Frodo

Members-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Frodo

-

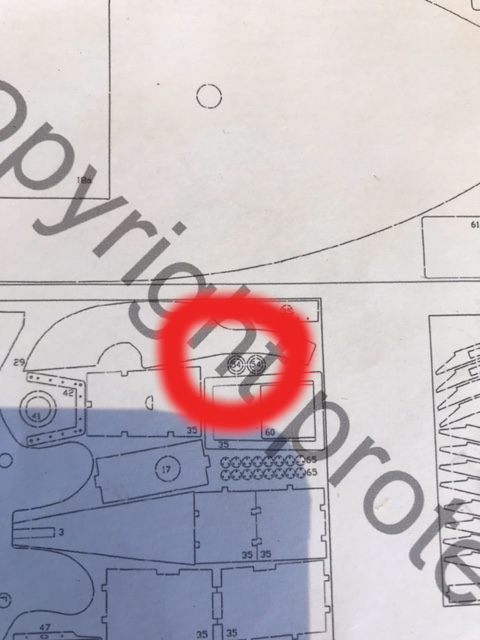

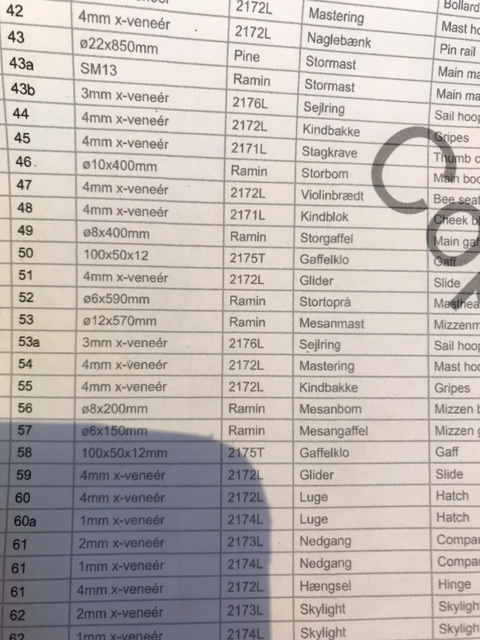

Funny, when I had used all the parts from the kit I had 2 rings extra, and I could not figure out where they were suppose to go. Apparently I've missed the nbr 54 "mast hoops". Thanks for noticing George. See attached pictures, guess they say it all 12mm rings: Pictures from the instructions (that I didnt notice until you made me aware George). I think I will cut one of them in to halves and mount at the base just for the look. I dont think there is a technical need for the support rings ("Mast Hoops").

