wglasford

Members-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wglasford

-

Back to working on this model. Took a break to complete all the other mostly completed models and even created a 3D printed model of The Big Carl crane. This is now the only model I have in-progress, a final push to get this one complete. Continuing to work my way up the superstructure, creating the smoke stacks and main stack. Things have gone from mostly plastic parts to mostly photo etch. And the parts are getting really small and fragile. These little hatches are 2x3mm in size. The ends of the tweezers are feeling really big. Here are pictures of the forward tower/smoke stack and the aft smoke stack. They are not glued on yet because more parts need to go on and some of it still needs to be painted. I'm holding off on adding the more delicate parts.

-

The Bofor directors, MK51, needed some side handles. The Pontos instructions showed them in various pictures but never identified the numbers. I found them, they are 751 and 752. The round perforated base plates are Eduard parts. This is the side handles on before painting them.

-

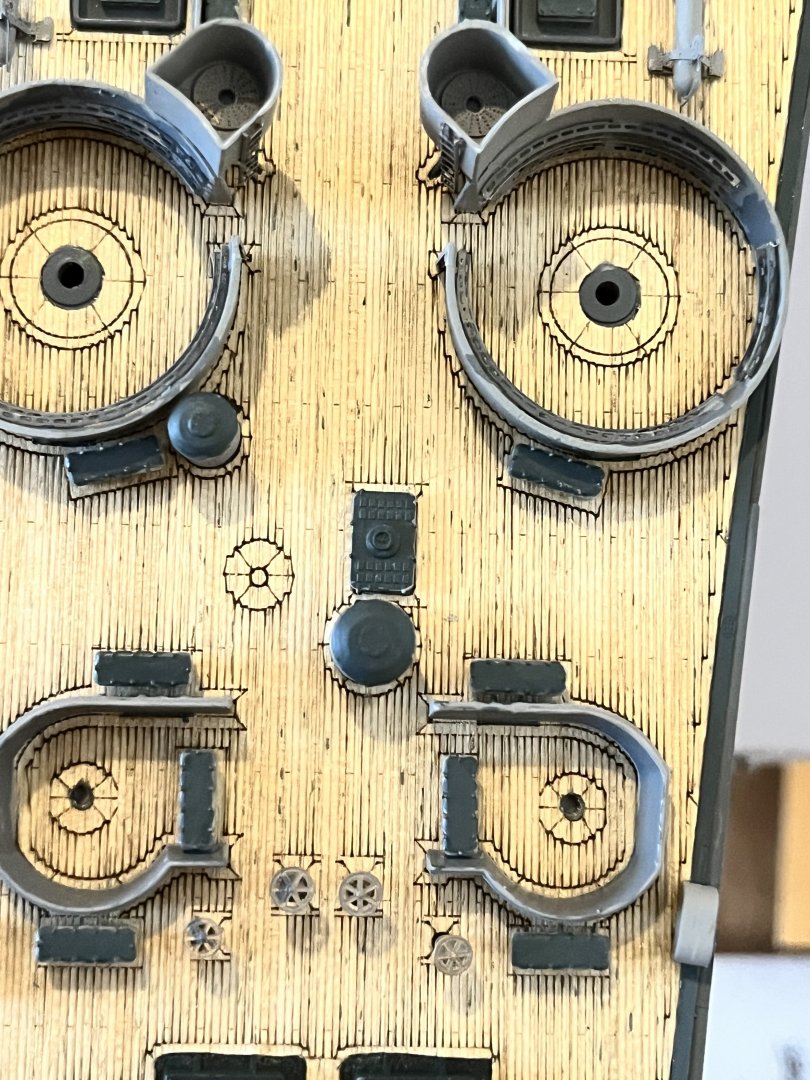

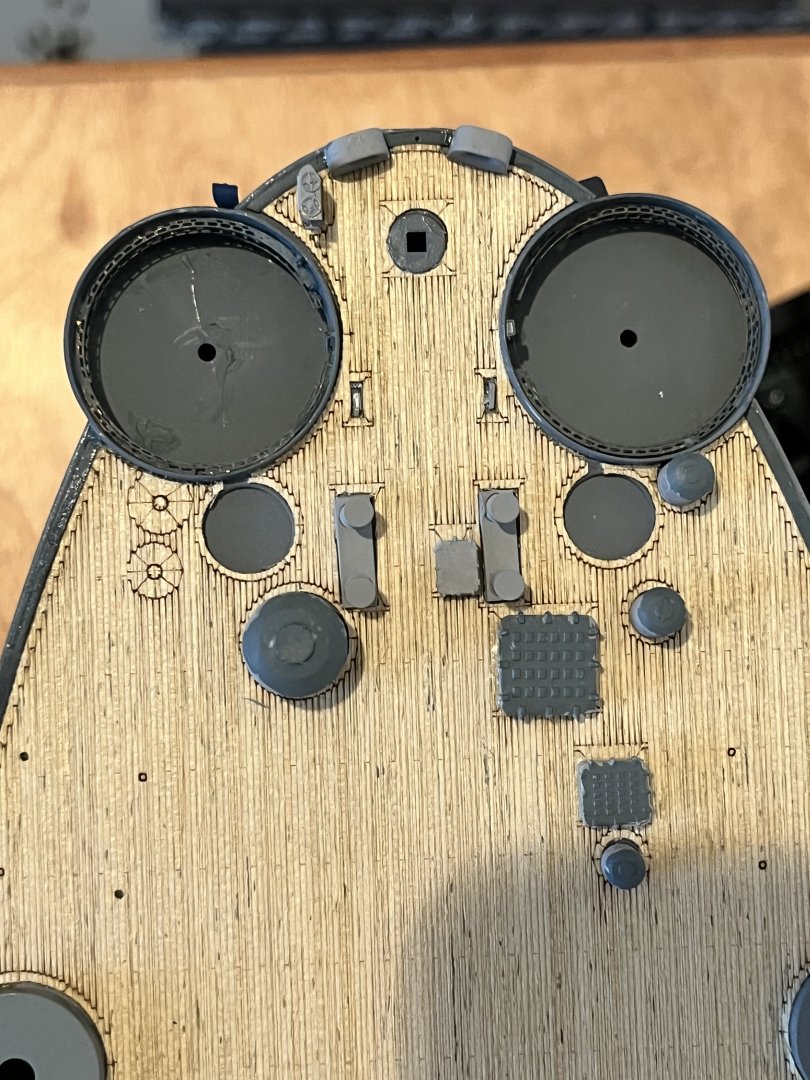

The Eduard parts come through again. Here are the 5" twin loading machines. Pontos ignore these. Notice on the drawing from The Floating Drydock that the loaders are mirror images of each other. The Eduard parts agree with this. Unfortunately the plastic kit parts are not mirror images so I had to cut off tabs and make do. Here are the loaders set into place before painting. Notice that there are also curved rails that are not set in place yet.

-

