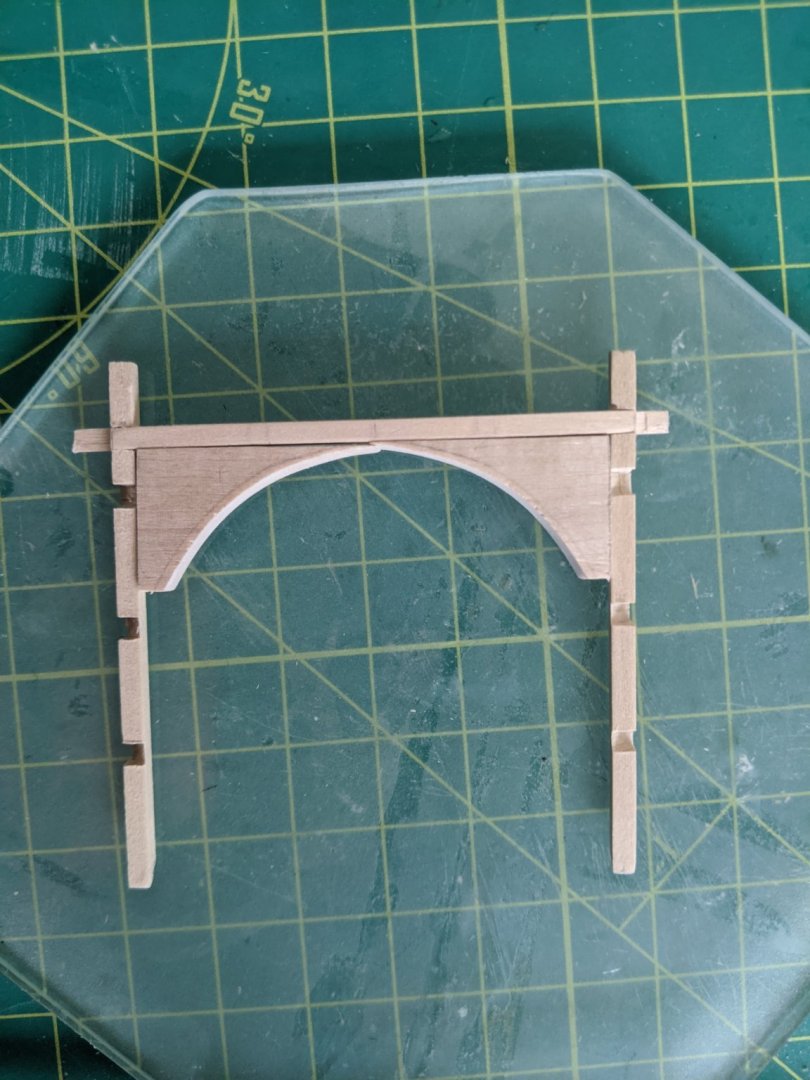

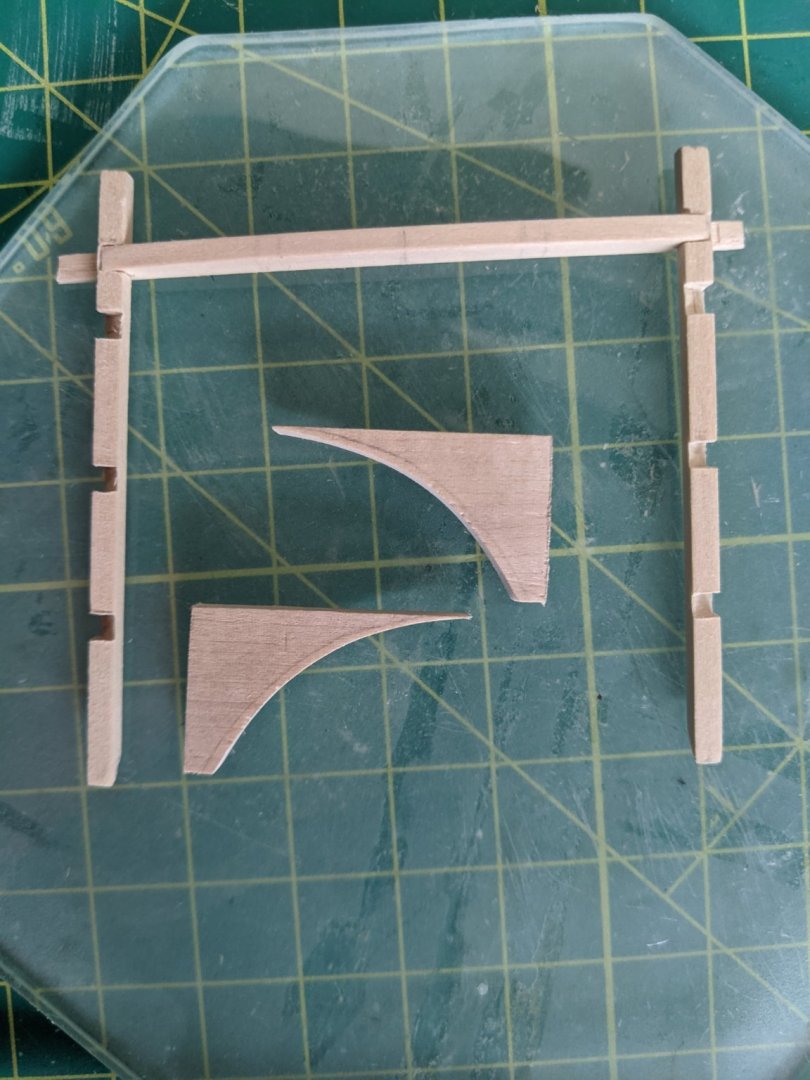

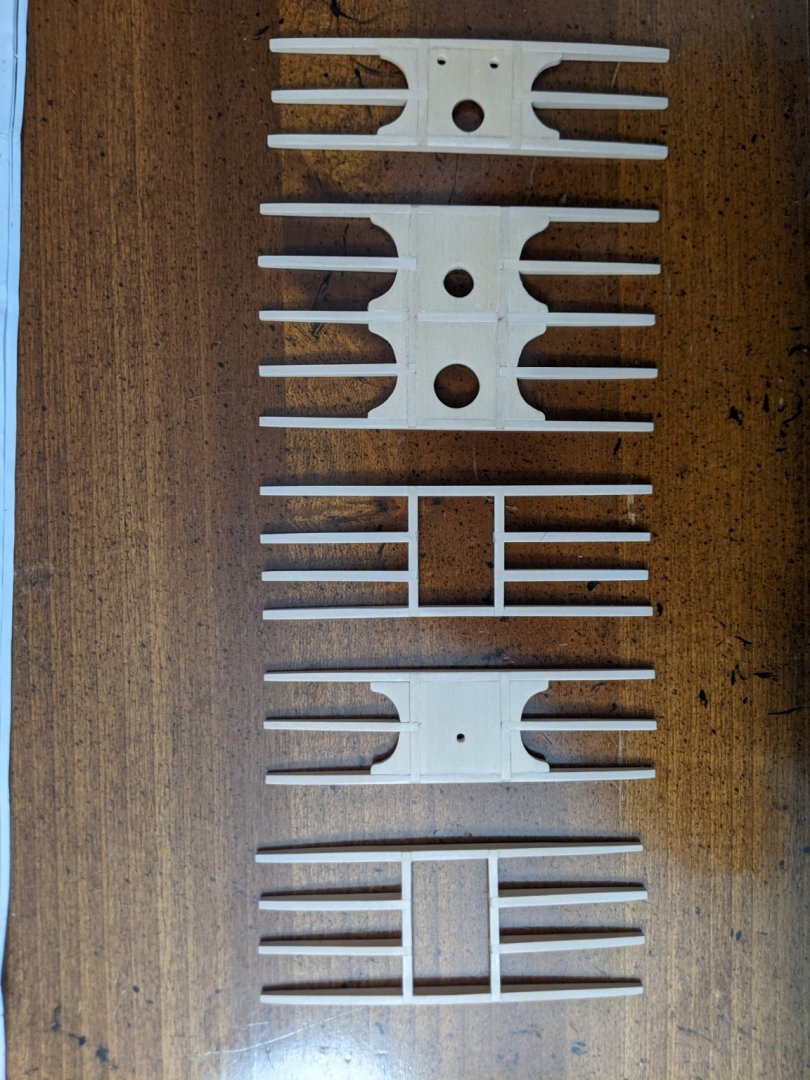

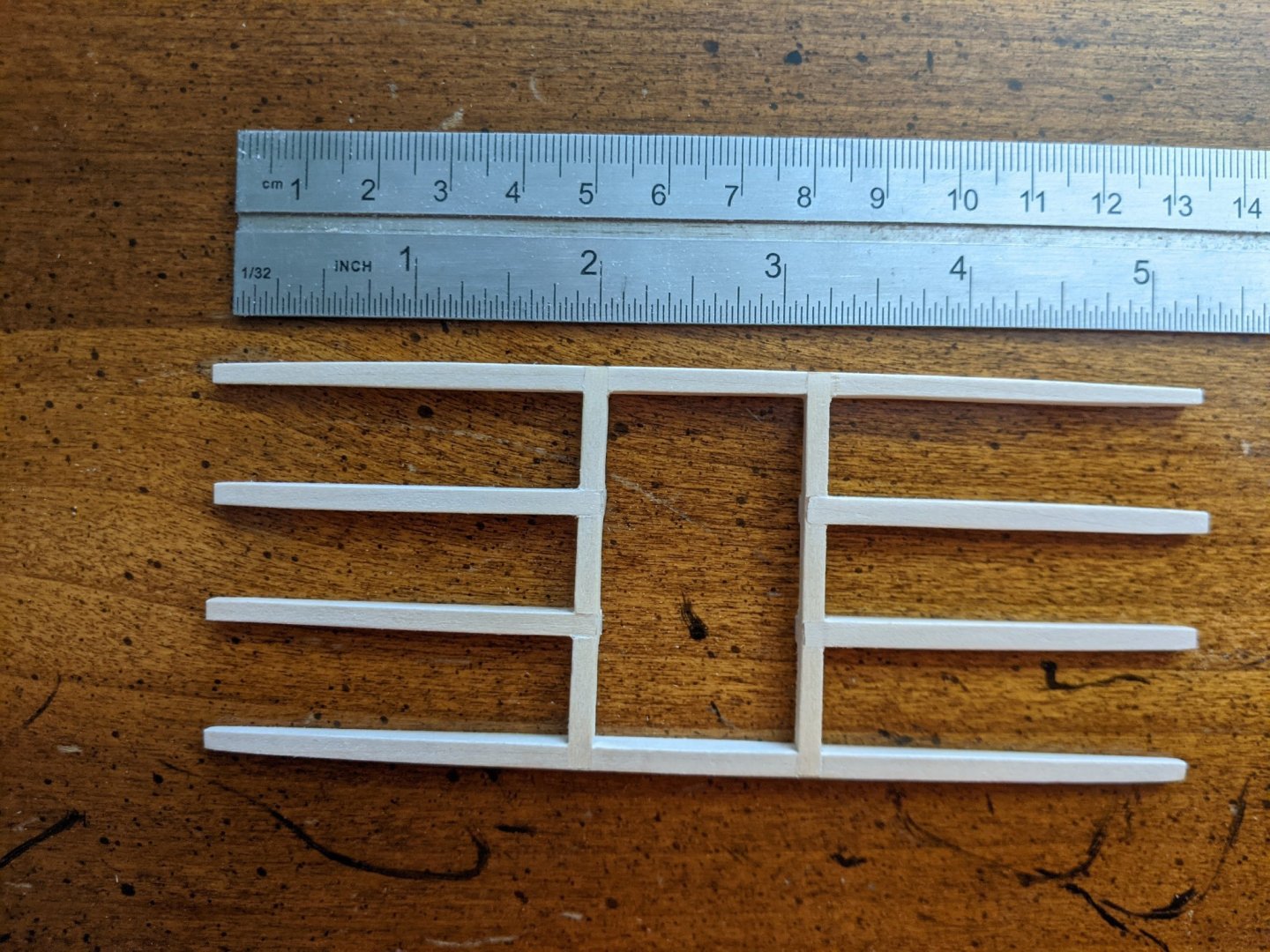

All deck beam assemblies complete, with the exception of the cockpit assembly, which is the most complex one. It is under construction at the moment. Thanks to gsdpic's log, I took extra care drilling and mostly sanding the various holes. Pretty satisfied with the results. I plan on leaving the deck partially unplanked, but do plan to plank the center rows....about as wide as the mast pads.