-

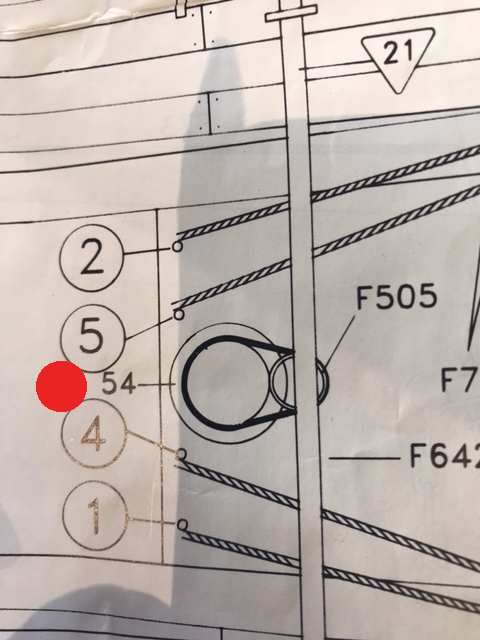

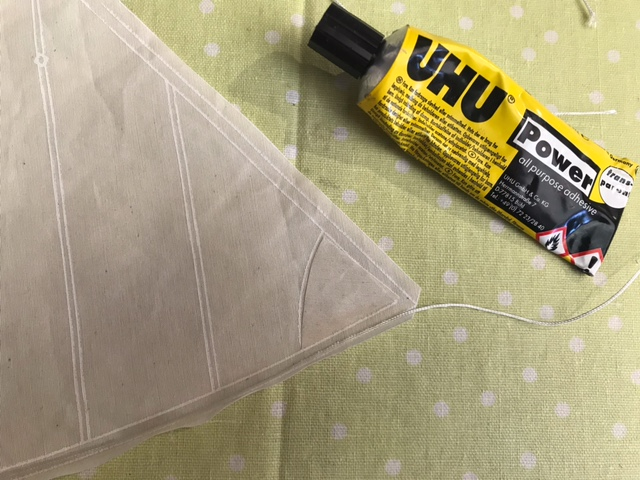

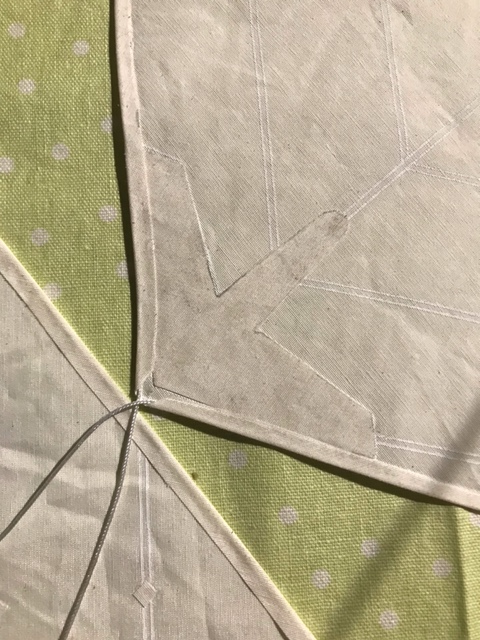

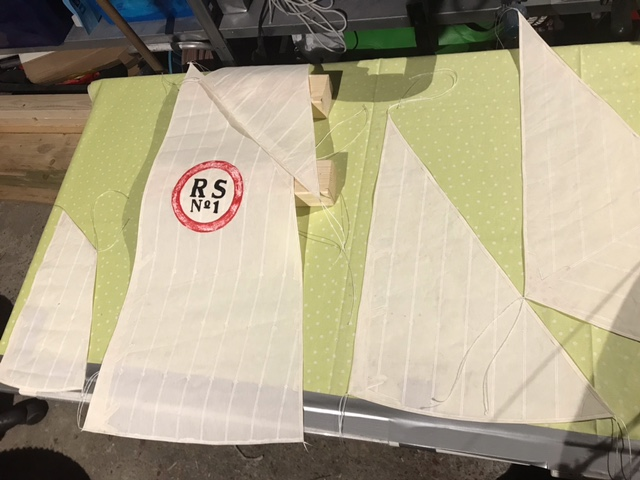

I've been working on the sails for a couple of days. The edges were folded and glued, however I decided to put a 1mm white cordline inside each fold/edge. Hopefully this will contribute to a more neat sail. Some of the excessive cordlines (white) may be used to make "loops" for clew/tackle points. Also made reinforcements at the sailcorners. Next step is to sow all the edges and whitelines... (I will not dismantle each panel, and Im not sure if its suppose to be done either) The "red ring" is made with Billing Boats Acryl and reacted to the adhesive from UHU. Needs to be re-painted once the glue has dried...

-

Finally we had a couple of days with sun and warm weather, and I could go ahead with the paintjob. Decided to go with black antifouling below the waterline. (Sorry for sunglare 🌞, will take some pictures later which is better) A minor mistake with the brush on the redline which will be corrected. The rudderhinge is still a mess, think I will change to pin-hinge. Does anyone know how to attach these "stickers" on the hull? With heat or water? No clue. Maybe they are broken.

-

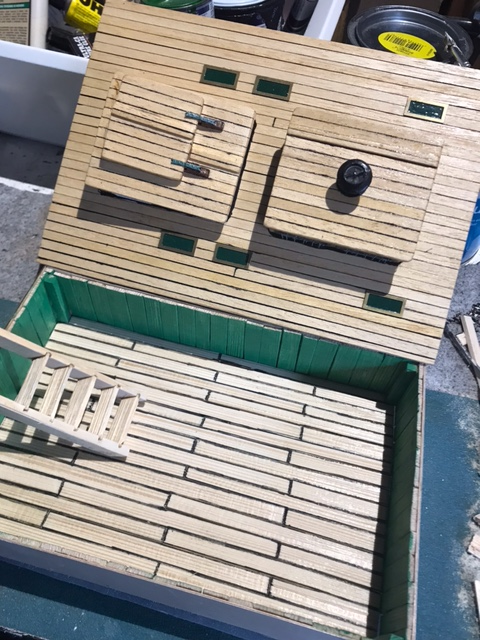

Here is an update on the Colin Archer build. Not much going on with the boat itself. I've ordered some ropes from Syren to complete the rig. They should arrive in approx. 3 weeks. However, I've more or less done the "look-alike-interior" "salon/cabin-box". Mostly build from scrap and leftovers from building the boat itself. The interior is not real-scale. But I had great fun making it (…and that's the main thing after all) The "black box", that will stand on a rack or in ropes below the removable deck, and "hover/hang" above the RC-baseplate as shown in previous posts: Removed structures: I will install some LED lights in the cabin later. Removed deck: The box is 50mm deep, 175mm wide, 255mm long. I wanted the floor to look "worn and torn", so I added some oil stains, then painted with grey and sanded with 180 paper, and at last covered in clear lacquer. Dining area with heating-oven: Its not a dishwasher, its the door to the restroom with a large mirror on the door Cooking-oven: Seamap on the wall next to heating-oven: PS. Dont tell my spouse I stole some handtowels to make linen and floor mats...