The bridge structure is now mostly complete except for the spotlight, the M37 director and the antennas. I need to figure out how to construct the antenna outrigger attachment points. The antennas will be fine black thread that goes up to the underside of the air defense station level. The outriggers need to be really small and thin, maybe some of the leftover brass etching. They will go on the outsides of the bridge in two places down to the conning tower, both sides of the walkway out to the spotlight, attached to the side railing where those side wall steps to nowhere go and to either side of the cable trunk that sits on top of the platform the has the two M56 directors.

-

The pilot house level is coming together. Every time I look there are more parts to add. The front control boxes are some of the smallest parts yet. That one little part is 1x1mm. This part is going to be interesting to paint. And here is the pilot house level mostly complete. The further up I go there are fewer plastic parts and many more Pontos brass parts. On top of where the MK56 Directors will go there are round platforms with perforated holes that came from the Edward kit. The Eduard parts have proven to be a good addition the Pontos kit.

-

There are center bofors, 3 per side. Lots of small parts. One side is complete and set in place for now except for some final painting.

-

Here is the final wooden decking in place. The forward tower is just set in place for now, not yet painted.

-

There are people out there building this model that complain about the front tower not fitting down solidly due to the structure that the M37 director sits on being too tall. I got worried about this and figured it is better to discover the problem early when there are more fix options so I test fitted the long wall followed by the forward tower with the pilot house level platform set in place, the one that holds the search light, M37 and M51 directors. Everything fits in place exactly as it should. I'm not sure if Trumpeter identified and fixed the problem or if there is some gotcha still lurking out there that I have not run across yet. I will keep test fitting as I go to make sure this does not become a problem.