-

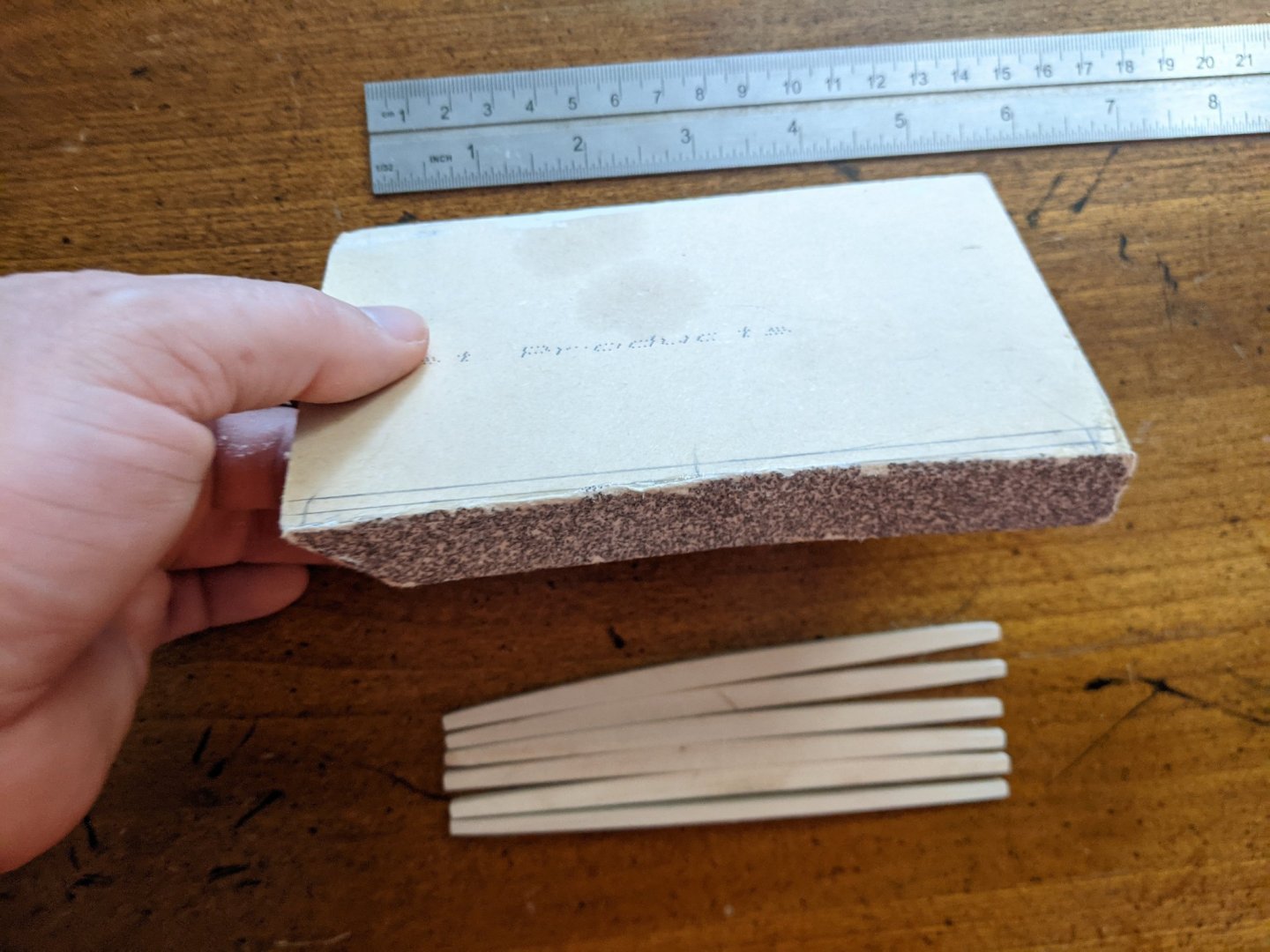

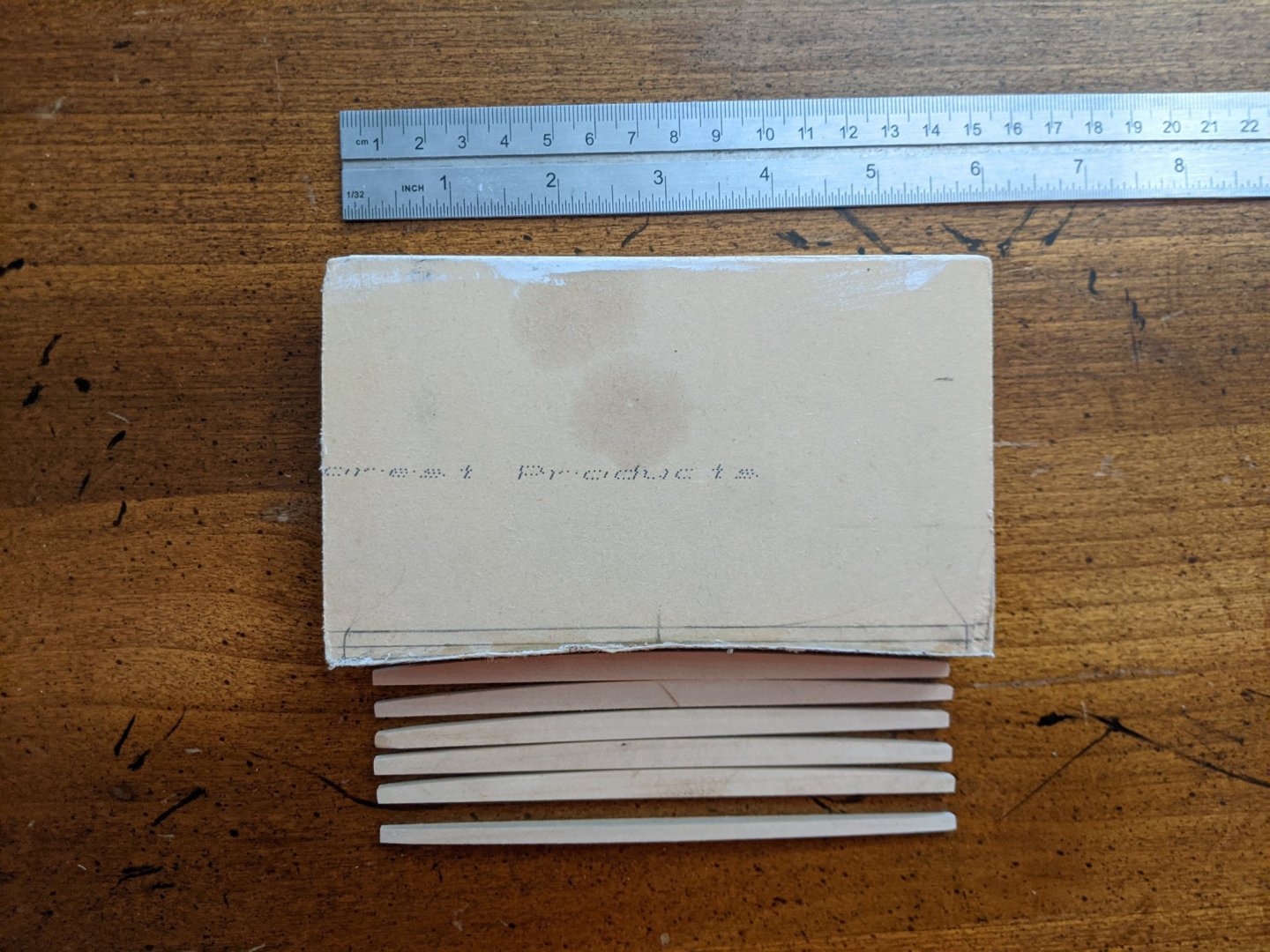

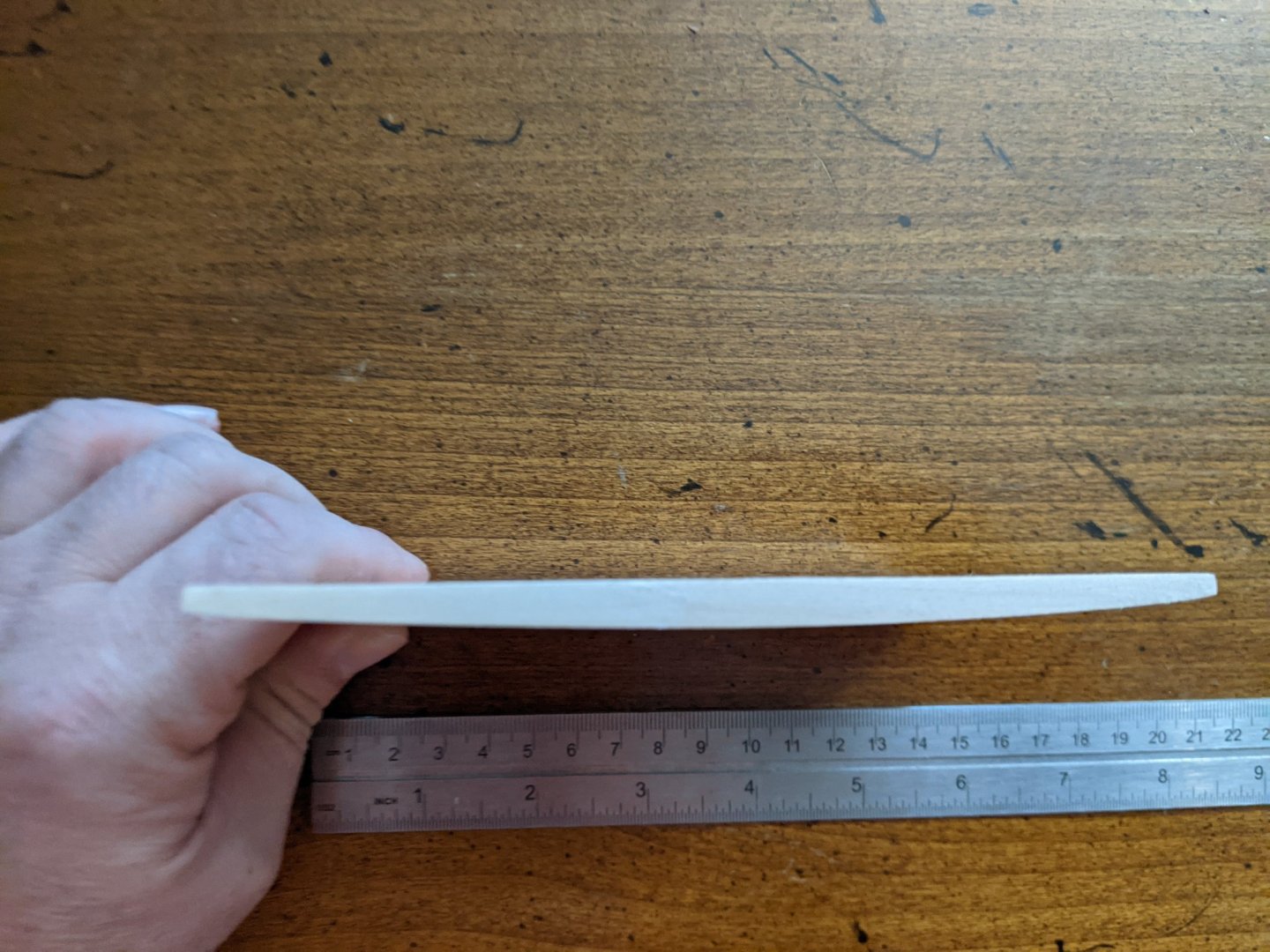

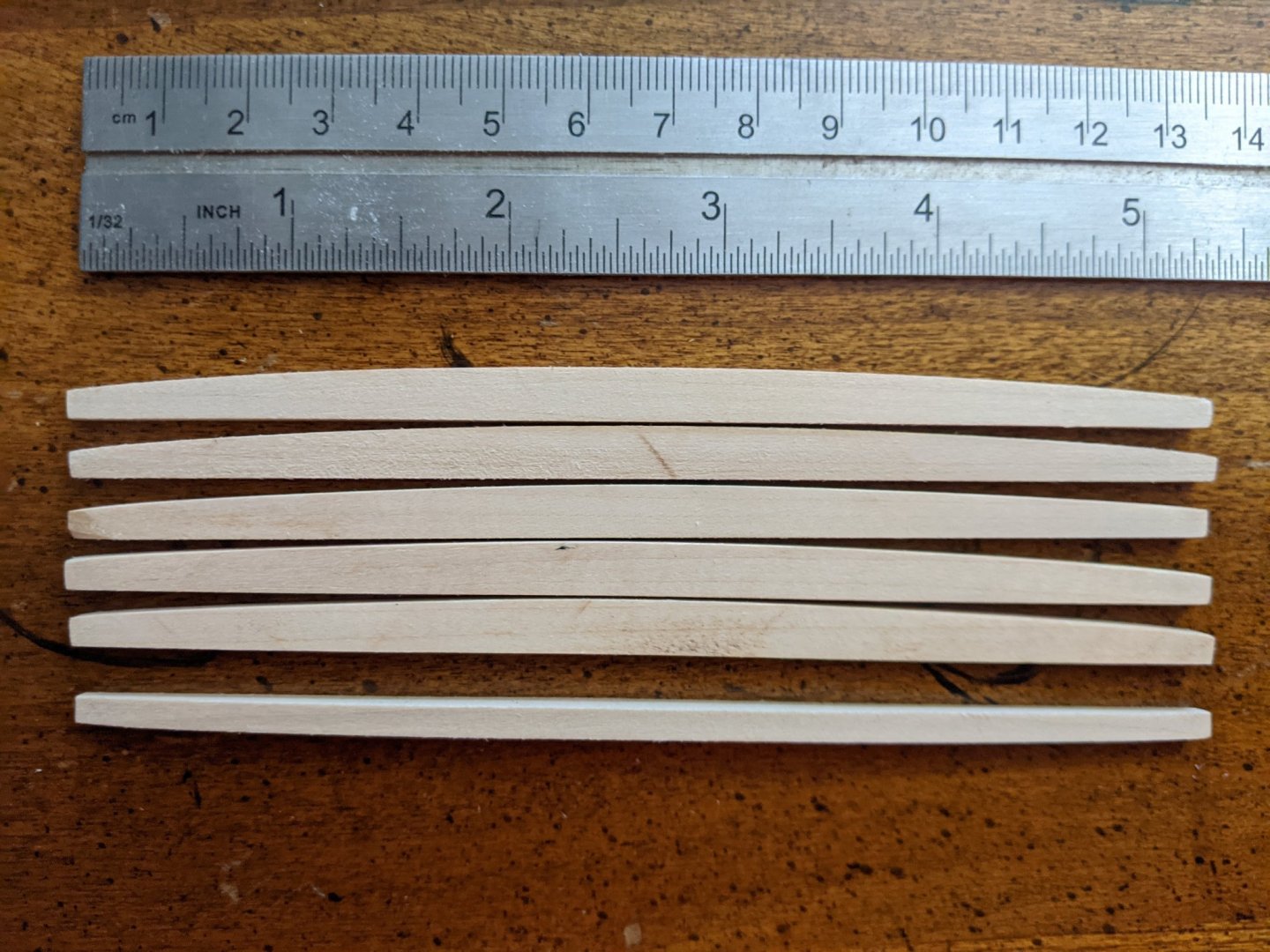