-

Hehe, 1:100 ish... could be closer to 1:15, Im just improvising some interior - Not as nice as the salon you are making Geam 🙂 I'm trying to build a "salonbox" above the "RC-baseplate". Making the walls from a piece of spruce: Wall: Floor: Floor is nated and will be painted/oiled later. Plan is to make some furnitures, a restroom etc in there as well. The "salonbox" is 50mm deep, and will be attached to the mainhatch (deck). Just made a small ladder to see if it will work. I haven't glued the structures to the deck, might use some magnets to make them removable so one could peek into the "salonbox".

-

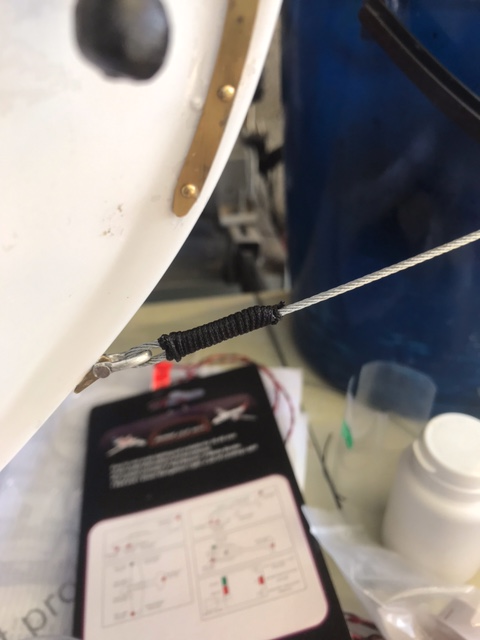

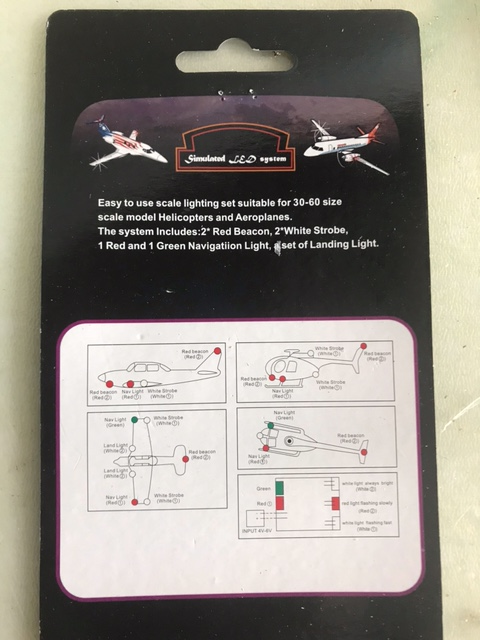

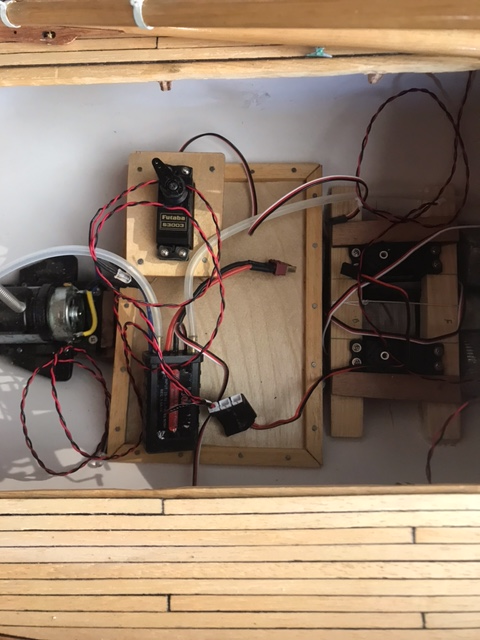

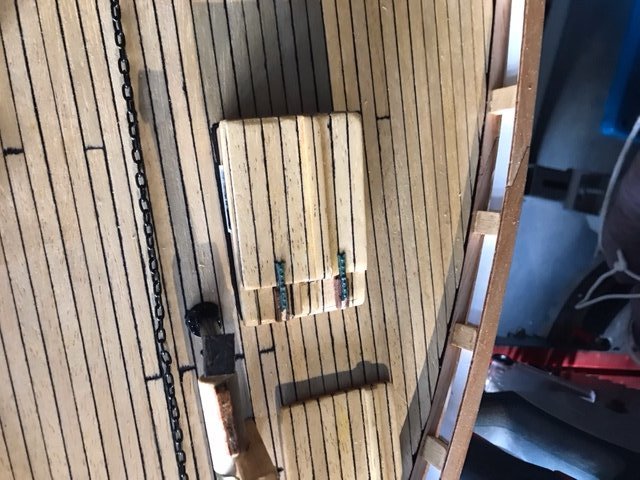

Some minor progress today. Covered the "wireloops" with rope (I'm using 1mm Black Cordline). Looks fairly ok I guess. Also bought an simulated LED system for RC-planes which should do the "lightjob" on the boat. I plan to use two white lights in the salon...maybe. It would be nice to have one of them for an aft lantern also... The red and green are installed inside the lanterns... For some odd reason the lanterncasing is hovering 0,5mm in the air, I believe this is due to the glue swells when it dries... need to cover that gap with a detail. The black and red wire (-/+) are wrapped in 1mm black cordline, so It blends in ok without showing the electrical wires. I also made an "RC-baseplate", the plan is to attach it with heavy duty Velcro on in the hull so it can be removed if required (the lead is underneath). Battery, receiver, LED-control, escalator with watercooling and steeringservo will sit on top of "RC-baseplate". The steeringservo is placed in a rack 40mm above the "RC-baseplate" so it is in-line with the ruddercontrol. Guess I will make a 1:100ish interior/salon while I am waiting for the temperature outside to increase so I can paint the boat one day 😏