-

There are so many little ladder rungs to glue on. I have finally settled into what works best for me. I use two tweezers. First I use the angled tweezers which I call the dry tweezers to pick up the next rung and set it in place. Then I press the rung into place with the end of my thumb nail. With the rung dry fitted I use an end of the straight tweezers which I call the wet tweezers to grab a small amount of CA and place that on one end of the rung. It gets really frustrating if the dry tweezers get any glue on them. In this case dry off the tweezers and use the back of an exacto knife to scrape off any glue residue. It also helps to periodically scrape the glue off the wet tweezers.

-

On the side of the navigation bridge level at the back corners there are little structures The Floating Drydock plans call "side running lights". I assume these are the navigation lights so starboard = green and port = red.

-

The first three levels above the main deck are mostly complete. All except the guns, railings and everything that attaches the 1st level to the main deck since these first 3 decks are just set in place for now. Here are pictures based on frame number. First up is Port side, frame 68-90. Port side, frame 90-115. Port Side, frame 115-138. I see that the mop rack is conflicting with the three round bits glued to the main deck. Going to have to fix that... Port side, frame 138-151. Starboard side, frame 68-80. Starboard side, frame 80-108. Starboard side, frame 120-138. Starboard side, frame 138-151. Every time I study the plans I discover more things I missed, but these levels are mostly complete. I am reprinting the spare plane float to add supports so it is all one piece. In the mean time I am adding parts to the flag bridge level.

-

There is a rack of mops shown on the plans at Frame 108, the backside of a 5" gun support. The way I figure it, a mop handle is about 1" or 2.5cm in diameter. At scale that translates to about half the diameter of a 30 gauge wire. 30 gauge is small enough so I attempted to glue bits of thread to the end of the wire. It is tedious and tough to do without the thread absorbing glue all the way along the thread. I used CA glue activator and just a slight bit of glue. Once the threads were added I frayed the ends. The rack is made out of styrene strips. Here is my mop rack.

