tj456

Members-

Posts

65 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tj456

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

My wife also descended from someone on that ship. I'm using MS plans and multiplying everything by 4, and a picture I took in Plymouth of the replica for colors. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

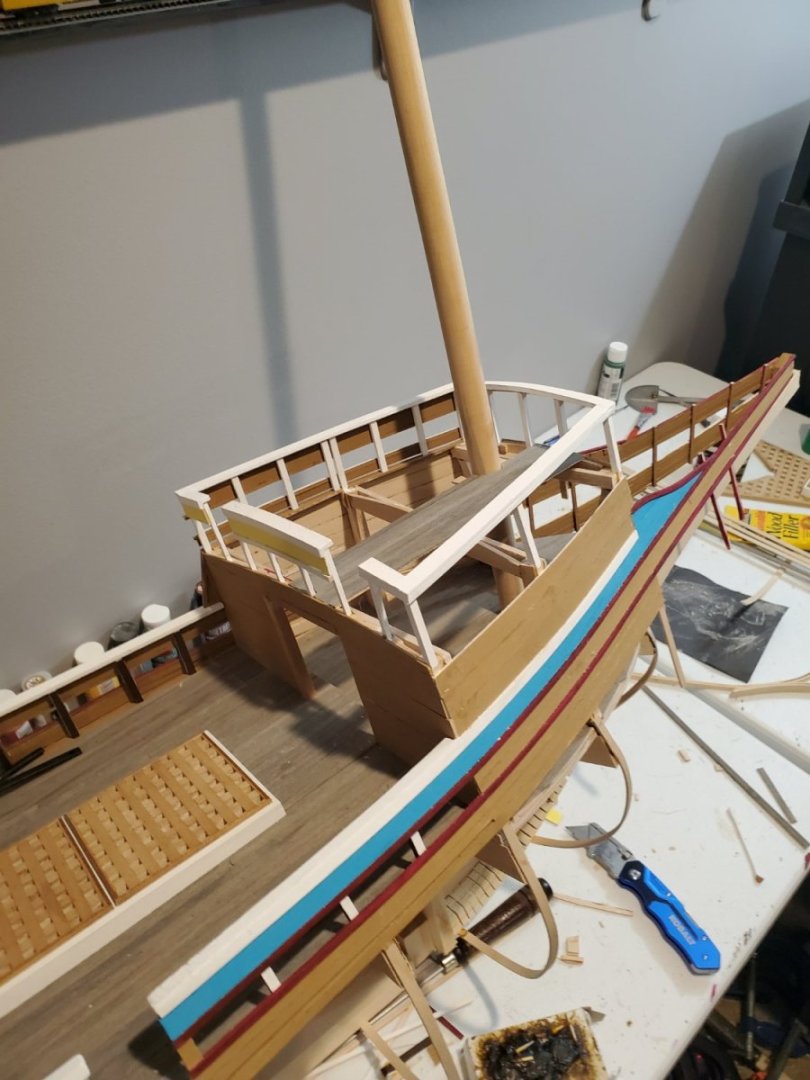

So far planking one side 1st hasn't bit me yet. There's a pretty strong frame to prevent warpage. However topside work should have been done on both sides simultaneously. Live and learn. I've never done such a large model before and I wanted to get an early idea of how it would look -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