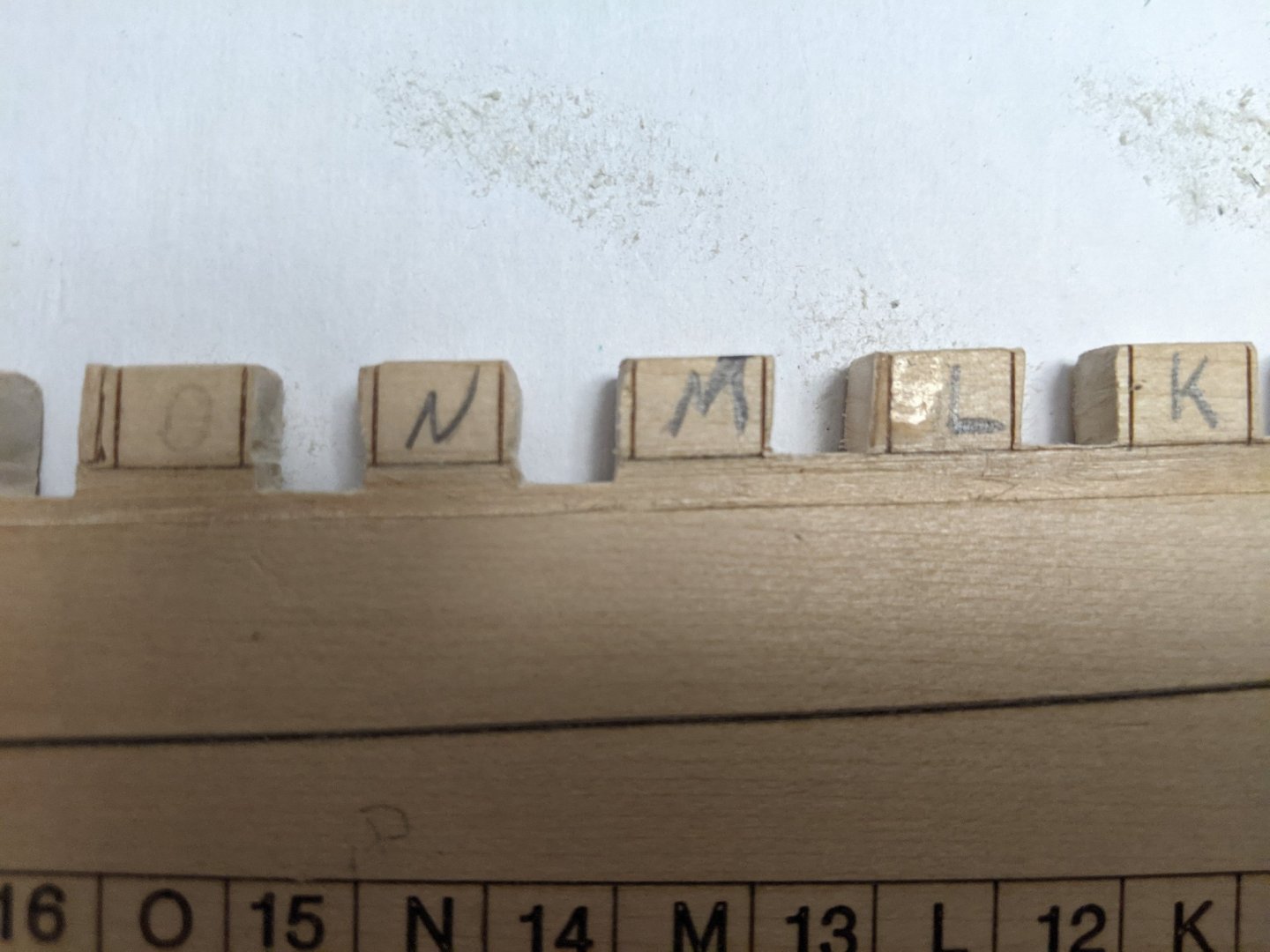

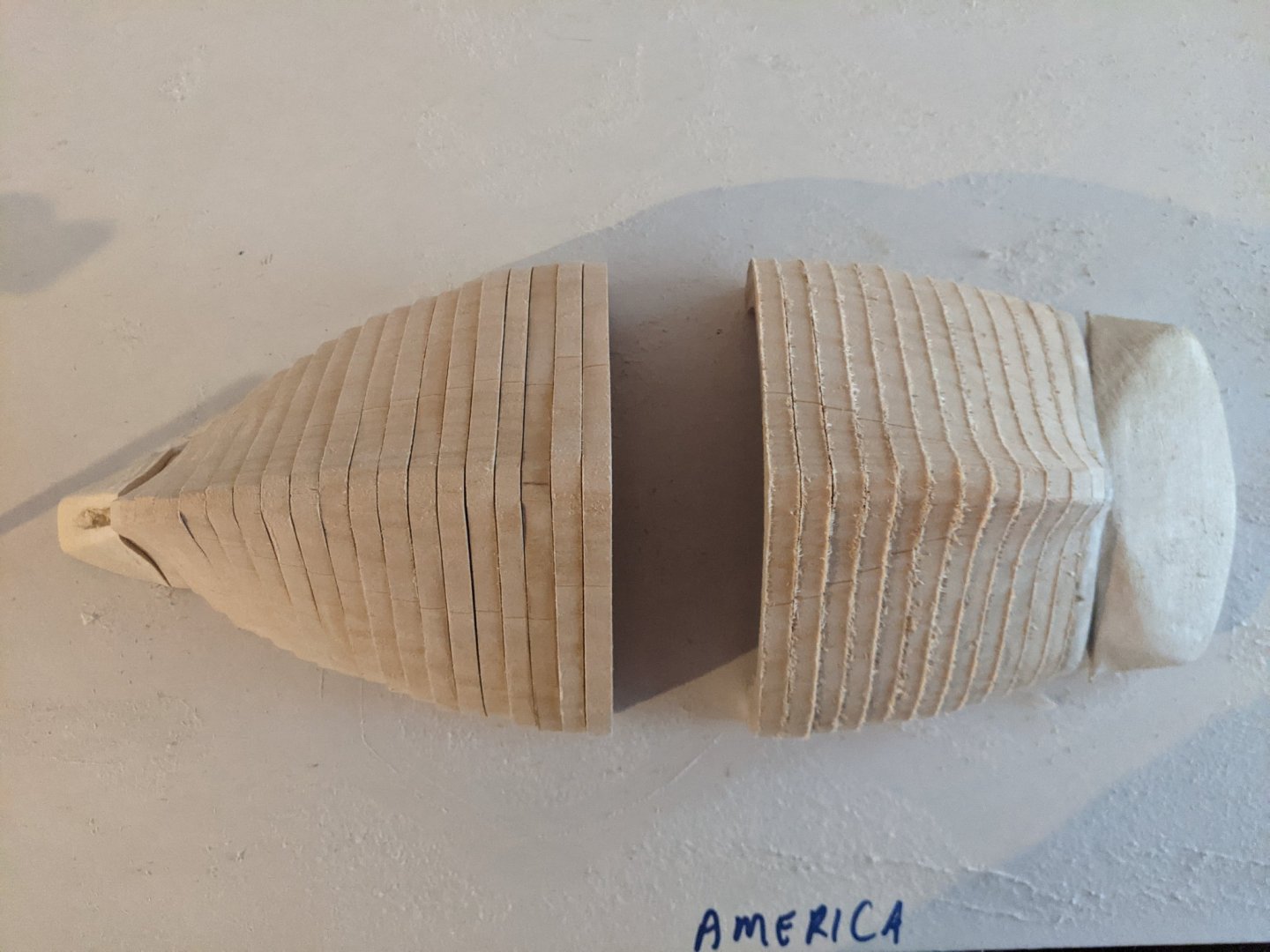

Long time since last post. frames finally ready/symmetrical. Bearding line chiseled in. As seen on @gsdpic's build log, the laser etched lines are way off. Not only is spacing for frames too wide, the rabbet line was set way too low. See picture, I had to sand down between frames N and M to make the garboard plank fit correctly to the bearding line. See the difference between frames M&L. Roughly a 1/16th to 1/8th inch difference. I will have to sand down all the remaining notches to match.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.