-

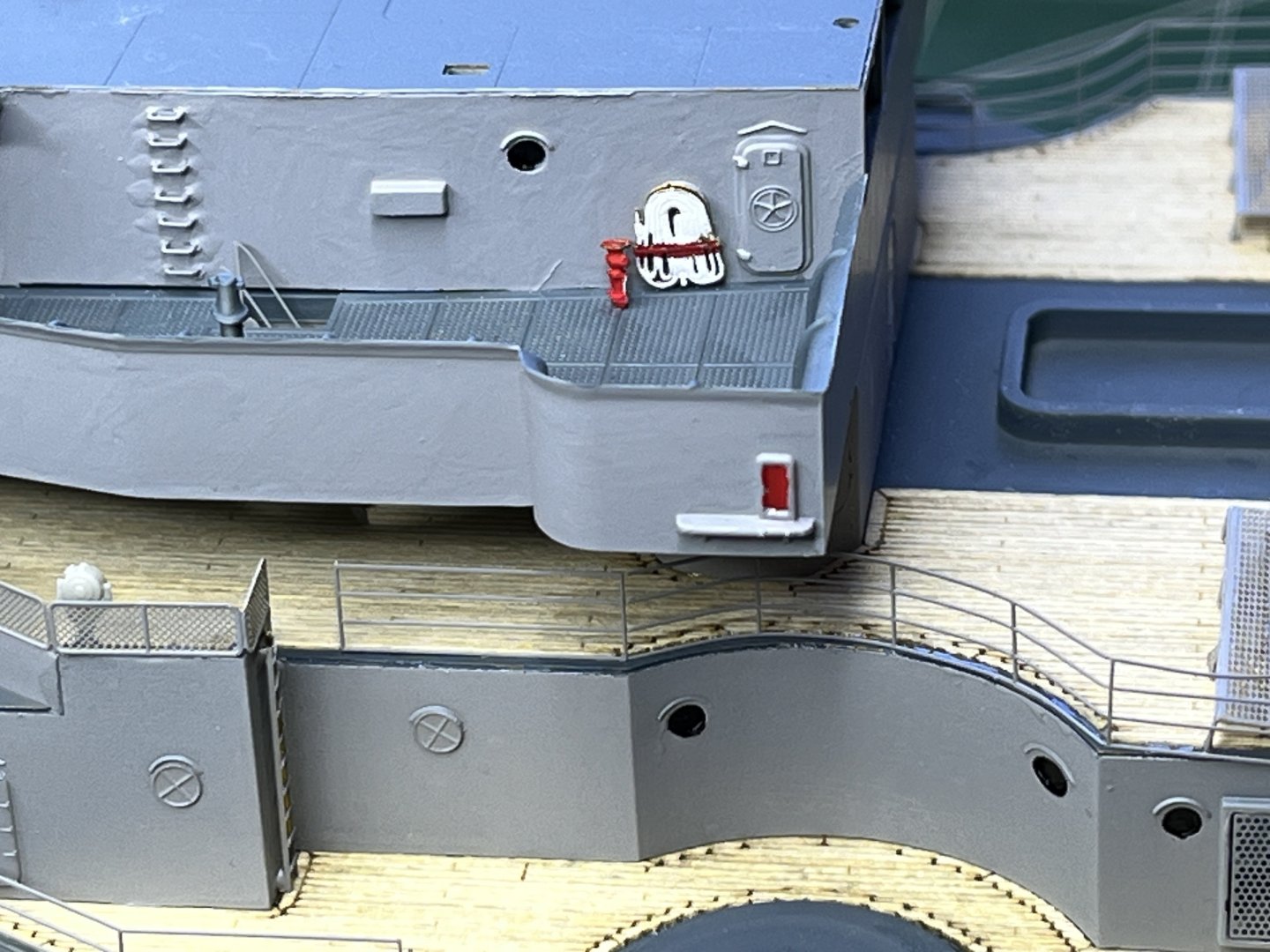

The Pontos 21002F1 kit is definitely taking the concept of crazy small parts to the next level. These fire plugs probably wouldn't even be worth it except they are red and will stand out nicely in a mostly grey model.

-

Here is the refueling rack and hoses installed. Also the paravane boom parts and the anchor chain jacks installed on the breakwater.

-

I have also identified other missing parts, two missing ammo lockers along with the paravane booms and anchor chain jacks. If you want to download all these parts and print them yourself I have published them for free. I never charge for my parts. The model is called USS Missouri 1/200 Scale Missing Parts and it located here along with all my other 3D models: https://www.printables.com/@bglasford1