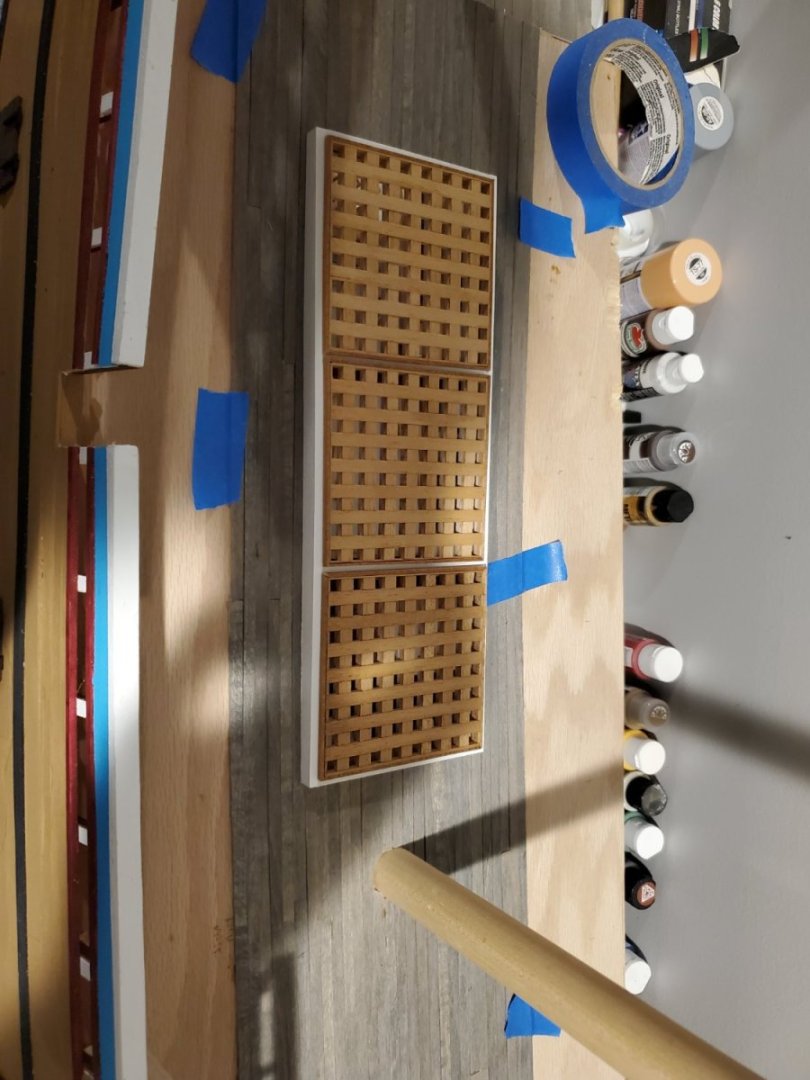

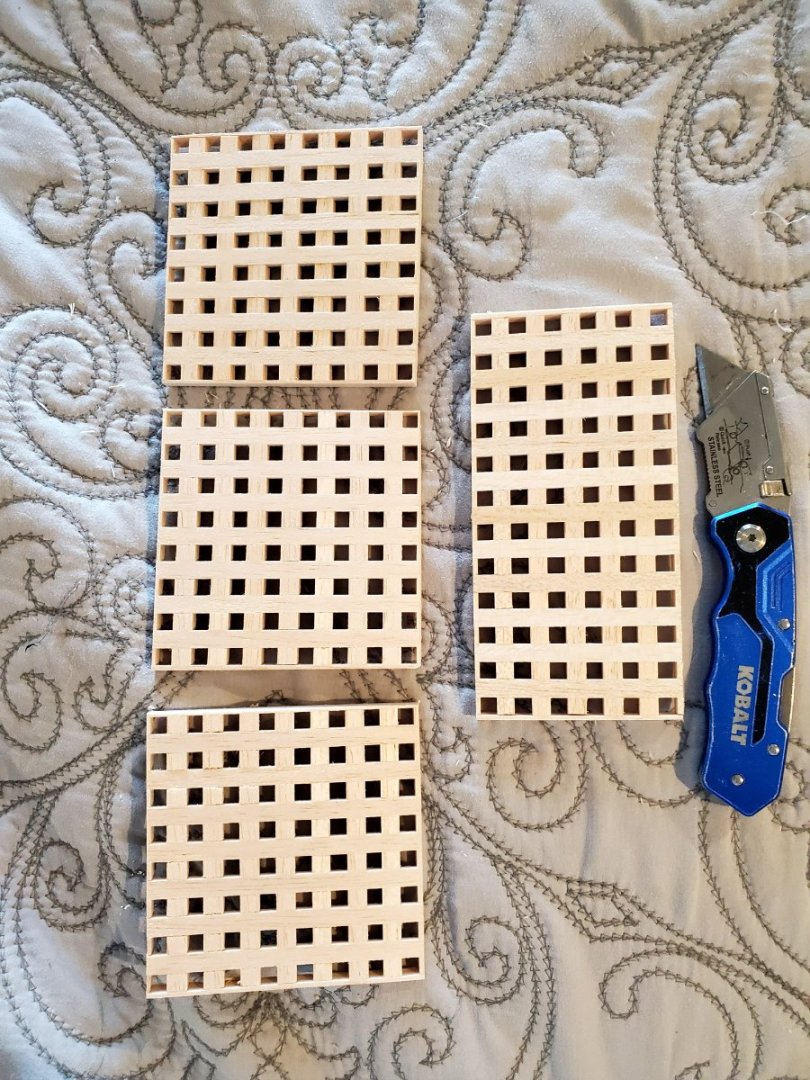

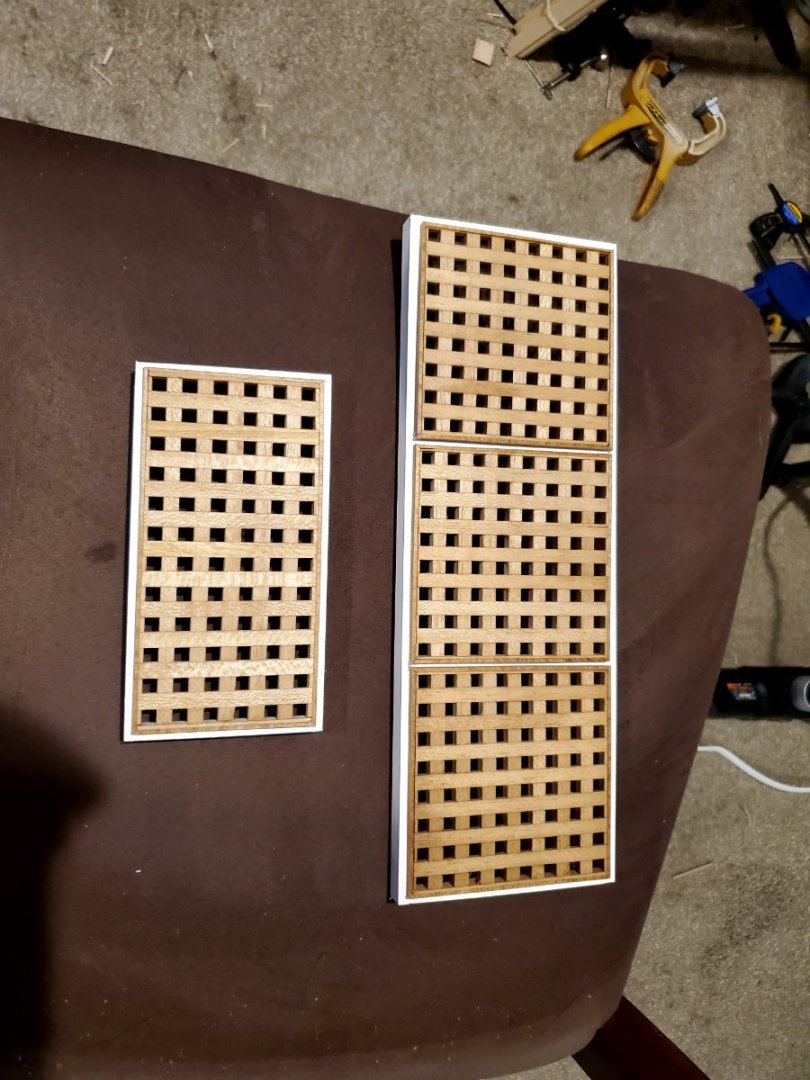

Time for some ladders. I need 6 so I made a jig to make 6 ladders the same. 4 for the main deck and 2 shorter ones to get to the poop deck. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Thanks. Those are CNW train cars and even a Soo Line box car. I grew up in Rhinelander WI and I remember my grandparents coming up on the train from Crystal Lake Illinois. The train station is still there but its a stock brokerage now. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Good question. I have thought about this and the ribs in combination with the planking, all glued on every edge, make for a strong enough and light structure. The completed port side easily takes the weight of the entire ship layinf on its side with no problem. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Now it's just a matter of repeating the port side planking. The hard part is doing it the same (more or less) so the lines even out on the stern. I am going to take advantage of the learning curve here and make improvements where I see fit. One can only see one side at a time and one side will probably be against a wall when displayed. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Here are the starboard ribs installed. I put the middle one in 1st and then stretched a temporary strip from it to both the bow and stern for reference to get the curves right. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

The 1st pic is the jig with ribs on it. The 2nd pic is the ribs out of the jig after 36 hours. I soaked the ribs in water for 6 hours, put them on the jig, and took my wife's iron and ironed them for a couple of minutes. My size 11 shoe is in the picture for scale but they are all 18 inches long. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Now that the port side is mostly complete I have turned my attention to the starboard side. This picture gives a good view of the inside of the port side and is a good start point for the jig I made for the ribs. The port side ribs were just tensioned and bent but I had to clean up minor errors to make the lines flow nicely. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