-

So this morning I started with the meltdown... after 10 minutes I lost my patience and looked for another solution. Instead of melting the leadblocks I could easily shape them to fit into the keel. Luckily I didnt have to do much adjustment. With some duct tape 2 halves are put together ~ 1kg. Approx 6 kg of lead in the keel. 4x0,5 kg can be moved around and are attached with heavy duty Velcro. I don't want to have a sealed lead solution in case I get water in the keel and have to remove them. Next step will most likely be to install the servos and some of the RC-stuff

-

Since the rig is tightened with 1,5mm stainless steel wire, I decided to make the tensioners 12mm longer than what the buildinstructions depicted. I'm hoping that this will give me the possibility to tighten the forestay before it goes sailing in summertime. (Current buildtemperature is around 5 Celsius, and I expect the rig to slack a bit at 20-30 Celsius).

-

The bow is almost complete, and ready for paintjob as the rest of the hull. Shackle at end of wire is made of "lead steel", which is easy to work with and robust enough to hold the bowspear. Bowspear, 1,5mm stainless steel wire. Currently it is soldered and covered with shrinktube, plan to cover it with a rope.

-

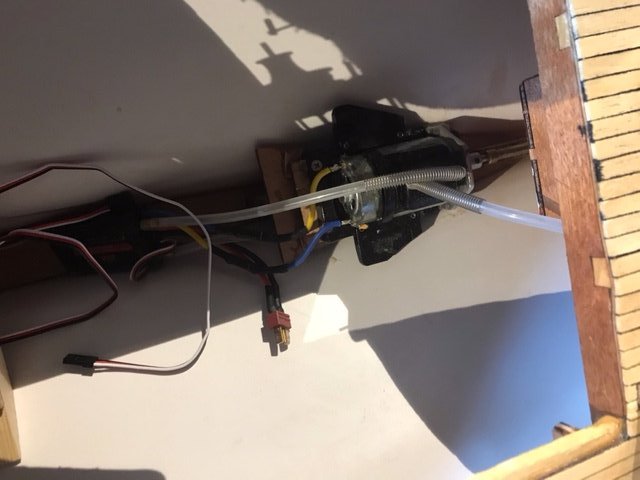

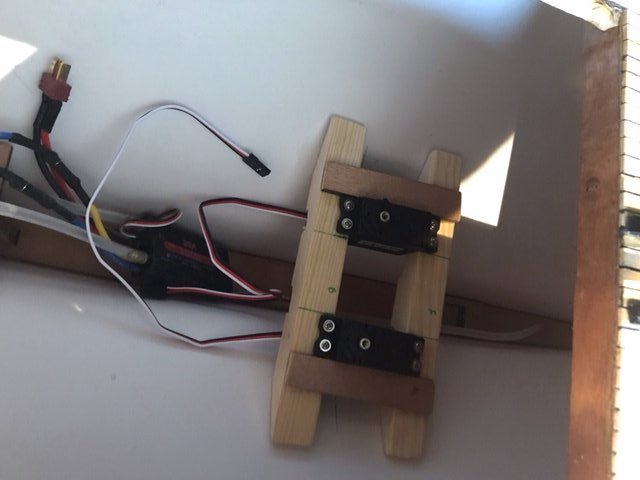

The engine fitted spot on, and even came with a water cooling system incl a regulator. 2xWindforce 1006MG Sailwinches from Krick (www.krick-modell.de art nr 79073) as depicted in pic nr2 was mounted on a bed. My plan is to wait until the rig and sails are complete to decide where to place them in the hull. I am considering velcro-straps...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.