-

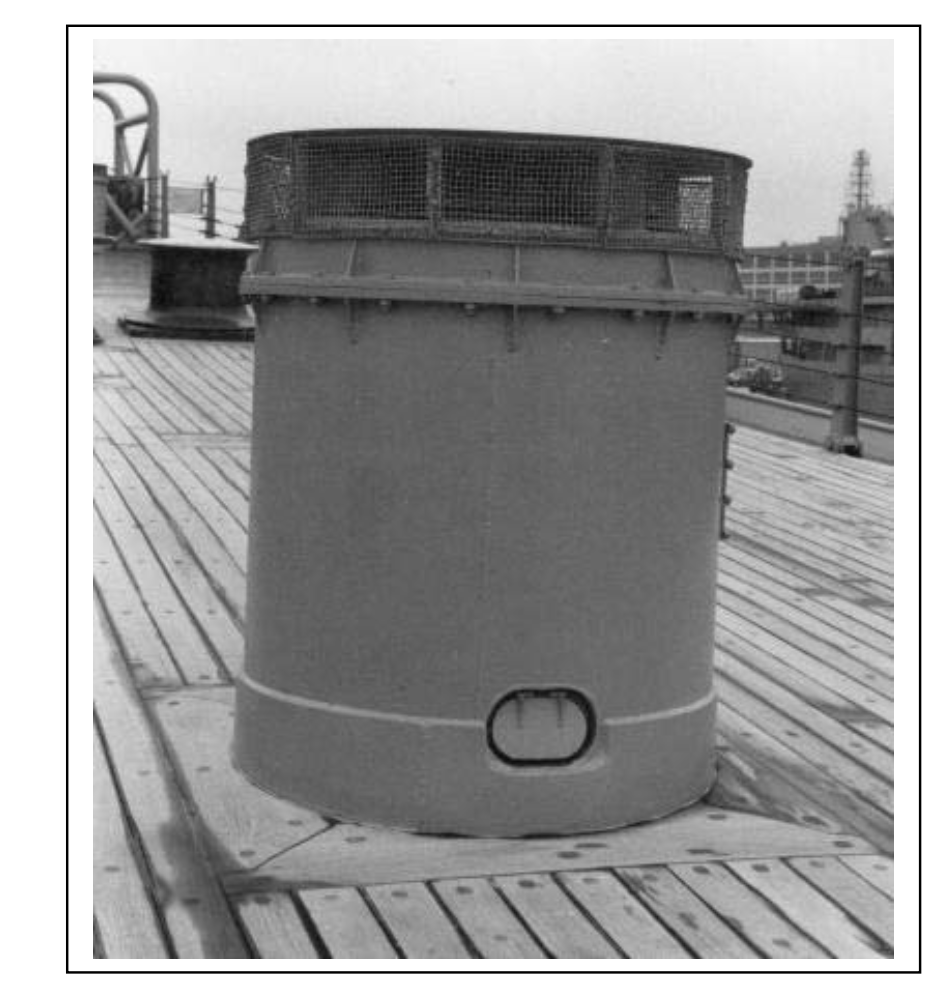

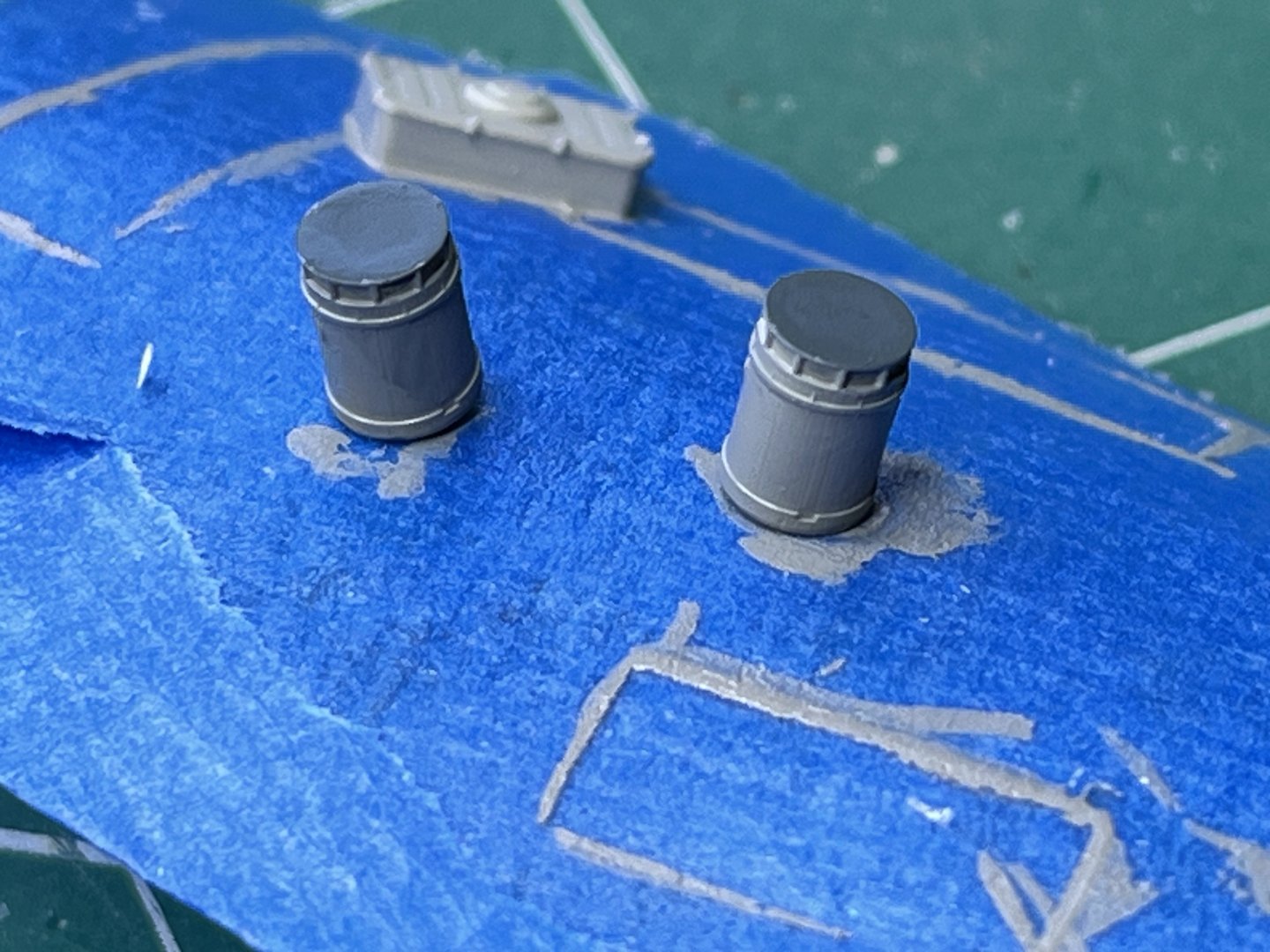

The Pontos wooden decks are a fantastic addition to the model. They do however show you when you are missing something. Both fore and aft there are missing vents. From the blueprints by The Floating Drydock, all three are 18" bucket vents. The kit does not provide these nor does any other detail kit so again it's the 3D printer to the rescue. Here is a picture of the missing vent on the foredeck. And here is the location of the missing vents on the aft deck. Here is a picture of an 18" vent per The Floating Drydock. Here are two of the parts I created. I really like the way the resin printer could even print the tiny little angled supports for the attachment rings. I chose not to model the bolts, they seemed too small.

-

I finally got a 3D resin printer. WOW! This is really worth it. These printers usher in a new era of modeling. Instead of the old days of cobbling together a reasonable facsimile of a part using bits of styrene. It is a simple matter of making exactly what you want using a CAD program and then printing the part. I have spent the last 3 years learning Fusion 360, making and printing large models using an FDM printer. The only issue was the detail of small parts. The FDM printer can print down to 0.10mm layers. This 3D resin printer prints layers at 0.05mm high with a pixel resolution of 18x18 microns. Here is the refueling rack that contains the hoses used to refuel between ships at sea. The part is exactly the correct size based on The Floating Drydock plans. There are hoses two deep according to pictures and the Gibbs and Cox model. I started with the overall size and the correct number of supports, then sized the hoses accordingly. Each hose is 0.8mm in diameter with a 1.0mm collar at each end. Very happy with the results. Now on to painting the part.

-

I decided to go with the Pontos fire hoses on the walls. I found it easiest to paint them before cutting them loose and to start with the red stripe, then paint the white on either side. I think I will stick with the life rings that are already there. Will probably go back and touch up the orange, should have done the white first. Same with the red stripes on the bottles.