The bow did not come out as well as the stern but some serious sanding and spackle fixed my mistakes. Hopefully the learning curve will increase for the starboard side. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

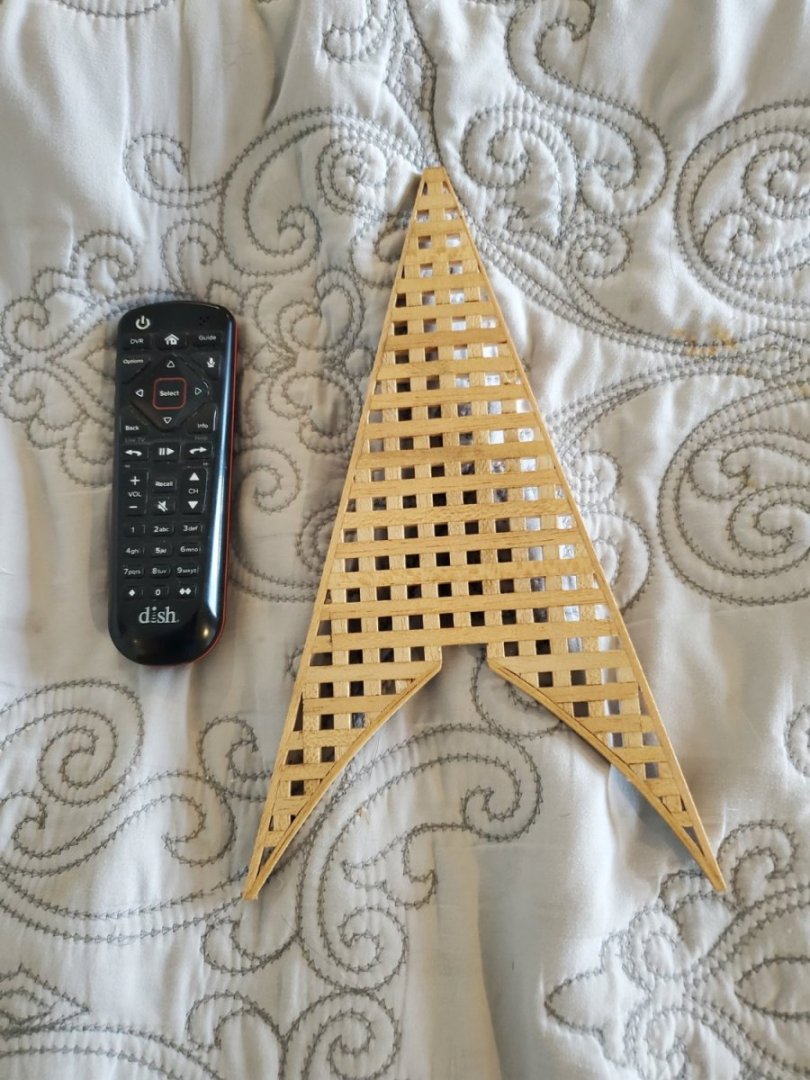

An interesting article and thanks. I did the tapers to a point because it was easy on the big belt sander. Here's what the end results came out looking like: -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

I'm now working down the portside hull. The Mayflower didn't carry much weaponry so the easy way was to just glue gun port covers on to the hull. The hinges are simply 1/16 x 1/16 strips glued to a 1/16 x 1/8 piece of scrap. It looks good and was cheap and easy. The hull planking is proving to be more difficult than the smaller models I have built in the past. You really have to taper most planks but still maintain the lines for ease of the next row. Luckily I have a large stationary belt sander which makes this easier. Any tips on planking or any other issues would be greatly appreciated as this is a 1st for me. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

I also added some temporary masts and spinnaker just to get an idea of how big this thing is going to be. The final length will be 81 inches. -

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

-

Mayflower by tj456 - 1/19 scale

tj456 replied to tj456's topic in - Build logs for subjects built 1501 - 1750

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.e0d4bf181eb341182995b2c91bf2072b.jpeg)

.thumb.jpeg.893e2e93bf9e6dfa4c1ea07ab180047f.jpeg)

.thumb.jpeg.f81b7753a275f0da0c05304b6bf6af31.jpeg)

.thumb.jpeg.5f46f4971b80873ad41c1484b799e95f.jpeg)

.thumb.jpeg.b0ff7c2f9bc05ef4f8973d9fa46e6c61.jpeg)