-

The kit tanks are a bit too large. I really like these which I got from Model Monkey. Some of the tanks have the end bit broken off, but I got 4 of these sets so there should be plenty of tanks. They need a base plate so I used some styrene for that. These tanks are definitely 3D printed using a resin printer. I went ahead and ordered one of these printers. This kind of printer is indispensable for printing smaller parts. As soon as I get it up and running I will re-slice and print the spare float for the plane. A resin printer should be a great compliment to the filament printer.

-

When it comes to painting the fire hoses hanging on the walls I'm not yet satisfied with the results. They are really small and the strap holding them in place is so small I used the smallest brush I have, a 000 size and that seems HUGE compared to what needs to be painted. Fortunately I can paint it over with the light grey and start over. I may take and older brush and snip off all but a few bristles and up the magnification.

-

For the larger reels I used the Pontos parts, 5 of them. The center spool is an original kit part. With the two end spools glued onto the kit part, I next wound some black thread on to simulate the hose, then added the stand and outer spool parts.

-

The fire reels are small. I can't even imagine trying to create these for a 1/350 scale model. I have three choices, the original kit part, the Pontos parts and the Edwards parts. The original part is a bit clunky and I can't even imagine painting them. The Pontos reel has 3 parts and the Edwards part is a single part so I went with Edwards on this one. To make painting simple I airbrushed the parts before cutting them out. Both of these options do not have a center spool and need one. I looked around and realized the easy solution is to use a bit of 3D PLA black filament. It cost me essentially nothing and doesn't need painting.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.